The proportional measurements of differing mattress formats represent a crucial factor in selecting appropriate sleep surfaces. A key comparison lies between the larger and more compact options available, influencing individual comfort and spatial considerations. These dimensional distinctions cater to varying needs and room sizes.

Understanding the disparities in surface area is paramount for optimizing sleep quality and bedroom functionality. The decision impacts sleeping arrangements for couples, individuals desiring more space, and the overall aesthetic of the bedroom. Historical precedents reveal evolving preferences for larger sleeping surfaces as living spaces have adapted to accommodate them.

The following sections will delve into the specifics of these mattress formats, exploring their individual dimensions, suitability for different sleepers, and the implications for bedroom design and budget considerations. A detailed analysis will facilitate informed purchasing decisions.

Selecting the Right Mattress Size

Choosing between mattress sizes requires careful evaluation of individual requirements and spatial limitations. The following tips provide guidance for making an informed decision.

Tip 1: Measure Bedroom Space: Before considering mattress options, accurately measure the bedroom. Adequate space is essential to allow for comfortable movement around the bed and placement of other furniture. A room too small may feel cramped with a larger mattress.

Tip 2: Evaluate Sleeping Partners: If sharing a bed, consider the sleeping styles and space needs of each partner. Tossing and turning during the night can be disruptive, so a larger surface provides greater personal space and minimizes disturbance.

Tip 3: Consider Individual Size: Taller individuals often benefit from a larger mattress due to increased legroom and overall comfort. Ensure that the mattress length adequately accommodates the user’s height to avoid discomfort and restricted movement.

Tip 4: Analyze Budget Constraints: Larger mattresses typically incur higher costs, including the mattress itself, as well as associated bedding and frames. Evaluate the budget and allocate resources appropriately, balancing desired comfort with financial considerations.

Tip 5: Assess Long-Term Needs: Consider future life changes that may influence mattress needs, such as potential changes in sleeping arrangements or health conditions. Selecting a mattress that accommodates these potential changes can offer greater long-term value.

Tip 6: Review Mattress Types: Mattress type influences the feel and support it can provide. Some materials are better suited for some mattress sizes. Research if memory foam, latex or hybrid mattress are suited for your preference.

Tip 7: Think of Bedding Needs: Consider beddings that are suitable for mattress types. It is important to balance the material and sizes to create a comfortable sleeping experience.

By carefully considering these factors, consumers can make a well-informed decision regarding mattress size, optimizing sleep quality and bedroom functionality. Selecting the appropriate mattress dimensions is a crucial step in creating a comfortable and supportive sleep environment.

The next sections will cover specific mattress dimensions and their features in detail, to give the readers additional insights in choosing the right mattress for them.

1. Surface area

Surface area is a critical differentiator between king and queen-sized mattresses, directly influencing sleep comfort and spatial considerations. The larger surface area of the king provides increased personal space for sleeping partners, minimizing disturbances caused by movement during the night. This is particularly relevant for individuals who are restless sleepers or those sharing a bed with a partner who has different sleep schedules.

For instance, a standard king mattress typically offers a significant increase in surface area compared to a queen, translating to several additional inches in both width and length. This added space allows each sleeper more room to stretch out and find a comfortable position, reducing the likelihood of accidental contact or encroachment on the other’s space. The cause is the dimensions of the mattress, the effect is an improved sleep experience. The size is critical for a good night’s rest.

The practical significance of understanding the surface area differences lies in optimizing sleep quality and bedroom functionality. Careful consideration of individual needs and spatial limitations enables informed purchasing decisions, ensuring that the chosen mattress format aligns with both comfort preferences and the available room dimensions. The challenge of smaller bedrooms may push the consumer towards a queen, even if a king offers more comfortable sleep. Ultimately, the surface area plays a pivotal role in the overall sleep experience and bedroom environment.

2. Bedroom size

The available square footage of a bedroom profoundly influences the practicality and suitability of mattress size selection. Careful consideration of room dimensions is paramount to ensure comfortable movement, furniture placement, and overall aesthetic balance. Choosing between mattress formats requires a measured assessment of spatial constraints.

- Room Dimensions and Circulation

Adequate space is essential for navigating the bedroom without obstruction. A larger mattress format, while providing greater sleeping area, can impede foot traffic and limit access to closets or other furniture pieces. The layout of the room, including door and window placement, must be factored into the decision.

- Furniture Integration

The size and placement of accompanying furniture, such as nightstands, dressers, and chairs, are directly affected by mattress dimensions. A disproportionately large mattress can visually overwhelm the room and reduce the functionality of other essential furnishings. A balanced arrangement is crucial for aesthetic harmony.

- Minimum Clearance Requirements

Industry standards recommend a minimum clearance of two feet around the perimeter of the bed to allow for comfortable movement and ease of bed making. Failure to adhere to these guidelines can result in a cramped and uncomfortable living space. The mattress size should be chosen to accommodate these minimum clearances.

- Visual Aesthetics and Proportionality

The relationship between mattress size and room dimensions affects the overall visual appeal of the bedroom. A smaller room may feel disproportionately crowded with a very big mattress, while a large room might swallow a smaller mattress, making it appear insignificant. Achieving a visual balance is key to creating an inviting and harmonious atmosphere.

In summary, the square footage and configuration of a bedroom exert a significant influence on the appropriateness of mattress formats. The optimal choice necessitates a careful evaluation of spatial constraints, furniture integration, and aesthetic considerations. Thoughtful planning ensures that the selected mattress enhances both sleep comfort and the overall functionality of the living space.

3. Sleeping partners

The number and sleeping habits of individuals sharing a bed directly influence the optimal mattress size selection. A primary consideration when evaluating mattress dimensions rests on accommodating the needs of all sleeping partners. Insufficient space can lead to disrupted sleep patterns, discomfort, and reduced overall sleep quality. A larger mattress, typically a king-size, offers increased individual space, mitigating the impact of movement and variations in sleep schedules. For example, couples with differing sleep schedules, or one partner being a restless sleeper, often find a king-size more suitable due to its greater surface area, minimizing disturbances.

Conversely, a queen-size mattress may prove sufficient for couples with compatible sleep habits and limited bedroom space. However, even in these cases, considering the long-term potential for changes in sleeping arrangements or individual needs remains crucial. For instance, if one partner experiences a medical condition requiring more space or a different sleeping position, the limitations of a queen-size mattress may become apparent. The correlation between sleeping partners and mattress selection underscores the need for a balanced assessment of individual comfort requirements and spatial constraints.

In summary, the selection between mattress dimensions is significantly impacted by the number and sleep characteristics of individuals sharing the bed. Prioritizing the accommodation of all sleeping partners through informed size selection is essential for promoting optimal sleep health. Challenges can arise when balancing individual preferences with spatial limitations and budgetary considerations, emphasizing the importance of comprehensive planning and a long-term perspective when making mattress purchasing decisions.

4. Cost differential

The financial investment associated with mattress selection varies significantly based on size, construction materials, and brand reputation. A notable difference exists when comparing the expenses related to king-size versus queen-size mattress options. This cost differential extends beyond the initial purchase price, influencing supplementary expenditures.

- Initial Purchase Price

The upfront cost of a king-size mattress is generally higher than that of a queen-size mattress. This disparity stems from the increased materials required for the larger surface area. The cost can vary depending on the brand, mattress type (e.g., memory foam, innerspring, hybrid), and any specialized features. Budget-conscious consumers should compare prices across retailers and consider sales events to mitigate this initial investment.

- Bedding and Accessories

Bedding and accessories, such as sheets, comforters, and mattress protectors, typically cost more for king-size beds. The larger dimensions necessitate increased fabric usage, resulting in higher manufacturing costs passed on to the consumer. Replacement costs over the mattress’s lifespan should be factored into the overall cost assessment. Specialty materials will also raise prices significantly.

- Bed Frame and Foundation

A sturdy and appropriately sized bed frame and foundation are essential for supporting the mattress. King-size bed frames tend to be more expensive due to the increased size and load-bearing requirements. The material and design complexity of the frame also contribute to the price differential. A faulty support system can cause problems to a mattress.

- Transportation and Delivery

The transportation and delivery costs associated with a king-size mattress may be higher than those for a queen-size mattress. The larger dimensions and weight can necessitate specialized handling and larger vehicles, increasing logistical expenses. Consumers should inquire about delivery fees and any additional charges for in-home setup.

In summary, the cost associated with different mattress sizes encompasses several factors beyond the initial purchase price. Bedding, frames, foundations and delivery costs also should be considered. Comparing the total cost for each option is crucial for informed decision-making, balancing comfort preferences with budgetary constraints.

5. Bedding availability

The relationship between bedding availability and mattress size directly impacts consumer choice and satisfaction. Variability exists in the selection, style, and price points of bedding suitable for king versus queen-sized mattresses. This impacts the consumers purchase decision because it limits the expression of personal style through bedding choices if they were to choose a particular size. For example, a consumer who wants a particular designer pattern may choose a queen sized mattress because thats what the designer has options for.

The significance of this correlation lies in the consumer experience. Reduced availability of bedding options for larger or less common mattress sizes can lead to frustration and limited design flexibility. Conversely, a broader selection of readily available and competitively priced bedding enhances the appeal of specific mattress dimensions. The practical consequence of understanding this dynamic relates to inventory management for retailers and design decisions for bedding manufacturers. Bedding manufacturers may see lower profits if they chose to design for king or queen sized bedding due to material requirements.

In summary, bedding availability serves as an integral component in the overall value proposition of varying mattress sizes. Limitations in selection and higher price points for certain dimensions can present challenges for consumers. By addressing these disparities, retailers and manufacturers enhance consumer satisfaction, solidifying the connection between mattress selection and the seamless integration of complementary bedding products. Failing to address this need will cause a consumer to lean toward a mattress size that will give them the options they want in bedding availability and design.

Frequently Asked Questions

This section addresses common inquiries regarding the dimensional differences and suitability of varying mattress formats. Clarification of these points facilitates informed purchasing decisions.

Question 1: What are the precise dimensional differences between king and queen-size mattresses?

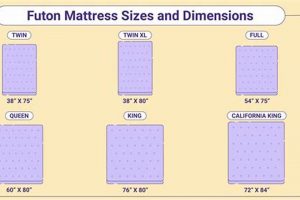

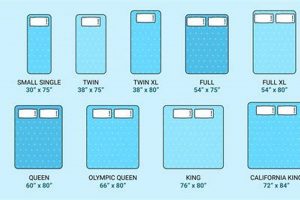

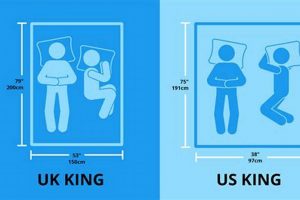

Standard king-size mattresses measure approximately 76 inches wide by 80 inches long. Queen-size mattresses measure approximately 60 inches wide by 80 inches long. The primary difference lies in width, with the king-size offering 16 additional inches.

Question 2: How does bedroom size influence mattress selection?

Larger mattresses require proportionally larger rooms to allow for comfortable movement and furniture placement. Smaller bedrooms may feel cramped with a king-size mattress, while larger rooms may accommodate a king-size mattress without compromising functionality.

Question 3: Is a king-size mattress always the best choice for couples?

While a king-size mattress offers increased personal space, its suitability depends on individual sleeping habits and room dimensions. Couples with compatible sleep styles and limited space may find a queen-size mattress adequate.

Question 4: What are the cost implications of choosing a king-size mattress?

King-size mattresses typically incur higher costs, including the initial purchase price, as well as bedding and frame expenses. Budgetary considerations should be factored into the decision-making process.

Question 5: Does mattress type affect the perceived size and comfort?

Yes, the internal construction of a mattress can influence its feel and support. For example, memory foam can contour to the body, potentially making a smaller mattress feel more spacious. Mattress type is an important element in the decision-making process.

Question 6: What is the minimum recommended bedroom size for a king-size mattress?

While specific recommendations vary, a bedroom measuring at least 12 feet by 12 feet is generally considered suitable for a king-size mattress. This allows for adequate clearance around the bed for movement and furniture placement.

The considerations outlined above address critical aspects of mattress selection. Comprehending these factors is essential for maximizing sleep quality and overall bedroom functionality.

The following sections will expand upon specific mattress features and their impact on comfort and support.

Concluding Remarks on Mattress Size Considerations

This exposition has illuminated the critical factors in evaluating mattress size, focusing specifically on the dimensional distinctions. These differences, primarily observed in surface area and overall footprint, exert considerable influence on sleep quality, bedroom functionality, and budgetary considerations. A comprehensive understanding of these elements is essential for discerning consumers.

The informed selection of a mattress hinges on a careful assessment of individual requirements, spatial constraints, and financial resources. A thoughtful decision ensures an optimized sleep experience and a harmonious integration of the chosen mattress within the broader context of the living space. The pursuit of restorative sleep warrants a deliberate and well-informed approach to mattress size selection.