Infant sleep surfaces manufactured by Simmons are designed to provide a firm and supportive area for babies. These products are constructed to meet safety standards and often incorporate features intended to promote comfortable and secure sleep. An example includes a dual-sided model, offering a firmer side for infants and a slightly softer side for toddlers.

The necessity of a proper sleep environment for infants is widely recognized for its impact on development and safety. These products aim to contribute to a secure sleeping space, minimizing potential hazards. Historically, the company has adapted its designs and manufacturing processes to adhere to evolving safety guidelines and consumer expectations, focusing on durability and support.

The subsequent sections will elaborate on specific materials used in the construction, discuss relevant safety certifications, and analyze typical product features found within this product category, providing a detailed overview of what constitutes a suitable sleep surface for infants.

Recommendations for Selecting Infant Sleep Surfaces

The following recommendations are provided to assist in the selection of a suitable infant sleep surface. Prioritizing safety and ensuring a proper fit within the crib are crucial considerations.

Tip 1: Firmness Verification: Ensure the sleep surface is sufficiently firm. A firm surface reduces the risk of infant suffocation. Press down on the sleep surface; it should quickly regain its shape and not conform excessively to the applied pressure.

Tip 2: Size and Fit Precision: Verify the product dimensions align with the interior dimensions of the crib. Gaps between the product and the crib frame present a safety hazard.

Tip 3: Safety Certification Review: Confirm the product carries certifications from recognized safety organizations such as ASTM International or JPMA. These certifications indicate the product has undergone testing to meet established safety standards.

Tip 4: Material Composition Assessment: Examine the materials used in the construction. Opt for materials that are non-toxic and free from harmful chemicals. Certifications such as CertiPUR-US can verify foam safety.

Tip 5: Waterproofing and Cleanliness: Select a model with a waterproof or water-resistant cover. This feature aids in maintaining hygiene and prevents the absorption of liquids, which can harbor bacteria.

Tip 6: Regular Inspection Protocol: Conduct routine inspections for signs of wear and tear, such as sagging, tears, or deterioration. Replace the product if any damage is detected.

Tip 7: Adherence to Safe Sleep Practices: Remember that a safe sleep environment extends beyond the product itself. Always place infants on their backs to sleep and avoid the use of loose bedding, pillows, and bumpers.

By adhering to these recommendations, caregivers can contribute to a safer and more secure sleep environment for infants. Selecting an appropriate sleep surface is a critical component of safe sleep practices.

The subsequent sections will delve into specific considerations related to the longevity and maintenance of infant sleep surfaces, further enhancing understanding of their role in infant care.

1. Firmness

Firmness is a critical attribute when evaluating infant sleep surfaces. For these products, it directly impacts infant safety and development. Insufficient firmness poses a suffocation hazard, while excessive firmness may compromise comfort. Therefore, selecting a product with appropriate firmness is paramount.

- SIDS Risk Mitigation

The relationship between firmness and Sudden Infant Death Syndrome (SIDS) is well-established. A firm surface reduces the risk of the infant’s face becoming entrapped, potentially obstructing breathing. Research suggests that softer surfaces contribute to a higher risk of SIDS, underscoring the necessity of a firm sleep surface. This attribute is carefully considered and engineered into products such as simmons crib mattresses to provide a safe sleep environment for infants.

- Spinal Development Support

Appropriate firmness provides essential support for the infant’s developing spine. A surface that is too soft may lead to spinal misalignment and hinder proper development. The firmness helps to maintain the infant’s natural spinal alignment during sleep, promoting healthy musculoskeletal development. Simmons crib mattresses are often designed with this critical aspect of development in mind.

- Product Testing and Standards Compliance

Firmness is a key parameter assessed during safety testing and certification processes. Standards organizations, such as ASTM International, specify minimum firmness requirements for infant sleep surfaces. Manufacturers such as Simmons subject their products to rigorous testing to ensure compliance with these standards. This commitment to compliance provides assurance that the product meets established safety benchmarks.

- Material Composition and Construction

The firmness of a sleep surface is directly related to its material composition and construction. Higher-density foam or innerspring systems typically provide greater firmness. The internal structure and materials are carefully selected to achieve the desired firmness level. Manufacturers of infant sleep surfaces, including Simmons, employ specific construction techniques to optimize firmness while maintaining comfort and safety.

These facets demonstrate the significance of firmness in relation to infant sleep surfaces. The interaction of material selection, testing standards, and health risks underscores the need to select products that provide appropriate firmness to promote infant safety and healthy development.

2. Dimensions

Dimensional conformity is paramount when considering infant sleep surfaces. The precise fit of the product within the crib frame directly impacts infant safety, negating potential hazards associated with ill-fitting sleep surfaces. Understanding dimensional requirements is thus essential for selecting appropriate products like Simmons crib mattresses.

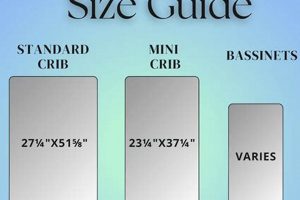

- Standard Crib Dimensions

Standard-size cribs in the United States adhere to established dimensional guidelines. These guidelines are intended to ensure uniformity and compatibility across different manufacturers. A standard crib typically measures approximately 28 inches in width and 52 inches in length. Simmons crib mattresses are designed to conform to these standard dimensions, enabling a secure fit within the crib frame.

- Gap Prevention

The primary purpose of dimensional accuracy is to prevent gaps between the sleep surface and the crib frame. Gaps present a significant entrapment hazard, potentially leading to infant injury or suffocation. Sleep surfaces that are too small may allow infants to become wedged in the space between the surface and the crib sides. Manufacturers, including Simmons, carefully engineer their products to minimize or eliminate such gaps.

- Dimensional Tolerances

While standard dimensions exist, manufacturing processes inevitably involve tolerances, or permissible variations from the stated dimensions. Acceptable tolerances are typically specified within safety standards. Reputable manufacturers, such as Simmons, adhere to strict quality control procedures to ensure that their products fall within these acceptable tolerances. This minimizes the risk of dimensional discrepancies leading to safety concerns.

- Measurement Verification

Prior to use, it is advisable to verify the dimensions of both the crib and the sleep surface. Accurate measurement can confirm that the sleep surface provides a snug fit, without excessive gaps. If significant discrepancies are noted, the product should not be used until the dimensional issue is resolved. This verification step adds another layer of precaution to ensure infant safety.

In summary, dimensional accuracy is a fundamental requirement for infant sleep surfaces. Adherence to standard dimensions, coupled with careful manufacturing processes and verification steps, contributes to a safer sleep environment. The correct dimensions of Simmons crib mattresses are crucial for ensuring infant safety.

3. Safety Certifications

Safety certifications serve as a crucial validation of infant sleep surface products. The presence of certifications from recognized organizations indicates that a specific Simmons crib mattress has undergone testing and meets established safety standards. These certifications are not merely symbolic; they represent a tangible commitment to minimizing risks associated with infant sleep environments. For example, a CertiPUR-US certification signifies that the foam used in the mattress has been tested for harmful chemicals and volatile organic compounds (VOCs). Similarly, a GREENGUARD Gold certification implies that the product has low chemical emissions, contributing to healthier indoor air quality. The absence of such certifications should raise concerns regarding the product’s safety and suitability for infant use.

The practical significance of safety certifications lies in their ability to offer consumers a degree of assurance regarding product safety. Certifications act as a third-party verification system, reducing reliance solely on manufacturer claims. For instance, a crib mattress bearing the JPMA (Juvenile Products Manufacturers Association) certification has been tested by independent laboratories to ensure compliance with ASTM (American Society for Testing and Materials) standards. This process encompasses assessments of flammability, structural integrity, and chemical content. Consumers can leverage these certifications as a decision-making tool, prioritizing products that have demonstrated adherence to recognized safety benchmarks. Specifically, Simmons crib mattresses that actively pursue and achieve these certifications demonstrate a commitment to infant safety that distinguishes them from products lacking such validation.

In conclusion, safety certifications are an indispensable element in the selection of infant sleep surfaces. These certifications represent a rigorous evaluation process, offering a degree of confidence in the safety and quality of a Simmons crib mattress. While no certification can eliminate all risks, their presence significantly reduces the likelihood of exposure to harmful chemicals and unsafe design elements. Prioritizing crib mattresses with recognized safety certifications is a fundamental step toward ensuring a safer sleep environment for infants. Understanding the specific criteria and implications of each certification type allows for informed decision-making, fostering increased confidence in the chosen infant sleep product.

4. Material safety

Material safety constitutes a critical element in the assessment of infant sleep surfaces. The selection of materials used in the construction of a Simmons crib mattress directly impacts infant health and well-being. Understanding material composition is essential for mitigating potential risks associated with chemical exposure and allergenic reactions.

- Foam Composition and Certifications

Many Simmons crib mattresses incorporate foam components for comfort and support. The specific type of foam used, and its chemical composition, directly impact safety. Certifications such as CertiPUR-US indicate that the foam has been tested for harmful substances like formaldehyde, phthalates, and heavy metals. The presence of such certifications provides assurance that the foam meets stringent safety standards and minimizes potential health risks to the infant. The absence of these certifications raises concern about the chemical profile of the foam.

- Fabric Selection and Treatment

The fabric used in the mattress cover also plays a role in material safety. Certain fabrics may contain allergenic dyes or chemical treatments. Look for fabrics that are labeled as organic or hypoallergenic, indicating a reduced risk of irritation or allergic reactions. Furthermore, the fabric should be free from flame retardants that may pose health risks. Simmons crib mattresses that utilize certified organic fabrics and avoid harmful chemical treatments prioritize infant safety.

- Waterproofing Materials

Many crib mattresses include a waterproof layer to protect the core from spills and accidents. The materials used for this waterproofing should be non-toxic and free from PVC (polyvinyl chloride), a plastic that can release harmful chemicals. Opt for waterproofing materials that are made from polyethylene or other non-toxic alternatives. Simmons crib mattresses employing polyethylene waterproofing offer a safer and more environmentally responsible choice.

- Adhesive and Binding Agents

Adhesives and binding agents are used to hold the various layers of the mattress together. These materials should be low-VOC (volatile organic compound) to minimize off-gassing of potentially harmful chemicals. Exposure to high levels of VOCs can cause respiratory irritation and other health problems. Simmons crib mattresses that utilize low-VOC adhesives prioritize indoor air quality and infant health.

The interplay of foam composition, fabric selection, waterproofing materials, and adhesives directly influences the overall material safety profile of a Simmons crib mattress. Selecting a product that utilizes certified safe materials minimizes potential risks to infant health, contributing to a more secure sleep environment. Prioritizing material safety is a critical aspect of informed decision-making when choosing an infant sleep surface.

5. Water resistance

Water resistance is a crucial feature in infant sleep surfaces, particularly those manufactured by Simmons. The presence of a water-resistant layer mitigates the absorption of liquids, such as urine or spit-up, into the core of the mattress. This prevents the growth of bacteria and mold, which can pose health risks to the infant. For instance, without water resistance, a single incident of fluid absorption can create a breeding ground for microorganisms, potentially leading to allergic reactions or respiratory issues. The effectiveness of the water-resistant barrier is a direct determinant of the product’s longevity and hygienic properties, making it an essential component of a Simmons crib mattress.

The practical application of water resistance extends to ease of cleaning and maintenance. A water-resistant surface allows for quick and efficient cleaning with a damp cloth, minimizing the need for harsh chemicals that could be detrimental to the infant’s health. Consider the scenario of nightly bedwetting; a water-resistant surface enables swift cleanup, preventing staining and odor retention. Furthermore, the integration of water resistance into the mattress design necessitates the use of specific materials and construction techniques, impacting the overall durability and performance of the product. The absence of adequate water resistance renders the sleep surface vulnerable to damage and significantly reduces its lifespan.

In summary, water resistance is a critical attribute of Simmons crib mattresses, directly impacting hygiene, durability, and ease of maintenance. Its presence is not merely a convenience but a necessity for safeguarding infant health and ensuring the longevity of the product. The efficacy of the water-resistant layer is paramount, requiring careful consideration of materials and construction methods. Neglecting water resistance in the selection process can lead to significant challenges related to hygiene and product lifespan, ultimately compromising the sleep environment for the infant.

6. Durability

Durability, in the context of an infant sleep surface such as a Simmons crib mattress, refers to its ability to withstand prolonged use, repeated cleaning, and the general wear and tear associated with infant care. A durable mattress maintains its structural integrity, firmness, and safety features over an extended period, providing continued support and a safe sleep environment for the infant.

- Material Resilience and Longevity

The materials employed in the construction directly impact durability. High-density foam cores, reinforced innerspring systems, and tear-resistant fabrics contribute to a longer lifespan. For instance, a mattress utilizing a high-density foam retains its shape and firmness more effectively than one made with lower-density materials. Similarly, a mattress cover constructed from a durable, woven fabric resists tearing and abrasion, withstanding frequent cleaning and use. The selection of resilient materials is a key factor in determining the overall durability of a Simmons crib mattress.

- Construction Integrity and Quality Control

The method of construction and the rigor of quality control measures influence the long-term performance of the mattress. Reinforced seams, secure binding agents, and consistent manufacturing processes contribute to a more robust and durable product. A mattress with poorly constructed seams may exhibit premature wear and tear, compromising its structural integrity. Stringent quality control protocols ensure that each Simmons crib mattress meets specified durability standards, minimizing the risk of defects and extending its usable lifespan.

- Resistance to Deformation and Sagging

A durable crib mattress resists deformation and sagging over time. Repeated use can compress the internal materials, leading to a loss of firmness and support. A mattress designed to resist compression maintains its shape and provides consistent support for the infant, promoting healthy spinal alignment and a safe sleep surface. Simmons crib mattresses incorporate design elements and materials intended to minimize deformation and sagging, ensuring long-term performance.

- Cleanability and Stain Resistance

A durable crib mattress is easy to clean and resists staining. Spills, accidents, and regular use can soil the surface, requiring frequent cleaning. A mattress with a water-resistant cover and stain-resistant properties simplifies cleaning and prevents the absorption of liquids, which can damage the internal materials. The ability to withstand repeated cleaning without degradation is an important aspect of durability. Simmons crib mattresses often feature water-resistant covers designed for easy cleaning and stain resistance, contributing to their overall durability.

The interplay of material resilience, construction integrity, resistance to deformation, and cleanability collectively determine the durability of a Simmons crib mattress. A durable mattress provides long-term value, maintains its safety features, and ensures a consistently supportive and hygienic sleep environment for the infant. The selection of a crib mattress should prioritize durability as a critical factor, ensuring a safe and reliable product throughout the infant’s crib-sleeping years.

Frequently Asked Questions about Infant Sleep Surfaces

The following questions address common inquiries and concerns regarding infant sleep surfaces, providing clarity and guidance for caregivers.

Question 1: What constitutes appropriate firmness for an infant sleep surface?

Appropriate firmness is characterized by a surface that is sufficiently rigid to prevent indentation or conforming to the infant’s body shape. When pressed, the surface should quickly regain its shape without leaving a lasting impression. This firmness reduces the risk of suffocation.

Question 2: How often should an infant sleep surface be replaced?

Replacement frequency is contingent upon condition and usage. Visible signs of wear, sagging, or structural damage necessitate immediate replacement. Absent such issues, replacement is recommended after a period of approximately five years, or as specified by the manufacturer.

Question 3: Are specific safety certifications necessary for infant sleep surfaces?

The presence of safety certifications from recognized organizations, such as ASTM International or JPMA, indicates adherence to established safety standards. These certifications demonstrate that the product has undergone testing for flammability, chemical emissions, and structural integrity. These certifications should be viewed as a prerequisite.

Question 4: What materials are considered safe for use in infant sleep surfaces?

Safe materials are characterized by low or non-existent levels of harmful chemicals, such as formaldehyde, phthalates, and heavy metals. Certifications like CertiPUR-US or GREENGUARD Gold signify that the materials have been tested for chemical emissions and meet established safety thresholds. Natural and organic materials are also considered safe alternatives, provided they meet flammability standards.

Question 5: How should an infant sleep surface be cleaned and maintained?

Cleaning protocols involve the use of mild soap and water. Harsh chemicals or abrasive cleaners are to be avoided. A water-resistant cover facilitates cleaning and prevents the absorption of liquids. Regular inspection for signs of wear and tear is essential for maintaining safety and hygiene.

Question 6: What is the recommended placement for an infant during sleep?

The recommended sleep position for infants is supine, or on their back. This position minimizes the risk of Sudden Infant Death Syndrome (SIDS). The use of pillows, blankets, and other soft bedding is to be avoided. A firm sleep surface, free from obstructions, is essential for safe sleep.

In summary, selecting an infant sleep surface involves careful consideration of firmness, safety certifications, material safety, maintenance protocols, and recommended sleep practices. Adherence to these guidelines contributes to a safer and healthier sleep environment for the infant.

The subsequent sections will explore the environmental impact of infant sleep surfaces and offer guidance on responsible disposal practices.

Conclusion

This exploration has outlined critical aspects of selecting an appropriate infant sleep surface, focusing on criteria relevant to products such as the Simmons crib mattress. Key points include the necessity of firmness, dimensional accuracy, adherence to safety certifications, the importance of material safety, and the contribution of water resistance and overall durability to product longevity and infant well-being. The information presented aims to provide a comprehensive understanding of the features and considerations pertinent to ensuring a safe and supportive sleep environment.

The responsibility for selecting suitable infant products rests with caregivers. Prioritizing safety, conducting thorough research, and carefully evaluating product specifications are paramount. Continued vigilance regarding evolving safety standards and recommendations is essential for promoting infant health and security within the sleep environment. A proactive and informed approach represents a commitment to the well-being of the most vulnerable population.

![Best Babyletto Midi Crib Mattress [Guide] For Your Crib Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Babyletto Midi Crib Mattress [Guide] For Your Crib | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1347-300x200.jpg)

![Crib Mattress vs. Twin Size Bed: Choosing Right [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Crib Mattress vs. Twin Size Bed: Choosing Right [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1346-300x200.jpg)