A sleep surface designed for infants, crucial for safe sleep practices, is characterized by its unyielding nature. This design minimizes the risk of indentation or contouring under an infant’s weight. The absence of plushness is a defining feature, ensuring the baby rests on a flat, stable plane.

Utilizing a stable sleep surface is paramount for reducing the risk of Sudden Infant Death Syndrome (SIDS) and other sleep-related infant fatalities. A consistent, supportive plane promotes proper spinal alignment and reduces the likelihood of suffocation or entrapment. Historically, guidelines from pediatric health organizations have emphasized the necessity of this feature as a cornerstone of infant safety.

The subsequent sections will delve into the specific materials used in construction, regulatory standards governing production, and guidelines for selecting the appropriate option to ensure the utmost safety and well-being of the child.

Guidance on Selecting Infant Sleep Surfaces

The following recommendations are designed to assist caregivers in making informed choices regarding infant sleep surfaces, prioritizing safety and optimal development.

Tip 1: Prioritize Rigidity: Assess the firmness of the sleep surface by applying pressure to its center and edges. Minimal give indicates a suitable level of support necessary for infant safety.

Tip 2: Verify Compliance with Safety Standards: Ensure the chosen product adheres to safety regulations established by recognized organizations. Look for certifications that validate rigorous testing and adherence to safety protocols.

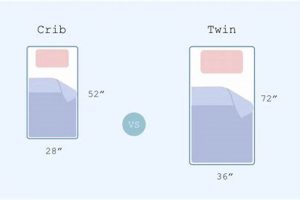

Tip 3: Confirm Proper Fit Within the Crib Frame: Measure the interior dimensions of the crib and compare them to the dimensions of the sleep surface. Gaps between the mattress and crib sides pose entrapment hazards.

Tip 4: Inspect for Durable Construction: Evaluate the quality of materials and stitching. Robust construction ensures longevity and prevents premature wear that could compromise the integrity of the sleep environment.

Tip 5: Consider Breathable Materials: Opt for coverings and materials designed to promote airflow. Breathability can reduce the risk of overheating and improve overall sleep comfort.

Tip 6: Maintain Cleanliness: Regularly clean the sleep surface according to the manufacturer’s instructions. A clean environment reduces the risk of allergen buildup and promotes hygiene.

Tip 7: Avoid Aftermarket Additions: Refrain from adding extra padding or cushioning. Such additions can compromise firmness and increase the risk of suffocation.

Adherence to these recommendations contributes to creating a safer sleep environment for infants, reducing the risks associated with SIDS and other sleep-related incidents.

The subsequent section will provide a comprehensive overview of the current research and scientific evidence supporting the importance of stable sleep surfaces for infant well-being.

1. Support

The term “support” as it relates to infant sleep surfaces, specifically within the context of a rigid sleep plane, directly refers to the degree of resistance offered against compression. In the context of “firm crib mattress,” support signifies the mattress’s ability to maintain a flat, unyielding surface under an infant’s weight, minimizing the risk of indentation or contouring. This characteristic is paramount because a yielding surface can create pockets or depressions that pose a suffocation hazard. Consider, for instance, an infant placed on a mattress that conforms excessively to their body shape. This contouring can obstruct airways, especially when the infant is placed on their stomach or rolls onto their side. The intended outcome of adequate support in a firm sleep surface is to mitigate this hazard by ensuring the infant’s face remains clear of obstruction, promoting safe breathing.

Furthermore, insufficient support can contribute to improper spinal alignment during sleep, potentially affecting musculoskeletal development. A stable plane provides a consistent foundation, encouraging a neutral spinal posture. The practical implication of this understanding is that caregivers should rigorously assess the support offered by a sleep surface before allowing an infant to use it. This assessment involves applying pressure across the surface to identify areas of excessive give or compression, thereby ensuring the selection of a product that aligns with established safety guidelines.

In summary, the concept of support is inextricably linked to infant safety when discussing rigid infant sleep surfaces. The ability of the product to deliver consistent, unyielding resistance against compression is not merely a comfort consideration but a crucial safety attribute. Selecting a product with adequate support is a pivotal step in creating a secure sleep environment and promoting infant well-being, while minimizing risks associated with SIDS and other sleep-related dangers.

2. Safety Standards

Regulatory benchmarks are integral to ensuring infant sleep surfaces mitigate potential hazards. Adherence to these standards provides a framework for manufacturers and a measure of assurance for caregivers.

- Federal Safety Regulations

Governmental bodies establish minimum safety requirements that manufacturers must meet. These often include tests for structural integrity, flammability, and presence of harmful chemicals. Failure to comply can result in recalls and penalties, emphasizing the legal mandate for adhering to safety protocols in production.

- ASTM International Standards

ASTM International develops voluntary consensus standards, widely recognized and adopted in the industry. These standards specify performance requirements related to firmness, dimensions, and materials, among other factors. Compliance with ASTM standards is often viewed as a benchmark for product quality and safety.

- Third-Party Certifications

Independent organizations offer certifications based on testing and verification of compliance with established standards. These certifications provide an additional layer of assurance for consumers, indicating that a product has been independently evaluated and meets specific safety criteria.

- Labeling and Information Requirements

Regulations mandate specific labeling requirements, including information about materials used, care instructions, and warnings about potential hazards. Clear and accurate labeling enables caregivers to make informed decisions and use products safely.

Navigating the landscape of regulations and certifications may seem complex, but the ultimate goal is to ensure infant sleep surfaces conform to established benchmarks for safety and quality, thereby minimizing risks and promoting infant well-being.

3. Proper Fit

The term “proper fit,” in the context of an infant sleep environment, denotes the dimensional compatibility between the crib frame and the sleep surface. This relationship directly impacts infant safety. When the sleep surface is smaller than the interior dimensions of the crib, gaps are created. These gaps present a risk of infant entrapment, potentially leading to suffocation or injury. For example, if a sleep surface is significantly undersized, an infant could become wedged between the edge of the sleep surface and the crib railing. Therefore, the sleep surface should fit snugly within the crib frame, minimizing or eliminating any discernible spaces.

The importance of a precise fit is accentuated when considering the properties of a firm sleep surface. A rigid plane resists compression and contouring, but it also lacks the ability to conform to the crib frame. Therefore, any dimensional discrepancy becomes a potential hazard, unlike a softer sleep surface that might partially fill a gap through compression. Achieving a proper fit necessitates accurate measurement of the interior crib dimensions and comparison against the dimensions provided by the sleep surface manufacturer. Furthermore, caregivers must regularly inspect the fit as part of routine safety checks, especially after assembling a new crib or replacing the sleep surface. Even slight variations in manufacturing tolerances can compromise safety over time.

In summary, a proper fit is not merely a matter of convenience but a crucial safety component of a functional crib. Gaps resulting from an improperly sized sleep surface introduce a demonstrable risk of infant entrapment and suffocation, particularly when using a rigid product designed to maintain a flat plane. Diligent attention to accurate measurement and regular inspection is essential for mitigating these risks and ensuring a secure infant sleep environment.

4. Material Composition

The selection of materials directly influences the performance and safety characteristics of rigid infant sleep surfaces. The internal core composition and the external covering impact firmness, breathability, and potential off-gassing. For example, a core made of high-density polyurethane foam provides substantial support, maintaining the flatness crucial for preventing suffocation hazards. Conversely, a core containing low-density materials may compress excessively, compromising safety. Likewise, coverings made of natural fibers, such as cotton, can promote air circulation, mitigating the risk of overheating, a known SIDS risk factor. In contrast, synthetic coverings might restrict airflow, potentially increasing the infant’s body temperature. Thus, material choice directly affects the product’s ability to provide a secure sleep environment.

Beyond structural integrity and breathability, the selection of materials affects exposure to potentially harmful chemicals. Some materials, such as certain plastics and adhesives, can release volatile organic compounds (VOCs), which may negatively affect infant health. Therefore, manufacturers often opt for materials certified as low-VOC or free from substances like phthalates and flame retardants. Certification programs such as GREENGUARD offer an independent verification of low chemical emissions. The practical significance of this understanding is that caregivers should diligently examine product labeling, seeking out certifications indicating minimal chemical exposure. Ignoring material composition can inadvertently expose an infant to substances that could impact respiratory function or overall development.

In summary, the material composition of infant sleep surfaces represents a critical determinant of safety and comfort. The internal core influences support and stability, while the external covering impacts breathability and chemical exposure. Understanding the interplay between material choices and product performance allows caregivers to make informed decisions that prioritize infant well-being. The responsible selection of materials contributes directly to minimizing risks associated with SIDS and promoting a healthier sleep environment.

5. Durability

The lifespan of an infant sleep surface directly relates to its capacity to consistently provide a safe sleep environment. Durability, in the context of a rigid infant sleep surface, signifies its resistance to degradation under prolonged use and environmental factors. A diminished capacity to maintain firmness compromises safety, potentially creating hazardous indentations or soft spots. For instance, a mattress exhibiting sagging or compression after a year of use no longer provides the flat, stable plane necessary for safe infant sleep. This degradation necessitates replacement, underscoring durability as a critical performance characteristic. The structural integrity of the core materials, the quality of the covering, and the seams holding the components together directly determine the longevity of the product.

The practical implication of understanding durability extends to cost considerations. While seemingly more expensive, a product with demonstrated longevity may prove more economical in the long run compared to frequently replacing inferior items. Furthermore, the choice of materials directly affects the product’s resistance to moisture, stains, and microbial growth. Enhanced resistance to these factors contributes to maintaining a hygienic sleep environment and prolonging the product’s usable life. Examples include mattresses constructed with water-resistant covers and antimicrobial-treated cores. Failure to consider durability can lead to premature wear and tear, compromising the product’s safety features and increasing the risk of hazardous conditions for the infant.

In summary, the durability of a rigid infant sleep surface represents a key aspect of infant safety and economic value. The ability to consistently provide a firm, stable, and hygienic sleep environment over an extended period is essential. Evaluating the quality of materials, construction techniques, and relevant certifications provides a basis for assessing durability. Selecting a durable product minimizes safety risks, reduces replacement costs, and contributes to a healthier sleep environment for the infant.

Frequently Asked Questions About Firm Crib Mattresses

The following questions address prevalent concerns regarding infant sleep surfaces, specifically focusing on rigidity and safety.

Question 1: What defines “firm” in the context of infant sleep surfaces?

Firmness refers to the sleep surface’s resistance to compression. An appropriately rigid sleep surface should exhibit minimal give when pressure is applied. Excessive yielding indicates inadequate support and potential safety hazards.

Question 2: Why is a rigid sleep surface recommended for infants?

A rigid surface reduces the risk of Sudden Infant Death Syndrome (SIDS) by preventing suffocation. A yielding surface can conform to the infant’s face, obstructing airways. Rigidity maintains a flat, open plane, minimizing this risk.

Question 3: How does one assess the firmness of a sleep surface before purchase?

Apply direct pressure to various points on the sleep surface, including the center and edges. The surface should exhibit minimal indentation. Visual inspection alone is insufficient; physical testing is essential.

Question 4: Are there specific regulatory standards governing the firmness of infant sleep surfaces?

Yes. Government regulations and organizations like ASTM International establish performance criteria. Verify that the product meets or exceeds these benchmarks before use.

Question 5: Can a topper or additional padding be added to a firm infant sleep surface?

No. Adding aftermarket padding negates the safety benefits of the rigid surface. These additions can create suffocation hazards and are strongly discouraged.

Question 6: How does the material composition affect the firmness and safety of the sleep surface?

Materials such as high-density foam contribute to firmness. Additionally, breathable materials can mitigate overheating risks. Select materials certified as low-VOC to minimize chemical exposure.

Prioritizing rigidity and adhering to safety guidelines are paramount when selecting infant sleep surfaces. Informed choices are crucial for safeguarding infant well-being.

The subsequent section will address the disposal and recycling of used infant sleep surfaces, promoting environmentally responsible practices.

Firm Crib Mattress

The preceding analysis has underscored the critical role of a firm crib mattress in fostering a secure sleep environment for infants. The attributes of support, adherence to safety standards, precise fit within the crib frame, careful material composition, and overall durability are paramount in mitigating risks associated with Sudden Infant Death Syndrome (SIDS) and other sleep-related incidents. The selection of a sleep surface should be guided by a thorough understanding of these factors, prioritizing the health and well-being of the child.

As research continues to evolve, caregivers must remain vigilant in staying informed about best practices and updated recommendations. By embracing a proactive approach to infant sleep safety, families can significantly reduce potential hazards and cultivate a sleep environment conducive to healthy development. Continued diligence in this area is essential for safeguarding the most vulnerable members of society.