The structural component supporting a baby’s sleeping surface, found within certain types of infant beds, provides a foundation for the overlying cushioning. This framework contributes significantly to the firmness and stability of the sleep environment. For instance, a unit comprised of interconnected metal coils offers a resilient base, promoting even weight distribution.

Such a base offers increased airflow and helps distribute a babys weight evenly, potentially aiding in a more comfortable sleep experience. Traditionally crafted from metal, these systems provide enhanced support compared to solid platforms. The use of a spring-based understructure has evolved over time, reflecting advancements in materials and engineering aimed at optimizing infant sleep safety and comfort.

Understanding the intricacies of the foundational structure is essential when selecting appropriate sleep products. The following sections will delve into specific considerations regarding material composition, safety standards, and compatibility with various crib models, providing valuable insights for informed decision-making.

Crib Mattress Spring Frame

The selection and proper maintenance of this underlying support system are crucial for infant safety and sleep quality. These tips offer guidance on evaluating and caring for this integral component of the crib.

Tip 1: Verify Compliance with Safety Standards: Ensure the spring frame adheres to current safety regulations established by recognized organizations. Certification marks provide assurance of rigorous testing and compliance.

Tip 2: Inspect for Structural Integrity: Before use, carefully examine the metal framework for any signs of bending, rust, or breakage. Compromised structural integrity can pose a hazard.

Tip 3: Confirm Proper Fit within the Crib: The dimensions of the spring frame must precisely match the interior dimensions of the crib. Gaps between the frame and crib walls can create entrapment risks.

Tip 4: Assess Coil Density and Support: Higher coil density generally translates to greater support and durability. Examine the coil arrangement to ensure even distribution of weight.

Tip 5: Clean Regularly and Thoroughly: Periodically clean the spring frame with a damp cloth and mild detergent. Remove any dust or debris to maintain a hygienic sleep environment.

Tip 6: Avoid Placing Excessive Weight: Refrain from placing heavy objects on the spring frame, as this can lead to deformation or damage over time.

Tip 7: Monitor for Squeaking or Noise: Excessive noise from the spring frame may indicate wear or loose connections. Address these issues promptly to prevent disturbance to the infant’s sleep.

Adhering to these recommendations promotes a safe and supportive sleep environment for the infant. Regular inspection and appropriate maintenance contribute significantly to the longevity and functionality of the component.

In conclusion, careful consideration of these tips during selection and ongoing maintenance will contribute to the child’s well-being. The subsequent sections will address additional aspects related to infant sleep product safety.

1. Support

The primary function of a foundation is to provide adequate support for the overlying sleep surface. In infant beds, this role is often fulfilled by a coil structure. The density, gauge, and configuration of the coils directly influence the firmness and stability of the surface. Insufficient structural integrity can lead to uneven weight distribution, creating pressure points that disrupt sleep and may contribute to developmental issues. A foundation that lacks adequate spring coil may sag or compress prematurely, compromising support and necessitating replacement.

Consider a scenario where an infant sleeps on a frame with compromised spring support. Over time, the lack of uniform resistance can lead to postural distortions, affecting spinal alignment. Conversely, a well-engineered spring system maintains a consistent level of support across the entire surface, promoting proper skeletal development. For example, designs incorporating perimeter rods offer enhanced edge support, preventing sagging and ensuring consistent firmness from edge to edge. Further, some configurations may also add layers of mesh or other material to better support the baby’s form.

Therefore, recognizing the fundamental connection is crucial for selecting products. The quality of support directly impacts infant comfort, safety, and long-term physical well-being. Careful evaluation of coil density, frame construction, and compliance with safety standards is essential. Prioritizing robust infrastructure ensures appropriate support, promoting sound sleep and healthy development.

2. Durability

The longevity of a spring structure directly correlates with its material composition and manufacturing processes. Substandard materials or inadequate construction yield premature degradation, compromising structural integrity and posing potential safety hazards. Rusting, bending, or breakage of the metal components undermines the intended level of support, potentially creating an uneven sleep surface. For example, a frame constructed from low-gauge steel may deform under consistent pressure, leading to sagging and a non-uniform sleeping area. Conversely, high-quality steel, coupled with reinforced welds, enhances resistance to deformation and prolongs the usable lifespan.

The practical significance of ensuring resilience extends beyond mere product longevity. A reliable support system minimizes the risk of unexpected failures that could disrupt sleep or, more seriously, pose a threat of injury. For example, a sudden collapse of a weakened base could result in an infant becoming entrapped or suffering physical harm. Therefore, the initial cost savings associated with a less durable product may be offset by the potential need for premature replacement or, more critically, the risk of compromising infant safety. Regular inspection for signs of wear and tear is crucial in mitigating these risks and ensuring ongoing structural integrity.

In summary, structural integrity is not merely an attribute but a fundamental requirement for infant sleep products. Prioritizing robust construction and vigilant monitoring are essential to ensure ongoing functionality, minimize safety risks, and provide a consistent, supportive sleep environment. The relationship between material quality, construction methods, and long-term performance underscores the importance of informed purchasing decisions based on verified durability standards.

3. Safety Standards

Compliance with established guidelines is paramount in the manufacture and use of these bed components. Regulations are designed to mitigate potential hazards, ensuring infant safety during sleep. These standards encompass various aspects, including material composition, structural integrity, and dimensional requirements. Failure to adhere to these standards can result in product recalls, legal liabilities, and, most critically, potential harm to infants. For example, the Consumer Product Safety Commission (CPSC) mandates specific testing protocols to verify that manufactured goods withstand simulated use conditions, minimizing the risk of collapse or component failure. These protocols address issues such as metal fatigue, weld strength, and the presence of hazardous substances.

The implementation of these regulations stems from documented instances of injury and fatality associated with non-compliant products. Examples include entrapment caused by excessive spacing between the frame and the crib walls, suffocation hazards resulting from flimsy support materials, and exposure to toxic substances from substandard coatings. Consequently, adherence to safety standards is not merely a procedural formality but a critical component of risk mitigation. Manufacturers are obligated to demonstrate compliance through rigorous testing and certification processes. Furthermore, retailers are expected to verify that the products they offer meet these standards, and consumers are encouraged to seek out certified products and to report any safety concerns to regulatory agencies.

In conclusion, adherence to enforced standards is not an option but an obligation in the manufacture and distribution of the specified item. These standards are the result of ongoing research, incident analysis, and collaborative efforts among regulatory bodies, industry representatives, and consumer advocacy groups. Ongoing vigilance and continuous improvement in safety protocols are essential to ensure the well-being of infants during their formative years. This comprehensive approach, encompassing design, manufacturing, testing, and consumer awareness, is vital to prevent product-related injuries and fatalities.

4. Proper Fit

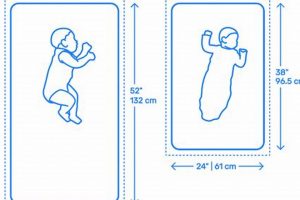

The correspondence between the dimensions of the spring understructure and the interior dimensions of the crib is critical for infant safety. Inadequate dimensional matching can introduce potential hazards, undermining the intended protective function of the crib environment.

- Elimination of Entrapment Hazards

Precise dimensional accuracy minimizes the risk of gaps between the frame and the crib’s inner surfaces. Excessive gaps can create entrapment points where an infant’s limbs, head, or torso could become lodged, posing a suffocation or injury risk. Regulatory standards specify maximum allowable gaps to mitigate this hazard.

- Ensuring Stable Support

A loose-fitting base may shift or tilt within the crib, creating an uneven or unstable sleeping surface. This instability can disrupt sleep, impede proper spinal alignment, and potentially increase the risk of rolling or falling. A secure and stable foundation is essential for maintaining a safe and consistent sleep environment.

- Preservation of Mattress Integrity

A frame that is either too small or too large can deform or damage the mattress. An undersized support structure may cause the mattress to sag or compress unevenly, reducing its lifespan and diminishing its supportiveness. Conversely, an oversized foundation may cause the mattress to buckle or bunch, creating uncomfortable pressure points.

- Adherence to Regulatory Standards

Safety standards stipulate specific dimensional tolerances for crib components, including the spring base. Compliance with these standards ensures that the product has undergone rigorous testing to minimize safety risks associated with improper fit. Certification marks indicate adherence to these regulatory requirements.

The preceding facets highlight the multifaceted importance of dimensional precision. These considerations emphasize the critical role of the support structure to ensure safety and structural integrity. Selection based on verified dimensional accuracy promotes a secure and stable sleep environment for the infant.

5. Air Circulation

Air circulation within a baby’s sleep environment is directly influenced by the design and materials of the foundational structure supporting the mattress. Adequate air permeability contributes to temperature regulation and the dissipation of moisture, minimizing the risk of overheating and the growth of microorganisms.

- Reduced Risk of Overheating

An open structure facilitates the movement of air, preventing the accumulation of heat around the infant’s body. Materials with low breathability can trap heat, potentially leading to discomfort or, in extreme cases, hyperthermia. A spring frame allows heat to dissipate through the open coil network.

- Minimization of Moisture Build-Up

Infants generate moisture during sleep, and inadequate ventilation can result in its accumulation within the mattress and bedding. A properly ventilated system allows moisture to evaporate, reducing the risk of bacterial or fungal growth, which can trigger allergic reactions or respiratory problems. The open design inherent in the construction promotes airflow around the mattress.

- Material Selection and Breathability

The type of materials used in the construction of the encompassing mattress influences the overall breathability of the sleep surface. Combining a spring frame with a mattress made of breathable materials, such as cotton or wool, maximizes airflow and minimizes moisture retention. Non-breathable materials can impede air movement, negating the benefits of the open structural support system.

- Maintenance and Airflow

Regular cleaning of the framework and the surrounding mattress is essential to maintain optimal airflow. Dust, debris, or spills can obstruct the ventilation pathways, reducing the effectiveness of the system. Periodic vacuuming or wiping down of the base structure helps to preserve its air-permeable properties.

The relationship between adequate ventilation and a safe sleep environment underscores the importance of carefully considering the support structure. The spring type structure, coupled with breathable mattress materials and diligent maintenance practices, collectively contributes to temperature regulation and moisture control, promoting infant health and comfort.

6. Weight Distribution

Even distribution of weight across the sleep surface is paramount for infant comfort and musculoskeletal development. The underlying structural component plays a critical role in achieving this equilibrium, ensuring the infant’s body is adequately supported and pressure points are minimized.

- Coil Density and Support Uniformity

The number of coils per unit area influences the degree of support provided. Higher coil density generally translates to more uniform weight distribution, preventing localized sagging and promoting proper spinal alignment. Inadequate density can result in concentrated pressure points, potentially leading to discomfort and disrupted sleep patterns. For example, systems with strategically placed coils in the center third of the frame may offer enhanced support in areas of increased pressure.

- Gauge of Steel and Structural Integrity

The thickness of the steel wire used in the coil construction directly affects the overall resilience of the structure. Thicker gauge steel is more resistant to deformation under prolonged pressure, maintaining its shape and ensuring consistent support over time. Frames constructed with thinner gauge steel may exhibit premature sagging, compromising weight distribution and reducing the lifespan of the product.

- Frame Design and Perimeter Support

The design of the surrounding frame contributes to edge support, preventing the infant from rolling toward the periphery of the crib. Reinforced edges help maintain uniform firmness across the entire surface, ensuring consistent weight distribution regardless of the infant’s position. Systems lacking adequate edge support may exhibit significant sagging near the edges, creating an uneven and potentially unsafe sleeping environment.

- Material Composition and Surface Conformity

The materials used in the mattress construction affect how the surface conforms to the contours of the infant’s body, influencing weight distribution. Softer materials, such as memory foam, can distribute weight more evenly than firmer materials, reducing pressure points. However, the support system beneath the mattress must provide adequate resistance to prevent excessive sinking, which can compromise support and potentially pose a suffocation hazard.

Consideration of coil density, steel gauge, frame design, and material composition is crucial to evaluate the efficacy of a foundational unit. A product exhibiting a robust design and adherence to safety standards promotes optimal weight distribution, fostering sound sleep and supporting healthy musculoskeletal development. Furthermore, regular inspection for signs of wear and tear ensures continued performance and safety.

Frequently Asked Questions

The following section addresses common inquiries regarding support structures, providing essential information to assist in making informed decisions.

Question 1: What are the primary benefits of using a design in a crib?

Such a construction enhances air circulation beneath the mattress, potentially reducing the risk of overheating. The structure also distributes weight more evenly, promoting comfort and support. Further, the understructure increases airflow and ensures structural integrity for a safe sleep environment.

Question 2: How does one determine if a certain component meets established safety standards?

Compliance is typically indicated by certification marks from recognized testing organizations. Review product labeling and manufacturer documentation for details regarding specific standards met, such as those from ASTM International or the CPSC.

Question 3: What are the key factors to consider when assessing the structural integrity?

Examine the quality of the materials used, weld strength (if applicable), and the overall construction. Look for signs of rust, bending, or breakage, which may indicate compromised integrity and potential safety hazards.

Question 4: How often should the sleep support system be inspected for wear and tear?

Regular inspections are recommended, ideally at least every time the bedding is changed. Pay close attention to any changes in firmness, stability, or the presence of unusual noises, as these may indicate underlying problems.

Question 5: Can any sleep support be used with any standard-size crib?

No. Proper fit is crucial for safety. Always verify that the dimensions match the interior dimensions of the crib. Gaps between the foundation and the crib walls can create entrapment hazards.

Question 6: What are the recommended cleaning and maintenance practices for the metallic structures?

Regularly clean the framework with a damp cloth and mild detergent. Avoid using harsh chemicals or abrasive cleaners, which can damage the surface. Ensure the unit is completely dry before placing the mattress back into the crib.

In summary, attention to safety standards, structural integrity, proper fit, and regular maintenance is crucial for maximizing the benefits and longevity of the foundational support component.

The subsequent section will delve into product selection recommendations.

Conclusion

The preceding exploration of the structural underpinnings of infant sleep environments has illuminated key factors influencing safety, support, and durability. The integrity and suitability of a crib mattress spring frame directly affect infant well-being, necessitating careful consideration of materials, construction, and adherence to established safety protocols. Vigilance in product selection and regular maintenance practices are essential to mitigate potential risks.

The understanding of these fundamentals is not merely an academic exercise but a practical imperative. By prioritizing structural integrity and safety in the sleep environment, caregivers contribute significantly to the healthy development and well-being of infants. Continued advancements in materials science and engineering hold the promise of further enhancing the safety and efficacy of these critical components. A continued commitment to safety is crucial.

![Top Rated Best Crib Mattress 2024 - [Buying Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Top Rated Best Crib Mattress 2024 - [Buying Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1359-300x200.jpg)