A sleeping surface designed to fit within the frame of an elevated bed intended for multiple occupants represents a specific bedding category. These mattresses conform to standardized dimensions, offering a balance between individual space and overall bunk bed size. As an example, consider a scenario where a growing teenager needs more sleeping space than a twin mattress provides but the overall room dimensions restrict the implementation of a larger bed like a queen or king. In this case, this mattress option offers a practical solution.

The importance of selecting the correct size and type is paramount for safety and comfort. It ensures the mattress fits securely within the bunk bed frame, mitigating the risk of slippage. Furthermore, this type of sleeping solution provides adequate space for a restful night’s sleep without overwhelming the available area. Historically, bunk beds were primarily utilized in shared living spaces like dormitories or military barracks. However, their adoption in residential settings has increased, driven by a need for space optimization and efficient room usage, making the properly sized mattress a key component.

The subsequent sections will delve into the factors influencing the selection of a suitable mattress, focusing on dimensions, thickness considerations, material options, and safety standards. A comparison of different mattress types and an outline of installation and maintenance procedures will also be provided.

Essential Considerations

Selecting the proper sleeping surface for a bunk bed requires careful evaluation to ensure safety, comfort, and longevity. The following guidance offers key insights for informed decision-making.

Tip 1: Measure the Bunk Bed Frame Accurately: Before purchasing, meticulously measure the interior dimensions of the bunk bed frame. Match these measurements to the specified dimensions of a full size mattress for bunk bed. Variations, even slight, can compromise safety and fit.

Tip 2: Adhere to Thickness Restrictions: Bunk beds often have thickness limitations dictated by safety rails. Exceeding the maximum recommended mattress thickness reduces the effectiveness of the safety rails, increasing the risk of falls. Consult the bunk bed manufacturer’s guidelines for acceptable thickness ranges.

Tip 3: Prioritize Fire Retardancy: Mattress flammability poses a significant safety concern. Ensure the selected mattress meets or exceeds applicable fire safety standards and regulations. Look for certifications indicating compliance.

Tip 4: Choose a Supportive Core: The internal support system of the mattress is crucial for spinal alignment and comfort. Options include innerspring, foam, or hybrid constructions. Evaluate the sleeper’s weight and sleeping preferences to determine the appropriate support level.

Tip 5: Consider Weight Capacity: Bunk beds and their associated mattresses have maximum weight capacity ratings. Verify that the selected mattress and its intended user do not exceed these limitations. Overloading can compromise structural integrity and increase the risk of collapse.

Tip 6: Opt for Durable Construction: Bunk beds often experience more wear and tear than standard beds. Select a mattress constructed with durable materials and reinforced seams to withstand frequent use and potential impacts.

Tip 7: Assess Edge Support: Strong edge support prevents roll-off and maximizes the usable sleeping surface. This is particularly important in bunk bed applications, where space may be limited. Check for reinforced edges or specialized construction techniques.

These considerations represent crucial elements in choosing the appropriate bedding. Proper application of these insights contributes to a safer and more comfortable bunk bed experience.

The subsequent section will examine specific mattress types suitable for bunk beds, delving into the advantages and disadvantages of each.

1. Dimensions and Thickness

The dimensions and thickness of a mattress specifically intended for bunk bed use are critical parameters directly affecting safety, functionality, and overall comfort. Precise adherence to specified measurements is non-negotiable to ensure proper fit and mitigate potential hazards.

- Length and Width Conformity

The length and width must precisely match the interior dimensions of the bunk bed frame. Undersized mattresses create dangerous gaps, posing entrapment risks. Oversized mattresses may not fit, causing distortion and potential structural damage to the frame. Manufacturers typically adhere to standardized measurements (e.g., 54 inches wide and 75 inches long), however, verification against the specific bunk bed frame is essential.

- Thickness Constraints and Safety Rail Height

Bunk beds typically feature safety rails designed to prevent falls from the upper bunk. Mattress thickness directly impacts the effectiveness of these rails. Exceeding the maximum recommended thickness reduces the height of the safety rail above the mattress surface, significantly increasing the risk of accidental falls. Compliance with the manufacturer’s prescribed thickness limits is crucial for user safety.

- Impact on Vertical Space

In bunk bed configurations, vertical space is often limited, particularly on the lower bunk. An excessively thick mattress reduces the available headroom, potentially causing discomfort or restricting movement. Selecting a mattress with a suitable thickness optimizes the usable space while maintaining adequate support.

- Weight Distribution and Frame Integrity

While thickness itself doesn’t directly determine weight capacity, it often correlates with the mattress’s internal construction and materials. Thicker mattresses may contain denser materials, potentially increasing overall weight. It’s crucial to ensure that the combined weight of the mattress and the occupant remains within the bunk bed frame’s specified weight limits to prevent structural failure.

The interrelationship between dimensions and thickness in the context of bedding designed for elevated sleeping solutions directly affects safety, usability, and long-term structural integrity. Proper consideration of these factors is essential for creating a secure and comfortable sleeping environment within the spatial constraints of a bunk bed.

2. Weight Capacity

Weight capacity is a critical specification directly impacting the safety and functionality of a full size mattress intended for bunk bed use. This parameter defines the maximum load, encompassing both the mattress’s own weight and the weight of the occupant(s), that the bunk bed structure can safely support. Exceeding this limit can lead to structural failure, potentially resulting in injury.

The construction of the bunk bed frame and the composition of the full size mattress directly influence the overall weight capacity. Manufacturers rigorously test their products to determine these limits, which are typically stated in product documentation. For instance, a bunk bed frame constructed from solid hardwood will generally possess a higher weight capacity than one made from less robust materials. Similarly, a mattress with a high-density foam core may contribute more to the overall weight compared to one with an innerspring system. Real-life scenarios underscore the importance of adhering to these weight restrictions. Overloading a bunk bed could lead to bent or broken support beams, compromising the integrity of the structure. This can occur when multiple children occupy the upper bunk simultaneously or when a heavier individual sleeps on a bed not designed to accommodate their weight. Understanding and respecting the weight capacity is not merely a recommendation; it is a fundamental safety requirement.

In summary, weight capacity is an indispensable consideration when selecting a mattress for a bunk bed. Compliance with the manufacturer’s specified limits ensures the structural integrity of the bunk bed and the safety of its occupants. Disregarding this crucial factor can have significant and potentially dangerous consequences.

3. Material and Support

The selection of materials and the design of the support system are integral to the functionality and suitability of a full size mattress for bunk bed applications. These factors directly influence comfort, durability, and safety, particularly within the constraints of a bunk bed environment. The mattress’s core support, whether constructed from innerspring coils, foam, or a hybrid combination, dictates its ability to maintain spinal alignment and distribute weight effectively. Inadequate support can lead to discomfort, pressure points, and potentially long-term musculoskeletal issues. For instance, a low-density foam core might compress excessively under weight, failing to provide adequate support and potentially contributing to back pain. Conversely, an innerspring system with insufficient coil density may sag over time, diminishing its supportive properties. A hybrid system, combining the benefits of both foam and coils, aims to optimize both comfort and support, but material quality remains paramount.

The outer layers of a sleeping surface also play a crucial role. Materials like memory foam, latex, or quilted fabrics contribute to the initial feel and contouring properties of the mattress. However, their impact extends beyond mere comfort. Breathability is a critical consideration, particularly in bunk bed setups where ventilation might be limited. Materials that trap heat can lead to discomfort and disrupt sleep. Moreover, the durability of these outer layers directly affects the mattress’s lifespan. Thin or poorly constructed coverings can quickly wear down, exposing the underlying support structure and compromising its integrity. As an example, consider a bunk bed mattress used in a summer camp setting. It will endure frequent use, and a robust, easily cleanable outer cover is essential to withstand potential spills and maintain hygiene. The interplay of material choice and support system design determines the overall performance and longevity of the mattress.

In summary, material and support are inextricably linked in determining the suitability of a sleeping surface. Selection necessitates a careful evaluation of intended use, sleeper weight, and desired comfort characteristics. Compromising on material quality or support design can negatively impact comfort, safety, and durability, rendering the mattress unsuitable for the demanding environment of a bunk bed. Choosing appropriate components ensures a comfortable and safe sleeping experience within the constraints of the bunk bed framework.

4. Safety Compliance

The imperative of safety compliance governs the design, manufacture, and use of mattresses intended for bunk bed applications. Adherence to established safety standards mitigates potential hazards and ensures the well-being of individuals utilizing these sleeping arrangements. The relationship between these safety benchmarks and the design elements of a mattress for bunk beds warrants careful examination.

- Flammability Standards (16 CFR Part 1633 and 16 CFR Part 1632)

United States federal regulations, specifically 16 CFR Part 1633 and 16 CFR Part 1632, mandate stringent flammability testing for all mattresses sold within the country. These standards require mattresses to resist ignition from open flames, reducing the risk of fire propagation. Mattresses for bunk beds must comply with these regulations, often incorporating fire-resistant materials or chemical treatments to meet the required performance levels. Failure to adhere to these standards poses a significant safety hazard, potentially leading to rapid fire spread and severe injuries in the event of a fire.

- Bunk Bed Safety Rail Height Regulations

Although regulations may not explicitly define mattress thickness limits, safety guidelines for bunk beds emphasize the critical relationship between mattress height and the effectiveness of safety rails. Excessive mattress thickness reduces the safety rail’s effective height, diminishing its capacity to prevent falls. Manufacturers of bunk beds typically specify a maximum recommended mattress thickness to ensure compliance with these implied safety parameters. Selecting a mattress that exceeds this limit compromises the safety design of the bunk bed, increasing the risk of accidental falls, particularly from the upper bunk.

- Weight Capacity and Structural Integrity

Safety compliance extends to the structural integrity of the mattress and its capacity to withstand intended loads. Mattresses must be designed to support the weight of occupants without compromising their structural integrity or posing a risk of collapse. While no specific regulation explicitly governs mattress weight capacity, manufacturers must adhere to general product safety standards, ensuring that their mattresses are suitable for the intended use and weight limitations of the bunk bed frame. Exceeding the recommended weight limits can lead to mattress deformation, instability, and potential failure, increasing the risk of injury.

- Material Safety and Chemical Emissions

Increasingly, safety compliance encompasses scrutiny of the materials used in mattress construction, particularly concerning chemical emissions. Certifications such as CertiPUR-US indicate that the foam components of a mattress have been tested for harmful substances and meet specific standards for emissions of volatile organic compounds (VOCs). These certifications aim to minimize potential health risks associated with prolonged exposure to chemicals released from mattress materials. Selecting mattresses with these certifications reduces the risk of respiratory irritation, allergic reactions, and other adverse health effects, particularly for children and individuals with sensitivities.

The multifaceted nature of safety compliance demands meticulous attention to flammability standards, safety rail height considerations, weight capacity limitations, and material safety attributes. Adhering to these principles ensures the safe and reliable performance of mattresses designed for bunk bed use, safeguarding the well-being of occupants and minimizing potential hazards associated with these elevated sleeping arrangements.

5. Durability

Durability, in the context of a full size mattress intended for a bunk bed, represents its ability to withstand consistent use and maintain its structural integrity and comfort characteristics over an extended period. The increased demand placed on mattresses in bunk bed settings, often involving younger users or shared spaces, necessitates a heightened emphasis on durable construction. Substandard materials or assembly techniques can result in premature sagging, deformation, or breakdown of internal components, ultimately reducing the mattress’s lifespan and compromising its intended function. For example, a mattress frequently subjected to jumping or excessive weight concentration will experience accelerated wear compared to one used in a more controlled environment. This underscores the importance of selecting mattresses constructed with robust materials and reinforced seams.

The choice of materials significantly impacts a mattress’s long-term performance. High-density foams, tempered steel coils in innerspring systems, and durable fabric covers contribute to overall resilience. Lower-quality materials, such as low-density foams or thinly woven fabrics, are more prone to compression, tearing, and degradation. Furthermore, the mattress’s construction methods, including quilting patterns and edge support mechanisms, play a vital role in maintaining its shape and preventing premature wear. Consider a situation where a bunk bed is used in a vacation rental property. The mattress will experience significantly higher usage than in a typical residential setting, demanding a more durable construction to withstand the increased wear and tear. Proper mattress rotation can also prolong the lifespan, distributing wear evenly across the surface.

In summary, durability is a critical attribute of a full size mattress intended for bunk bed use. Its importance stems from the increased demands placed on these mattresses and the need to ensure long-term comfort, support, and safety. Selection of durable materials, robust construction techniques, and adherence to proper maintenance procedures are essential to maximizing the mattress’s lifespan and ensuring a satisfactory user experience. Failure to prioritize durability can result in premature mattress failure, increased replacement costs, and potential compromises to user comfort and safety.

Frequently Asked Questions

This section addresses common inquiries regarding the selection and utilization of bedding specifically designed for full-size bunk beds. The information presented aims to clarify critical aspects and dispel potential misconceptions.

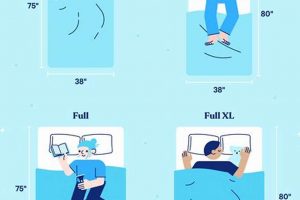

Question 1: What are the standard dimensions for a full-size mattress intended for bunk bed use?

A full-size mattress typically measures 54 inches in width and 75 inches in length. However, precise measurements should be verified against the interior dimensions of the bunk bed frame before purchase to ensure proper fit and prevent safety hazards.

Question 2: What is the maximum recommended thickness for a mattress to be used on a bunk bed?

The maximum recommended thickness varies depending on the bunk bed’s design. Consult the manufacturer’s specifications for the bunk bed frame. Exceeding the recommended thickness reduces the safety rail’s effectiveness and increases the risk of falls.

Question 3: Are there specific fire safety standards that apply to full-size mattresses for bunk beds?

All mattresses sold in the United States, including those for bunk beds, must comply with federal flammability standards, specifically 16 CFR Part 1633. Ensure the mattress label indicates compliance with these regulations.

Question 4: What type of mattress construction is best suited for a bunk bed application?

The optimal construction depends on individual preferences and requirements. However, considerations include support, durability, and weight. Innerspring, foam, and hybrid mattresses are all viable options, provided they meet the necessary safety and weight capacity requirements.

Question 5: How does the weight capacity of a full-size mattress for a bunk bed impact its suitability?

The combined weight of the mattress and the occupant must not exceed the bunk bed frame’s specified weight capacity. Exceeding this limit can compromise the structural integrity of the bunk bed and pose a safety risk. Refer to the bunk bed manufacturer’s guidelines for weight limits.

Question 6: Is it necessary to rotate or flip a full-size mattress used on a bunk bed?

Rotation and flipping can extend the lifespan of a mattress by distributing wear evenly. However, not all mattresses are designed to be flipped. Consult the manufacturer’s recommendations for specific maintenance procedures.

Proper understanding of dimensions, thickness limitations, fire safety regulations, construction options, weight capacity constraints, and maintenance procedures contributes to the informed selection and safe utilization of a full-size mattress within a bunk bed configuration.

The next section will address installation and maintenance considerations for ensuring optimal performance and longevity of mattresses used with bunk beds.

Conclusion

The preceding analysis has underscored the multifaceted considerations inherent in the selection and utilization of a full size mattress for bunk bed applications. Critical factors, including dimensional conformity, thickness constraints, material composition, adherence to safety standards, and durability characteristics, exert a significant influence on the suitability and performance of these sleep surfaces. Failure to address these elements adequately can compromise safety, comfort, and the overall integrity of the bunk bed structure.

Prudent decision-making demands meticulous attention to manufacturer specifications, regulatory guidelines, and individual needs. Prioritizing safety, comfort, and longevity remains paramount to ensure a positive and secure bunk bed experience. Responsible implementation of the principles outlined herein fosters a safer and more conducive environment for rest and recuperation. Further research and vigilance in adhering to evolving safety standards are strongly encouraged to optimize the performance and safety of elevated sleeping arrangements.

![Best Tri Fold Full Mattress [Deals!] Sleep Solution Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Tri Fold Full Mattress [Deals!] Sleep Solution | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-2881-300x200.jpg)