A common bedding component, it is a synthetic material offering support and comfort. Manufactured by reacting polyols and isocyanates, the resulting substance exhibits varying degrees of density and firmness, influencing its suitability for diverse sleeping preferences. Examples range from basic, low-density versions found in budget-friendly options to high-density formulations used in premium sleep products.

Its widespread use is attributable to its affordability and versatility. Providing cushioning and pressure relief, it conforms to the sleeper’s body, potentially alleviating discomfort. Historically, this material presented a cost-effective alternative to traditional spring mattresses, democratizing access to comfortable sleep surfaces. Furthermore, advancements in manufacturing have led to enhanced durability and reduced off-gassing.

The subsequent sections will delve into the different types, construction methods, potential advantages, and key considerations when choosing such a sleep surface. Furthermore, information regarding care, maintenance, and disposal will be provided.

Guidance for Optimization and Longevity

Effective utilization and maintenance extend the lifespan and enhance the performance of this product. The following guidelines are provided to ensure optimal use.

Tip 1: Ensure Proper Support: The foundation upon which it rests significantly impacts its performance. Use a solid, supportive base, such as a platform bed or a box spring in good condition, to prevent sagging and uneven wear.

Tip 2: Employ a Mattress Protector: A waterproof and breathable protector safeguards against spills, stains, and dust mites, thus preserving its hygiene and extending its longevity.

Tip 3: Rotate Regularly: Rotate the surface end-to-end every three to six months. This practice distributes wear evenly and prevents localized compression.

Tip 4: Address Spills Promptly: In the event of a spill, immediately blot the affected area with a clean, dry cloth. Avoid harsh chemicals; opt for a mild detergent diluted in water, followed by thorough air drying.

Tip 5: Consider Professional Cleaning: Periodic professional cleaning, typically every one to two years, removes accumulated dust, allergens, and stains that are not readily addressed with household methods.

Tip 6: Monitor for Degradation: Regularly inspect for signs of wear, such as indentations or loss of support. Early detection allows for timely intervention or replacement.

Tip 7: Understand Density Implications: Higher density formulations generally offer greater durability and resistance to compression, while lower densities may be more susceptible to wear. Choose a density appropriate for the intended use and expected lifespan.

Adhering to these recommendations can maximize the lifespan, maintain the integrity, and optimize the comfort provided. By following these simple practices, ensure a more restful and hygienic sleep experience.

The following section will address common questions and concerns regarding this sleep surface.

1. Density

Density, measured in pounds per cubic foot (PCF), directly correlates with the durability, support, and overall performance characteristics of bedding products made from this material. Higher density indicates a greater amount of material packed into a given volume. This increased material concentration results in improved resistance to compression, leading to enhanced long-term support and reduced likelihood of sagging over time. For example, a high-density version, exceeding 5 PCF, is frequently employed in the support cores of hybrid or all-foam mattresses to provide a stable foundation, while a lower density version, below 3 PCF, is typically reserved for comfort layers where enhanced cushioning is desired, and long-term durability is less critical. The manufacturing process manipulates cell size and structure to achieve specified densities.

The practical significance of density lies in its impact on the lifespan and the comfort experience. A higher density formulation not only resists compression fatigue better but also tends to provide more consistent support across the surface. This is particularly relevant for individuals seeking orthopedic support or those with higher body weights. Conversely, while lower densities offer initial softness and contouring, they are more prone to developing body impressions and losing their supportive capabilities sooner. Improper selection based on density can lead to premature failure, requiring more frequent replacement and negating any initial cost savings. The selection of appropriate density is a crucial consideration that should align with the intended use, budget, and individual preferences.

In summary, the density is a primary determinant of the quality and longevity. The selection should be based on the intended use and desired balance between initial comfort and long-term performance. Ignoring density considerations can lead to dissatisfaction and diminished value. Further research into specific density ratings and material certifications is advisable before making a purchase.

2. Firmness

Firmness, a tactile characteristic, describes the degree of resistance to compression exhibited by a polyurethane foam mattress. It is a subjective property, quantified on a scale often ranging from extra-soft to extra-firm. The level of firmness directly affects the support provided to the body, influencing spinal alignment and pressure distribution. A too-soft surface may allow excessive sinking, potentially leading to misalignment, while a too-firm surface may create pressure points, particularly at the shoulders and hips. For example, an individual with back pain may find relief with a medium-firm mattress that offers a balance of support and cushioning, preventing spinal distortion.

The inherent structure and density of the polyurethane foam are key determinants of firmness. Manufacturers can manipulate the chemical composition and cell structure during the manufacturing process to achieve specific firmness levels. High-density foams generally exhibit greater firmness compared to low-density counterparts. Furthermore, the addition of different additives or layering techniques can be employed to fine-tune the feel. Individuals choosing a mattress primarily prioritize firmness to achieve optimal sleep quality. Retailers often provide firmness ratings and descriptions to guide customers. However, personal preference and body type play crucial roles in determining the ideal level of firmness.

In summary, firmness is a critical attribute that significantly impacts the comfort and support characteristics. Understanding the relationship between foam density, construction methods, and firmness levels is essential for selecting a mattress suited to individual needs. The interplay between firmness and other factors, such as sleeping position and body weight, should be carefully considered to optimize sleep quality and minimize discomfort. A trial period, if offered, enables individuals to assess the selected firmness in a real-world setting, ensuring the selection aligns with their specific requirements.

3. Thickness

The thickness of a polyurethane foam mattress directly influences its overall comfort, support, and durability characteristics. Measured from the top surface to the bottom, this dimension determines the volume of material available for both conforming to the body and providing underlying support. Insufficient thickness, typically found in budget options, can result in bottoming out, where the sleeper’s weight compresses the foam to the point where it offers inadequate cushioning and support from the underlying bed frame or foundation. Conversely, excessive thickness, while potentially increasing initial comfort, may not necessarily translate to improved long-term support, particularly if the internal foam layers are of insufficient density or quality. A common example is a twin-sized dorm mattress, often around 6 inches thick, which may be adequate for a smaller individual but insufficient for a larger adult. A thicker, 10-12 inch mattress might provide better support and pressure relief for heavier individuals.

Thickness contributes to the ability of the mattress to accommodate varying body weights and sleeping positions. A thicker mattress generally allows for a greater distribution of pressure, minimizing pressure points that can cause discomfort and disrupt sleep. This is particularly crucial for side sleepers, who require sufficient thickness to allow the shoulder and hip to sink in without contacting the support structure beneath. Furthermore, the thickness of the mattress affects its ability to isolate motion transfer, minimizing disturbances caused by a partner’s movements. The layering of different densities and types of polyurethane foam within a thicker mattress allows for the creation of distinct comfort and support zones, catering to specific areas of the body. The thickness of a mattress affects its compatibility with bed frames and fitted sheets.

In summary, the thickness is a critical determinant of a polyurethane foam mattresss suitability for a given individual. It is essential to consider body weight, sleeping position, and any specific orthopedic needs when selecting a mattress thickness. While increased thickness can generally improve comfort and support, the quality and density of the internal foam layers are equally important. A balanced approach, considering both thickness and material properties, is crucial for optimizing sleep quality and ensuring long-term satisfaction. The increasing demand for thicker mattresses in the marketplace underscores the significance of thickness as a key performance indicator.

4. Composition

The formulation is central to determining its characteristics, performance, and potential environmental impact. A detailed examination of the various components and their interactions is essential for understanding its properties and implications.

- Polyols

Polyols constitute the primary building blocks, typically derived from petroleum or plant-based sources. The type of polyol used significantly impacts the foam’s density, flexibility, and resilience. For instance, a polyether polyol will generally produce a more durable and resilient foam compared to a polyester polyol. The choice of polyol affects the comfort and longevity of the final product.

- Isocyanates

Isocyanates react with polyols to form the polyurethane polymer network. The most common isocyanate used is toluene diisocyanate (TDI) or methylene diphenyl diisocyanate (MDI). TDI-based foams are generally less expensive but may have a stronger odor, while MDI-based foams offer improved durability and reduced off-gassing. The specific isocyanate used influences the firmness, density, and overall stability of the mattress.

- Additives

A wide array of additives is incorporated to modify properties and improve processing. These can include blowing agents to create the cellular structure, surfactants to stabilize the foam, flame retardants to meet safety standards, and colorants for aesthetic purposes. The selection and concentration of additives affect the foam’s flammability, density, and odor. Furthermore, the use of specific flame retardants is subject to regulatory scrutiny due to potential health and environmental concerns.

- Density Modifiers and Fillers

Density modifiers and fillers are sometimes added to reduce cost or alter physical properties. Calcium carbonate, for example, can be used to increase density and improve firmness. However, excessive use of fillers may compromise the foam’s long-term durability and resilience. The type and amount of fillers can alter the product’s lifespan and suitability for various applications.

The interplay of these components dictates the ultimate characteristics and environmental footprint. Variations can influence factors ranging from comfort and support to potential off-gassing and recyclability. Thorough understanding of the ingredient list becomes essential to make informed decisions.

5. Conformity

Conformity, in the context of a polyurethane foam mattress, refers to its ability to adapt to the unique contours of an individual’s body. This characteristic significantly influences pressure distribution, spinal alignment, and overall sleep comfort. Variations in foam density, elasticity, and surface design contribute to the degree of conformity achieved.

- Pressure Redistribution

A primary function of conformity is to redistribute pressure exerted by the body on the mattress surface. By conforming to the body’s shape, the material reduces concentrated pressure on bony prominences, such as the shoulders, hips, and knees. Effective redistribution minimizes pressure points, thereby alleviating discomfort and promoting circulation. Individuals experiencing joint pain or pressure sensitivity benefit significantly from mattresses exhibiting high levels of conformity.

- Spinal Alignment

Proper spinal alignment is crucial for maintaining musculoskeletal health and preventing back pain. Conformity supports the natural curvature of the spine, ensuring that it remains aligned throughout the night. A mattress that conforms adequately to the body’s contours prevents the spine from sagging or arching excessively, thereby reducing strain on the spinal muscles and ligaments. The degree of conformity needed to achieve optimal spinal alignment varies based on individual body weight, sleeping position, and spinal conditions.

- Motion Isolation

Conformity also plays a role in motion isolation, the ability of a mattress to minimize the transfer of movement from one side of the bed to the other. When one individual moves or shifts position, a conforming mattress absorbs the motion, preventing it from propagating across the surface and disturbing the other sleeper. This is particularly beneficial for couples or individuals who are easily awakened by movement.

- Material Dependency

The degree of conformity relies on the polyurethane foam composition used in the layers of mattress. Each layer must provide good level of pressure relief, which also affect durability of the products. The depth of materials will improve surface conformity, hence reducing pressure.

The degree to which a polyurethane foam mattress conforms to the body is a key factor determining its overall comfort and support. Choosing a mattress with appropriate levels of conformity, tailored to individual needs and preferences, is essential for optimizing sleep quality and minimizing physical discomfort. The effectiveness of conformity will decrease over the time depends on usage and proper care.

6. Breathability

Breathability, concerning a polyurethane foam mattress, refers to its ability to facilitate airflow and dissipate heat. This characteristic is critical for maintaining a comfortable sleeping temperature and preventing the accumulation of moisture. Polyurethane foam, by its inherent structure, tends to retain heat due to its closed-cell nature. This can lead to elevated sleeping temperatures, causing discomfort and disrupting sleep. For instance, individuals residing in warmer climates or those prone to night sweats are particularly susceptible to the effects of poor breathability. Consequently, manufacturers employ various strategies to enhance airflow within and through the foam layers.

Techniques to improve breathability include open-cell foam structures, ventilation channels, and the incorporation of breathable materials in the mattress cover. Open-cell foam allows for greater air circulation compared to closed-cell foam, facilitating heat dissipation. Ventilation channels, strategically placed within the foam layers, create pathways for air to flow through the mattress, promoting cooling. The use of breathable fabrics, such as cotton or bamboo, in the mattress cover further enhances breathability by wicking away moisture and allowing air to circulate. For example, a mattress utilizing open-cell memory foam and a cotton cover will generally exhibit superior breathability compared to a mattress constructed solely from closed-cell foam with a synthetic cover. Improper execution of ventilation strategies may result in uneven support or reduced durability, requiring careful design considerations.

Ultimately, breathability is a significant factor influencing the comfort and overall sleep experience. Insufficient breathability can lead to overheating and discomfort, while enhanced breathability promotes a cooler, drier, and more restful sleep environment. Individuals should consider the breathability characteristics of a polyurethane foam mattress, alongside other factors such as firmness and support, to ensure a suitable choice. Furthermore, advancements in material science are continually producing new and improved methods for enhancing breathability in foam-based bedding products. These ongoing innovations aim to mitigate the inherent heat retention properties of polyurethane foam and provide a more comfortable sleep surface.

7. Longevity

The lifespan of a polyurethane foam mattress is intrinsically linked to the characteristics of its constituent materials and construction techniques. Density, a primary determinant, directly influences resistance to compression and degradation over time. Higher density foams generally exhibit superior durability, maintaining their support and shape for extended periods compared to lower-density counterparts. For example, a high-density polyurethane foam core can withstand years of use before exhibiting significant sagging or loss of support, while a low-density alternative may deteriorate rapidly under similar conditions. The practical consequence of selecting an inappropriate density is a diminished lifespan and the potential for premature replacement, increasing long-term costs.

Beyond density, the composition plays a critical role. The specific types of polyols, isocyanates, and additives used in the foam formulation affect its resistance to oxidation, hydrolysis, and other degradation processes. Antioxidants and stabilizers are often incorporated to mitigate these effects, extending the material’s lifespan. Furthermore, the presence of fillers or low-quality components can compromise durability, accelerating wear and tear. Proper maintenance practices, such as regular rotation and the use of a mattress protector, can also significantly contribute to longevity. These simple actions minimize uneven wear, prevent liquid damage, and reduce the accumulation of dust mites, all of which can shorten the lifespan of the product. For instance, neglecting to rotate a mattress can result in localized compression and premature sagging in areas of high use.

The longevity of a polyurethane foam mattress is a complex interplay of material quality, construction, usage patterns, and maintenance. Understanding the relationship between these factors is crucial for making informed purchasing decisions and maximizing the value of the investment. While initial cost may be a primary consideration, prioritizing durability and proper care can ultimately lead to a more cost-effective solution over the long term. Addressing challenges includes proper foam formulation, which could affect comfort, quality and safety of product as well.

Frequently Asked Questions Regarding Polyurethane Foam Mattresses

The following addresses common inquiries and misconceptions surrounding this sleep surface. The information presented is intended to provide clarity and assist in making informed decisions.

Question 1: What is the typical lifespan of a polyurethane foam mattress?

Lifespan varies significantly based on foam density, construction quality, and usage patterns. A high-density model, properly maintained, may last 7-10 years. Lower density or poorly maintained models may degrade in as little as 3-5 years.

Question 2: Are there potential health concerns associated with off-gassing from polyurethane foam?

New mattresses may emit volatile organic compounds (VOCs), resulting in a noticeable odor. This off-gassing is generally considered harmless, diminishing within a few days. Certifications such as CertiPUR-US ensure low VOC emissions.

Question 3: How does firmness impact suitability for different sleeping positions?

Side sleepers typically benefit from softer surfaces that conform to the body’s contours, alleviating pressure on the shoulders and hips. Back sleepers generally require medium-firm support to maintain spinal alignment. Stomach sleepers often prefer firmer surfaces to prevent excessive sinking.

Question 4: What is the optimal density for enhanced durability and support?

For lasting support and resistance to compression, a density of at least 4 pounds per cubic foot (PCF) is recommended. Higher densities offer greater longevity and are particularly suitable for heavier individuals.

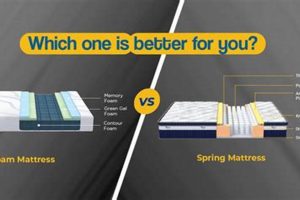

Question 5: How does this type of mattress compare to innerspring or latex mattresses?

Compared to innerspring, it often provides superior pressure relief and motion isolation. Compared to latex, it is typically less expensive but may not be as durable or breathable. The optimal choice depends on individual preferences and budget.

Question 6: What are the key maintenance practices to extend its lifespan?

Regular rotation (every 3-6 months) prevents uneven wear. A waterproof mattress protector safeguards against spills and stains. Avoiding jumping or placing excessive weight on specific areas minimizes the risk of damage.

Understanding these common concerns assists prospective buyers in selecting a product best suited to their needs and preferences. Addressing these questions enables informed decision-making.

The following section addresses disposal methods and environmental considerations.

Conclusion

This exploration of the polyurethane foam mattress encompasses its composition, characteristics, and considerations for selection, use, and maintenance. Key aspects such as density, firmness, thickness, and breathability significantly influence its suitability for diverse needs. The longevity and performance are contingent upon material quality, construction, and adherence to appropriate maintenance practices.

As the demand continues to evolve, informed consumers contribute to a market that prioritizes both comfort and environmental responsibility. Continued research and innovation in sustainable materials and responsible disposal methods are essential for mitigating the environmental impact and ensuring that the polyurethane foam mattress remains a viable and responsible bedding choice.

![Easy How-To: Cut Foam Mattress Like a Pro [DIY Guide] Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Easy How-To: Cut Foam Mattress Like a Pro [DIY Guide] | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-335-300x200.jpg)