A support structure, typically constructed from steel, designed to accommodate a specific size of bedding. This type of foundation provides a stable base for a sleeping surface, elevating it from the floor. A common example is a simple, foldable unit used in guest rooms or for children’s beds.

These structures offer several advantages, including improved airflow around the mattress, which can help regulate temperature and reduce moisture buildup. Their durability and ease of assembly make them a practical choice for many consumers. Historically, such foundations evolved from simple wooden bed frames to more sophisticated metal designs, reflecting advancements in materials and manufacturing techniques.

The subsequent sections will delve into the various types, features to consider when purchasing, assembly guidelines, and maintenance tips associated with these essential bedroom components. These considerations will guide informed decisions when selecting the most appropriate option.

Guidance for Selecting a Bed Foundation

The selection of an appropriate bed foundation necessitates careful consideration of several factors to ensure optimal support, durability, and longevity of the bedding.

Tip 1: Assess Weight Capacity: Verify the unit’s specified maximum weight limit. Exceeding this limit can compromise the structural integrity of the foundation, potentially leading to premature failure and voiding any applicable warranties.

Tip 2: Evaluate Slat Spacing: Closer slat spacing provides superior support. Gaps exceeding a few inches may result in uneven weight distribution, causing sagging and accelerated wear to the bedding.

Tip 3: Consider Headboard Compatibility: If a headboard is desired, ensure that the foundation is designed to accommodate headboard attachment. Check for pre-drilled holes or universal brackets for compatibility.

Tip 4: Inspect Locking Mechanisms: For foldable units, rigorously examine the locking mechanisms. These mechanisms are crucial for maintaining stability and preventing accidental collapse. Prioritize foundations with robust and reliable locking systems.

Tip 5: Evaluate Height Considerations: The foundation’s height influences the overall bed height. Account for individual preferences and mobility limitations when determining the appropriate height. A height that is too low or too high may cause discomfort.

Tip 6: Examine Material Quality: Inspect the quality of the metal. Powder-coated steel offers enhanced resistance to rust and corrosion, extending the foundation’s lifespan.

Adhering to these guidelines facilitates the selection of a bed foundation that provides adequate support, ensures longevity of the bedding, and enhances overall sleep quality.

The following sections will address assembly procedures and maintenance best practices, offering additional insights into optimizing the performance and lifespan of the chosen support structure.

1. Durability

The longevity of a bed foundation is paramount, dictating its value proposition over time. The composition and construction of a foundation directly impact its ability to withstand prolonged use and maintain structural integrity.

- Material Composition and Fatigue Resistance

The type of metal used plays a crucial role. Steel, particularly when treated to resist corrosion, offers superior durability compared to weaker alloys. The frame’s ability to withstand repeated stress and weight loading without deformation is a key indicator of fatigue resistance.

- Weld Integrity and Joint Strength

The points where the metal components are joined are inherently weaker. High-quality welds, employing techniques like MIG or TIG welding, ensure a robust connection capable of enduring significant stress. Weak or poorly executed welds represent potential points of failure.

- Slat Design and Load Distribution

The design and spacing of slats influence how weight is distributed across the surface. Closely spaced slats provide more uniform support, reducing stress on individual points and minimizing the risk of sagging or breakage. Wider slat spacing can concentrate weight, leading to premature wear.

- Finish and Corrosion Protection

The application of a protective finish, such as powder coating, shields the metal from environmental factors that contribute to corrosion. Rust weakens the metal, compromising its structural integrity and shortening its lifespan. A durable finish effectively mitigates this risk.

Considering these facets, a well-constructed support structure will demonstrate resistance to bending, breaking, and corrosion. This resistance ensures long-term functionality, making durability a critical factor in assessing overall value.

2. Support

A primary function of a bed foundation is to provide adequate support for the mattress and the occupant. The design and construction of the foundation directly influence the level of support offered, which, in turn, impacts the sleeper’s comfort and the mattress’s longevity. Insufficient support can lead to mattress sagging, uneven weight distribution, and ultimately, compromised sleep quality. For instance, a poorly designed frame with widely spaced slats may allow the mattress to deform over time, especially in areas of concentrated pressure. The selection of a foundation with appropriate support characteristics is crucial for maintaining proper spinal alignment and preventing premature wear of the mattress.

Variations in foundation design address different support needs. Solid platforms offer the most uniform support, distributing weight evenly across the entire mattress surface. Alternatively, slatted designs provide a degree of flexibility, allowing for some contouring to the sleeper’s body. However, the spacing and strength of the slats are critical to ensuring adequate support without compromising mattress integrity. A real-world example is the use of reinforced steel in high-stress areas of the frame to prevent bending or breakage. This targeted reinforcement demonstrates how manufacturers address specific support challenges in their designs.

Effective support within the context of a bed foundation represents a fundamental design consideration. The selection of materials, construction methods, and design features directly impacts the foundation’s ability to provide long-term, reliable support. Understanding these elements allows for informed purchasing decisions, ultimately contributing to improved sleep quality and extended mattress life. Failures in structural support can lead to discomfort and void manufacturer warrenties. Thus, emphasis on load bearing and material composition is essential.

3. Portability

The characteristic of portability, pertaining to a bed foundation, refers to its ease of relocation and transport. This aspect is particularly relevant for individuals residing in temporary accommodations, frequently moving, or requiring a space-saving solution for storage. A lightweight, easily disassembled and reassembled support structure is advantageous in such scenarios. The design often incorporates foldable elements or modular components, facilitating compact storage and simplified transportation. For instance, foldable metal frames designed for bedding can be easily collapsed and transported in a vehicle, providing a readily available sleeping arrangement in various settings.

The significance of portability extends beyond mere convenience. In situations involving disaster relief or emergency housing, the rapid deployment of beds is crucial. Lightweight, portable metal frames enable the efficient establishment of temporary shelters, ensuring individuals have access to a comfortable and sanitary sleeping environment. Furthermore, portability can contribute to cost savings by eliminating the need for professional moving services or specialized transportation equipment. The ability to easily move and store the foundation also enhances its long-term utility, as it can be readily adapted to changing living arrangements or storage requirements.

In summary, portability enhances the practicality and versatility of a bed foundation. The design attributes that contribute to portability, such as lightweight materials and foldable mechanisms, directly impact the ease with which the foundation can be transported and stored. The benefits derived from portability span diverse applications, ranging from individual convenience to emergency response efforts. Therefore, portability represents a significant consideration when evaluating the suitability of a bed foundation, particularly for individuals with dynamic lifestyles or specific spatial constraints.

4. Assembly

The assembly process is an intrinsic element of support structures. The design of these foundations necessitates a straightforward and efficient construction process to ensure stability and functionality. Incorrect or incomplete assembly can compromise the structural integrity of the frame, leading to instability and potential failure. A well-designed unit will include clear, concise instructions and utilize intuitive connection mechanisms to minimize the risk of errors during assembly.

Real-world examples illustrate the importance of proper construction. Frames with poorly designed locking mechanisms or inadequate hardware can exhibit instability, resulting in noise and reduced mattress support. Conversely, units featuring robust interlocking components and high-quality fasteners offer greater stability and durability. The time required for assembly can also vary significantly depending on the design complexity and the clarity of the instructions. This demonstrates that ease of assembly is not merely a convenience but a critical factor in ensuring the long-term performance of the foundation. The instructions are critical for most consumer and if the part is missing or broken can effect consumer experience.

In summary, the assembly process is a critical determinant of the bed foundation’s overall performance and longevity. Simplified designs, clear instructions, and robust connection mechanisms are essential for ensuring proper construction. Attention to these details during the design and manufacturing phases results in a more reliable and user-friendly product. Any compromise on construction ease and robustness can lead to a compromised consumer experience and the voidance of product warranties.

5. Compatibility

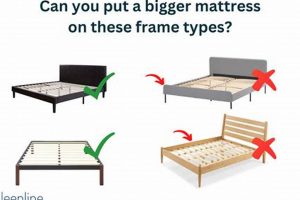

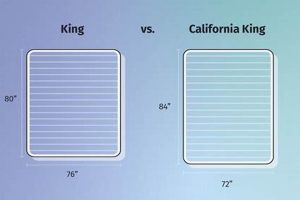

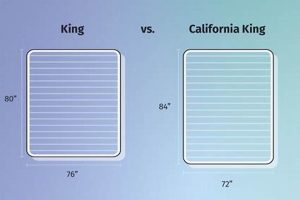

The term “compatibility” denotes the degree to which a metal bed foundation integrates with other bedding components and bedroom furnishings. It is a multifaceted consideration encompassing size matching, structural integration with headboards or footboards, and aesthetic harmony within the room’s decor. Incompatibility in any of these areas can diminish the bed system’s functionality, stability, or visual appeal. Size discrepancies, for example, can result in inadequate mattress support, accelerated wear, or safety hazards. Structural incompatibility hinders the secure attachment of headboards, compromising the bed’s design and stability. Aesthetic incompatibility can disrupt the overall cohesiveness of the bedroom environment, impacting user satisfaction.

Practical application of compatibility considerations manifests in various ways. Prior to purchase, careful measurement of the bedding and available space is essential to ensure proper fit. Verification of headboard attachment mechanisms and dimensions is equally critical, preventing frustration during installation. Consideration of the metal frame’s finish and style in relation to existing furniture promotes visual harmony. The emergence of adjustable bed frames further emphasizes compatibility, requiring careful assessment of mattress flexibility and weight capacity. Manufacturers increasingly address compatibility challenges through standardized sizing and versatile attachment designs.

In summary, ensuring the compatibility of a metal bed frame with other elements is paramount for optimal performance and user experience. Failures in compatibility checks can range from simple aesthetic displeasure to safety issues and the need for return shipping. This interrelationship between components requires a thorough approach. Ultimately, a compatible bed system enhances sleep quality, extends the lifespan of bedding components, and contributes to a more aesthetically pleasing bedroom environment. The considerations outlined emphasize the importance of compatibility to an informed approach to bed frame purchase.

6. Storage

The efficient utilization of space is often a key consideration in modern living environments. This necessitates incorporating storage solutions into furniture design. Metal bed foundations, specifically those designed for smaller sleeping surfaces, can offer integrated or compatible storage options to maximize functionality within limited spaces.

- Under-Bed Clearance

The height of the space beneath the frame directly impacts storage potential. Adequate vertical clearance allows for the placement of storage containers, drawers, or even trundle beds beneath the mattress platform. A frame with minimal clearance restricts storage options, limiting its utility in space-constrained environments. Consider, for example, the difference between a low-profile platform frame and one elevated to accommodate storage bins.

- Integrated Drawer Systems

Some metal bed frames feature built-in drawers directly integrated into the frame’s structure. These drawers provide a convenient and discreet storage solution for clothing, linens, or other personal items. The drawer construction and mechanism affect both storage capacity and ease of access. Inspecting drawer dimensions and glide functionality ensures that the integrated system meets specific storage needs.

- Foldable Frame Designs

Frames designed for smaller mattresses often incorporate foldable designs to minimize storage footprint when not in use. This is particularly advantageous in guest rooms or temporary living spaces. Foldable frames can be easily collapsed and stored against a wall or in a closet, freeing up valuable floor space. The folding mechanism’s durability and ease of operation are important factors to consider.

- Compatibility with Storage Accessories

Even without integrated drawers, certain metal bed frames are designed to accommodate aftermarket storage accessories. Bed risers, for example, can increase under-bed clearance, creating space for storage containers. Selecting a frame with a simple, unobstructed design maximizes compatibility with a variety of storage solutions. Assessing the frame’s construction ensures that it can safely support the weight of both the mattress and any added storage.

The integration of storage solutions within or alongside metal bed foundations enhances their practicality and value, particularly in smaller living spaces. Prioritizing storage considerations during the selection process ensures that the chosen bed system effectively addresses both sleep and storage needs. This integration reflects a growing demand for multi-functional furniture designs that optimize space utilization. The use of under bed storage is a good solutions for customers in small spaces.

7. Cost

The acquisition cost of a metal bed foundation designed for a smaller mattress represents a significant consideration for many consumers. The price point directly influences purchasing decisions, particularly within budget-conscious demographics such as students, those furnishing temporary residences, or individuals seeking economical solutions for guest rooms. The inherent relationship between material quality, manufacturing processes, and design complexity establishes a spectrum of price ranges. Lower-cost options often employ thinner gauge steel and simpler construction methods, potentially compromising long-term durability. Conversely, higher-priced frames may incorporate heavier gauge steel, reinforced joints, and enhanced finishes, justifying the increased expense through extended lifespan and improved stability. For example, a basic, foldable metal frame might retail for under $100, while a more robust, platform-style frame with integrated support features could exceed $200 or more.

The operational cost associated with the use of such foundations extends beyond the initial purchase. A poorly constructed frame may necessitate premature replacement due to structural failure, incurring additional expenses. Inadequate support provided by a low-cost frame can accelerate mattress wear, leading to replacement costs and diminished sleep quality. Conversely, a durable and supportive foundation can protect the mattress investment, extending its lifespan and minimizing long-term expenses. For example, a consumer opting for a less expensive frame may find themselves replacing their mattress sooner than someone who invested in a high-quality foundation. Furthermore, assembly difficulties or the lack of compatibility with other bedding components can result in additional costs associated with professional assembly or the purchase of supplementary hardware.

In summary, the cost associated with a metal foundation extends beyond the initial price tag. A comprehensive evaluation necessitates consideration of long-term durability, mattress support, potential replacement costs, and assembly expenses. While lower-priced options may appear attractive initially, investing in a more robust and well-designed foundation can prove more economical in the long run. This assessment demonstrates that the decision of which bed frame to purchase should factor both immediate and future economic impact and benefit. Balancing cost and quality determines overall user satisfaction and return on investment.

Frequently Asked Questions

The following addresses common inquiries regarding metal bed foundations designed for smaller mattresses, providing clarity on pertinent aspects.

Question 1: What is the expected lifespan of a typical metal frame?

The longevity of a metal bed foundation is dependent on several factors, including the quality of materials, construction methods, and usage conditions. A well-constructed frame utilizing heavy-gauge steel and reinforced joints can reasonably be expected to last for ten years or more under normal use. However, frames constructed from thinner materials or subjected to excessive weight loads may exhibit reduced lifespans.

Question 2: Can a metal foundation damage a mattress?

A poorly designed or improperly assembled metal foundation can indeed contribute to premature mattress wear. Inadequate support, sharp edges, or protruding components can cause indentations, sagging, or fabric damage. Selecting a frame with smooth surfaces, closely spaced slats, or a solid platform design minimizes the risk of mattress damage.

Question 3: What weight capacity should be considered when selecting a metal frame?

The weight capacity should exceed the combined weight of the mattress and all occupants by a significant margin to ensure long-term structural integrity. Manufacturers typically specify a maximum weight capacity for each frame model. Exceeding this limit can lead to bending, breakage, or complete failure of the foundation.

Question 4: Are all metal foundations compatible with headboards?

Not all metal foundations are designed for headboard attachment. Compatibility depends on the presence of pre-drilled holes or universal brackets on the frame. Prior to purchase, one must verify that the frame is compatible with the desired headboard or that appropriate adapters are available.

Question 5: How can one minimize noise associated with metal foundations?

Noise generation is a common concern with metal bed foundations. Tightening all bolts and screws, lubricating joints with silicone-based lubricant, and using rubber or felt pads between the frame and the floor can minimize squeaking or rattling noises. Frames with welded joints tend to be quieter than those with bolted connections.

Question 6: Are metal foundations susceptible to rust?

Metal foundations lacking a protective finish are vulnerable to rust, particularly in humid environments. Frames coated with powder coating or a similar rust-resistant finish offer enhanced protection against corrosion. Regular inspection and maintenance can further prevent rust formation.

In conclusion, awareness of these aspects empowers consumers to make informed decisions when selecting and maintaining metal bed foundations.

The subsequent section will address troubleshooting common issues encountered with metal frames, offering practical solutions.

Conclusion

This examination has elucidated the multifaceted attributes of the twin mattress metal frame. Durability, support, portability, assembly ease, compatibility, storage solutions, and cost considerations each contribute significantly to the overall value proposition. Strategic assessment of these elements empowers informed purchasing decisions, optimizing both immediate comfort and long-term utility.

The prudent selection and diligent maintenance of a twin mattress metal frame represent a foundational investment in sleep quality and resource management. As material science and design innovation progress, continued refinement of these support structures promises enhanced performance and adaptability, reinforcing their enduring relevance in residential and commercial settings.