The dimensions of a sleeping surface intended for use within the confines of a commercial vehicle cabin vary depending on the truck model and intended use. These measurements are critical for ensuring driver comfort and compliance with safety regulations. For instance, a sleeper cab might necessitate a larger surface area than that required for a day cab.

Appropriate dimensions provide adequate rest, contributing to driver alertness and reducing the risk of accidents. Furthermore, correctly chosen dimensions optimize available space, allowing for other essential equipment within the cabin. Historically, improvements in over-the-road vehicle design have prioritized driver well-being, leading to a greater emphasis on providing adequate rest areas within the truck.

The subsequent sections will delve into specific measurements, types of materials used in their construction, and factors to consider when selecting the optimal sleeping arrangement for professional drivers. This exploration will provide comprehensive guidance on achieving the best possible rest environment in a commercial vehicle.

Guidance on Selecting an Appropriate In-Cab Sleeping Surface

The following recommendations assist in choosing an in-cab sleeping surface. These insights aim to maximize driver comfort and promote restorative rest periods during long-haul operations.

Tip 1: Measure Available Space: Accurately assess the dimensions of the designated sleeping area within the truck cab. Note any obstructions or irregularities that might impact the fit. Document these measurements precisely to ensure compatibility with available options.

Tip 2: Prioritize Thickness: Consider the occupant’s weight and preferred sleeping position when determining thickness. Greater thickness typically equates to improved support and pressure relief, particularly for heavier individuals or side sleepers.

Tip 3: Evaluate Material Composition: Investigate different materials, such as memory foam, latex, or innerspring. Each material offers distinct characteristics regarding support, temperature regulation, and durability. Select a material that aligns with individual preferences and environmental factors.

Tip 4: Assess Firmness Level: Firmness is a subjective factor. However, consider the impact of firmness on spinal alignment. A medium-firm surface often provides a balance between support and comfort for a range of sleeping positions.

Tip 5: Consider Temperature Regulation: For drivers operating in varying climates, consider options designed for enhanced temperature regulation. Features such as gel infusions or breathable covers can mitigate overheating and promote more comfortable sleep.

Tip 6: Inquire About Warranty and Return Policies: Prior to purchase, review the manufacturer’s warranty and return policies. This due diligence provides recourse in the event of defects or dissatisfaction with the selected product.

Tip 7: Seek Reputable Brands: Opt for well-established brands known for quality and reliability. Customer reviews and industry ratings can provide valuable insight into the long-term performance of the product.

Adhering to these suggestions enhances the probability of securing a sleeping surface that optimizes rest and recuperation, contributing to driver well-being and operational safety. Careful consideration of these elements directly impacts the quality of rest obtained within the confines of the truck cab.

The subsequent sections will address related topics, including proper maintenance and cleaning protocols, to ensure the longevity and hygiene of the selected in-cab sleeping surface.

1. Length

The linear dimension, measured from one end to the other, dictates the suitability of a sleeping surface within a truck’s cabin. Insufficient length results in constrained posture, hindering restful sleep and potentially contributing to fatigue-related incidents. Conversely, excessive length might impede movement within the cab or interfere with safety features. The relationship between this dimension and overall driver well-being is direct and demonstrable. For example, a standard sleeper berth might accommodate a 75-inch length. However, drivers exceeding six feet in height require a length of at least 80 inches to achieve adequate spinal alignment and minimize discomfort.

Selecting an appropriate length mitigates musculoskeletal strain and promotes undisturbed sleep cycles. Commercial driving often entails prolonged periods of seated activity, exacerbating pre-existing back issues. A carefully chosen length provides support and allows for full extension, thereby reducing pressure points and enhancing circulation. Consider the practical implications of a truck driving company mandating a standardized length of 70 inches for all of its trucks. While this might standardize procurement, it fails to account for the varying anthropometric data of its drivers, potentially jeopardizing employee health and productivity.

In conclusion, length is a critical, non-negotiable factor in determining the overall suitability of a truck mattress. Inadequate length compromises driver health and safety, while excessive length introduces logistical challenges. Understanding the correlation between this dimension and individual needs allows for informed decision-making, promoting both driver well-being and operational efficiency. The dimension must be meticulously measured and chosen in conjunction with the cab dimensions to promote healthy sleep habits.

2. Width

The transverse dimension, denoted as width, directly influences the usable surface area within a truck’s sleeper berth. Inadequate width compromises freedom of movement and restricts available space for rest, leading to discomfort and potentially disrupted sleep patterns. The cause-and-effect relationship is evident: reduced width precipitates restricted movement, leading to poor sleep quality. Width, therefore, is a critical component of overall dimensions and is essential to consider when determining if the space will comfortably accommodate a driver.

Consider the practical significance. A surface with insufficient width might force a driver to sleep in a fixed or curled position, leading to musculoskeletal strain. Conversely, excessive width could hinder access to essential controls or equipment within the cab. For instance, a driver working long hours may need to access various truck controls from the sleeping bunk. Practical field examples show that a width of 42 inches is a common industry standard, whereas drivers requiring more space often seek out 48-inch options in custom or aftermarket solutions.

Width selection also depends on the truck model. An older truck model may have a narrower sleeper berth than newer designs, directly impacting the range of available widths. Accurately measuring the width of the sleeper berth is essential to avoid compatibility issues. Selecting an appropriate width maximizes comfort and ensures unimpeded access to other vital elements within the cabin, ultimately contributing to driver well-being and operational safety. The key insight is understanding the careful balance between comfort and functionality within the constrained space of a truck cab.

3. Thickness

Thickness, as it relates to in-cab sleeping arrangements, is a critical dimension influencing support, comfort, and the overall effectiveness of the sleep surface. This dimension directly affects the distribution of pressure and the level of spinal support provided, impacting driver well-being and operational safety.

- Impact on Support and Pressure Distribution

Greater thickness typically corresponds to enhanced support and improved pressure distribution. Thicker surfaces can better conform to the body’s contours, reducing pressure points and minimizing discomfort, particularly for individuals with higher body mass. A thinner surface may result in inadequate support, leading to pressure concentration and potential musculoskeletal strain. For example, a surface with a 4-inch thickness may prove insufficient for a driver exceeding 250 pounds, whereas a 8-inch thickness might provide more optimal support.

- Influence on Spinal Alignment

Thickness contributes significantly to maintaining proper spinal alignment during sleep. Adequate thickness allows the spine to maintain its natural curvature, reducing the risk of back pain and promoting restful sleep. Insufficient thickness may cause the spine to deviate from its ideal alignment, leading to discomfort and potential long-term health issues. For instance, a sleep surface that is too thin may cause the hips to sink excessively, distorting the natural spinal curvature.

- Effect on Material Performance and Longevity

The thickness of the core materials impacts their ability to withstand prolonged use and maintain their supportive properties. Thicker materials generally exhibit greater durability and resistance to compression, ensuring consistent support over time. Thinner materials may degrade more rapidly, leading to reduced support and diminished comfort. As an example, a high-density memory foam mattress with a 6-inch core is likely to offer greater long-term support than a similar mattress with a 4-inch core.

- Accommodation of Different Sleeping Positions

Thickness interacts with preferred sleeping positions to determine comfort and support. Side sleepers often require greater thickness to accommodate the curvature of the spine and distribute pressure on the hips and shoulders. Back sleepers may benefit from moderate thickness to maintain spinal alignment without excessive sinking. Stomach sleepers may prefer a thinner, firmer surface to prevent spinal hyperextension. Considering individual sleeping preferences is crucial when selecting an appropriate thickness.

In summary, thickness is a fundamental aspect of the overall dimensions of a truck mattress. Its impact on support, spinal alignment, material performance, and accommodation of sleeping positions underscores its importance in ensuring driver comfort and well-being. Accurate measurement and careful consideration of individual needs are essential when selecting a mattress of optimal dimensions.

4. Corner Radius

Corner radius, a seemingly minor component of overall sleeping surface dimensions, assumes significant importance within the confines of a truck cab. Its relevance stems from its direct impact on fit, safety, and spatial optimization. In truck cabs, the space is often constrained and non-rectangular; therefore, corners that are squared are often an impediment to comfortable use and safety. A properly considered corner radius allows the sleeping surface to conform to the contours of the available space, maximizing usable area and preventing unnecessary gaps or obstructions. An ill-fitting corner radius can create pressure points against the cab walls, damaging the interior and compromising comfort. The effect of this dimension on the overall sleeping experience should not be underestimated.

Consider real-world examples: Custom-designed sleeping surfaces often incorporate precise corner radii to accommodate specific truck models, particularly those with curved or irregularly shaped sleeper berths. Manufacturers frequently provide dimension charts detailing corner radii to ensure compatibility with their vehicles. Neglecting this detail can result in a sleeping surface that either fails to fit altogether or necessitates forced installation, potentially damaging both the surface and the cab interior. Custom truck beds and the corner radius of the mattress that accompanies them, are a high consideration to promote safe working and adequate rest for the driver.

In summary, the corner radius is a critical dimension when considering sleeping surfaces for commercial vehicles. Accurate measurement and precise matching of this dimension to the cab’s interior geometry are vital for optimizing space utilization, preventing damage, and enhancing driver comfort. It is essential to consult manufacturer specifications and consider custom solutions when necessary to ensure the proper corner radius for a given truck model. It is a small detail that can contribute greatly to the overall comfort of the long-haul driver.

5. Custom Cuts

Custom cuts in relation to sleeping surface dimensions represent a deviation from standard, pre-defined measurements to accommodate unique spatial constraints within a truck cab. The connection between custom cuts and specified sleeping surface dimensions is direct: the former is a modification of the latter to achieve optimal fit and functionality. The necessity for such modifications arises from the inherent variability in cab designs across different truck manufacturers and models. A standardized sleeping surface often fails to address specific obstructions, irregular shapes, or limited space, necessitating custom alterations to ensure proper installation and utilization. Without precise custom cuts, a commercially available surface may not be safely or comfortably installed within the intended vehicle.

Real-world examples of the relationship between custom cuts and sleeping surface dimensions are abundant in the trucking industry. Older trucks or those with modified interiors frequently require non-standard shapes to navigate wheel wells, storage compartments, or modified console configurations. Additionally, sleeper berths may incorporate cutouts to accommodate safety features, such as seatbelt mechanisms or escape hatches. Failing to account for these specific spatial constraints can lead to ill-fitting surfaces that impede movement within the cab, compromise driver safety, and ultimately, negate the intended benefits of providing a comfortable rest area. The absence of custom cuts where necessary therefore directly affects the overall dimensions and function of the installed mattress.

In summary, custom cuts represent a crucial component in optimizing sleeping surface dimensions for truck cabs. The connection between custom cuts and specified dimensions reflects the need for tailored solutions to address the diverse range of spatial configurations encountered in commercial vehicles. By accurately accounting for obstructions, safety features, and irregular shapes, custom cuts ensure proper fit, maximize usable space, and enhance driver comfort, contributing to improved safety and operational efficiency. Ignoring the need for appropriate custom cuts is counterproductive to promoting health and wellness for the truck driving industry and community.

6. Weight Limit

The weight limit, a critical specification of any sleeping surface, is intrinsically linked to its dimensions. The physical dimensions, particularly thickness and density of materials, dictate the ability of a mattress to support a specific load. Exceeding this limit results in compromised support, accelerated material degradation, and reduced lifespan of the product. The correlation between exceeding weight capacity and diminished performance is direct and predictable. As an illustration, a thinner mattress, irrespective of its length and width, inherently possesses a lower capacity compared to a thicker model constructed from identical materials. In this case, the overall dimensions affect the weight sustainability of the truck mattress.

Weight limitations dictate appropriate utilization, preventing premature structural failure. For instance, a mattress designed for a 250-pound occupant might exhibit significant compression and reduced support when subjected to a 350-pound load. This overloading affects spinal alignment and leads to discomfort, ultimately negating any intended benefits. Manufacturers provide these limits for a reason, it is essential to adhere to them to uphold a safer and healthier sleep environment. It is also important to note that the weight restriction considers the weight distribution on the sleeping surface itself. A mattress designed with a wider or longer bed, will require more support from the structural materials and, therefore, the weight capacity restriction will also require adjustments.

Understanding weight limits relative to sleeping dimensions is imperative for informed selection, ensuring both product longevity and driver well-being. Ignoring these specifications leads to compromised sleep quality, potential musculoskeletal issues, and ultimately, a reduction in operational safety. Selection of a higher grade material or even a custom build for the sleeping surface might allow for greater weight capabilities than the standard options. Proper consideration of the specification when determining the truck mattress size, is paramount to the long-term health and usage of the sleeper and commercial driver.

7. Material Density

Material density, defined as mass per unit volume, is fundamentally linked to sleeping surface dimensions, specifically influencing durability, support, and overall comfort. Within the context of commercial vehicles, material density directly impacts the ability of a mattress to withstand prolonged use and maintain its structural integrity under continuous pressure. Lower density materials tend to compress and degrade more rapidly, resulting in diminished support and an uneven sleeping surface. Conversely, higher density materials offer superior resistance to compression, ensuring consistent support over extended periods. The dimensions of the mattress, combined with material density, determine its load-bearing capacity and its ability to conform to the contours of the occupant’s body.

Consider practical scenarios. A truck mattress with significant dimensions, such as a length of 80 inches and a width of 42 inches, constructed from low-density foam will likely exhibit premature sagging, particularly in areas subjected to concentrated pressure. This sagging compromises spinal alignment and promotes discomfort, ultimately hindering restorative sleep. In contrast, the same dimensions of sleeping surface, composed of high-density memory foam or latex, will retain its shape and provide consistent support, even under prolonged use. The effect of different weights on different material densities is an important consideration, the heavier the sleeper, the denser the mattress should be to provide proper support for the truck drivers’ well-being. Material density is also a primary determinant of the sleeping surfaces vibration dampening properties, contributing to decreased motion transfer. The dimension, along with proper material selections, therefore creates an equilibrium that promotes restful and long-lasting sleep.

In summary, material density is an inseparable element when evaluating sleeping surface dimensions. Its influence on support, durability, and vibration dampening is directly correlated to the overall performance and longevity. Choosing appropriate material densities, consistent with the dimensions of the surface and the anticipated load, is a critical step in optimizing comfort and ensuring the driver’s well-being. Ignoring the relationship between these factors will inevitably lead to compromised sleep quality, premature product failure, and potentially, negative impacts on driver health and safety. When purchasing for a fleet, accounting for the range of drivers and potential loads may necessitate selecting a high-density material that can accommodate the largest occupant in the fleet. In this regard, a higher quality product may prove more cost-effective, in the long run, improving driver satisfaction and lowering the chances of needing a replacement.

Frequently Asked Questions Regarding Truck Mattress Size

The following questions address common inquiries and concerns pertaining to the dimensions of sleeping surfaces used in commercial vehicles. These insights aim to provide clarity and assist in informed decision-making for both drivers and fleet managers.

Question 1: What standard truck mattress sizes exist?

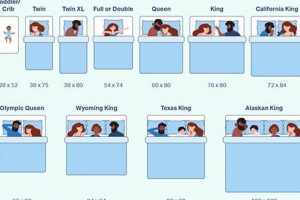

While considerable variation occurs across manufacturers and models, commonly encountered dimensions include 32×72 inches, 36×76 inches, 38×80 inches, and 42×80 inches. Custom dimensions are also available from various suppliers.

Question 2: How does truck mattress size affect driver health?

Inadequate length or width restricts movement and forces unnatural sleeping positions, potentially leading to musculoskeletal strain, compromised circulation, and disrupted sleep cycles. Optimal dimensions promote proper spinal alignment and reduce pressure points, contributing to improved health and alertness.

Question 3: What factors should be considered when selecting a truck mattress size?

Key considerations include the available space within the sleeper berth, the driver’s height and weight, preferred sleeping position, and any pre-existing medical conditions. Accurate measurement of the sleeping area is essential prior to purchase.

Question 4: How does thickness impact the performance of a truck mattress?

Thickness directly influences support and pressure distribution. Greater thickness generally corresponds to enhanced support and improved pressure relief, particularly for heavier individuals or side sleepers. Thinner mattresses may prove inadequate for providing sufficient support and maintaining proper spinal alignment.

Question 5: Are custom truck mattress sizes necessary?

In certain situations, custom dimensions are essential to accommodate unique spatial constraints or irregular shapes within the sleeper berth. Older trucks or those with modified interiors may necessitate custom cuts or non-standard sizes to ensure proper fit and functionality.

Question 6: How does material density relate to truck mattress size and longevity?

Material density significantly impacts the mattress’s ability to withstand prolonged use and maintain its structural integrity. Higher density materials offer superior resistance to compression and degradation, ensuring consistent support and extending the lifespan of the mattress. A well balanced mattress, in material and construction, will ultimately offer a safer and more comfortable sleep environment.

In summary, careful consideration of sleeping surface dimensions is paramount for ensuring driver comfort, promoting health and safety, and optimizing operational efficiency. Accurate measurements, attention to individual needs, and informed selection of materials are crucial elements in this process.

The subsequent section provides resources for further investigation into this subject, including links to relevant industry standards and supplier catalogs.

In Summary of Truck Mattress Size

This exploration emphasizes the critical considerations inherent in selecting the appropriate sleeping surface for commercial vehicle operators. Key aspects, including length, width, thickness, corner radius, custom cuts, weight limit, and material density, directly impact driver health, safety, and operational efficiency. Precise measurements, individual needs assessment, and informed material selection are crucial to ensure adequate support and comfort within the confines of a truck cab.

The dimensions of the in-cab sleeping surface are not merely a matter of comfort; they are a vital component of driver well-being and road safety. Continued diligence in researching and implementing best practices related to this area remains paramount for fostering a safer and more efficient transportation industry. Fleet managers and owner-operators must prioritize the proper selection and maintenance of truck mattresses, to ensure the sustainability and success of the commercial truck driving community.

![Buy Best Queen Size Sofa Mattress [Deals Inside] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Buy Best Queen Size Sofa Mattress [Deals Inside] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-2332-300x200.jpg)