A flexible bedding option, often composed of polyurethane or memory materials, designed to fit a convertible frame is a practical solution for space-saving and multi-functional furniture. An example would be a tri-fold base that unfolds into a bed using this type of mattress. Its construction prioritizes conforming to the body and ease of folding and unfolding.

The utility of these beddings stems from their adaptability, providing sleeping accommodations where space is limited. Historically, the concept of convertible furniture gained traction in urban environments and smaller living spaces, offering a convenient way to maximize functionality. Benefits include a relatively lower cost compared to traditional mattresses, ease of transport, and adaptability to various sleeping positions.

The composition, dimensions, and features available for these foldable mattresses vary significantly. This article will delve into the specifics of material types, construction methods, considerations for selecting the appropriate thickness, and factors influencing the overall comfort and durability.

Essential Considerations for Selecting a Convertible Bedding Solution

Choosing the right bedding for a convertible frame requires careful consideration of several factors to ensure both comfort and longevity. The following tips offer guidance on making an informed decision.

Tip 1: Assess Density and Firmness. Material density directly impacts support and durability. Higher density options generally offer better support and resist sagging over time. Firmness should align with individual sleeping preferences; side sleepers may prefer a softer surface, while back sleepers may benefit from firmer support.

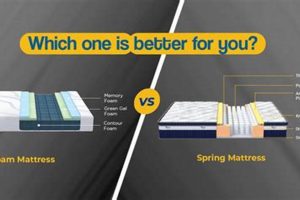

Tip 2: Evaluate Material Composition. Polyurethane, memory, and latex are common materials. Each offers unique characteristics regarding temperature regulation, motion isolation, and pressure relief. Research the properties of each material to determine the best fit for individual needs.

Tip 3: Determine Appropriate Thickness. Thickness influences comfort and foldability. Thicker options generally provide greater comfort but may compromise the ease of folding and unfolding. Consider the frame’s design and the desired balance between comfort and convenience.

Tip 4: Check for Certifications. Certifications, such as CertiPUR-US, indicate that the product has been tested for harmful substances and meets specific environmental standards. Prioritize certified options to ensure safety and quality.

Tip 5: Consider Cover Material. The cover material impacts breathability and cleaning ease. Options such as cotton or bamboo offer good breathability, while synthetic materials may be more resistant to stains and spills. Choose a cover material that aligns with lifestyle and maintenance preferences.

Tip 6: Inspect Stitching and Construction. Examine the stitching and overall construction for signs of quality craftsmanship. Secure seams and consistent stitching contribute to the durability of the mattress.

Tip 7: Factor in Weight Capacity. Convertible frames have weight limitations. Ensure that the selected mattress, combined with the weight of potential occupants, does not exceed the frame’s specified weight capacity to prevent damage or structural failure.

Careful attention to density, material, thickness, certifications, cover, stitching, and weight capacity ensures that the selected convertible bedding solution provides optimal comfort, durability, and safety.

These considerations establish a foundation for understanding the different types of materials and construction techniques used in convertible bedding. The subsequent section will provide a more in-depth analysis of these technical aspects.

1. Material Density

Material density is a critical factor influencing the performance and longevity of any foam-based mattress, especially those designed for convertible frames. Density, measured in pounds per cubic foot (PCF), directly correlates with the support, durability, and overall comfort provided by the mattress. Choosing a futon mattress with appropriate density is essential for ensuring both comfortable sleep and long-term utility.

- Support and Spinal Alignment

Higher density foam provides greater support, maintaining proper spinal alignment during sleep. Inadequate density can lead to sagging, which can contribute to back pain and discomfort. A foam mattress for a futon with a density of 4 PCF or higher is generally recommended for adequate support, particularly for individuals with higher body weights or those who prefer a firmer sleeping surface.

- Durability and Longevity

Density directly impacts the mattress’s lifespan. Lower density foams degrade more quickly under pressure, resulting in indentation and a loss of support over time. Higher density foams resist compression and maintain their shape for longer periods, extending the overall lifespan of the foam mattress for futon. Investing in a denser mattress can offer better long-term value.

- Motion Isolation

Denser foams generally exhibit better motion isolation properties. This means that movement on one side of the mattress is less likely to be transferred to the other side. For couples sharing a futon mattress, a higher density option can minimize disruptions caused by tossing and turning during the night. This is particularly relevant for memory foam, where higher density improves its ability to absorb and dampen motion.

- Temperature Regulation

While density itself doesn’t directly determine temperature regulation, it can influence airflow and breathability within the mattress. Very high-density foams can sometimes trap heat, particularly if the mattress lacks proper ventilation features. Choosing a foam mattress for a futon with breathable cover materials and open-cell foam structures can help mitigate heat retention issues, regardless of density.

The selection of an appropriate material density for a convertible frame mattress requires a careful assessment of individual needs and preferences. While higher density often translates to enhanced support and durability, factors such as sleeping position, body weight, and temperature sensitivity should be considered. Ultimately, the goal is to strike a balance between density, comfort, and overall functionality to ensure a satisfactory sleep experience.

2. Thickness Options

The thickness of a foam mattress designed for a convertible frame is a significant determinant of comfort, practicality, and suitability for diverse applications. Variations in mattress thickness affect support, ease of folding, and overall user experience. Understanding the available thickness options is critical to selecting a product that aligns with specific requirements.

- Comfort Level

Thickness directly relates to the cushioning and support provided. Thicker mattresses generally offer greater comfort due to increased material volume. A thicker option better distributes body weight, reducing pressure points. Conversely, thinner mattresses may compromise comfort, especially for individuals seeking enhanced support or pressure relief. The choice hinges on balancing the desire for cushioning with practical considerations such as frame compatibility.

- Folding Mechanism Compatibility

The folding mechanism of a convertible frame dictates the acceptable mattress thickness. Overly thick mattresses may hinder the frame’s ability to fold and unfold smoothly, potentially damaging the mechanism or rendering the conversion process cumbersome. Thinner mattresses, while easier to fold, may lack sufficient cushioning. Selecting a mattress thickness that complements the specific frame design is crucial for optimal functionality. For example, a tri-fold frame often necessitates a thinner profile compared to a bi-fold design.

- Storage Considerations

Thickness affects the space occupied when the convertible frame is in its folded configuration. Thicker mattresses increase the overall bulk, potentially making storage more challenging, especially in confined spaces. Thinner mattresses are more easily stowed, offering a practical advantage in environments where space is limited. This becomes especially relevant when the convertible unit is frequently transitioned between seating and sleeping arrangements.

- Cost Implications

Mattress thickness often correlates with cost, as thicker options typically require more materials and more complex manufacturing processes. Consumers must weigh the benefits of increased comfort against budgetary constraints. Thinner mattresses represent a more economical choice but may necessitate compromises in terms of support and longevity. A careful assessment of long-term value, considering both upfront cost and expected lifespan, is advisable.

These varied considerations regarding thickness underscore the importance of aligning mattress selection with intended use and environmental constraints. The optimal choice balances comfort, practicality, and budgetary considerations, ensuring both functionality and user satisfaction when utilizing a foam mattress on a convertible frame.

3. Folding Capability

The folding capability of a foam mattress designed for convertible furniture is a crucial determinant of its overall functionality and user convenience. The design and material composition directly influence the mattress’s ability to conform to the frame’s folding mechanism. Inadequate folding capability can lead to difficulties in transitioning between seating and sleeping configurations, potentially causing damage to the frame or the mattress itself. Therefore, understanding the characteristics that contribute to optimal folding is essential for selecting a compatible mattress. For instance, a rigid or overly thick mattress may resist bending at the designated folding points, creating undue stress on the frame’s hinges and rendering the conversion process cumbersome. Conversely, a mattress with insufficient density may fold too easily, lacking the necessary support in either the seating or sleeping position. The desired outcome is a balance between pliability and structural integrity.

The internal construction plays a significant role in a foam mattresss folding aptitude. Multi-layered mattresses, incorporating a combination of high-density and lower-density foams, are often engineered to facilitate bending. Strategically placed hinges or grooves within the foam core can further enhance flexibility at specific folding points. Real-world examples demonstrate the practical significance of this. Consider a convertible sofa bed used in a studio apartment; a mattress with excellent folding characteristics allows for seamless conversion from a sofa during the day to a bed at night, maximizing the available space. Conversely, a poorly designed mattress might require considerable effort to fold and unfold, diminishing the convenience and usability of the convertible furniture.

In summary, folding capability is not merely a secondary consideration but a primary functional attribute of foam mattresses intended for convertible frames. A mattress that folds readily and reliably contributes to the overall convenience and efficiency of the convertible furniture, enhancing its utility and appeal. Selecting a compatible mattress requires careful evaluation of its construction, density, and the presence of features designed to promote flexibility at designated folding points, ensuring seamless transitions between configurations. Challenges remain in achieving the ideal balance between folding ease and support; however, ongoing advancements in material science and mattress design continue to improve the folding capabilities of foam mattresses, further solidifying their role in versatile and space-saving furniture solutions.

4. Support Structure

The support structure within a convertible frame mattress is a critical factor determining its suitability for use as both a seating surface and a sleeping platform. Its influence spans comfort, durability, and the overall longevity of the product. The design and materials used in the support structure directly impact the ability of the mattress to distribute weight effectively and maintain its shape over time.

- Core Density and Distribution

The density of the foam core, coupled with its distribution throughout the mattress, dictates the level of support provided. Higher density foam concentrated in the center of the mattress can prevent sagging, particularly when used in a seating configuration. Similarly, reinforced edges contribute to stability and prevent premature wear along the perimeter. Failure to adequately distribute density can result in uneven support and a compromised sleeping surface. For example, a mattress with a low-density core may initially appear comfortable but will quickly lose its supportive qualities under sustained use, leading to discomfort and potential back problems.

- Layered Construction Techniques

The arrangement of different foam layers within the mattress contributes to the overall support structure. Incorporating a firm base layer, often composed of high-density polyurethane foam, provides a stable foundation. Softer layers, such as memory foam or latex, can then be added to enhance comfort without sacrificing underlying support. The strategic layering of these materials allows for a customized support profile, catering to different sleeping preferences. In contrast, a single-layer foam mattress may lack the necessary structural integrity to provide adequate support and pressure relief, leading to discomfort and reduced durability.

- Integrated Support Systems

Some convertible frame mattresses incorporate internal support systems, such as innerspring coils or strategically placed foam rails, to enhance structural integrity. These integrated systems provide additional reinforcement, particularly in areas prone to sagging or compression. The inclusion of innerspring coils, for example, can significantly improve support and responsiveness, mimicking the feel of a traditional mattress. However, these integrated systems must be carefully designed to maintain the mattress’s foldability and compatibility with the convertible frame. Poorly integrated support systems can create rigid areas that impede the folding process or damage the frame’s mechanism.

- Edge Support Reinforcement

Reinforcing the edges of a convertible frame mattress is crucial for preventing edge collapse and maximizing usable surface area. Edge collapse can occur due to repeated sitting or sleeping near the edge of the mattress, leading to discomfort and a reduction in the overall sleeping space. Edge support can be achieved through the use of denser foam rails, reinforced stitching, or integrated wire frames. Well-designed edge support not only enhances comfort but also extends the lifespan of the mattress by preventing premature wear and tear along the perimeter. Conversely, a mattress lacking adequate edge support will quickly develop a sloped or rounded edge, diminishing its aesthetic appeal and compromising its functionality.

The effectiveness of the support structure within a convertible frame mattress hinges on the careful selection of materials, the strategic distribution of density, and the integration of supplementary support systems. A well-designed support structure not only ensures comfort and proper spinal alignment but also contributes to the longevity and overall value of the product. Ignoring the importance of support can result in a substandard sleeping experience and premature degradation of the mattress, ultimately negating the benefits of its convertible design.

5. Cover Material

The outer encasement of a foam mattress significantly impacts its performance, durability, and hygiene. The choice of materials directly affects breathability, temperature regulation, ease of cleaning, and protection of the foam core from damage. The connection between the fabric and the interior material is symbiotic; the cover serves not only as a protective barrier but also influences the overall comfort and longevity of the sleep surface. Consider a futon mattress subject to frequent use in a living room setting: a durable, stain-resistant cover, such as a tightly woven polyester blend, is essential to withstand spills and general wear. A delicate or non-removable cover, conversely, could lead to premature degradation and sanitation issues.

Material composition influences practical application. Natural fibers like cotton and bamboo offer breathability and moisture-wicking properties, suitable for warmer climates or individuals prone to night sweats. Synthetic materials like polyester and microfiber provide increased durability and stain resistance, making them ideal for households with children or pets. Furthermore, features such as zippers for easy removal and washing enhance the overall utility of the futon mattress. An example is a zippered, machine-washable cover; it simplifies maintenance and extends the lifespan of the mattress by preventing the accumulation of dust mites, allergens, and odors. The absence of such features results in higher maintenance requirements and potential hygiene concerns.

In conclusion, the fabric is an integral component, directly influencing its functionality and longevity. The selection should align with specific needs, considering factors such as durability, breathability, ease of maintenance, and allergy sensitivities. Ignoring the importance of this encasement can lead to compromised comfort, hygiene issues, and a reduced lifespan. The interplay between the fabric and the core is crucial for optimizing the performance and value of the foam mattress.

6. Size Consistency

Precise dimensional conformity is crucial for integrating a foam mattress within a convertible frame. Variations in size can compromise functionality, comfort, and safety, thereby underscoring the necessity for strict adherence to specified measurements.

- Frame Accommodation

A mattress with dimensions exceeding the frame’s specifications may prove impossible to install or impede the conversion mechanism. Conversely, a mattress that is too small may shift during use, creating gaps that reduce sleeping surface area and potentially lead to discomfort. Accurate dimensions ensure secure and proper fitting within the intended frame.

- Folding Integrity

Variations in size can disrupt the folding mechanism’s intended operation. If one section of the mattress is shorter or longer than specified, the folding process may be uneven, potentially placing undue stress on the frame and shortening the lifespan of both the frame and the mattress. Consistent dimensions across all sections are essential for smooth, reliable folding.

- Seating and Sleeping Surface Uniformity

Inconsistencies in size can create uneven surfaces, affecting both seating and sleeping comfort. A mattress that is wider at one end than the other, for example, will result in an unstable seating platform and an unlevel sleeping surface. Uniform dimensions ensure a consistent feel and support across the entire mattress, regardless of its configuration.

- Standardization and Compatibility

Adherence to industry-standard dimensions promotes compatibility across different frames and mattress types. Standard sizes simplify the replacement process, allowing consumers to easily find a suitable replacement without requiring custom measurements. Failure to adhere to standard sizes creates challenges in finding appropriate replacements and can limit consumer choices.

The interplay between size consistency and a positive user experience is undeniable. Attention to dimensional accuracy is not merely a manufacturing detail, but rather a fundamental aspect that directly impacts functionality, comfort, and longevity. A correctly sized mattress ensures compatibility, reliable folding, and a consistent surface, ultimately enhancing the value and usability of the convertible frame.

Frequently Asked Questions

The following questions address common concerns and provide clarity regarding the use of foam mattresses on convertible frames.

Question 1: What material densities are recommended for optimal support and longevity?

Foam densities of 3.0 PCF (pounds per cubic foot) or higher are advisable for adequate support and resistance to sagging. Higher density options generally extend the lifespan of the mattress and maintain spinal alignment during sleep.

Question 2: How does mattress thickness affect the folding capability of a convertible frame?

Mattress thickness should be carefully matched to the frame’s folding mechanism. Overly thick options may impede folding, while excessively thin options may lack sufficient cushioning. Consult the frame manufacturer’s specifications for recommended mattress thickness ranges.

Question 3: What cover materials are most suitable for ease of cleaning and durability?

Tight-weave synthetic fabrics, such as polyester blends, provide enhanced stain resistance and durability. Removable, machine-washable covers are highly recommended for simplified maintenance and hygiene.

Question 4: How important is edge support in a foam mattress designed for a convertible frame?

Edge support is critical for preventing edge collapse and maximizing usable sleeping surface. Reinforced edges contribute to stability and prevent premature wear along the mattress perimeter.

Question 5: What certifications should be considered when evaluating foam mattresses?

Certifications such as CertiPUR-US indicate that the foam has been tested for harmful substances and meets specific emissions standards. Prioritize certified options to ensure safety and quality.

Question 6: How does the layering of different foam types contribute to overall comfort and support?

Layered construction techniques, incorporating a firm base layer and softer top layers, allow for a customized support profile. A firm base provides stability, while softer layers enhance comfort and pressure relief.

Careful consideration of material density, thickness, cover materials, edge support, certifications, and layering techniques contributes to the selection of a convertible bedding solution that delivers optimal comfort, durability, and functionality.

The subsequent section will provide guidance on proper maintenance and care to extend the life of the mattress.

Concluding Remarks on Foam Mattress for Futon

This exploration has delineated the significant aspects influencing the selection of a foam mattress for futon. Key considerations include material density, thickness options, folding capability, support structure, cover material, and size consistency. Each attribute contributes uniquely to the overall functionality and longevity of the product, impacting both comfort and practicality. Understanding these elements is paramount for making an informed purchase decision.

The utility of convertible furniture continues to expand. Selecting an appropriate foam mattress for futon is vital for maximizing the benefits of such adaptable furnishings. Continued advancements in material science and design promise further refinements in convertible bedding solutions, enhancing their performance and durability. Individuals are encouraged to leverage the insights provided herein to ensure a worthwhile investment in a versatile and enduring addition to their living space.

![Foam DIY: How to Cut a Mattress [Easy Guide] Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Foam DIY: How to Cut a Mattress [Easy Guide] | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-443-300x200.jpg)

![Best Foam or Spring Mattress for Toddler [Guide 2024] Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Best Foam or Spring Mattress for Toddler [Guide 2024] | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-383-300x200.jpg)

![Easy How-To: Cut Foam Mattress Like a Pro [DIY Guide] Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Easy How-To: Cut Foam Mattress Like a Pro [DIY Guide] | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-335-300x200.jpg)