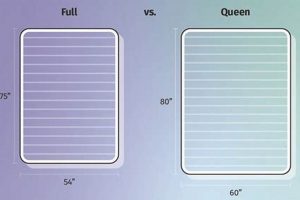

The dimensional parameters of a 54-inch by 75-inch bed define its physical footprint, influencing its suitability for various bedroom sizes and user body types. These dimensions dictate the compatibility with standard bedding accessories and the overall sleep surface area available.

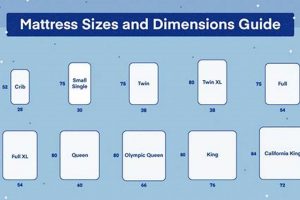

Adhering to precise measurements allows manufacturers to ensure consistent product quality and enables consumers to confidently select appropriate mattresses for their needs. These standardized sizes provide a basis for comparison across different brands and models, simplifying the purchasing process and reducing potential fit issues. This uniformity also facilitates the development of complementary products such as bed frames, sheets, and mattress protectors.

Understanding the intricacies of these dimensional considerations is paramount when selecting sleep solutions. Subsequent sections will delve into the material compositions, construction methodologies, and performance characteristics that further differentiate offerings within this size category.

Essential Considerations for 54″ x 75″ Mattress Selection

The selection of a mattress adhering to established dimensional standards requires careful consideration of several critical factors to ensure optimal suitability and longevity.

Tip 1: Assess Room Dimensions. Accurately measure the intended placement area to confirm compatibility with the 54-inch width and 75-inch length. Adequate clearance around the perimeter is crucial for accessibility and aesthetic balance.

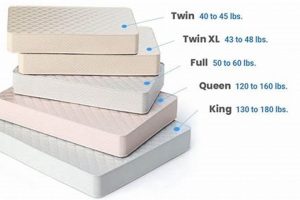

Tip 2: Evaluate Weight Capacity. Determine the maximum load-bearing capability of the mattress to ensure it adequately supports the intended users without compromising structural integrity or comfort. Refer to manufacturer specifications for guidance.

Tip 3: Examine Material Composition. Investigate the types of materials used in construction, such as memory foam, innerspring coils, or latex. Each material offers distinct performance characteristics related to support, temperature regulation, and durability. Certifications (e.g., CertiPUR-US) can indicate compliance with specific quality standards.

Tip 4: Scrutinize Construction Quality. Evaluate the manufacturing techniques employed, paying close attention to seam integrity, edge support, and overall craftsmanship. Robust construction contributes to enhanced durability and prevents premature sagging or deformation.

Tip 5: Review Warranty Provisions. Carefully examine the terms and conditions of the manufacturer’s warranty, including coverage duration and potential exclusions. A comprehensive warranty provides recourse in the event of manufacturing defects or premature failure.

Tip 6: Check for Proper Support System. Different types of support systems (like innerspring or pocketed coils) offer varied levels of support. Choose a system that aligns with individual sleep preferences and body type.

Tip 7: Consider Thickness and Profile. The height of the mattress can impact bed height and overall aesthetics. Thicker mattresses often provide more cushioning and support but may require deeper pocket sheets.

Selecting a mattress based on established dimensional standards entails a comprehensive assessment of various parameters. Addressing these factors ensures a tailored and enduring sleep solution.

These critical considerations should guide purchasing decisions and provide a foundation for optimal sleep quality. Subsequent analysis may delve into specific brand comparisons and comparative product analyses.

1. Nominal Dimensions (54" x 75")

The nominal dimensions of 54 inches by 75 inches represent the foundational specification defining what is commonly known as a full-size mattress. These measurements serve as the primary determinant for compatibility with bed frames, bedding, and overall room layout. Deviation from these dimensions, even marginally, can lead to issues such as ill-fitting sheets, instability on standard bed frames, and inefficient utilization of bedroom space. For instance, a mattress exceeding these dimensions may not properly fit a standard full-size bed frame, requiring the purchase of a new frame. Conversely, a smaller mattress would leave unsightly gaps and potential instability. Therefore, these nominal dimensions act as a critical control parameter in the manufacturing and consumer selection processes.

The adherence to these specified measurements is not solely a matter of convenience; it directly impacts the ergonomic support provided. When designed correctly, the surface area accommodates a single adult comfortably or can accommodate two smaller individuals. Non-compliance with the 54″ x 75″ standard can translate into inadequate space for restful sleep, potentially leading to discomfort, disrupted sleep patterns, and negative health outcomes. Real-world consequences include couples experiencing restricted movement or individuals experiencing edge roll-off due to undersized mattresses marketed as “full-size.”

In summary, the nominal dimensions are an inseparable and pivotal aspect of the wider “full size mattress specifications.” Their accuracy influences product usability, ergonomic function, and compatibility with existing infrastructure. While other specifications (material, firmness, etc.) refine the sleeping experience, these core dimensions establish the foundational framework for a successful mattress purchase. Challenges arise when manufacturers deviate from these standards or consumers fail to verify measurements before purchase, underscoring the need for standardized oversight and informed consumer choices.

2. Thickness Variations

Thickness variations, within the framework of full size mattress specifications, represent a critical dimension influencing both the comfort and support characteristics of the product. While the length and width define the sleep surface area, the thickness determines the depth and volume of materials used, impacting factors such as pressure relief, temperature regulation, and overall durability.

- Impact on Support and Comfort

The overall thickness of a 54″ x 75″ mattress often correlates directly with the amount of material utilized in its construction. A thicker mattress can accommodate more substantial comfort layers, potentially enhancing pressure relief and conforming capabilities. Conversely, a thinner mattress may prioritize a firmer feel due to limited space for plush components. The selection of an appropriate thickness should consider individual body weight, sleep position, and personal preferences for firmness and support. Examples include heavier individuals often benefiting from thicker mattresses to prevent bottoming out, while stomach sleepers may prefer thinner, firmer profiles.

- Influence on Bed Height and Aesthetics

Thickness contributes directly to the final height of the bed. This has both practical and aesthetic implications. A thicker mattress on a low-profile bed frame may result in an uncomfortably high sleep surface, making it difficult to enter and exit the bed. Conversely, a thinner mattress on a high bed frame may appear visually unbalanced and require the use of a bed skirt to conceal the frame. The overall thickness should be carefully considered in relation to the bed frame and surrounding bedroom furniture to maintain ergonomic accessibility and visual harmony.

- Material Distribution and Layering

The thickness of a mattress dictates how manufacturers distribute various materials within its layers. A thicker mattress allows for more complex layering, potentially incorporating multiple comfort layers with varying densities and compositions, as well as a robust support core. This intricate layering can enhance pressure relief, motion isolation, and temperature regulation. For instance, a thick mattress may feature a top layer of gel-infused memory foam for cooling, followed by a transitional layer of responsive foam, and a base layer of high-density support foam or coils. Thin mattresses typically have simplified constructions with fewer distinct layers.

- Consequences for Durability and Longevity

While not the sole determinant, thickness often correlates with the overall durability of the mattress. A thicker mattress, with its greater material volume, can potentially withstand greater wear and tear over time. However, the quality and density of the materials used are equally important. A thinner mattress constructed from high-quality, durable materials may outperform a thicker mattress made from inferior materials. Consumers should evaluate the overall construction and material composition alongside the thickness to assess the long-term durability of the mattress.

Thickness variations are therefore a crucial component within full size mattress specifications, impacting comfort, support, aesthetics, and potentially durability. The optimal thickness depends on a combination of individual factors and the overall construction of the mattress, requiring careful consideration by consumers during the selection process. Accurate assessment of thickness, in conjunction with other specifications, enables informed purchasing decisions and facilitates optimal sleep quality.

3. Support Core Composition

The support core represents a critical element within the broader spectrum of full size mattress specifications. It forms the foundation of the mattress, responsible for providing primary support, distributing weight, and influencing overall firmness and durability.

- Innerspring Systems

Innerspring systems consist of interconnected or individually wrapped coils. These systems offer varying degrees of support and motion transfer depending on coil gauge, design, and configuration. Lower gauge coils tend to be firmer, while higher gauge coils provide a softer feel. Examples include Bonnell coils (interconnected) and pocketed coils (individually wrapped), each offering distinct performance characteristics. The choice of innerspring system directly affects the mattress’s ability to contour to the body and minimize motion disturbance.

- Foam Cores

Foam cores utilize various types of foam, such as polyurethane foam, memory foam, or latex, to provide support. Polyurethane foam offers a cost-effective option with varying densities affecting firmness. Memory foam contours to the body, providing pressure relief but potentially retaining heat. Latex offers a responsive and durable option with natural breathability. The density and type of foam used in the core significantly influence the mattress’s support, comfort, and temperature regulation properties.

- Hybrid Constructions

Hybrid constructions combine elements of both innerspring and foam cores. These mattresses typically feature an innerspring base layer for support and a foam comfort layer for pressure relief. The combination aims to leverage the benefits of both materials, offering a balance of support, comfort, and motion isolation. Examples include a pocketed coil base with a memory foam or latex comfort layer. The design of the hybrid system dictates the final performance characteristics of the mattress.

- Support Core Zoning

Zoning within the support core refers to the use of different coil gauges or foam densities in specific areas of the mattress to provide targeted support. For example, firmer coils or higher-density foam may be used in the center third of the mattress to support the heavier hip region, while softer coils or lower-density foam may be used in the shoulder and leg areas. Zoning aims to optimize spinal alignment and pressure relief. The effectiveness of zoning depends on the accuracy of its design and the individual’s body type and sleep position.

The support core composition plays a pivotal role in determining the overall performance of a full size mattress. The choice of materials, construction techniques, and zoning strategies significantly impacts support, comfort, durability, and temperature regulation. Accurate specification and evaluation of the support core are essential for ensuring a mattress that meets individual needs and preferences, underscoring its importance within the broader context of full size mattress specifications.

4. Edge Support Structure

Edge support structure, as an integral component of full size mattress specifications, dictates the stability and usable surface area along the perimeter of the sleeping platform. The quality and design of edge support significantly impact a mattress’s ability to resist compression and maintain its shape under applied pressure. Inferior or absent edge support frequently leads to noticeable sagging along the sides, effectively reducing the usable sleep surface and potentially causing a feeling of instability or roll-off when positioned near the edge. For example, a mattress lacking reinforced edges may exhibit significant compression when an individual sits on the side to dress or read, accelerating wear and diminishing overall comfort. This deficiency can further exacerbate issues for individuals with mobility limitations, as the lack of firm edge support complicates ingress and egress. Thus, robust edge support is not merely a cosmetic feature but a functional requirement that directly impacts usability and longevity.

Various construction techniques contribute to effective edge support, including the use of high-density foam encasements, perimeter wire supports, or reinforced coil systems. High-density foam encasements, often implemented in foam or hybrid mattresses, provide a firm boundary that resists compression and maintains the mattress’s shape. Perimeter wire supports, commonly found in innerspring mattresses, create a rigid framework around the coil system, enhancing stability and preventing edge collapse. Reinforced coil systems utilize firmer coils along the perimeter to provide targeted support where it is most needed. The selection of an appropriate edge support structure should align with the overall design and intended use of the mattress. Furthermore, the presence and effectiveness of edge support can influence the perceived size of the mattress, as a stable edge allows for greater utilization of the available surface area. Accurate assessment of edge support is essential for individuals seeking a comfortable and durable sleep solution, especially those who share the bed or require assistance with mobility.

In conclusion, edge support structure is a critical, often overlooked, aspect of full size mattress specifications. Its presence directly affects the usability, stability, and longevity of the mattress. Understanding the different construction techniques and their respective benefits enables consumers to make informed purchasing decisions, selecting a mattress that meets their individual needs and provides a consistent and supportive sleep experience. The absence of adequate edge support can lead to premature wear, reduced comfort, and potential safety concerns, underscoring the importance of carefully evaluating this feature when considering a full size mattress.

5. Material Certifications

Material certifications represent a critical, yet often overlooked, aspect within full size mattress specifications. These certifications provide independent verification that a mattress and its components meet specific standards related to chemical emissions, material composition, and durability. Their relevance lies in ensuring consumer safety, promoting responsible manufacturing practices, and providing a basis for informed purchasing decisions.

- CertiPUR-US Certification

CertiPUR-US certification applies to flexible polyurethane foam used in mattresses. It verifies that the foam has been tested and certified by an independent laboratory to meet specific criteria for emissions, content, and durability. Specifically, CertiPUR-US certified foams are made without ozone depleters, PBDEs, TDCPP or TCEP (“Tris”) flame retardants, mercury, lead, and other heavy metals. They also have low volatile organic compound (VOC) emissions for indoor air quality (less than 0.5 parts per million). In the context of full size mattress specifications, this certification provides assurance that the foam components meet stringent health and safety requirements.

- OEKO-TEX Standard 100 Certification

OEKO-TEX Standard 100 certification applies to textile components, including mattress covers and ticking. This certification verifies that every component of the product, from the fabric to the thread and accessories, has been tested for harmful substances. It ensures that the textile materials are safe for human health and do not contain any substances at levels that could be dangerous. When evaluating full size mattress specifications, the presence of OEKO-TEX Standard 100 certification indicates that the textile components have undergone rigorous testing for chemical safety.

- Global Organic Textile Standard (GOTS) Certification

GOTS certification applies to mattresses containing organic textile fibers, such as organic cotton or wool. This certification ensures that the entire textile supply chain, from the harvesting of raw materials to the manufacturing and labeling of the finished product, meets strict environmental and social criteria. GOTS certification verifies that the organic fibers are grown without the use of synthetic pesticides or fertilizers and that the manufacturing processes adhere to environmentally sound practices. For full size mattress specifications, GOTS certification provides assurance of the organic integrity of textile components.

- GREENGUARD Certification

GREENGUARD certification focuses on chemical emissions from products and materials. It verifies that a product has been tested and certified to have low chemical emissions, improving indoor air quality. GREENGUARD certification has two levels: GREENGUARD Certified and GREENGUARD Gold Certified. The Gold level has stricter emission requirements and considers additional health-based criteria. For full size mattress specifications, GREENGUARD certification signifies that the mattress emits low levels of VOCs, contributing to a healthier sleep environment.

These material certifications serve as valuable indicators of product safety and environmental responsibility within full size mattress specifications. By providing independent verification of material composition and emissions levels, these certifications empower consumers to make informed choices, promoting a healthier and more sustainable sleep experience. The inclusion of such certifications within a mattress’s specifications can significantly impact consumer confidence and contribute to brand reputation.

Frequently Asked Questions Regarding Full Size Mattress Specifications

This section addresses common inquiries pertaining to dimensional, material, and performance characteristics of mattresses adhering to the 54-inch by 75-inch standard. Information provided aims to clarify essential considerations for informed purchasing decisions.

Question 1: What are the precise dimensional tolerances permitted for a mattress designated as “full size”?

While nominal dimensions are 54 inches in width and 75 inches in length, manufacturing tolerances typically allow for variations of up to one inch in either dimension. Significant deviations should raise concerns about accurate product labeling and potential compatibility issues.

Question 2: How does mattress thickness influence overall support and comfort?

Thickness contributes to the volume of materials used in construction, impacting both support and comfort characteristics. Thicker mattresses often accommodate more substantial comfort layers, enhancing pressure relief. Thickness alone, however, is not the sole determinant of quality; material density and construction techniques also play critical roles.

Question 3: What is the significance of coil count in innerspring mattresses adhering to full size specifications?

Coil count generally correlates with support and durability in innerspring mattresses. Higher coil counts can provide more individualized support and better weight distribution. However, coil gauge (thickness) and coil type (e.g., Bonnell vs. pocketed) are equally important factors influencing performance.

Question 4: What material certifications should be considered when evaluating a full size mattress?

Certifications such as CertiPUR-US (for foam), OEKO-TEX Standard 100 (for textiles), and GOTS (for organic materials) provide independent verification that the mattress meets specific standards for chemical emissions, material composition, and manufacturing processes. These certifications offer assurance of product safety and environmental responsibility.

Question 5: How does edge support contribute to the overall usability of a full size mattress?

Effective edge support enhances the usable sleep surface by preventing sagging along the perimeter. It provides a stable edge for sitting and reduces the sensation of roll-off, particularly beneficial for individuals sharing the bed or those with mobility limitations.

Question 6: Is a higher price point always indicative of superior quality in full size mattresses?

Price does not always correlate directly with quality. While more expensive mattresses may incorporate premium materials and advanced construction techniques, factors such as brand reputation, marketing costs, and retail markups also contribute to pricing. Careful evaluation of material specifications, construction quality, and independent reviews is essential for making informed purchasing decisions, regardless of price point.

Key takeaways involve understanding that dimensional accuracy, material composition, and construction techniques are all crucial when assessing a 54″ x 75″ mattress. Relying solely on marketing claims or price points can be misleading. Independent verification and careful evaluation of product specifications are essential for ensuring a satisfactory purchase.

The subsequent section will provide a detailed comparison of popular mattress brands and models within the full size category, highlighting their respective strengths and weaknesses based on the specifications discussed.

full size mattress specifications

The preceding exploration of full size mattress specifications underscores the multifaceted nature of selecting a suitable sleep surface. Dimensional accuracy, encompassing length, width, and thickness, forms the foundational element, ensuring compatibility with standard bed frames and bedding accessories. Material composition, ranging from innerspring systems to foam cores and hybrid constructions, dictates support characteristics, pressure relief, and temperature regulation. Furthermore, the implementation of effective edge support enhances usability and longevity, while material certifications provide critical assurance of product safety and environmental responsibility.

A comprehensive understanding of full size mattress specifications empowers consumers to navigate the complex landscape of available options and make informed purchasing decisions that align with individual needs and preferences. Continued adherence to standardized testing protocols and transparent disclosure of material information will further enhance consumer confidence and promote responsible manufacturing practices within the bedding industry. Prioritizing meticulous evaluation of these specifications remains paramount in ensuring a comfortable, supportive, and durable sleep experience.