The selection of appropriate sleep surfaces involves considering materials with distinct properties. Two prominent contenders are derived from different sources and exhibit varying characteristics influencing comfort, support, and durability. One is produced from the sap of rubber trees, processed into a resilient and buoyant material. The other is a synthetic viscoelastic polymer, known for its ability to conform to the body’s shape and distribute weight.

The impact of sleep quality on overall health and well-being is significant. Proper spinal alignment, pressure relief, and temperature regulation are crucial factors contributing to restful sleep. Historically, advancements in materials science have led to innovations in sleep technology, offering consumers a wider range of options designed to enhance sleep experience and address specific needs, such as allergies or musculoskeletal concerns. The evolution of these materials reflects a growing awareness of the importance of sleep for physical and cognitive function.

The following discussion will delve into the attributes of each material, examining differences in manufacturing processes, performance characteristics, and suitability for diverse sleep preferences. Key considerations will include firmness, breathability, motion isolation, and long-term performance, providing a basis for informed decision-making when selecting a mattress.

Selection Guidance

The selection of a sleep surface necessitates a comprehensive understanding of individual needs and material properties. The following guidance offers insights to inform the decision-making process.

Tip 1: Assess Firmness Preferences: Evaluate desired firmness levels based on sleep position and body weight. Individuals who sleep on their side often benefit from a softer surface that contours to the body, while back and stomach sleepers may require a firmer surface for adequate spinal support.

Tip 2: Evaluate Motion Isolation Requirements: Consider the sensitivity to movement. If sharing the bed with a partner, select a material known for its ability to minimize motion transfer, preventing disturbances from partner movements.

Tip 3: Analyze Temperature Sensitivity: Recognize the propensity to overheat during sleep. Materials with enhanced breathability promote airflow and dissipate heat, creating a cooler sleep environment. Open-cell structures and natural fibers can contribute to improved temperature regulation.

Tip 4: Scrutinize Durability Expectations: Examine the expected lifespan of the sleep surface. Materials with higher density and resilience typically exhibit greater longevity, resisting compression and maintaining support over time.

Tip 5: Investigate Off-Gassing Potential: Inquire about volatile organic compound (VOC) emissions. Certifications from reputable organizations, such as CertiPUR-US, indicate that the material has been tested for harmful substances and meets established standards.

Tip 6: Consider Hypoallergenic Properties: Evaluate the potential for allergic reactions. Natural materials often possess inherent antimicrobial properties, inhibiting the growth of dust mites and allergens.

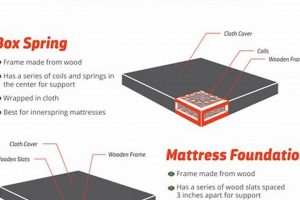

Tip 7: Research Support Structure: Investigate the construction and quality of the underlying support system. A robust foundation enhances the overall performance and durability of the sleep surface, distributing weight evenly and preventing sagging.

These considerations provide a framework for informed selection, enabling consumers to prioritize factors aligning with individual sleep needs and preferences. A well-informed decision contributes to enhanced sleep quality and overall well-being.

The subsequent sections will provide more details related to comparative maintenance and value retention.

1. Material Origin

The fundamental composition of sleep surfaces significantly influences their performance characteristics and environmental impact. The distinction in raw materials sets the stage for divergent properties regarding comfort, durability, and sustainability. Therefore, comprehending the origin is crucial for informed selection.

- Natural Rubber Harvesting

Natural results from processing sap extracted from rubber trees (Hevea brasiliensis). This sustainable agricultural practice involves tapping the trees without causing permanent damage. The harvested latex is then processed, typically using the Dunlop or Talalay method, to create foam. The eco-friendliness of production largely depends on responsible forest management and ethical labor practices.

- Synthetic Polymer Production

is derived from petroleum-based chemicals, undergoing a polymerization process to create a viscoelastic material. This process involves the combination of monomers, resulting in a substance capable of conforming to pressure and slowly returning to its original shape. The environmental implications of synthetic foam production involve the use of fossil fuels and the potential release of volatile organic compounds (VOCs).

- Production Method Variation

The journey from raw resource to finished goods contrasts sharply. Transformation includes tapping, collection, refinement, and vulcanization. By contrast, memory foam is often chemically produced and requires careful management of emissions and waste.

- Environmental Footprint Implications

Assessing sustainability requires a holistic evaluation of the entire lifecycle. Renewable resource utilization and biodegradable characteristics present potential advantages over reliance on non-renewable resources. Considerations include transportation, manufacturing processes, and end-of-life disposal methods. Choosing options with certifications from environmental organizations validates responsible production practices.

Ultimately, the origin directly impacts consumer experience, environmental stewardship, and long-term value. The understanding of these aspects enables individuals to align purchasing decisions with environmental consciousness and performance expectations.

2. Density Variance

Density, measured in pounds per cubic foot (PCF), is a critical determinant of performance and longevity. In both materials, density influences support, durability, and overall feel. Greater density generally indicates a more robust structure capable of withstanding compression and maintaining its shape over time. Lower density variants tend to exhibit reduced support and a shorter lifespan, potentially leading to sagging and diminished comfort.

exhibits a broader range of density options compared to its counterpart. Lower-density options, around 2-3 PCF, are often found in entry-level products or comfort layers, providing initial cushioning but potentially lacking long-term resilience. Higher-density versions, ranging from 4-6 PCF or more, offer superior support, conforming closely to the body and minimizing pressure points. This property makes high-density favorable for individuals seeking enhanced spinal alignment and pressure relief. In contrast, typically presents a more consistent density range, often between 4-7 PCF. Higher-density options provide a firmer feel and greater resistance to compression, while lower-density variations offer a softer, more responsive surface. The consistency in density contributes to its reputation for durability and consistent support characteristics. A mattress crafted with a lower-density core will likely degrade more rapidly compared to one built with a higher-density core.

Ultimately, density variance is a key factor differentiating these materials. Understanding its influence on support, durability, and overall feel empowers consumers to make informed decisions aligning with their individual sleep preferences and long-term value expectations. Improper material selection regarding density could lead to premature degradation and loss of the intended support characteristics, affecting sleep quality and overall product satisfaction. Therefore, careful consideration of density is essential for optimizing the investment in a sleep surface.

3. Support Dynamics

Support dynamics, the manner in which a sleep surface conforms to and bolsters the body, represent a critical differentiator. The materials’ inherent properties dictate their response to pressure, influencing spinal alignment, pressure relief, and overall comfort.

- Conforming Ability

Exhibits a distinct capacity to contour precisely to the body’s shape. Upon contact, it softens and molds around curves, distributing weight evenly and minimizing pressure concentrations. This characteristic is particularly beneficial for side sleepers, as it accommodates the shoulders and hips, promoting spinal alignment. By contrast, typically offers more uniform support. While it conforms to the body, it generally provides a more buoyant and less enveloping feel. This property can be advantageous for back and stomach sleepers, providing necessary support to prevent excessive sinking of the hips or torso.

- Pressure Relief Mechanisms

excels at pressure relief due to its viscoelastic properties. It absorbs and redistributes pressure, reducing stress on sensitive areas such as joints and pressure points. This capability makes it a suitable choice for individuals with arthritis, fibromyalgia, or other conditions characterized by chronic pain. The pressure relief provided by aids in reducing tossing and turning, promoting deeper and more restful sleep. offers a different form of pressure relief, relying on its elasticity and responsiveness. It cushions the body without excessive sinking, creating a feeling of floating. This type of support is often preferred by individuals who prefer a more responsive and less conforming sleep surface.

- Spinal Alignment Influence

Maintaining proper spinal alignment is paramount for preventing back pain and promoting overall musculoskeletal health. The support dynamics of a sleep surface play a crucial role in achieving this. The conforming ability of assists in maintaining spinal alignment by filling in gaps between the body and the mattress. This helps prevent spinal compression and reduces strain on back muscles. The buoyant support from promotes spinal alignment by preventing excessive sinking and maintaining a more neutral spinal posture. The appropriate selection ensures correct posture.

- Responsiveness and Rebound

Responsiveness refers to how quickly a sleep surface recovers its shape after pressure is removed. exhibits a slower response time, gradually returning to its original form. This characteristic contributes to its conforming and pressure-relieving properties. The slow response can also create a feeling of being “stuck” in the mattress for some individuals. generally exhibits a faster response time, quickly regaining its shape when pressure is removed. This responsiveness creates a more buoyant and energetic feel, allowing for easier movement and preventing the sensation of being trapped in the mattress.

The nuances in support dynamics contribute to divergent user experiences. Understanding these differences empowers consumers to align their selection with their specific needs and preferences. Individual variations in body type, sleep position, and underlying health conditions necessitate a tailored approach to sleep surface selection.

4. Thermal Properties

Thermal properties are a critical determinant of sleep comfort, influencing temperature regulation and overall sleep quality. The intrinsic characteristics of sleep surface materials dictate their ability to dissipate or retain heat, impacting the microclimate surrounding the sleeper. Disparities in thermal properties can significantly differentiate the sleep experience provided by the material options.

- Airflow and Ventilation

Airflow within a sleep surface is paramount for dissipating heat and preventing the accumulation of moisture. Exhibits an open-cell structure, promoting enhanced ventilation and airflow. The interconnected cells allow air to circulate freely, facilitating heat dissipation and maintaining a cooler sleep environment. In contrast, tends to have a denser and less permeable structure, restricting airflow and trapping heat. The closed-cell structure limits ventilation, potentially leading to overheating and discomfort, particularly for individuals prone to night sweats. The degree of airflow directly impacts the perceived temperature during sleep.

- Heat Retention Capacity

Heat retention refers to a material’s ability to absorb and store heat. Possesses a lower heat retention capacity compared to its counterpart. Due to its open-cell structure and enhanced airflow, it dissipates heat more readily, preventing the buildup of excessive warmth. exhibits a higher heat retention capacity due to its denser structure and limited airflow. It tends to absorb and retain heat, potentially creating a warmer sleep environment. Individuals who sleep hot may find this characteristic undesirable, leading to discomfort and disrupted sleep.

- Material Composition and Conductivity

The composition of a sleep surface material influences its thermal conductivity, which refers to its ability to transfer heat. The inherent properties of, derived from the sap of rubber trees, contribute to its moderate thermal conductivity. It conducts heat away from the body at a moderate rate, preventing excessive heat buildup. Synthetic polymer composition results in relatively low thermal conductivity. This means it is less efficient at conducting heat away from the body, contributing to higher heat retention. Enhanced designs could include the infusion of gel.

- Impact of Sleep Position and Ambient Temperature

Sleep position and ambient temperature interact with material thermal properties to influence the sleep experience. Individuals who sleep on their side or stomach tend to generate less heat compared to back sleepers, potentially mitigating the impact of materials with higher heat retention. Ambient temperature plays a crucial role in determining the overall thermal environment surrounding the sleeper. In warmer climates, choosing materials with enhanced airflow and lower heat retention becomes increasingly important for maintaining sleep comfort. Conversely, in colder climates, the heat-retaining properties of may be perceived as an advantage, providing added warmth and insulation.

The interplay of airflow, heat retention, composition, and external factors dictates the thermal performance. The degree of thermal regulation influences sleep latency, sleep duration, and overall sleep quality. Consumers should carefully consider their individual sleep patterns, environmental conditions, and temperature preferences when selecting a sleep surface material. Choices informed by an understanding of these properties promote a cooler, more restful sleep experience. Further understanding of product lifespan continues to offer insight.

5. Durability Metrics

Durability metrics serve as quantifiable indicators of a sleep surface’s lifespan and resistance to degradation. When evaluating options, these metrics become paramount in assessing long-term value and performance. Material composition, density, and manufacturing processes directly influence a mattress’s ability to withstand continuous use and maintain its structural integrity. Lower durability scores typically correlate with premature sagging, reduced support, and a shorter usable lifespan, requiring earlier replacement. In the context, understanding these measures is critical for aligning purchasing decisions with individual needs and expectations for sustained comfort.

Consider the impact of compression set, a key metric indicating a material’s ability to recover its original thickness after prolonged pressure. possesses inherent resilience, exhibiting minimal compression set over time. This contributes to its reputation for maintaining consistent support and comfort characteristics, often lasting for many years. Conversely, can be more susceptible to compression set, particularly lower-density variations. Over time, repeated compression can lead to permanent deformation, reducing its ability to provide adequate support and pressure relief. Real-world examples of mattresses with low durability scores often manifest as visible sagging in areas of high pressure, such as the hip or shoulder region. Similarly, reduced edge support can result in difficulty getting in and out of bed, compromising safety and convenience. The practical significance lies in the potential cost savings associated with selecting a more durable mattress, reducing the frequency of replacements and maximizing the return on investment.

In summary, durability metrics are essential in the comparative analysis of sleep surfaces. These metrics, encompassing factors such as compression set, density, and material composition, directly influence a mattress’s lifespan and performance. The choice between these materials requires a careful evaluation of these measures, ensuring that the selected option aligns with the individual’s needs, preferences, and long-term value expectations. Failure to consider these aspects can result in premature degradation, diminished sleep quality, and increased costs associated with earlier replacement, underscoring the importance of informed decision-making in mattress selection.

6. Cost Analysis

The economic evaluation of sleep surfaces necessitates a comparative analysis of initial purchase price, expected lifespan, and associated maintenance costs. Examining materials like products reveals disparities influenced by sourcing, manufacturing processes, and inherent material properties. Initial investment for is often higher, reflecting the sustainable harvesting practices and specialized processing involved in creating high-quality foam. The higher cost is frequently attributed to the resource-intensive nature of raw material extraction and processing, as well as the premium associated with its natural origin. A parallel analysis of suggests a generally lower entry point, primarily due to the synthetic nature of its production and economies of scale achieved through mass manufacturing.

Long-term cost considerations are equally pertinent. Despite a potentially higher initial investment, options often exhibit superior durability, resisting compression and maintaining support for an extended period. A longer lifespan translates to a reduced frequency of replacements, mitigating overall expenditure. A less durable may necessitate earlier replacement, offsetting the initial cost savings. Furthermore, potential healthcare savings linked to improved sleep quality merit consideration. Better spinal alignment and pressure relief might decrease the need for medical interventions related to back pain or musculoskeletal disorders. Conversely, the potential for off-gassing and associated health concerns might necessitate additional expenses for air purification or alternative mitigation strategies related to materials. Certifications from reputable organizations, such as OEKO-TEX, can add to initial costs but may provide long-term value by ensuring compliance with safety standards. The maintenance of both surface types constitutes an additional economic factor. Foam, with its open-cell structure, is often more breathable, requiring less frequent cleaning to prevent moisture buildup and microbial growth. Conversely, the denser structure of might necessitate more diligent cleaning practices to maintain hygiene and prevent allergen accumulation.

Ultimately, a comprehensive economic evaluation requires assessing both immediate and long-term costs, alongside intangible factors such as health benefits and environmental impact. While may represent a higher upfront investment, its potential for extended durability and improved sleep quality can provide significant long-term value. A decision based solely on initial price can prove economically short-sighted, neglecting the benefits and potential drawbacks of each material. In summary, cost analysis should integrate initial investment, long-term durability, potential health benefits, and the impact on environmental stewardship, enabling consumers to make well-informed decisions aligned with their economic and health-related priorities.

Frequently Asked Questions

The following section addresses prevalent inquiries concerning two common mattress materials. The information presented aims to provide clarity and facilitate informed decision-making.

Question 1: Is one material inherently superior for all individuals?

No. The ideal mattress material depends on individual sleep preferences, body weight, sleep position, and underlying health conditions. A thorough assessment of personal needs is recommended.

Question 2: Do foam mattresses off-gas harmful chemicals?

Synthetic foam may release volatile organic compounds (VOCs), especially when new. Selecting mattresses with CertiPUR-US certification can minimize exposure to harmful chemicals. Natural options minimize this risk.

Question 3: Which material provides better support for back pain?

Both materials can offer adequate support. However, foam’s conforming properties are often preferred by individuals with back pain, as it distributes weight and reduces pressure on the spine.

Question 4: Which type is more durable?

Generally exhibits greater durability and resistance to compression set. Synthetic variants can degrade more quickly, particularly lower-density options.

Question 5: How do the materials compare in terms of temperature regulation?

is more breathable due to its open-cell structure, facilitating heat dissipation. tends to retain heat, potentially leading to discomfort for individuals prone to overheating.

Question 6: Is there a significant price difference between the two materials?

typically commands a higher price point due to its natural origin and specialized manufacturing processes. Synthetic options are generally more affordable upfront.

The selection of a mattress material should be based on a comprehensive evaluation of individual needs and material properties. This information provides a framework for informed decision-making.

The subsequent section offers concluding remarks summarizing the key distinctions and considerations discussed.

Conclusion

This exploration of latex foam mattress vs memory foam has delineated the nuanced distinctions between these two prevalent sleep surface materials. Key differentiators include material origin, density variance, support dynamics, thermal properties, durability metrics, and cost implications. exhibits natural sourcing, breathability, and long-term resilience, whereas viscoelastic options provide conforming support, but may present challenges related to heat retention and durability.

The ultimate selection depends on aligning individual needs with material characteristics. Prospective purchasers must weigh the benefits of natural sourcing and durability against the affordability of synthetic alternatives. Rigorous consideration of these factors will yield a more informed decision, optimizing sleep quality and long-term value. The analysis presented offers a basis for discerning the most appropriate sleep solution.