A sleep surface of this type, primarily intended for individual use, integrates viscoelastic foam material and measures ten inches in thickness. This construction offers a balance between support and conforming comfort, frequently utilized in smaller sleeping spaces.

Such mattresses present a potentially cost-effective option for furnishing guest rooms, dormitories, or smaller bedrooms. The foam composition aims to distribute weight evenly, potentially alleviating pressure points. Historically, foam mattresses emerged as alternatives to traditional innerspring designs, seeking to improve comfort and motion isolation.

The subsequent discussion will delve into the factors influencing the purchase decision, the characteristics that differentiate it from other models, and considerations regarding its suitability for specific sleep preferences and physical requirements.

Guidance on Selecting a Viscoelastic Foam Sleep Surface (Twin, 10-inch)

The following guidance provides crucial insights for evaluating and choosing a ten-inch viscoelastic foam mattress, twin-sized, ensuring an informed purchasing decision.

Tip 1: Assess Density. The density of the foam directly correlates with its durability and support. Higher density materials tend to resist sagging and provide longer-lasting comfort. Examine product specifications carefully.

Tip 2: Consider Layer Construction. A layered design often includes a firmer base foam for support and a softer comfort layer on top. This combination optimizes both spinal alignment and pressure relief. Investigate the specific layers used.

Tip 3: Evaluate Motion Isolation. Viscoelastic foam inherently minimizes motion transfer. This characteristic is particularly beneficial for light sleepers who share a bed, although less relevant for a twin-sized bed typically occupied by a single individual.

Tip 4: Examine Temperature Regulation. Traditional viscoelastic foam can retain heat. Look for mattresses incorporating cooling technologies, such as gel infusions or open-cell structures, to mitigate this issue.

Tip 5: Verify Certifications. Certifications like CertiPUR-US indicate that the foam has been tested for harmful chemicals and VOC emissions. Prioritize certified products to ensure safety and environmental responsibility.

Tip 6: Scrutinize the Trial Period. A generous trial period allows individuals to evaluate the mattress in their home environment. Review the return policy to understand the terms and conditions.

The diligent application of these tips will increase the likelihood of selecting a comfortable, supportive, and durable viscoelastic foam sleep surface that meets individual needs.

The following sections will explore specific brands and models, and discuss optimal care and maintenance practices for such mattresses.

1. Size Dimensions

The physical dimensions of a viscoelastic foam sleep surface, particularly a twin model measuring ten inches in thickness, are fundamental to its functionality and suitability. Precise measurements determine compatibility with bed frames, available space within a room, and the individual’s sleeping area. Therefore, accurate evaluation of size is paramount.

- Standard Twin Size

The standard twin mattress dimensions, typically around 38 inches wide and 75 inches long, are a critical benchmark. Deviations from these standards, even minor, can impact fit within standard bed frames or compromise intended sleep space. This size is commonly selected for children’s rooms, dormitories, or areas with limited square footage.

- Height Considerations (10-inch Thickness)

The ten-inch thickness influences overall bed height and accessibility. When combined with a bed frame and box spring (if used), the total height must be considered in relation to the user’s physical abilities and comfort preferences. Insufficient height may necessitate bending, while excessive height may pose a challenge for entry and exit.

- Spatial Planning

Precise knowledge of mattress dimensions is essential for spatial planning. The dimensions must be factored into room layout to ensure adequate clearance for movement and furniture placement. Overlooking this aspect can result in an overcrowded and functionally impaired living space.

- Weight Distribution and Support

While technically separate from simple dimensional measurements, the size of the mattress directly impacts its weight distribution and support capabilities. A larger surface area generally distributes weight more evenly, potentially improving comfort and reducing localized pressure points. However, the ten-inch thickness, coupled with foam density, plays a larger role in actual support effectiveness.

In conclusion, a meticulous understanding of the size dimensions is indispensable when assessing a ten-inch viscoelastic foam mattress in twin configuration. Accurate measurements facilitate proper bed frame selection, optimize spatial planning, and contribute to a more comfortable and functional sleep environment. Neglecting this aspect can lead to avoidable inconveniences and compromised sleep quality.

2. Foam Density

Foam density, a critical parameter for a ten-inch viscoelastic foam mattress in twin configuration, directly influences durability, support, and long-term performance. It is measured in pounds per cubic foot (lbs/ft) and quantifies the amount of material packed into a given volume. Higher density generally signifies a more substantial and resilient foam structure. In the context of a ten-inch twin mattress, foam density dictates its ability to withstand compression and maintain its shape over extended periods of use. Lower-density foams are more prone to sagging and indentation, thus reducing their effective lifespan and diminishing their ability to provide adequate spinal support. For instance, a mattress with a high-density base layer will resist compression from body weight more effectively than one with a low-density base, translating to better postural alignment during sleep.

The practical implications of foam density extend to motion isolation and temperature regulation. While viscoelastic foam inherently minimizes motion transfer, higher-density foams tend to exhibit superior motion isolation capabilities, reducing the likelihood of disturbances from movement during sleep. Conversely, higher density can also lead to increased heat retention, as the denser material restricts airflow. Consequently, manufacturers often incorporate cooling technologies, such as gel infusions or open-cell structures, to mitigate this effect in high-density foam mattresses. The density of the comfort layers also plays a crucial role in determining the overall feel of the mattress, influencing its plushness and responsiveness. A high-density comfort layer may offer a firmer feel compared to a low-density layer, regardless of the overall mattress thickness.

In summary, foam density is an indispensable factor in evaluating a ten-inch viscoelastic foam mattress. It determines its durability, support characteristics, motion isolation, and temperature regulation properties. Selection of a mattress with appropriate foam densities, balanced with considerations for cooling technology and individual comfort preferences, is paramount for ensuring a satisfactory sleep experience and maximizing the longevity of the product. Compromising on foam density may result in premature degradation and reduced overall value.

3. Support Structure

The support structure within a ten-inch viscoelastic foam mattress in twin configuration constitutes the foundational element determining its ability to maintain proper spinal alignment and distribute weight effectively. It dictates the mattress’s overall firmness, its capacity to resist sagging over time, and its suitability for individuals with specific sleep postures or body weights. Variations in support structure can arise from differing core materials, such as high-density foam, coil systems (though less common in full foam designs), or zoned support layers. The interaction between the support structure and the upper viscoelastic foam layers is crucial; the support system provides a stable base that allows the memory foam to contour to the body without excessive compression or sinkage. Inadequate support leads to spinal misalignment, potentially exacerbating back pain or discomfort. For example, a heavier individual on a mattress with a weak support structure may experience significant sinkage, leading to an unnatural spinal curvature during sleep.

The design of the support structure directly influences the longevity of the mattress. A well-constructed support system, using high-density materials and potentially incorporating reinforced edges, is more resistant to deformation under constant pressure. Conversely, a poorly designed support structure will likely degrade more rapidly, resulting in premature sagging and a reduction in overall comfort. The configuration and materials used within the support structure also influence the mattress’s breathability and temperature regulation. While viscoelastic foam is known for heat retention, a well-designed support structure, possibly incorporating channels or airflow-enhancing materials, can promote ventilation and mitigate this issue. Real-world examples demonstrate the impact of support structure on user satisfaction. A twin mattress used in a dorm room, subjected to daily use and varying body weights, requires a robust support structure to maintain its integrity and provide consistent comfort over the course of its lifespan. Mattresses failing in this regard lead to complaints of discomfort and requests for replacement.

In summation, the support structure is a critical and often overlooked component of a ten-inch viscoelastic foam mattress. Its design and materials directly impact comfort, spinal alignment, durability, and temperature regulation. Understanding the characteristics of the support structure is crucial for making informed purchasing decisions and ensuring long-term satisfaction with the mattress. Challenges remain in balancing the need for robust support with the desire for a plush, conforming feel, but innovative designs continue to emerge that address these competing priorities. This understanding is essential for consumers and retailers aiming to provide optimal sleep solutions.

4. Heat Dissipation

Heat dissipation is a significant consideration when evaluating a ten-inch viscoelastic foam mattress, particularly in the twin size. The inherent properties of viscoelastic foam, while providing contouring comfort, often lead to heat retention, impacting the overall sleep experience. Understanding the mechanisms of heat dissipation is crucial for selecting a product that promotes a comfortable sleep environment.

- Material Composition and Airflow

The density and structure of the foam directly affect airflow. Denser foams restrict air circulation, trapping heat. Open-cell foam structures are designed to enhance airflow, facilitating heat dissipation. Real-world examples include mattresses incorporating convoluted foam layers or channels to promote ventilation, thus mitigating heat build-up. In the context of a ten-inch twin mattress, the smaller surface area may exacerbate heat retention if airflow is not adequately addressed.

- Cooling Technologies: Gel Infusions and Phase Change Materials

Manufacturers often integrate cooling technologies to counteract heat retention. Gel infusions within the foam are intended to absorb and dissipate heat. Phase change materials (PCMs) absorb heat as they transition from a solid to a liquid state, providing a cooling effect. These technologies can be particularly effective in reducing heat accumulation in viscoelastic foam. The effectiveness of these technologies depends on their concentration and distribution within the mattress layers. Without proper implementation, they offer limited benefit.

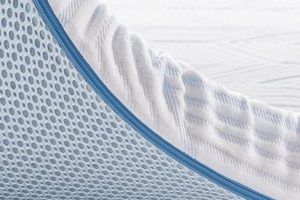

- Mattress Cover Fabric and Breathability

The mattress cover plays a significant role in temperature regulation. Breathable fabrics, such as cotton or bamboo, allow for better airflow compared to synthetic materials. Some covers incorporate moisture-wicking properties to further enhance cooling. A poorly designed cover can negate the benefits of other cooling technologies implemented within the mattress. Therefore, careful selection of cover materials is essential.

- Environmental Factors and Individual Physiology

Environmental factors, such as room temperature and humidity, influence the effectiveness of heat dissipation. Individual physiology, including metabolic rate and body weight, also plays a role. A mattress that performs well in one environment may not be suitable in another. Similarly, individuals who tend to sleep hot may require mattresses with enhanced cooling features. External factors must be considered when assessing heat dissipation performance.

In summary, heat dissipation in a ten-inch viscoelastic foam mattress, particularly in a twin size, is influenced by material composition, cooling technologies, cover fabric, and environmental factors. Addressing heat retention requires a holistic approach, integrating multiple strategies to ensure a comfortable and cool sleep environment. Selection should be based on individual needs and environmental conditions, with careful consideration given to the properties of the mattress components.

5. Edge Support

Edge support, within the context of a ten-inch viscoelastic foam mattress (twin), refers to the structural reinforcement along the perimeter of the mattress. This feature directly affects the usable surface area and the stability experienced when sitting or sleeping near the edges. The inherent nature of viscoelastic foam, known for its conforming properties, can lead to edge compression and a feeling of roll-off if adequate edge support is absent. Consequently, the absence of sufficient edge support in a ten-inch twin memory foam mattress compromises its utility and longevity. A common example is a user sitting on the edge of the mattress to put on shoes; without reinforcement, the edge may compress excessively, causing discomfort and potentially accelerating wear. The effect is magnified over time, leading to permanent sagging and a reduction in the effective sleep surface.

Manufacturers employ various techniques to enhance edge support. These include the use of high-density foam rails, encasements of steel springs or coils around the perimeter, or a combination of both. The effectiveness of these methods varies, with higher-density foam rails generally providing moderate support suitable for lighter individuals, while spring or coil systems offer greater stability and weight-bearing capacity. In practical applications, a dorm-room setting, where the twin mattress may serve dual purposes as a sleeping surface and a seating area, the presence of robust edge support becomes particularly important. It ensures that the mattress can withstand the rigors of both sleeping and sitting, extending its lifespan and improving user satisfaction.

In conclusion, edge support is an integral characteristic of a ten-inch viscoelastic foam mattress (twin), impacting both its functional area and structural integrity. The absence of this feature leads to compromised comfort, reduced usability, and accelerated wear. Implementing effective edge reinforcement methods is essential for ensuring a durable and supportive sleep surface, particularly in settings where the mattress is subjected to frequent use and varied weight distribution. The understanding of edge support mechanisms and their impact on mattress performance is crucial for informed purchasing decisions and optimal product utilization.

6. Motion Isolation

Motion isolation, the capacity of a sleep surface to minimize the transmission of movement, is a salient characteristic when considering a ten-inch viscoelastic foam mattress, particularly in the twin configuration. While typically associated with shared sleeping spaces, its presence in a twin mattress can contribute to enhanced sleep quality, even for single occupants. The subsequent discussion explores the facets of motion isolation in this context.

- Material Damping Properties

Viscoelastic foam inherently possesses damping properties, absorbing and dissipating kinetic energy rather than transferring it across the mattress surface. This characteristic stems from the foam’s ability to conform to the applied pressure, minimizing ripple effects. A ten-inch thickness, composed entirely of viscoelastic foam, maximizes this damping effect. A practical example would be a restless sleeper shifting positions; the motion is largely contained to the immediate area, minimizing disruption to other areas of the mattress. The extent of damping is directly related to the foam’s density and composition.

- Twin Size and Isolated Zones

Although a twin mattress is intended for single occupancy, motion isolation remains relevant. External vibrations, such as those from nearby traffic or building activity, can be dampened by the mattress, contributing to a more undisturbed sleep. The small surface area of the twin mattress effectively creates an isolated sleep zone, reducing the impact of these external disturbances. Moreover, subtle movements of the sleeper, such as repositioning during the night, are less likely to cause widespread disturbance across the limited surface.

- Support Core Influence

While the viscoelastic foam layers are primarily responsible for motion isolation, the underlying support core also plays a role. A stable and non-responsive support core enhances the damping effect of the upper layers. Conversely, a support core with excessive bounce or springiness can counteract the motion isolation provided by the foam. A well-designed ten-inch twin viscoelastic foam mattress will feature a support core optimized to complement the damping properties of the foam layers.

- Comparison to Other Mattress Types

In comparison to innerspring mattresses, viscoelastic foam mattresses generally exhibit superior motion isolation capabilities. The interconnected coils of innerspring systems tend to transmit movement across the mattress surface, while the damping properties of viscoelastic foam minimize this effect. Hybrid mattresses, combining innerspring and viscoelastic foam layers, offer a compromise between these two extremes. However, a ten-inch twin mattress composed entirely of viscoelastic foam provides the most effective motion isolation for a single occupant.

In conclusion, motion isolation remains a relevant characteristic even in a ten-inch viscoelastic foam mattress designed for individual use. The material’s inherent damping properties, coupled with the isolated nature of the twin size, contribute to a more undisturbed sleep. While not as critical as in shared sleeping arrangements, the presence of effective motion isolation enhances the overall sleep experience and minimizes the impact of external disturbances.

Frequently Asked Questions

The following addresses common inquiries concerning the selection, use, and maintenance of a ten-inch viscoelastic foam mattress in the twin configuration. These questions aim to provide clarity and assist in making informed decisions.

Question 1: What is the expected lifespan of a ten-inch viscoelastic foam mattress (twin)?

The lifespan of such a mattress varies depending on factors including foam density, usage patterns, and care. Generally, a well-maintained mattress of this type can be expected to last between seven and ten years. However, mattresses constructed with lower-density foam or subjected to excessive weight or wear may exhibit a shorter lifespan.

Question 2: How does the ten-inch thickness affect the support provided?

The ten-inch thickness allows for sufficient layering of different foam densities to provide both support and comfort. Typically, a firmer base layer provides support, while a softer top layer offers contouring. However, the specific densities and configurations of these layers significantly influence the overall support level. A mattress with insufficient support may lead to spinal misalignment.

Question 3: Are there any specific bed frames recommended for this type of mattress?

This type of mattress is compatible with most standard twin-size bed frames, including platform beds, slatted frames, and adjustable bases. However, it is crucial to ensure that the frame provides adequate support across the entire mattress surface to prevent sagging or uneven wear. Slatted frames should have slats spaced no more than a few inches apart.

Question 4: How should a ten-inch viscoelastic foam mattress (twin) be cleaned?

Spot cleaning with a mild detergent and water is recommended for minor stains. Avoid harsh chemicals or excessive moisture. A mattress protector is advisable to prevent stains and spills. Professional cleaning may be necessary for more significant soiling. Regular vacuuming can help remove dust and allergens.

Question 5: Does this type of mattress require flipping or rotating?

Many modern viscoelastic foam mattresses are designed with a specific top and bottom and do not require flipping. However, rotating the mattress 180 degrees every few months can help to distribute wear evenly and prolong its lifespan. Consult the manufacturer’s instructions for specific recommendations.

Question 6: What are the potential drawbacks of a ten-inch viscoelastic foam mattress (twin)?

Potential drawbacks may include heat retention, which can be mitigated by mattresses incorporating cooling technologies. Additionally, some individuals may find the conforming feel of viscoelastic foam to be too soft or lacking in responsiveness. The initial off-gassing odor, while generally harmless, may be noticeable upon unpacking.

These FAQs provide a foundational understanding of the characteristics and considerations associated with this type of mattress. Further research and evaluation are encouraged to ensure a purchase that aligns with individual needs.

The subsequent discussion will focus on specific brands and models of this mattress type, providing comparative analyses and consumer reviews.

Concluding Remarks on Viscoelastic Foam Mattresses (Twin, 10-inch)

The preceding analysis has explored the multifaceted characteristics of a ten-inch viscoelastic foam mattress in the twin configuration. Key areas of focus have encompassed size dimensions, foam density, support structure, heat dissipation, edge support, and motion isolation. Understanding these parameters is paramount to making an informed purchasing decision. The suitability of such a mattress hinges on individual needs, sleeping preferences, and environmental factors.

While this exploration provides a comprehensive overview, further research into specific brands and models is strongly encouraged. Consideration should be given to independent reviews, warranty terms, and trial periods offered by manufacturers. The investment in a quality sleep surface is an investment in long-term health and well-being; diligent evaluation is therefore warranted.

![Best 6 Inch Bunk Bed Mattress [For Safety & Comfort] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best 6 Inch Bunk Bed Mattress [For Safety & Comfort] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3751-300x200.jpg)