A standardized sleep system designed for two adults, the configuration provides both support and comfort through a coordinated pairing. Typically, this includes a wide rectangular surface designed to evenly distribute weight, alongside a structural base that elevates and reinforces the sleeping platform.

The significance lies in its capacity to optimize sleep quality, offering ample space for couples without demanding excessive floor area. Its popularity stems from a balance of affordability, comfort, and space efficiency, widely adopted as a practical solution in residential bedrooms. Over time, improvements in materials and design have enhanced durability and ergonomic support, contributing to its sustained prevalence.

The following sections will delve into the specifics of selecting optimal mattress characteristics, understanding frame construction variations, and considerations for setup and maintenance of such sleep systems.

Essential Considerations for a Queen Bed Mattress and Frame Set

Selecting an appropriate sleep system requires careful evaluation of several factors to ensure optimal comfort, support, and longevity.

Tip 1: Mattress Material Evaluation: Explore various mattress materials such as memory foam, innerspring, latex, and hybrids. Each offers distinct comfort levels and support characteristics. Individuals should consider their sleep preferences, including preferred firmness and temperature regulation, to make an informed selection.

Tip 2: Frame Construction and Support: Assess the frame’s structural integrity and weight-bearing capacity. Solid wood or reinforced metal frames provide superior stability and prevent premature wear. Evaluate slat spacing; closer spacing offers better mattress support and minimizes sagging.

Tip 3: Size and Space Assessment: Confirm the dimensions of the combined mattress and frame assembly are appropriate for the designated bedroom space. Ensure sufficient clearance for movement around the bed and consider any protruding elements of the frame design.

Tip 4: Height Considerations: Determine the desired bed height based on individual preferences and physical limitations. Taller frames may facilitate easier ingress and egress, while lower profiles can create a more modern aesthetic.

Tip 5: Foundation Compatibility: Verify that the chosen frame is compatible with the selected mattress type. Some mattresses require a specific type of foundation to maintain warranty compliance and prevent damage.

Tip 6: Noise Reduction Features: Consider frames equipped with noise reduction features, such as padded joints or secure locking mechanisms, to minimize squeaking or creaking during movement.

Tip 7: Warranty Review: Thoroughly examine the warranty terms for both the mattress and frame. Understand the coverage period, exclusions, and procedures for filing a claim. This ensures protection against manufacturing defects and premature failure.

Adhering to these considerations promotes a well-informed decision, resulting in a sleep system that contributes to improved sleep quality and overall well-being.

The next section outlines best practices for assembly, maintenance, and care to maximize the lifespan of the selected “queen bed mattress and frame set.”

1. Size Standardization

Adherence to size standards is paramount in ensuring compatibility and optimal performance within a “queen bed mattress and frame set.” Deviations from established dimensions can lead to functional issues, compromising both comfort and structural integrity.

- Mattress Fit and Support

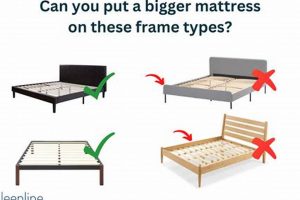

Size standardization ensures the mattress fits securely within the frame, providing adequate support and preventing shifting or sagging. A mattress that is too small leaves unsupported areas, potentially leading to uneven weight distribution and premature wear. Conversely, an oversized mattress may not fit within the frame, compromising structural stability.

- Bedding Compatibility

Standard queen size dimensions facilitate the ease of acquiring appropriately sized bedding, including sheets, comforters, and bedspreads. Non-standard sizes necessitate custom-made bedding, incurring additional expense and limiting design options. This impacts convenience and overall cost-effectiveness.

- Frame Design and Integration

Frame manufacturers design their products to accommodate standardized queen mattress dimensions. This allows for consistent design across various frame styles, ensuring that the mattress is properly supported and that the overall aesthetic is maintained. Deviations can affect design symmetry and load-bearing capabilities.

- Shipping and Handling Efficiency

Standardized sizes contribute to streamlined shipping and handling processes. Manufacturers can optimize packaging and logistics, reducing transportation costs and minimizing the risk of damage during transit. This benefits both the seller and the consumer through cost savings and improved product condition upon arrival.

The cumulative effect of size standardization within a “queen bed mattress and frame set” extends beyond mere convenience. It directly influences the product’s performance, longevity, and overall value proposition, underscoring the necessity for manufacturers and consumers alike to prioritize adherence to established dimensional guidelines.

2. Material Compatibility

Material compatibility within a “queen bed mattress and frame set” directly influences the system’s longevity, performance, and user safety. Incompatible pairings can lead to premature degradation of components, compromised support, and potential health hazards. For instance, placing a memory foam mattress, which relies on a solid, even surface for support, on a frame with widely spaced slats can cause the foam to sag prematurely, reducing its lifespan and potentially voiding the warranty. Conversely, a heavy innerspring mattress might overburden a lightweight, poorly constructed frame, leading to structural failure and posing a safety risk.

The importance of material compatibility extends to the consideration of chemical interactions. Some flame-retardant treatments used on mattresses may react negatively with certain frame finishes, releasing volatile organic compounds (VOCs) into the sleeping environment. Similarly, latex mattresses, which are naturally antimicrobial, may require specific frame materials that do not impede airflow, preventing moisture buildup and the growth of mold or mildew. Real-life examples include wooden frames treated with formaldehyde-based finishes reacting adversely with sensitive individuals, leading to allergic reactions or respiratory issues. Therefore, careful selection of materials, considering both physical and chemical properties, is crucial for a safe and durable sleep system.

In conclusion, understanding material compatibility is not merely an aesthetic consideration but a fundamental requirement for ensuring the functionality, safety, and longevity of a “queen bed mattress and frame set.” By considering the physical and chemical properties of both the mattress and frame materials, consumers can mitigate potential risks and optimize their investment in a high-quality, durable, and healthy sleep environment. Failure to acknowledge these interdependencies can result in compromised sleep quality, reduced product lifespan, and potential health concerns.

3. Support structure

The support structure is an integral component of any “queen bed mattress and frame set”, directly influencing sleep quality and mattress longevity. Its primary function is to provide a stable and even platform for the mattress, distributing weight uniformly to prevent sagging and deformation. A substandard support structure can lead to uneven weight distribution, resulting in pressure points and discomfort for the sleeper. The cause-and-effect relationship is evident: inadequate support leads to mattress degradation and compromised sleep quality. For example, a frame with widely spaced slats or a weak center beam will fail to adequately support a heavy memory foam mattress, causing the mattress to sink in certain areas and develop permanent indentations. This illustrates the critical need for a robust support system designed to match the weight and construction of the specific mattress.

Various support structures exist, each with distinct characteristics. Solid platforms offer maximum support but can restrict airflow, potentially leading to moisture buildup in some mattress types. Slatted frames provide better ventilation but require careful slat spacing and material strength to ensure adequate support. Box springs, while traditionally used, are increasingly replaced by more durable and supportive alternatives. The practical significance of understanding these differences lies in the ability to select a support structure that optimizes mattress performance and extends its lifespan. A poorly chosen support can negate the benefits of a high-quality mattress, resulting in a less comfortable and shorter-lived sleep system. Therefore, consideration of the mattress type, the sleeper’s weight, and the overall construction of the support are essential.

In summary, the support structure is not merely an accessory but a fundamental element of a “queen bed mattress and frame set.” Its quality directly impacts sleep comfort, mattress durability, and overall value. Challenges arise in matching the appropriate support to the specific mattress type and ensuring the structure can withstand prolonged use. Addressing these challenges requires a thorough understanding of the interplay between the mattress and its support system, ultimately leading to a more comfortable and long-lasting sleep experience. Prioritizing the selection of a suitable support structure translates to a direct improvement in the overall performance of the entire sleep system.

4. Frame Durability

Frame durability is a critical factor influencing the long-term performance and value of a “queen bed mattress and frame set”. A robust frame ensures consistent support for the mattress, preventing premature wear and contributing to overall sleep quality. Insufficient frame durability can lead to structural instability, noise, and ultimately, failure of the sleep system.

- Material Composition and Longevity

The choice of materials directly dictates frame durability. Solid hardwoods, reinforced steel, and quality engineered wood products offer superior resistance to stress and deformation compared to low-density particleboard or thin-gauge metals. Real-world examples include solid oak frames enduring decades of use, while particleboard frames may exhibit sagging or breakage within a few years. The material’s inherent strength and resistance to moisture and pests are vital considerations.

- Joint Construction and Stability

The method of joining frame components significantly impacts its structural integrity. Dovetail joints, mortise-and-tenon joints, and reinforced metal brackets provide superior stability compared to simple screw connections or stapled joints. A frame with poorly constructed joints is prone to loosening and squeaking over time. This can compromise the mattress support and create distracting noises during sleep.

- Weight Capacity and Load Distribution

A durable frame must possess adequate weight capacity to support the combined weight of the mattress and occupants. Exceeding the frame’s specified weight limit can lead to bending, cracking, or complete collapse. The frame’s design should distribute weight evenly across its surface to prevent localized stress points. Examples include center support legs on wider frames to prevent sagging in the middle.

- Finish Quality and Protection

The finish applied to the frame not only enhances its aesthetic appeal but also protects it from environmental factors. Durable finishes, such as powder coating or multi-layer lacquer, resist scratches, moisture damage, and insect infestation. A poorly applied or inadequate finish can lead to rust, warping, or decay, ultimately compromising the frame’s structural integrity.

In conclusion, prioritizing frame durability in a “queen bed mattress and frame set” translates to a long-term investment in sleep quality and product lifespan. Selecting a frame constructed from quality materials, featuring robust joinery, and possessing adequate weight capacity ensures consistent mattress support and minimizes the risk of premature failure. A durable frame not only enhances sleep comfort but also contributes to the overall value and longevity of the sleep system.

5. Mattress Comfort

Mattress comfort is a subjective, yet crucial, component within a “queen bed mattress and frame set.” It directly influences sleep quality, impacting physical well-being and daytime cognitive function. The inherent comfort properties of the mattress stem from its construction, materials, and ability to conform to the individual’s body. Discomfort, conversely, can manifest as restlessness, pain, and sleep deprivation. An incompatible mattress choice can negate the benefits of a well-designed frame, rendering the entire sleep system ineffective. For example, a firm innerspring mattress may provide adequate support but offer insufficient pressure relief for individuals with joint pain, regardless of the frame’s stability.

The relationship between mattress comfort and the frame involves several practical considerations. The frame’s primary function is to provide a stable and level surface, but the mattress dictates the overall feel of the sleep surface. The frame’s design, such as the presence of slats or a solid platform, can indirectly impact mattress comfort. Widely spaced slats may allow a thin or poorly constructed mattress to sag, compromising its comfort and support characteristics. Similarly, a solid platform can restrict airflow, potentially leading to heat buildup and discomfort for individuals who sleep hot. Selecting a frame that complements the mattress type is therefore essential for optimizing comfort. Furthermore, factors such as mattress height relative to the frame influence ease of entry and exit, contributing to overall user experience.

In summary, mattress comfort is a fundamental element within a “queen bed mattress and frame set”, directly impacting sleep quality and user satisfaction. Challenges arise in identifying the optimal mattress comfort level for individual needs and preferences. By recognizing the interplay between mattress construction, frame design, and personal factors, it is possible to create a sleep environment that promotes restful and restorative sleep. Neglecting the importance of mattress comfort can result in a compromised sleep experience, regardless of the quality or durability of the accompanying frame.

6. Assembly Integrity

Assembly integrity, within the context of a “queen bed mattress and frame set,” refers to the degree to which the components are correctly and securely joined, resulting in a structurally sound and stable sleep system. A lack of assembly integrity directly impacts the frame’s ability to properly support the mattress and occupants, leading to compromised comfort, reduced lifespan of the components, and potential safety hazards. Improperly tightened bolts, misaligned joints, or missing support elements exemplify failures in assembly integrity. The cause-and-effect relationship is direct: compromised assembly leads to reduced performance and potential failure of the “queen bed mattress and frame set.” A real-life example involves a frame assembled with inadequately tightened screws. Over time, the screws loosen further, causing the frame to creak and wobble, ultimately leading to instability and potential collapse. The practical significance of understanding this is that careful and correct assembly is not merely a perfunctory step but a critical factor in ensuring the system’s functionality and safety.

Further analysis reveals that assembly integrity is not solely dependent on the quality of the components but also on the instructions provided and the user’s adherence to them. Clear, concise instructions with visual aids minimize the risk of errors during assembly. Furthermore, utilizing appropriate tools and techniques, such as torque wrenches for bolts or levels for alignment, contributes to a more secure and stable structure. Practical applications include manufacturers providing pre-assembled components to minimize user error and incorporating design features that simplify the assembly process. Quality control measures during manufacturing can also ensure that pre-drilled holes are properly aligned and threaded, facilitating easier and more secure assembly. Regular inspection and maintenance of the assembled system, including tightening of bolts and screws, are also essential for preserving assembly integrity over time.

In conclusion, assembly integrity is a non-negotiable component of a functional and safe “queen bed mattress and frame set.” Its importance stems from its direct impact on the system’s stability, durability, and comfort. Addressing challenges related to assembly integrity requires a multi-faceted approach, encompassing clear instructions, appropriate tools, quality control measures, and regular maintenance. Prioritizing assembly integrity ensures that the “queen bed mattress and frame set” performs as intended, providing years of comfortable and reliable sleep. Neglecting this aspect can lead to a compromised sleep experience and potential safety risks, highlighting the importance of meticulous attention to detail during the assembly process.

Frequently Asked Questions

The following addresses common inquiries regarding selection, maintenance, and lifespan considerations for a queen bed mattress and frame set.

Question 1: What is the standard lifespan of a queen bed mattress?

The typical lifespan of a queen bed mattress ranges from seven to ten years, depending on the materials used, the weight of the sleepers, and the level of care provided. Mattresses constructed with higher-quality materials and subjected to regular maintenance can exceed this timeframe.

Question 2: How often should a queen bed mattress be rotated?

It is recommended to rotate a queen bed mattress every three to six months to promote even wear and prevent the formation of body impressions. This practice extends the lifespan of the mattress and maintains consistent comfort levels.

Question 3: What frame types are most compatible with memory foam mattresses?

Memory foam mattresses generally perform best with solid platforms or frames featuring closely spaced slats (no more than 2-3 inches apart). These surfaces provide the necessary support to prevent sagging and maintain the mattress’s structural integrity.

Question 4: How does frame construction affect mattress longevity?

A well-constructed frame provides stable and even support for the mattress, preventing premature wear and tear. A frame with weak support or sharp edges can damage the mattress over time, reducing its lifespan and compromising comfort.

Question 5: What are the key indicators that a queen bed mattress needs replacement?

Key indicators include visible sagging, permanent body impressions, increased discomfort during sleep, and the presence of allergens or pests within the mattress. These signs suggest that the mattress is no longer providing adequate support or hygiene.

Question 6: What is the recommended weight capacity for a queen bed frame?

The recommended weight capacity for a queen bed frame typically ranges from 500 to 700 pounds, encompassing the combined weight of the mattress and sleepers. Exceeding this weight limit can compromise the frame’s structural integrity and potentially lead to failure.

Selecting a compatible frame and mattress, along with proper care, optimizes the performance and extends the useful life of the queen bed set.

The following sections will further explore options for maintaining a “queen bed mattress and frame set” to extend their lifespan.

Conclusion

The preceding analysis has explored critical elements regarding a “queen bed mattress and frame set.” From material compatibility and support structures to frame durability and assembly integrity, each aspect plays a definitive role in the overall performance and longevity of the sleep system. Considerations such as size standardization and mattress comfort further contribute to user satisfaction and sleep quality. A comprehensive understanding of these factors enables informed decision-making, leading to the selection of a system best suited for individual needs and preferences.

Recognizing the significance of each component in a “queen bed mattress and frame set” empowers consumers to prioritize quality and durability. Continued advancements in materials and design promise further enhancements in sleep technology. The informed pursuit of a compatible and well-maintained system is a direct investment in long-term well-being. Prudent consideration should be given to these key elements to ensure a satisfactory and lasting sleep experience.

![Best Foldable Mattress Frame [Space Saver!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Foldable Mattress Frame [Space Saver!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3167-300x200.jpg)

![Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3165-300x200.jpg)

![Best Extra Long Twin Mattress Frame [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Extra Long Twin Mattress Frame [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3164-300x200.jpg)

![Best Bed Frame for Tempurpedic Mattress [Guide 2024] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Bed Frame for Tempurpedic Mattress [Guide 2024] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3163-300x200.jpg)

![Choosing the Right: Bed Frame, Box Spring, & Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Choosing the Right: Bed Frame, Box Spring, & Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3162-300x200.jpg)