These combined sleep solutions offer a distinct advantage, providing both a supportive sleeping surface and a structural foundation. The conformance properties of the sleeping surface material are paired with a stable base to enhance the user’s sleep experience. An example would be a visco-elastic foam sleeping surface paired with a platform that provides support and elevation.

The integration of these elements is crucial for optimizing sleep quality. The support structure ensures proper weight distribution and prevents sagging, while the conformance properties of the upper layer alleviate pressure points. Historically, separate purchases were common; however, pre-matched sets offer convenience and ensure compatibility, streamlining the purchasing decision and guaranteeing a harmonized sleep system. The unified structure ensures prolonged lifespan and enhances the conformance and support benefits.

The subsequent discussion will explore the specific material compositions of these sleeping surfaces, the various types of support structures available, and the factors to consider when evaluating the suitability of such systems for individual needs.

Essential Considerations

The selection of integrated sleep systems necessitates careful consideration of several crucial factors to ensure optimal performance and longevity.

Tip 1: Assess Material Density. Higher density foam generally correlates with increased durability and support. Lower density foam may provide initial softness but may degrade more rapidly over time.

Tip 2: Evaluate Support Structure Rigidity. The bed frame must provide adequate support for the combined weight of the sleeping surface and the occupants. Insufficient support can lead to sagging and premature wear.

Tip 3: Consider Frame Material and Construction. Options range from wood to metal. Wood offers aesthetic appeal, while metal provides robust support. Construction should prioritize stability and minimize noise.

Tip 4: Verify Dimensions and Compatibility. Confirm that the surface dimensions accurately match the frame dimensions to prevent overhang or instability. Consult manufacturer specifications for precise measurements.

Tip 5: Examine Warranty and Return Policies. Thoroughly review the manufacturer’s warranty coverage and return policies. Understand the terms and conditions regarding defects, sagging, or other issues.

Tip 6: Research Cooling Properties. Certain foam formulations incorporate cooling gels or open-cell structures to mitigate heat retention. Consider these features if overheating is a concern.

Tip 7: Consider Edge Support. Sufficient edge support ensures stability when sitting on the edge of the sleeping surface and maximizes the usable sleeping area. Look for reinforced edges.

Tip 8: Assess Height Profile. The combined height of the surface and frame impacts ease of entry and exit. Consider the user’s mobility when selecting a system with a suitable height profile.

By adhering to these guidelines, the selection process for integrated sleep systems can be optimized, yielding a durable and comfortable sleep environment.

The subsequent section will discuss maintenance practices to prolong the lifespan of these components and ensure continued performance.

1. Material Density

Material density, measured in pounds per cubic foot (PCF), significantly affects the performance and longevity of visco-elastic foam sleeping surfaces integrated with a bed frame. A higher density typically indicates a greater quantity of material within a given volume, resulting in enhanced support, durability, and resistance to deformation. Conversely, lower density materials offer initial softness but are prone to quicker degradation and reduced support over time. For instance, a 5 PCF material will generally provide superior support and retain its shape longer than a 3 PCF material, assuming similar material compositions.

The relationship between density and support structure is also critical. While a high-density visco-elastic layer can provide excellent conformance, its benefits are diminished if the bed frame lacks adequate support. A flimsy frame may sag or flex, compromising the weight distribution intended by the sleeping surface design, regardless of the visco-elastic material’s density. Real-world examples include individuals experiencing premature sagging in their sleeping surface despite it having a relatively high density rating because the bed frame underneath was constructed from low-quality materials or lacked sufficient support slats. Therefore, selection should involve assessing both the material density of the visco-elastic component and the structural integrity of the bed frame.

Understanding the practical significance of material density facilitates informed consumer choices. While higher density variants often command a premium price, the investment can translate to a longer lifespan and sustained comfort. Consumers should correlate density ratings with manufacturer warranties and independent reviews to gauge the long-term performance. The interplay between sleeping surface density and support structure rigidity is fundamental to achieving a stable and comfortable sleep environment. A balanced approach, considering both factors, maximizes the value and utility of the integrated sleeping system.

2. Support Structure

The underlying framework is an indispensable element of a visco-elastic foam sleeping surface. Its primary function is to provide consistent support and distribute weight evenly, preventing deformation and ensuring the conformance properties of the visco-elastic material are optimized. Inadequate support can lead to sagging, premature wear, and a diminished sleep experience. The type of support system significantly impacts the overall performance and longevity of the entire unit. For example, a visco-elastic foam sleeping surface placed on a poorly constructed frame with inadequate slats will likely exhibit sagging in high-pressure areas, negating the benefits of the foam’s conformance capabilities.

Various support structures are available, each with distinct characteristics. Platform beds offer a solid, continuous surface, providing maximum support and minimizing the risk of sagging. Slat systems, comprising multiple horizontal supports, offer a degree of flexibility and ventilation, but their effectiveness depends on the number, spacing, and material of the slats. Metal frames provide robust support and durability, while wooden frames offer aesthetic appeal but may require additional reinforcement to prevent sagging over time. Practical applications include selecting a platform bed for individuals with higher body weights or opting for a reinforced slat system with closely spaced slats to provide adequate support for a visco-elastic foam sleeping surface. The choice should be based on individual needs and the specific characteristics of the visco-elastic component.

In summary, the support structure is a fundamental component. A properly designed and constructed support system ensures that the visco-elastic foam sleeping surface performs as intended, providing optimal comfort and durability. The selection of an appropriate support structure must align with the characteristics of the foam material and the individual user’s needs to create a stable and comfortable sleep environment. Challenges arise in assessing the long-term durability of different support systems, necessitating careful consideration of materials, construction, and manufacturer warranties. These factors are critical for ensuring the long-term performance of the integrated unit.

3. Frame Material

The selection of frame material is a crucial determinant in the overall performance and longevity of a sleep system, influencing factors ranging from structural stability to aesthetic integration. Understanding the properties and implications of different frame materials is essential for optimizing the user experience.

- Wood Frames: Aesthetics and Limitations

Wooden frames provide visual warmth and can complement various bedroom styles. However, the structural integrity of wood frames is contingent upon the type of wood used and the construction methods employed. Softwoods may be prone to warping or cracking under sustained weight, while hardwoods offer greater durability. A poorly constructed wooden frame can lead to sagging and uneven support, compromising the comfort and lifespan of the sleeping surface. For instance, a solid oak frame will provide superior support compared to a frame constructed from particleboard or soft pine.

- Metal Frames: Durability and Support

Metal frames, typically constructed from steel or aluminum, offer exceptional strength and resistance to deformation. Steel frames are particularly robust and can withstand significant weight, making them suitable for individuals seeking maximum support. Aluminum frames are lighter but may exhibit less rigidity than steel. The design of the metal frame, including the gauge of the metal and the welding techniques used, directly impacts its structural integrity. A well-constructed metal frame provides a stable and level foundation, enhancing the performance and longevity of the sleep surface.

- Upholstered Frames: Comfort and Style

Upholstered frames incorporate fabric or leather coverings over a wooden or metal substructure. These frames offer a softer aesthetic and can enhance comfort by providing a padded surface around the perimeter of the bed. However, the durability of upholstered frames depends on the quality of the fabric and the underlying frame material. Fabrics prone to wear and tear or a weak substructure can lead to premature deterioration and compromise the structural integrity of the frame.

- Adjustable Frames: Functionality and Customization

Adjustable frames, often constructed from metal, allow users to customize the position of the sleeping surface. These frames offer enhanced comfort and can alleviate certain medical conditions. The reliability of adjustable frames hinges on the quality of the motors, hinges, and control mechanisms. A poorly designed or manufactured adjustable frame may experience malfunctions or structural failures, rendering the bed unusable. The weight capacity of the adjustable frame is also a critical consideration, as exceeding the limit can result in damage and compromise safety.

In conclusion, the selection of frame material is a multifactorial decision that requires careful consideration of structural integrity, aesthetic preferences, and functional requirements. The frame material directly impacts the performance, durability, and overall user satisfaction. A well-chosen frame material will complement the performance and prolong the life of the visco-elastic sleeping surface, contributing to an optimized sleep environment.

4. Dimensions

The dimensional compatibility between a visco-elastic foam sleeping surface and its corresponding support structure is paramount for ensuring optimal performance, stability, and user safety. Accurate measurements and adherence to standardized sizing conventions are critical throughout the selection and installation processes.

- Standard Size Adherence

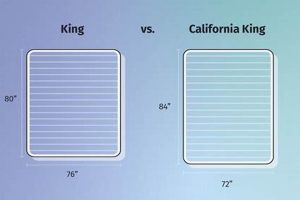

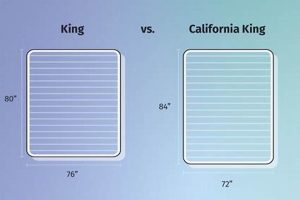

Adherence to established size standards (Twin, Twin XL, Full, Queen, King, California King) ensures compatibility between different manufacturers and facilitates the acquisition of appropriately sized bedding and accessories. Deviation from these standards can lead to fitment issues and compromise the structural integrity of the assembled unit. For instance, attempting to fit a queen-sized visco-elastic foam sleeping surface onto a full-sized support structure will result in overhang and potential instability.

- Thickness Considerations

The thickness of the visco-elastic foam sleeping surface impacts the overall height of the bed, influencing ease of entry and exit. The frame must be designed to accommodate the sleeping surface’s thickness while maintaining a comfortable and safe height for the user. For example, a high-profile foam sleeping surface paired with a tall frame may necessitate the use of a step stool for individuals with limited mobility.

- Internal Frame Dimensions

The internal dimensions of the support structure must precisely match the dimensions of the visco-elastic foam sleeping surface. Insufficient internal dimensions can cause the sleeping surface to compress or buckle, while excessive dimensions can lead to shifting and instability. Accurate measurements and careful consideration of tolerances are essential. Real-world examples include instances where a sleeping surface shifts within an oversized frame, resulting in discomfort and potential injury.

- Weight Distribution and Support

Dimensional considerations also extend to the distribution of weight across the support structure. The dimensions and spacing of slats or the surface area of a platform bed must be adequate to support the weight of the visco-elastic foam sleeping surface and the occupants. Inadequate support can lead to sagging, uneven weight distribution, and premature wear. A practical example is a bed with widely spaced slats that causes a heavy visco-elastic surface to sag in the spaces between the slats, affecting comfort and durability.

In summary, precise dimensional compatibility is a non-negotiable requirement for integrated sleep systems. Adherence to standardized sizes, consideration of sleeping surface thickness, accurate measurement of internal frame dimensions, and appropriate weight distribution are all crucial factors in ensuring optimal performance, stability, and longevity. Failure to address these dimensional aspects can result in discomfort, premature wear, and potential safety hazards. These factors all play a pivotal role to the relationship.

5. Warranty

The warranty associated with an integrated sleep system, encompassing both a visco-elastic foam sleeping surface and its support structure, serves as a contractual guarantee from the manufacturer regarding the product’s durability and performance. Its terms and conditions provide a critical framework for consumer protection and should be thoroughly examined prior to purchase.

- Coverage Scope and Duration

The scope of the warranty dictates which defects or issues are covered, ranging from manufacturing flaws to premature sagging or structural failures. The duration of the warranty specifies the period for which this coverage remains in effect. A longer warranty period generally indicates greater confidence on the part of the manufacturer regarding product durability. For example, a 10-year warranty might cover significant sagging exceeding a specified depth, while a 1-year warranty might only address manufacturing defects present upon initial delivery. Prorated warranties reduce coverage over time, impacting the value of claims as the product ages.

- Claim Procedures and Requirements

The warranty document outlines the procedures for filing a claim, including required documentation, proof of purchase, and photographic evidence. Strict adherence to these procedures is essential for claim approval. Manufacturers may require inspection of the product to verify the reported defect. Consumers should retain all relevant documentation and familiarize themselves with the claim process to ensure timely resolution of any warranty-related issues. Failure to follow prescribed procedures can result in claim denial.

- Exclusions and Limitations

Warranties typically include specific exclusions, such as damage resulting from misuse, abuse, or improper cleaning. Stains, burns, and normal wear and tear are often excluded from coverage. The warranty may also be voided if the product is used with an incompatible support structure or if the care instructions are not followed. Consumers should carefully review the exclusions to understand the limitations of the warranty coverage. Understanding these limitations prevents unrealistic expectations and facilitates informed decision-making.

- Interrelation of Sleeping Surface and Frame Warranties

When purchasing an integrated system, it is crucial to determine whether the visco-elastic foam sleeping surface and the frame are covered under a single warranty or separate warranties. Separate warranties may complicate the claim process and potentially lead to disputes regarding responsibility for interconnected issues. For instance, if the sleeping surface sags due to a defect in the frame, the consumer may need to file separate claims with different entities, leading to delays and potential conflicts. Integrated warranties offer simplified claim resolution and ensure comprehensive coverage of the entire system.

In summary, the warranty is a critical consideration when evaluating an integrated sleep system. A comprehensive warranty, with clearly defined terms, procedures, and exclusions, provides valuable protection against potential defects or performance issues. Thoroughly reviewing the warranty documentation and understanding its implications can mitigate risk and ensure long-term satisfaction with the purchase of a memory foam mattress with bed frame.

6. Cooling

Visco-elastic foam, by nature of its dense structure, often exhibits a tendency to retain heat, potentially leading to discomfort for the user. This characteristic presents a significant consideration when integrating such materials into a sleep system. The effect of heat retention can manifest as night sweats, restlessness, and a general reduction in sleep quality. The incorporation of cooling technologies is, therefore, not merely a comfort enhancement, but a functional component crucial for optimizing the sleep environment when utilizing a memory foam mattress with bed frame.

Several methods are employed to mitigate heat retention in visco-elastic foam. Gel-infused foam incorporates phase-change materials designed to absorb and dissipate heat. Open-cell foam structures promote airflow within the material, facilitating heat transfer. Surface treatments, such as breathable fabrics and moisture-wicking technologies, further enhance cooling by drawing heat away from the body. The effectiveness of these cooling mechanisms varies depending on the specific materials and construction techniques used. For example, a memory foam mattress with bed frame incorporating a gel-infused layer and an open-cell structure will generally exhibit superior cooling properties compared to a standard visco-elastic foam mattress with a conventional support structure and covering.

Addressing the inherent heat retention properties of visco-elastic foam is essential for ensuring a comfortable and restful sleep experience. Cooling technologies represent a critical component in integrated sleep systems, directly impacting user satisfaction and sleep quality. Continuous innovation in materials and design is aimed at further enhancing the cooling performance of visco-elastic foam products, thereby addressing the challenges associated with heat retention and optimizing the overall sleep environment.

Frequently Asked Questions

This section addresses common inquiries regarding integrated sleep systems composed of a visco-elastic foam sleeping surface and an accompanying support structure. The objective is to provide clear and concise answers to frequently encountered questions.

Question 1: What is the typical lifespan of a memory foam mattress when used with a compatible bed frame?

The lifespan varies based on factors such as material density, usage patterns, and maintenance practices. A high-quality visco-elastic foam sleeping surface, properly supported by a compatible bed frame, can reasonably be expected to last between 7 to 10 years. Substandard materials or inadequate support may significantly reduce this timeframe.

Question 2: Does the type of bed frame impact the performance of the memory foam mattress?

Yes. The support structure provided by the bed frame directly influences the conformance and longevity of the visco-elastic foam sleeping surface. Inadequate support can lead to sagging, uneven weight distribution, and premature wear, diminishing the benefits of the foam material.

Question 3: Are there specific frame materials that are better suited for use with memory foam mattresses?

Both wood and metal frames can be suitable, provided they offer adequate support and rigidity. Metal frames generally provide greater strength and resistance to deformation, while wooden frames can offer aesthetic appeal. The critical factor is the quality of construction and the ability to uniformly support the weight of the sleeping surface and occupants.

Question 4: How does material density influence the comfort and durability of a memory foam mattress?

Higher density visco-elastic foam typically provides enhanced support, durability, and resistance to deformation. Lower density materials may offer initial softness but are prone to quicker degradation and reduced support over time. The selection of an appropriate density depends on individual preferences and budgetary considerations.

Question 5: What are the key considerations when evaluating the warranty for a memory foam mattress and bed frame combination?

The scope and duration of the warranty, as well as any exclusions or limitations, should be carefully examined. A comprehensive warranty that covers both the sleeping surface and the frame provides greater protection against potential defects or performance issues. Understanding the claim procedures and requirements is also essential.

Question 6: Can a memory foam mattress exacerbate heat retention issues, and how can this be mitigated?

Visco-elastic foam can retain heat due to its dense structure. This can be mitigated through the use of cooling technologies such as gel-infused foam, open-cell structures, and breathable surface treatments. Selecting a memory foam mattress with these features can enhance comfort and reduce the risk of overheating.

These frequently asked questions offer essential guidance for navigating the selection and utilization of integrated sleep systems. Thorough consideration of these factors can contribute to a more informed purchasing decision and improved sleep quality.

The subsequent section will address best practices for maintaining your memory foam mattress with bed frame system.

In Conclusion

The preceding analysis has explored the multifaceted considerations involved in selecting an integrated sleep system, specifically focusing on the intersection of visco-elastic foam sleeping surfaces and their corresponding support structures. Key points of emphasis included material density, support structure rigidity, frame material composition, dimensional compatibility, warranty terms, and cooling technologies. A thorough understanding of these factors is crucial for optimizing both comfort and longevity.

The ongoing advancement in materials science and design principles continues to refine the performance and durability of these systems. Individuals are encouraged to carefully evaluate their specific needs and preferences, aligning those considerations with the objective attributes discussed herein. The successful integration of a memory foam mattress with bed frame represents a significant investment in long-term well-being, warranting due diligence and informed decision-making.