A support structure, typically constructed from welded steel components, provides the foundation upon which a mattress rests. This framework is engineered to bear the weight of the mattress and occupants, contributing to overall sleep comfort and longevity of the sleeping surface. Various designs exist, ranging from simple platforms to more elaborate systems with headboard and footboard attachments.

The utilization of durable metal offers several advantages, including enhanced strength, stability, and resistance to wear and tear. Such robustness ensures that the bed can withstand considerable weight and movement over extended periods. The construction materials also offer a hygienic surface that is easy to clean and maintain, contributing to a healthier sleep environment. Historically, simpler wooden frames were prevalent, but the introduction of metal offered superior durability and design flexibility.

The subsequent discussion will delve into the different types available, covering aspects such as size, construction methods, and features that influence both functionality and aesthetic appeal. Furthermore, the article will explore factors to consider when selecting one and how proper maintenance extends its service life.

Guidance for Optimal Selection and Use

Proper selection and maintenance are crucial for maximizing the lifespan and performance of a bed’s support system. Adhering to the following guidelines will ensure both restful sleep and a long-lasting investment.

Tip 1: Evaluate Weight Capacity. Before purchasing, verify that the chosen product is rated to support the combined weight of the mattress and all intended occupants. Exceeding the weight limit can lead to premature failure and compromised support.

Tip 2: Consider Slat Spacing. Closely spaced slats provide superior support, preventing mattress sagging. Opt for models with minimal gaps between slats, especially for heavier mattresses or individuals.

Tip 3: Inspect Weld Quality. Examine the welds joining the metal components. Strong, clean welds are essential for structural integrity and long-term durability. Avoid products with visible imperfections or weak points.

Tip 4: Check for Center Support. For larger beds, a center support beam is critical to prevent sagging in the middle. Ensure that the selected model includes this feature for optimal weight distribution.

Tip 5: Use a Mattress Protector. A mattress protector not only safeguards the mattress from stains and spills but also reduces friction between the mattress and the frame, preventing premature wear.

Tip 6: Periodically Tighten Bolts. Over time, bolts and screws may loosen. Regularly inspect and tighten all fasteners to maintain stability and prevent squeaking.

Tip 7: Avoid Exceeding Load Limits During Movement. When repositioning or moving the bed, avoid placing excessive stress on any single point. Distribute the weight evenly to prevent bending or breakage.

By carefully considering these points, individuals can ensure that their bed provides adequate support, promoting both sleep quality and the longevity of the mattress.

The final section will offer insights into troubleshooting common issues and explore options for recycling or disposing of old or damaged units responsibly.

1. Durability

The lifespan of a bed support system is directly correlated with the inherent material qualities and construction techniques employed. Metal, particularly steel, offers significant advantages in terms of withstanding sustained pressure and resisting deformation over extended use. The durability attribute is a critical factor in ensuring the long-term functionality and value of these bed components. The selection of appropriate gauge steel, coupled with robust welding processes, contributes to a framework capable of withstanding substantial weight and resisting the stresses associated with regular use. An inadequate frame construction, conversely, is prone to bending, cracking, or joint failure, necessitating premature replacement. Examples include instances where lightweight, poorly welded supports exhibit sagging or breakage under typical load conditions, highlighting the importance of prioritizing strength and resistance to wear.

The implications of superior durability extend beyond mere longevity. A structurally sound support contributes to the overall stability of the bed, mitigating motion transfer and minimizing disturbances during sleep. Furthermore, a resilient frame maintains its shape and structural integrity over time, ensuring consistent mattress support and preventing premature wear of the mattress itself. This indirect benefit represents a tangible economic advantage, as the need for mattress replacement is reduced when the underlying framework is able to perform its intended function effectively. The resistance to corrosion, another key aspect, extends the product’s useful life, especially in environments with high humidity or temperature fluctuations. Powder coating or similar protective finishes mitigate the risk of rust and degradation, further enhancing the durability attribute.

In conclusion, the durability of a bed support system is a fundamental requirement for ensuring both comfort and long-term value. Steel, when properly selected and fabricated, provides the necessary strength, stability, and corrosion resistance to withstand the rigors of daily use. A comprehensive understanding of the factors influencing durability, including material properties, construction techniques, and environmental considerations, is essential for making informed purchasing decisions and maximizing the lifespan of the bed. The challenges associated with ensuring durability lie in the need for stringent quality control during manufacturing and the selection of appropriate materials for specific use conditions.

2. Support

The provision of adequate support is a fundamental function of a steel mattress frame. The frame’s design and construction directly influence the degree to which it prevents mattress sagging and ensures proper weight distribution across the sleep surface. Inadequate support can lead to compromised spinal alignment, resulting in discomfort, pain, and potentially long-term health issues. A well-engineered steel frame mitigates these risks by offering a stable and uniform platform for the mattress. For example, consider the difference between a frame with widely spaced slats versus one with closely positioned supports; the latter demonstrably reduces mattress deformation and enhances overall support. This relationship underscores the intrinsic link between the steel frame and the physiological well-being of the user.

Furthermore, the type of steel utilized, the gauge thickness, and the welding techniques employed all contribute to the frame’s overall support capacity. High-quality steel, coupled with robust welding, creates a rigid structure capable of withstanding substantial weight without buckling or bending. Conversely, a frame constructed with thin-gauge steel and weak welds is susceptible to failure, especially under heavier loads. The practical implication of this is evident in scenarios where individuals experience premature mattress degradation or even frame collapse due to insufficient support. The inclusion of center support beams in larger frames is another critical design element that enhances weight distribution and prevents sagging in the middle of the mattress.

In summary, the support provided by a steel mattress frame is not merely a comfort feature but a fundamental requirement for promoting healthy sleep posture and preventing premature mattress wear. The material quality, construction methods, and design elements of the frame are all critical factors that determine its ability to effectively support the mattress and the occupants. Understanding this crucial connection enables informed purchasing decisions and ensures a sleeping surface that contributes to both physical well-being and long-term value. Challenges remain in standardizing support metrics and providing consumers with objective measures of frame performance.

3. Stability

The inherent stability of a bed structure is intrinsically linked to the materials and design of its components, particularly the frame. A steel mattress frame, when properly engineered, provides a rigid and unwavering foundation, crucial for undisturbed sleep. Instability within the frame, conversely, can lead to motion transfer, squeaking noises, and a compromised sense of security. The connection between the frame and stability is causal: the steel frame provides the stability necessary for optimal sleep, while deficiencies in the frame’s construction cause instability and its associated negative consequences. For example, a bed with a poorly welded steel frame may exhibit noticeable rocking or swaying motions when one partner shifts positions, directly impacting the other’s sleep quality. This demonstrates the importance of selecting a frame constructed with robust materials and precise assembly techniques.

Furthermore, the stability of a steel mattress frame is not solely determined by its material composition. The design of the frame, including the number and placement of support legs, the method of connecting frame members, and the presence of interlocking mechanisms, all contribute to its overall rigidity. A frame with insufficient support legs, for instance, may be prone to flexing or bowing under weight, leading to uneven weight distribution and premature mattress wear. Similarly, improperly tightened bolts or loose connections can introduce play into the frame, resulting in squeaking and wobbling. These examples illustrate the practical application of understanding the relationship between frame design and stability: informed consumers can identify and avoid frames with inherent design flaws that compromise stability.

In summary, the stability of a steel mattress frame is a critical factor influencing sleep quality, mattress longevity, and overall user satisfaction. The material properties of steel, the design of the frame, and the quality of its assembly all play a significant role in determining its stability. A comprehensive understanding of these factors empowers individuals to make informed purchasing decisions, ensuring a sleeping surface that provides a stable and secure foundation for restorative rest. The challenge lies in developing standardized stability testing methods to provide consumers with objective measures of frame performance, thereby reducing the reliance on subjective assessments and marketing claims.

4. Assembly

The assembly process of a steel mattress frame directly impacts its structural integrity, long-term stability, and user satisfaction. A poorly designed or executed assembly can compromise the frame’s intended performance, leading to premature wear, instability, and potential safety hazards. The ease and security of the assembly are therefore critical considerations.

- Component Interconnectivity

The manner in which individual steel components connect dictates the overall strength and rigidity of the assembled frame. Designs relying on simple bolt-together connections may be more prone to loosening and instability over time compared to frames utilizing interlocking mechanisms or welded joints. Secure and properly aligned interconnectivity is essential for distributing weight evenly and preventing stress concentrations.

- Instruction Clarity and Completeness

The clarity and completeness of assembly instructions significantly influence the ease and accuracy of the process. Ambiguous or incomplete instructions can lead to errors in assembly, resulting in a structurally compromised frame. Clearly illustrated diagrams, step-by-step procedures, and included hardware lists are crucial for ensuring a successful assembly experience.

- Hardware Quality and Compatibility

The quality and compatibility of the included hardware, such as bolts, screws, and brackets, directly impact the security and durability of the assembled frame. Low-quality or mismatched hardware can strip, break, or loosen over time, compromising the frame’s stability. Utilizing high-strength fasteners and ensuring proper thread engagement are essential for a robust and reliable assembly.

- Tool Requirements and Accessibility

The types and accessibility of tools required for assembly affect the overall convenience and efficiency of the process. Designs requiring specialized tools or complex procedures can be more challenging for users to assemble correctly. Simpler designs utilizing commonly available tools and straightforward assembly steps contribute to a more user-friendly experience.

In summary, the assembly process is an integral aspect of a steel mattress frame’s overall performance. Thoughtful design, clear instructions, high-quality hardware, and accessible tools are all essential for ensuring a successful and structurally sound assembly, ultimately contributing to user satisfaction and the frame’s long-term stability.

5. Size Compatibility

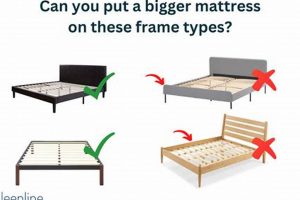

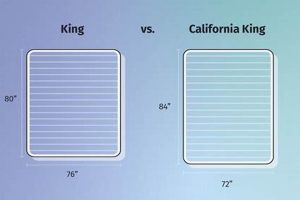

Size compatibility represents a critical factor in the effective utilization of a steel mattress frame. The dimensions of the frame must precisely correspond with those of the mattress intended for its support. A mismatch in size can lead to compromised structural integrity, uneven weight distribution, and accelerated wear of both the mattress and the frame itself. The steel mattress frame must match the size of the mattress to provide proper support. A frame that is too small will cause the mattress to overhang, creating pressure points and potential damage. Conversely, a frame that is too large will leave gaps, preventing uniform support and allowing the mattress to shift during use. These dimensional discrepancies are not merely aesthetic concerns; they directly impact sleep quality and the lifespan of the bedding components.

The standardization of mattress sizes (Twin, Full, Queen, King, California King) is intended to simplify the selection process. However, minor variations in manufacturing tolerances can still exist. Therefore, meticulous measurement and verification are essential. A practical example is the selection of a Queen-sized frame for a mattress that, due to manufacturing inconsistencies, is slightly undersized. This mismatch may result in the mattress sliding within the frame, generating noise and disrupting sleep. Accurate measurement of both the mattress and the frame prior to purchase can mitigate this risk. This compatibility extends to the height of the frame as well, impacting ease of access and aesthetic integration with bedroom furniture. Proper consideration of these factors is essential for optimizing both functionality and appearance.

In conclusion, size compatibility is paramount for ensuring the proper functioning and longevity of a steel mattress frame. A precise match between the frame and mattress dimensions is crucial for maintaining structural integrity, promoting even weight distribution, and maximizing sleep comfort. Neglecting this aspect can result in a range of issues, from premature wear to compromised support and instability. A thorough understanding of standard sizes and careful measurement prior to purchase are essential for achieving optimal size compatibility and realizing the full benefits of a steel mattress frame. The standardization of measurement practices presents an ongoing challenge for the industry.

6. Weight Capacity

The maximum load that a steel mattress frame can safely support, commonly referred to as its weight capacity, is a crucial performance parameter directly impacting the frame’s structural integrity and the safety of its occupants. Exceeding this limit induces stress beyond the material’s yield strength, potentially resulting in bending, deformation, or catastrophic failure. This capacity is a direct function of the steel grade, gauge thickness, welding quality, and overall design of the frame. Consider a scenario where a couple, exceeding the stated weight limit for a particular frame, experiences the gradual bowing of the central support beam over time. This illustrates the causal relationship: excessive load causes structural compromise.

The weight capacity rating is not arbitrary; it is typically determined through engineering calculations and physical testing, adhering to industry standards or manufacturer specifications. A higher rating generally indicates a more robust construction, capable of withstanding greater static and dynamic loads. Dynamic loads, such as those generated by movement during sleep, exert additional stress on the frame, further underscoring the importance of selecting a frame with an adequate weight capacity. The impact of selecting an appropriately rated frame extends beyond preventing structural failure. It also contributes to maintaining proper mattress support and preventing premature wear, thus extending the overall lifespan of the sleep system. Failure to observe weight capacity limits can invalidate warranties and pose a significant safety risk to users.

Therefore, understanding and adhering to the specified weight capacity is paramount when selecting a steel mattress frame. This knowledge enables informed purchasing decisions, ensuring a safe and durable sleeping surface that provides adequate support and prevents premature wear of the mattress. The challenge lies in the lack of universal standards for weight capacity testing and reporting, potentially leading to inconsistencies across different manufacturers. Consumers should prioritize products with clearly stated weight limits and seek independent verification when possible.

7. Corrosion Resistance

Corrosion, the degradation of materials through chemical reactions with their environment, poses a significant threat to the longevity and structural integrity of steel mattress frames. Steel, while offering strength and durability, is susceptible to oxidation, commonly known as rust, when exposed to moisture and oxygen. This process weakens the metal, compromising its ability to support weight and maintain its shape. The lack of corrosion resistance can lead to premature failure of the frame, necessitating costly replacements. For instance, a frame stored in a humid basement or coastal environment without adequate protection is likely to exhibit significant rust damage within a relatively short period, thereby reducing its lifespan and potentially causing structural instability.

The implementation of corrosion-resistant measures is therefore paramount in the manufacture and maintenance of steel mattress frames. Surface treatments, such as powder coating, galvanization, or the application of protective paints, create a barrier between the steel and the surrounding environment. These coatings prevent moisture and oxygen from reaching the metal surface, effectively inhibiting the corrosion process. Powder coating, for example, involves applying a dry, free-flowing powder electrostatically and then curing it under heat to form a durable, protective layer. This not only enhances corrosion resistance but also provides an aesthetically pleasing finish. Regularly inspecting and maintaining these protective coatings is essential to ensure their continued effectiveness. Scratches or chips in the coating should be promptly repaired to prevent corrosion from initiating at those points.

In summary, corrosion resistance is not merely a desirable attribute but a fundamental requirement for steel mattress frames, particularly in environments prone to humidity or temperature fluctuations. Protective coatings and regular maintenance are critical for mitigating the risk of corrosion and extending the service life of these essential bed components. The economic and safety implications of neglecting corrosion resistance underscore the importance of prioritizing this factor in both the design and upkeep of steel mattress frames. Standardizing corrosion resistance testing and providing transparent information to consumers remains an ongoing challenge within the industry.

Frequently Asked Questions

The following questions address common inquiries regarding steel mattress frames, offering factual and objective responses to assist in informed decision-making.

Question 1: What are the primary advantages of a steel mattress frame compared to other materials?

Steel frames generally offer superior strength, durability, and resistance to deformation compared to wooden or plastic alternatives. They are capable of supporting greater weight and are less prone to breakage under stress.

Question 2: How can one determine the appropriate weight capacity for a steel mattress frame?

The weight capacity is typically specified by the manufacturer. It is imperative to select a frame that exceeds the combined weight of the mattress and all intended occupants to ensure structural integrity and prevent premature failure.

Question 3: What factors contribute to the corrosion resistance of a steel mattress frame?

Protective coatings, such as powder coating or galvanization, significantly enhance corrosion resistance. These treatments create a barrier between the steel and the environment, preventing oxidation and rust formation.

Question 4: What maintenance practices are recommended for a steel mattress frame?

Regularly inspect the frame for loose bolts or damaged components. Tighten any loose fasteners and promptly repair any scratches or chips in the protective coating to prevent corrosion. Dusting or wiping down the frame with a damp cloth is also advisable.

Question 5: How does slat spacing affect the support provided by a steel mattress frame?

Closely spaced slats provide more uniform support, preventing mattress sagging and ensuring proper weight distribution. Wider slat spacing may lead to uneven support and accelerated mattress wear.

Question 6: Are all steel mattress frames universally compatible with different mattress types?

While standard sizes exist, minor variations in mattress dimensions can occur. It is crucial to verify the dimensions of both the mattress and the frame prior to purchase to ensure a proper fit and prevent instability.

These responses provide a foundational understanding of key considerations regarding steel mattress frames. Further investigation into specific product features and manufacturer specifications is recommended prior to making a purchase.

The subsequent section will explore the environmental aspects associated with steel mattress frames, including recycling options and sustainable sourcing practices.

Steel Mattress Frame

This exposition has thoroughly examined various facets of the support, including its material properties, design considerations, and performance characteristics. The critical importance of factors such as durability, stability, size compatibility, weight capacity, and corrosion resistance has been underlined. Proper selection, assembly, and maintenance of a contribute significantly to sleep quality, mattress longevity, and overall user safety.

The information presented herein serves as a foundation for informed decision-making. Prudent evaluation of individual needs, coupled with a comprehensive understanding of framework attributes, facilitates the selection of a that provides lasting value and supports restful sleep. Ongoing advancements in materials science and manufacturing techniques hold the potential to further enhance the performance and sustainability of these essential bedding components. Responsible end-of-life management, including recycling initiatives, remains a crucial aspect of minimizing environmental impact.