The dimensions of the sleeping surface within a Freightliner Cascadia are a critical consideration for drivers seeking comfort and adequate rest during long-haul operations. These measurements, typically expressed in inches, dictate the size of the mattress required for optimal fit within the sleeper berth. Different Cascadia models and trim levels may offer varying sleeper berth configurations, impacting the mattress dimensions needed. For example, a standard 72-inch raised roof sleeper cab typically requires a different mattress size compared to a smaller, day-cab configuration or a 48-inch sleeper.

Adequate rest is paramount for driver safety and regulatory compliance. A properly sized and comfortable mattress contributes significantly to improved sleep quality. This, in turn, can reduce fatigue, enhance alertness, and minimize the risk of accidents. Furthermore, comfortable rest facilitates better overall health and well-being for professional drivers, potentially leading to increased job satisfaction and reduced turnover rates within trucking companies. The consideration of sleeper berth size is not new; the trucking industry has long recognized the importance of driver comfort, though modern designs offer more options and better-engineered solutions than older models.

Given the variety in Freightliner Cascadia sleeper berth configurations, the following sections will delve into specific measurements, common mattress types, and factors to consider when selecting the appropriate sleeping surface to maximize driver comfort and optimize space utilization within the cab. These topics will include a discussion of standard sizes, custom options, and the impact of mattress thickness on overall comfort and available headroom.

Freightliner Cascadia Mattress Size

Selecting the correct sleeping surface for a Freightliner Cascadia is vital for driver comfort, health, and operational efficiency. The following guidelines offer crucial considerations to ensure an optimal fit and enhanced rest experience.

Tip 1: Measure the Sleeper Berth Accurately: Before purchasing a mattress, precisely measure the interior dimensions of the Cascadia’s sleeper berth. Account for any built-in cabinets or obstructions that may affect available space. Discrepancies in measurements can lead to ill-fitting mattresses, reducing comfort and usable space.

Tip 2: Consider Mattress Thickness: Mattress thickness impacts headroom within the sleeper berth. Select a thickness that provides adequate support and comfort without significantly reducing the available vertical space. A balance between comfort and functionality is crucial, especially for taller drivers.

Tip 3: Explore Custom Mattress Options: If standard sizes do not adequately fit the sleeper berth, consider custom-made mattresses. These can be tailored to the exact dimensions of the space, maximizing comfort and ensuring a proper fit. Custom options often allow for personalized firmness and material choices.

Tip 4: Prioritize Mattress Material and Support: Different mattress materials offer varying levels of support and temperature regulation. Memory foam, innerspring, and hybrid mattresses each have unique properties. Research and compare materials to determine which best suits individual preferences and sleeping habits. Proper spinal alignment is essential for restorative sleep.

Tip 5: Factor in Weight Considerations: The weight of the mattress can impact fuel efficiency, albeit marginally. While comfort and support should be prioritized, consider lighter materials if weight is a significant concern. Overloading the vehicle can lead to regulatory issues and safety concerns.

Tip 6: Check for Compatibility with Bedding: Ensure that standard bedding sizes are compatible with the selected mattress dimensions. Using ill-fitting sheets and blankets can reduce comfort and create unnecessary frustration. Consider purchasing bedding specifically designed for truck mattresses.

Tip 7: Assess Mattress Ventilation: Proper ventilation helps regulate temperature and prevent moisture build-up within the mattress. Look for mattresses with breathable materials and construction to enhance comfort and hygiene, especially in humid climates. Adequate ventilation can also extend the lifespan of the mattress.

Choosing the correct sleeping surface involves careful consideration of the sleeper berth dimensions, mattress material, support, and individual preferences. A well-chosen mattress promotes driver well-being and enhances overall operational efficiency.

The following sections will address common challenges related to mattress selection and provide guidance on addressing specific issues encountered within Freightliner Cascadia sleeper berths. These topics will include troubleshooting common fitting problems and advice on maintaining the integrity and lifespan of the chosen mattress.

1. Width and Length

The width and length dimensions are foundational determinants of the appropriate mattress size for a Freightliner Cascadia. These measurements directly dictate whether a mattress will adequately fill the available space within the sleeper berth, maximizing comfort and usability. Inadequate dimensions result in discomfort and inefficient use of the available space.

- Sleeper Berth Interior Dimensions

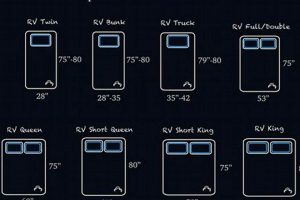

The interior width and length of the Cascadia’s sleeper berth define the maximum allowable dimensions for a mattress. These measurements vary depending on the sleeper configuration, with common options including 48-inch, 60-inch, and 72-inch berths. The accuracy of these measurements is critical; relying solely on nominal sizes without verifying actual dimensions can lead to incorrect mattress selection. For example, a 72-inch sleeper may not provide exactly 72 inches of usable mattress length due to interior paneling or storage compartments.

- Standard Mattress Sizes

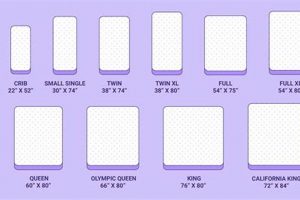

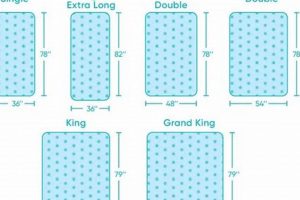

Standard mattress sizes, such as twin, full, queen, and king, are not directly applicable to the Freightliner Cascadia due to the unique dimensions of its sleeper berths. However, some manufacturers offer “truck mattresses” that approximate standard sizes while catering to the specific dimensions of truck cabs. Understanding the true dimensions, versus relying on approximate size categories, is essential. A “truck twin” may vary slightly in width or length from a standard twin mattress.

- Custom Mattress Solutions

When standard truck mattresses do not adequately fit the available space, custom-sized mattresses provide a solution. These can be manufactured to the precise width and length required, ensuring optimal fit and maximizing usable space. Custom solutions are particularly relevant for older Cascadia models with non-standard sleeper berth dimensions or for drivers seeking a flush fit to minimize gaps and movement. The ability to specify dimensions down to the inch can significantly enhance comfort.

- Impact on Sleep Quality

The relationship between mattress width/length and sleep quality is significant. A mattress that is too narrow restricts movement, leading to discomfort and disrupted sleep. A mattress that is too short forces the driver to contort their body, resulting in muscle strain and reduced restfulness. Proper width and length dimensions ensure that the driver can stretch out comfortably and achieve a restful sleep, which is crucial for maintaining alertness and safety during long-haul operations. Insufficient sleep due to an improperly sized mattress can lead to fatigue and increased risk of accidents.

The interplay between sleeper berth dimensions, standard mattress options, and custom solutions highlights the importance of accurate measurement and careful consideration when selecting a mattress for a Freightliner Cascadia. Ultimately, the goal is to provide a comfortable and safe sleeping environment that supports the driver’s well-being and operational efficiency.

2. Mattress Thickness

Mattress thickness, in the context of Freightliner Cascadia sleeping arrangements, significantly impacts comfort, functionality, and available space within the sleeper berth. Selecting an appropriate thickness requires careful consideration of various factors to ensure driver well-being and optimal utilization of the cab’s limited space.

- Headroom Constraints

The height of the sleeper berth roof in a Freightliner Cascadia imposes a direct constraint on mattress thickness. Excessive thickness reduces headroom, potentially causing discomfort and restricting movement within the cab. This is particularly relevant for taller drivers who require adequate vertical space for comfortable movement. A mattress that is too thick can also impede access to overhead storage compartments or interfere with other interior features.

- Support and Comfort Levels

Mattress thickness is often correlated with the level of support and comfort provided. Thicker mattresses typically incorporate more layers of padding and support materials, potentially enhancing pressure relief and spinal alignment. However, the relationship is not linear; a thinner, high-density foam mattress may offer comparable or superior support to a thicker, lower-density option. The optimal thickness depends on the specific materials used and the driver’s individual preferences regarding firmness and support.

- Sleeper Berth Configuration

The specific configuration of the sleeper berth within the Freightliner Cascadia influences the acceptable range of mattress thicknesses. A raised-roof sleeper offers greater vertical clearance, allowing for thicker mattresses without compromising headroom. Conversely, a standard-height or low-roof sleeper necessitates a thinner mattress to maintain adequate space. The presence of built-in storage compartments or other fixtures within the berth can further restrict the available space for a thicker mattress.

- Accessibility and Bedding Fit

Mattress thickness affects accessibility to the bed and the fit of standard bedding. An excessively thick mattress may make it difficult to climb into the sleeper berth, particularly for drivers with limited mobility. Furthermore, standard-sized sheets and blankets may not adequately fit a very thick mattress, requiring the purchase of specialized or custom-sized bedding. These practical considerations should be factored into the mattress selection process.

The selection of mattress thickness within a Freightliner Cascadia requires a careful balance between maximizing comfort and ensuring adequate headroom and functionality. Factors such as the sleeper berth configuration, driver height, and personal preferences regarding support and firmness must be considered to achieve an optimal sleeping environment. Overlooking these elements can compromise driver rest and overall operational effectiveness.

3. Sleeper Berth Configuration

The Sleeper berth configuration in a Freightliner Cascadia directly dictates the necessary mattress dimensions. Variances in sleeper size, roof height, and internal features create distinct spatial limitations. For instance, a 72-inch raised-roof sleeper provides significantly more volume than a 48-inch flat-roof variant. The physical boundaries of each configuration necessitate correspondingly sized mattresses to ensure proper fit and maximize available sleeping space. Ignoring these configuration-specific dimensions results in either wasted space, if the mattress is too small, or an inability to fit the mattress within the berth, if it exceeds the allowable measurements. Furthermore, built-in storage or appliances within the sleeper area impinge on the available mattress area, potentially requiring custom mattress solutions.

Real-world examples underscore the importance of configuration awareness. A common scenario involves drivers purchasing a standard “truck mattress” without verifying its compatibility with their specific Cascadia sleeper. If the driver operates a Cascadia with a non-standard or modified sleeper, the pre-fabricated mattress may not fit correctly, leading to discomfort and reduced sleep quality. Conversely, understanding the interplay between configuration and dimensions allows for precise mattress selection. Drivers who meticulously measure their sleeper berth and consider the presence of any internal obstructions can select a mattress that conforms precisely to the available space, optimizing comfort and functionality. This understanding also facilitates informed decisions regarding custom mattress orders, where precise dimensions can be specified to accommodate unique sleeper configurations.

In summary, the sleeper berth configuration serves as the primary determinant of appropriate mattress dimensions within a Freightliner Cascadia. Recognizing the impact of sleeper size, roof height, and internal features is crucial for selecting a mattress that maximizes comfort and utilization of available space. Challenges arise when drivers overlook configuration-specific dimensions or rely on generic “truck mattress” sizes. However, by meticulously measuring the sleeper berth and accounting for any internal obstructions, drivers can secure a mattress that provides optimal rest and supports their overall well-being, ultimately enhancing safety and operational efficiency.

4. Standard vs. Custom

The dichotomy between standard and custom mattress sizes within Freightliner Cascadia sleeper berths directly influences driver comfort and space utilization. Standard mattress options offer a cost-effective and readily available solution, designed to approximate common sleeper dimensions. However, variations in Cascadia models, modifications to existing berths, and individual preferences often render standard sizes suboptimal. This discrepancy arises because “standard” sizes represent averages, not precise fits. A standard truck mattress, for example, may leave gaps in the berth or compress against interior walls, impacting sleep quality. The selection of standard sizes, while convenient, necessitates accepting a degree of compromise in terms of fit and comfort.

Conversely, custom mattress solutions address the limitations of standard options by offering precise dimensional tailoring. Customization allows for accounting for unique sleeper berth configurations, including non-standard lengths, widths, and cutouts for storage compartments or appliances. This precise fit minimizes wasted space and eliminates pressure points caused by mattress compression. Furthermore, custom mattresses enable the selection of specific materials, firmness levels, and construction techniques, catering to individual preferences and addressing specific needs such as back support or temperature regulation. While custom mattresses entail higher initial costs and longer lead times, the enhanced comfort and improved sleep quality can lead to increased driver well-being and reduced fatigue-related risks.

In summary, the choice between standard and custom mattress sizes for a Freightliner Cascadia hinges on a trade-off between cost and comfort. Standard options provide convenience and affordability but may compromise fit and individual preferences. Custom solutions, while more expensive, offer superior comfort, precise fit, and tailored support. The optimal choice depends on a careful assessment of individual needs, sleeper berth characteristics, and budgetary considerations. The ultimate goal is to provide a sleep environment that promotes driver well-being and enhances operational safety.

5. Material Composition

The material composition of a mattress intended for a Freightliner Cascadia directly influences its suitability for use within the constrained space of the sleeper berth. The density and type of materials used impact the overall dimensions, particularly the thickness, and therefore the effective size of the mattress within the cab. For instance, a memory foam mattress of a given thickness will conform differently to the sleeper’s body compared to an innerspring mattress of the same thickness, affecting the perceived space available and the level of support provided. A high-density foam core may allow for a thinner overall mattress design while maintaining adequate support, thus optimizing space within the cab. Conversely, lower-density materials may necessitate greater thickness to achieve comparable support levels, potentially compromising headroom and maneuverability within the confined area. The choice of materials is thus inextricably linked to the effective utilization of the available area defined by the “freightliner cascadia mattress size.”

Consider a driver operating a Cascadia with a limited-height sleeper. If a mattress constructed primarily of bulky, low-density materials is selected, it may reduce the available headroom to an unacceptable level, creating an uncomfortable and potentially unsafe sleeping environment. In contrast, a mattress incorporating high-density memory foam or latex could provide adequate support and comfort within a thinner profile, preserving valuable headroom. Furthermore, the breathability of the materials affects temperature regulation and moisture management within the confined space. Materials with poor ventilation can lead to discomfort and potentially affect sleep quality, exacerbating fatigue. Therefore, understanding the properties of various mattress materials including their density, compressibility, breathability, and support characteristics is crucial for selecting a sleeping surface that optimizes both comfort and space utilization within the “freightliner cascadia mattress size” parameters.

In conclusion, the material composition of a Cascadia mattress is not merely a matter of comfort preference, but a critical determinant of its effective size and suitability for use within the limited confines of the sleeper berth. Proper material selection can optimize space, enhance support, and improve overall sleep quality, contributing to driver well-being and safety. Conversely, neglecting the material composition can lead to compromised comfort, reduced headroom, and potentially unsafe sleeping conditions. Therefore, a thorough understanding of material properties is essential for making informed decisions regarding the appropriate mattress for a “freightliner cascadia mattress size” application.

6. Weight Considerations

Weight, while seemingly secondary to dimensions and comfort, constitutes a relevant factor when selecting a mattress for a Freightliner Cascadia. The cumulative weight of all onboard equipment impacts fuel efficiency and compliance with regulatory weight limits. Therefore, a comprehensive assessment of mattress weight is essential.

- Regulatory Compliance and Axle Weight Distribution

Commercial vehicles operate under strict weight regulations to protect infrastructure and ensure safety. The placement of a mattress within the sleeper berth contributes to the overall distribution of weight across the vehicle’s axles. Exceeding axle weight limits can result in fines, penalties, and potential safety hazards. Consequently, selecting a lighter mattress option can assist in maintaining compliance, particularly when the vehicle is nearing its maximum permissible weight. An unexpectedly heavy mattress can push the vehicle over a legal limit, creating operational problems and financial burdens.

- Fuel Efficiency and Operating Costs

The total weight of a vehicle directly affects fuel consumption. While the weight of a mattress may represent a small fraction of the overall vehicle weight, even incremental weight reductions can contribute to improved fuel efficiency over time. For long-haul operators, these savings can accumulate significantly, reducing operating costs and enhancing profitability. Selecting a lightweight mattress constructed from modern materials can offer a tangible, albeit modest, improvement in fuel economy.

- Material Selection and Weight Trade-offs

Different mattress materials exhibit varying weight characteristics. For instance, innerspring mattresses tend to be heavier than memory foam or latex mattresses of comparable dimensions. The density of the foam used in memory foam mattresses also influences weight, with higher-density foams typically being heavier. When weight is a primary concern, careful consideration should be given to the material composition of the mattress, balancing weight reduction with desired levels of comfort and support. An informed decision requires understanding these trade-offs to optimize the sleeping experience while minimizing weight impact.

- Durability and Longevity Implications

While lighter mattresses may offer weight advantages, it is crucial to consider their durability and longevity. Some lightweight materials may be more prone to wear and tear, potentially requiring more frequent replacement. The long-term cost of replacing a less durable, lightweight mattress may outweigh the initial fuel savings. A balanced approach involves selecting a mattress that provides adequate support and comfort, minimizes weight, and offers reasonable durability to ensure a cost-effective solution over the lifespan of the vehicle.

Therefore, while the dimensions defined by “freightliner cascadia mattress size” are paramount, weight considerations should not be overlooked. The cumulative effect of onboard weight impacts both regulatory compliance and operational efficiency. Selecting a mattress that optimizes weight, without compromising comfort and durability, contributes to a more sustainable and cost-effective operation. Understanding the interplay between material properties, weight implications, and long-term costs is essential for making an informed decision that supports both driver well-being and business objectives.

Frequently Asked Questions

This section addresses common inquiries and clarifies misconceptions regarding mattress dimensions and selection for Freightliner Cascadia sleeper berths. The information provided aims to offer a comprehensive understanding of relevant factors to ensure optimal driver comfort and safety.

Question 1: What are the standard mattress sizes for a Freightliner Cascadia?

Standard mattress sizes commonly found in residential settings are generally inapplicable to Freightliner Cascadia sleeper berths. Truck mattresses, designed to approximate standard dimensions, are often marketed for these vehicles. However, precise dimensions vary depending on the specific Cascadia model and sleeper configuration. Verification of actual dimensions is essential before purchase.

Question 2: How does sleeper berth configuration influence mattress selection?

Sleeper berth configuration, including the length and roof height, directly dictates the maximum allowable mattress dimensions. Longer sleeper berths and raised-roof models accommodate larger mattresses. Short or flat-roof configurations necessitate smaller mattresses to maintain adequate headroom. Built-in storage compartments may further restrict available space, requiring custom-sized mattresses.

Question 3: What is the significance of mattress thickness in a Cascadia sleeper berth?

Mattress thickness impacts headroom within the sleeper berth. An excessively thick mattress reduces vertical space, potentially causing discomfort. The optimal thickness balances support and comfort with the need for adequate headroom and accessibility to storage compartments. Tall drivers should prioritize thinner mattresses to maximize available space.

Question 4: Are custom-sized mattresses necessary for Freightliner Cascadias?

Custom-sized mattresses are not always necessary, but they offer significant benefits in terms of fit and comfort. They are particularly useful for non-standard sleeper configurations or when precise dimensions are required to maximize available space. Custom options also allow for personalized firmness and material choices, catering to individual preferences.

Question 5: What materials are commonly used in Cascadia truck mattresses, and what are their benefits?

Common mattress materials include memory foam, innerspring, and latex. Memory foam conforms to the body, providing pressure relief. Innerspring mattresses offer traditional support. Latex provides a balance of support and responsiveness. Each material has unique properties regarding temperature regulation, durability, and comfort. Individual needs and preferences should guide material selection.

Question 6: How does mattress weight affect the operation of a Freightliner Cascadia?

While the weight of a mattress may seem insignificant, it contributes to the overall weight of the vehicle and impacts fuel efficiency. Selecting lighter materials can marginally improve fuel economy. Furthermore, exceeding axle weight limits can result in fines and safety violations. Therefore, weight should be considered alongside comfort and support when choosing a mattress.

The selection of an appropriate sleeping surface within a Freightliner Cascadia requires careful consideration of dimensions, sleeper berth configuration, mattress thickness, material composition, and weight. The information presented aims to facilitate informed decision-making, promoting driver well-being and operational efficiency.

The following section will address common pitfalls to avoid when determining and selecting a mattress for Freightliner Cascadia vehicles. This section will provide practical advice and actionable strategies to minimize errors in the selection process.

Freightliner Cascadia Mattress Size

The preceding discussion underscores the critical importance of accurately determining the dimensions for mattresses used within Freightliner Cascadia vehicles. The interplay between sleeper berth configuration, mattress thickness, material composition, and weight considerations collectively impacts driver comfort, safety, and regulatory compliance. A properly sized and well-chosen mattress promotes restorative sleep, mitigating fatigue and enhancing overall operational effectiveness. Neglecting these factors can lead to compromised comfort, reduced alertness, and potential safety risks.

The selection of a sleeping surface within a Freightliner Cascadia warrants careful attention to detail. Precise measurements, consideration of individual preferences, and adherence to weight regulations are paramount. Ultimately, prioritizing driver well-being through the appropriate choice of a mattress contributes significantly to a safer and more productive transportation industry. Continued awareness and diligence in this area remain essential for responsible fleet management and the health and safety of professional drivers.

![Best Pillow Top Queen Size Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Pillow Top Queen Size Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-2308-300x200.jpg)