A bedding accessory designed to enhance sleep comfort and support, this product consists of a layer of viscoelastic foam, typically 3 inches thick, and sized to fit a standard queen-size mattress. It is placed atop an existing mattress to modify its feel and contour to the sleeper’s body. For example, an individual with a firm mattress might use this to introduce a softer, more conforming surface.

The utilization of this type of bedding enhancement offers several potential advantages. It can alleviate pressure points, potentially reducing discomfort and improving sleep quality. Historically, such items have gained popularity as a cost-effective alternative to replacing an entire mattress, offering a way to extend the life of an existing bed while enhancing its comfort characteristics. Its significance lies in providing a customizable sleep experience tailored to individual preferences.

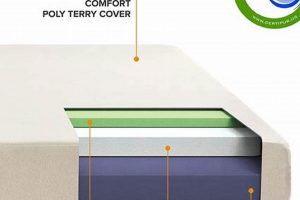

The following sections will delve into the specific material properties, support capabilities, and user considerations relevant when evaluating foam-based mattress enhancements of this type. Factors such as foam density, construction methods, and potential off-gassing will be addressed to provide a comprehensive understanding of its attributes.

Guidance on Viscoelastic Mattress Enhancements

The following considerations are relevant when selecting and utilizing a viscoelastic foam mattress enhancement. These points aim to optimize the sleep experience and ensure product longevity.

Tip 1: Assess Density. Higher density foam generally correlates with increased durability and support. Investigate the product specifications to determine density, as it impacts both comfort and lifespan.

Tip 2: Evaluate Thickness. While 3 inches offers a balance of comfort and support, individual preferences vary. Consider body weight and preferred sleeping position, as these factors influence the optimal thickness for pressure relief.

Tip 3: Consider Ventilation. Viscoelastic foam can retain heat. Look for products with ventilation channels or infused cooling gels to mitigate heat buildup during sleep.

Tip 4: Assess Support Capabilities. Different areas of the body require varied levels of support. Ensure the foam provides adequate support to maintain proper spinal alignment and alleviate pressure points.

Tip 5: Investigate Certifications. Seek certifications, such as CertiPUR-US, which indicate the foam has been tested for harmful substances and meets specific emissions standards. This ensures product safety and quality.

Tip 6: Allow for Off-Gassing. Newly manufactured foam may emit a slight odor. Allow the foam to air out in a well-ventilated area for 24-48 hours before use to dissipate any residual odors.

Tip 7: Use a Mattress Protector. Protect the viscoelastic foam from spills and stains by using a waterproof mattress protector. This prolongs the lifespan of the enhancement and maintains its cleanliness.

These points emphasize the importance of carefully considering the foam’s physical characteristics, support system, and safety certifications to make an informed purchasing decision. Properly managing the product’s environment also plays a key role in optimizing it lifespan and maintaining its condition.

The following sections provide additional information about cleaning, maintenance, and storage for viscoelastic foam mattress enhancers.

1. Density and Support

The density of the viscoelastic foam core directly influences the support capabilities within a 3-inch queen-size mattress enhancement. This relationship is fundamental to the product’s ability to provide adequate spinal alignment and pressure relief. Higher density generally translates to enhanced support and durability.

- Core Density and Load-Bearing Capacity

Viscoelastic foam density, measured in pounds per cubic foot (lbs/ft), dictates the material’s resistance to compression. A higher density foam (e.g., 4 lbs/ft or greater) can withstand greater loads and distribute weight more effectively, preventing excessive sinking and maintaining spinal alignment. This is crucial for individuals requiring substantial support, such as those with higher body weights or specific orthopedic needs. For instance, a denser foam will more effectively resist compression under the hips and shoulders, preventing spinal misalignment during sleep.

- Impact on Pressure Point Relief

While density contributes to support, its interaction with the conforming nature of viscoelastic foam dictates pressure relief. High-density foams, when properly formulated, distribute weight over a larger surface area, reducing concentrated pressure on bony prominences like hips and shoulders. This is vital for individuals experiencing joint pain or pressure sores. Low-density foams may not provide adequate pressure relief, leading to discomfort and potential aggravation of existing conditions. As an illustration, denser foam distributes the body’s weight more evenly, preventing localized pressure on the shoulder when sleeping on the side.

- Longevity and Resistance to Sagging

Density directly impacts the product’s long-term performance. Higher-density foam is less prone to compression and sagging over time, maintaining its supportive properties for an extended period. Lower-density foams, conversely, may exhibit premature sagging, particularly in areas subject to concentrated pressure, leading to reduced support and a decline in overall comfort. For example, a denser foam core is less likely to develop permanent indentations from nightly use compared to a lower-density counterpart.

- Support Layer Configuration and Firmness

The internal architecture and arrangement of the 3 inch memory foam mattress topper queen can also influence the support profile. Zoning support that is the arrangement of different foam densities in different zones of the mattress topper can help provide targeted support where it is needed. An example of this is a zoned construction where the head and leg sections of the topper have a lower density than the torso section of the topper. It could also be that the topper offers edge support, which is generally higher density foam designed to provide firm edges that make it easier to get in and out of bed.

In summary, the density of the viscoelastic foam used in a 3-inch queen-size mattress enhancement is a key determinant of its support characteristics, influencing its load-bearing capacity, pressure relief capabilities, and long-term durability. A careful consideration of density is essential for selecting a product that aligns with individual support needs and sleep preferences. The configuration of support layers in conjunction with foam density can provide additional benefits like zoned support or edge support.

2. Thickness considerations

Thickness is a critical factor in assessing the performance and suitability of a viscoelastic foam mattress enhancement, particularly in the context of a 3-inch queen-size model. It influences pressure relief, support, and overall comfort levels, shaping the sleep experience.

- Pressure Relief and Body Weight

The 3-inch thickness offers a specific level of contouring and pressure relief. Individuals with lower body weights may find this thickness sufficient for alleviating pressure points. However, those with higher body weights may require a thicker enhancement to prevent bottoming out, where the body compresses the foam completely, negating its intended pressure-relieving benefits. For example, a person weighing 250 pounds might experience less pressure relief on a 3-inch enhancement compared to someone weighing 150 pounds, potentially requiring a thicker model for optimal comfort.

- Mattress Firmness and Desired Feel

The existing mattress’s firmness level directly impacts the perceived feel of the 3-inch enhancement. A firmer mattress requires a thicker layer of viscoelastic foam to achieve a noticeable softening effect. Conversely, on a softer mattress, a 3-inch layer might create excessive sinkage and a lack of support. For instance, placing the enhancement on an extra-firm mattress will result in a moderate softening effect, while placing it on a plush mattress might lead to an overly soft and unsupportive sleep surface.

- Support and Spinal Alignment

Thickness contributes to the overall support provided by the enhancement. A 3-inch layer can offer adequate support for maintaining spinal alignment in various sleeping positions, provided the foam density is appropriate. However, inadequate thickness can lead to spinal misalignment, especially for side sleepers who require sufficient contouring to accommodate the shoulder and hip. Consider a scenario where a side sleeper experiences shoulder compression due to insufficient foam thickness, leading to discomfort and potential spinal strain.

- Heat Retention and Airflow

The thickness can impact heat retention and airflow within the mattress system. A thicker viscoelastic foam layer, while providing enhanced pressure relief, may also trap more heat, particularly if the foam lacks ventilation features. This can lead to discomfort for individuals prone to night sweats. For instance, a person residing in a warm climate might experience increased heat retention with a 3-inch enhancement, necessitating the selection of a product with cooling technologies like gel infusions or ventilation channels.

In summary, the 3-inch thickness of a queen-size viscoelastic foam enhancement represents a balance between pressure relief, support, and potential heat retention. Individual factors such as body weight, mattress firmness, sleeping position, and thermal sensitivity influence the optimal thickness for achieving a comfortable and supportive sleep experience. This underscores the importance of aligning product specifications with individual needs.

3. Ventilation properties

The ventilation properties of a 3-inch queen-size viscoelastic foam mattress enhancement are critical to its overall performance and user comfort. Viscoelastic foam, by its nature, tends to retain heat due to its dense structure and limited airflow. This inherent characteristic can lead to discomfort, particularly for individuals who sleep hot or reside in warmer climates. Therefore, manufacturers often incorporate ventilation strategies to mitigate heat buildup and improve breathability. The presence or absence of effective ventilation has a direct impact on the sleeper’s thermal regulation and, consequently, sleep quality. For example, a topper without proper ventilation may cause heat to accumulate around the sleeper’s body, leading to restlessness and disrupted sleep. Conversely, a topper with effective ventilation facilitates air circulation, dissipating heat and maintaining a more comfortable sleeping temperature.

Ventilation is achieved through various methods, including the incorporation of open-cell foam structures, the addition of ventilation channels or perforations, and the infusion of cooling materials such as gel beads. Open-cell foam features larger, interconnected air pockets, allowing for greater airflow compared to closed-cell foam. Ventilation channels, strategically placed within the foam, create pathways for air circulation, facilitating heat dissipation. Gel infusions absorb and dissipate heat, further enhancing the cooling effect. The effectiveness of these methods depends on the specific design and materials used. For instance, a topper with deep ventilation channels and gel infusions will likely provide superior cooling compared to one with only a basic open-cell structure. Similarly, an individual experiencing night sweats will find a topper with effective ventilation crucial for maintaining a comfortable sleep environment.

In conclusion, the ventilation properties represent a crucial design element of a 3-inch queen-size viscoelastic foam mattress enhancement. Adequate ventilation mitigates heat retention, promotes airflow, and enhances overall sleep comfort. Consumers should prioritize products with demonstrable ventilation features, especially if they are prone to overheating during sleep. The challenges associated with inherent heat retention in viscoelastic foam necessitate innovative solutions to provide a thermally neutral sleep surface, highlighting the importance of informed product selection based on individual needs and environmental factors.

4. Pressure point relief

Pressure point relief is a primary consideration for individuals seeking to enhance the comfort of their sleep surface. Within the context of a 3-inch queen-size viscoelastic foam mattress enhancement, this relief stems from the material’s ability to conform to the body’s contours, redistributing weight and reducing localized pressure on bony prominences.

- Conforming Properties of Viscoelastic Foam

Viscoelastic foam, also known as memory foam, exhibits a unique ability to deform under pressure and slowly return to its original shape. This characteristic allows the foam to mold around the sleeper’s body, distributing weight more evenly across the surface area. For example, when a side sleeper lies on the enhancement, the foam compresses around the shoulder and hip, preventing concentrated pressure on these areas. This redistribution of weight contributes to a reduction in discomfort and improved sleep quality.

- Impact on Spinal Alignment

Adequate pressure point relief is closely linked to proper spinal alignment. By conforming to the body’s natural curves, a 3-inch viscoelastic foam layer can help maintain the spine in a neutral position, reducing strain on the back and neck. For instance, a person with scoliosis may benefit from the conforming properties of the foam, as it can provide individualized support and minimize pressure on the affected areas of the spine.

- Influence of Foam Density and Thickness

The density and thickness of the foam influence its ability to provide pressure point relief. Higher density foams offer greater support and resistance to compression, preventing bottoming out and ensuring consistent pressure distribution. A 3-inch thickness represents a balance between pressure relief and support. Individuals with higher body weights may require a higher density foam to prevent excessive compression. As an example, a lightweight individual may find adequate pressure relief with a lower density foam, while a heavier individual would benefit from a higher density option to avoid sinking through the foam.

- Comparison to Other Mattress Materials

Viscoelastic foam offers distinct pressure point relief characteristics compared to other mattress materials such as innerspring or latex. Innerspring mattresses typically provide localized support but may not conform to the body’s contours as effectively as viscoelastic foam. Latex offers a more resilient and responsive feel but may not provide the same level of pressure relief. A 3-inch viscoelastic foam enhancement provides a cost-effective means of introducing pressure-relieving properties to an existing mattress that lacks this characteristic. For instance, an individual experiencing pressure points on an innerspring mattress may find relief by adding a viscoelastic foam enhancement, without the need to replace the entire mattress.

The multifaceted nature of pressure point relief, as facilitated by a 3-inch queen-size viscoelastic foam mattress enhancement, encompasses the material’s conforming properties, its impact on spinal alignment, the influence of foam density and thickness, and its comparison to alternative mattress materials. These factors collectively determine the effectiveness of the enhancement in reducing discomfort and promoting restful sleep. The 3-inch viscoelastic foam enhancement offers a practical solution for those seeking enhanced pressure relief.

5. Material certifications

Material certifications serve as verifiable indicators of a 3-inch queen-size viscoelastic foam mattress enhancement’s adherence to specific safety, performance, and environmental standards. These certifications provide consumers with assurances regarding the product’s composition and manufacturing processes, allowing for more informed purchasing decisions.

- CertiPUR-US Certification

The CertiPUR-US certification verifies that the viscoelastic foam has been tested by independent laboratories to meet specific criteria for content, emissions, and durability. This certification ensures the absence of prohibited phthalates, ozone depleters, PBDE flame retardants, mercury, lead, and other heavy metals. It also sets limits on volatile organic compound (VOC) emissions, contributing to improved indoor air quality. For example, a 3-inch queen-size viscoelastic foam mattress enhancement bearing the CertiPUR-US seal indicates that the product has undergone rigorous testing to minimize the risk of exposure to harmful chemicals.

- OEKO-TEX Standard 100 Certification

The OEKO-TEX Standard 100 certification focuses on the safety of textile materials, including the fabric cover of a 3-inch queen-size viscoelastic foam mattress enhancement. This certification verifies that the fabric has been tested for harmful substances, such as formaldehyde, pesticides, and allergenic dyes. It sets limits on the concentration of these substances, ensuring that the fabric is safe for prolonged skin contact. For example, a mattress enhancement with an OEKO-TEX Standard 100 certified cover minimizes the risk of skin irritation or allergic reactions.

- Global Organic Textile Standard (GOTS) Certification

The GOTS certification applies to textile products made from organic fibers. While not directly applicable to viscoelastic foam, it may pertain to the fabric cover of a 3-inch queen-size viscoelastic foam mattress enhancement if the cover is made from organic cotton or other organic fibers. This certification ensures that the organic fibers have been grown and processed according to strict environmental and social criteria. For example, a mattress enhancement with a GOTS-certified organic cotton cover indicates that the cotton has been grown without the use of synthetic pesticides or fertilizers, promoting sustainable agricultural practices.

- GREENGUARD Certification

The GREENGUARD certification assesses chemical emissions from products for indoor use. A 3 inch memory foam mattress topper queen with this certification means that it has been tested and shown to have low chemical emissions, helping to reduce indoor air pollution and the risk of chemical exposure. This is especially relevant because most memory foam products have some degree of VOC off-gassing when they are new. The certification ensures that the topper meets strict standards for chemical emissions, promoting a healthier indoor environment.

These material certifications, whether directly related to the foam composition or the textile components, collectively contribute to a greater understanding of a 3-inch queen-size viscoelastic foam mattress enhancement’s overall safety and environmental impact. By seeking products with these certifications, consumers can make informed choices that prioritize their health and well-being, as well as the sustainability of manufacturing practices. Certification ensures that the quality of the sleep environment is maintained with low emissions.

6. Off-gassing period

The off-gassing period is an inherent characteristic associated with a new 3-inch queen-size viscoelastic foam mattress enhancement. It arises from the release of volatile organic compounds (VOCs) trapped within the foam matrix during the manufacturing process. These VOCs, often produced by the chemical reactions involved in foam production, gradually dissipate into the surrounding environment after the product is unwrapped. The intensity and duration of the off-gassing period can vary depending on the specific type of foam used, the manufacturing techniques employed, and the environmental conditions to which the product is exposed. For instance, an enhancement made with higher density foam or one that has undergone more intensive chemical processing may exhibit a more pronounced off-gassing period than one made with lower density foam or simpler manufacturing methods. The practical significance of understanding this connection lies in the potential impact on indoor air quality and the consumer’s sensory experience.

The presence of VOCs released during the off-gassing period can result in noticeable odors, often described as chemical or plastic-like. While the vast majority of VOCs released from viscoelastic foam are considered to be at levels that pose minimal risk to human health, the odors themselves can be unpleasant and may cause temporary discomfort, such as headaches or respiratory irritation, particularly for individuals with sensitivities to chemicals. To mitigate these effects, manufacturers typically recommend airing out the mattress enhancement in a well-ventilated space for a specified period, often ranging from 24 to 72 hours, before placing it on the bed. For example, a consumer might unwrap the mattress topper and place it in a spare room with open windows for three days to allow the VOCs to dissipate before placing the enhancement on their bed. This practice minimizes the potential for odor-related discomfort during sleep. The effectiveness of ventilation can be influenced by factors such as humidity and temperature, higher temperature and lower humidity would allow for a shorter period of time.

In summary, the off-gassing period is an unavoidable consequence of viscoelastic foam production, and its intensity and duration are influenced by various factors. While the associated VOCs are generally considered to be present at low-risk levels, the resulting odors can be bothersome. Understanding the importance of ventilation and adhering to recommended airing-out periods are essential for minimizing the potential impact of off-gassing on indoor air quality and sleep comfort. One challenge that persists is the variability between products, necessitating consumers to rely on manufacturer guidelines and personal judgment when determining the appropriate airing-out duration. The connection between this outgassing and 3 inch memory foam mattress topper queen highlights the broader theme of understanding the interplay between material properties, manufacturing processes, and the consumer experience.

7. Protective layering

Protective layering is a critical element in maintaining the integrity and longevity of a 3-inch queen-size viscoelastic foam mattress enhancement. Due to the material’s inherent susceptibility to moisture, stains, and physical damage, employing protective measures is essential to preserve its performance and hygiene.

- Waterproof Mattress Protectors

Waterproof mattress protectors serve as an impermeable barrier against liquids, preventing spills, sweat, and other forms of moisture from penetrating the viscoelastic foam core. This is crucial, as moisture can degrade the foam’s structure, leading to reduced support and the growth of mold or mildew. For example, a sudden spill of liquid can be contained on the surface of the protector, preventing it from soaking into the foam and causing irreversible damage. The use of a waterproof protector is thus a primary defense against moisture-related deterioration.

- Breathable Fabric Covers

While waterproof protectors offer essential liquid resistance, some may limit airflow, potentially contributing to heat buildup. Breathable fabric covers, often made from materials like cotton or bamboo, provide a layer of protection against dust mites and allergens while allowing for adequate ventilation. These covers can be easily removed and laundered, promoting hygiene and preventing the accumulation of allergens within the foam. For instance, a breathable cotton cover can effectively trap dust mites, preventing them from penetrating the foam and triggering allergic reactions.

- Fitted Sheets and Top Sheets

Fitted sheets and top sheets serve as additional protective layers, minimizing direct contact between the sleeper and the mattress enhancement. These sheets help to absorb body oils and sweat, reducing the frequency with which the underlying protective layers need to be cleaned. They also provide a barrier against friction, which can cause wear and tear on the fabric cover of the enhancement. For example, regularly washing bedsheets removes accumulated oils and debris, preventing them from transferring to and damaging the foam core.

- Padded Mattress Encasements

Padded mattress encasements offer comprehensive protection, encasing the entire mattress enhancement in a sealed barrier. These encasements typically feature waterproof and breathable properties, providing robust protection against liquids, dust mites, allergens, and bed bugs. They are particularly useful for individuals with allergies or those seeking to safeguard their investment from potential infestations. For example, a bed bug-proof encasement can prevent bed bugs from infesting the mattress enhancement, ensuring a pest-free sleep environment.

Collectively, these protective layering strategies contribute to the long-term maintenance and performance of a 3-inch queen-size viscoelastic foam mattress enhancement. By mitigating the risks associated with moisture, allergens, and physical damage, protective layers ensure that the enhancement retains its comfort, support, and hygienic properties over time. The strategic combination of waterproof protectors, breathable covers, and regular laundering practices is therefore essential for optimizing the lifespan and value of this bedding investment. Furthermore, investing in a padded mattress encasement provides the most comprehensive protection.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, use, and maintenance of a viscoelastic foam bedding enhancement designed for a queen-size mattress.

Question 1: Does this type of product eliminate the need for a new mattress?

This product is designed to augment the comfort of an existing mattress. It can extend the lifespan of a mattress that is still structurally sound but lacks sufficient comfort. However, it will not remedy underlying structural issues or provide adequate support if the existing mattress is significantly worn or damaged.

Question 2: How frequently should a viscoelastic foam bedding enhancement be replaced?

The lifespan of this product varies depending on usage, foam density, and care. Signs of wear, such as permanent indentations or a loss of support, indicate the need for replacement. Generally, a high-quality product can last between 3 to 5 years with proper care.

Question 3: Is this type of product suitable for individuals with allergies?

Viscoelastic foam can potentially harbor dust mites and allergens. Utilizing a hypoallergenic mattress protector is recommended to minimize allergen accumulation. Additionally, products with certifications such as OEKO-TEX Standard 100 ensure that the materials used are free from known allergens.

Question 4: How does the density of the foam impact its performance?

Foam density, measured in pounds per cubic foot (lbs/ft), is a key determinant of support and durability. Higher density foams (e.g., 4 lbs/ft or greater) offer superior support, resist compression, and tend to have a longer lifespan compared to lower density foams.

Question 5: Can this type of product be cleaned?

Viscoelastic foam is generally not washable. Spot cleaning with a mild detergent and water is recommended for localized stains. Complete submersion in water can damage the foam’s structure. Always refer to the manufacturer’s instructions for specific cleaning recommendations.

Question 6: How does this bedding enhancement affect mattress warranty?

The application of an aftermarket bedding enhancement may, in some cases, void the original mattress warranty. It is advisable to consult the mattress warranty documentation or contact the manufacturer to clarify whether the use of a bedding enhancement will affect the warranty coverage.

In summary, selecting a suitable viscoelastic foam bedding enhancement requires careful consideration of factors such as mattress condition, foam density, maintenance requirements, and potential allergen concerns. Proper care and adherence to manufacturer guidelines can prolong the product’s lifespan and maximize its benefits.

The subsequent section will explore specific considerations for selecting a product based on individual sleep preferences and physical needs.

Conclusion

The preceding analysis has presented a comprehensive overview of the attributes and considerations associated with a 3 inch memory foam mattress topper queen. Key aspects examined include foam density, thickness, ventilation, pressure relief, material certifications, off-gassing, and protective layering. Each of these factors contributes to the overall performance, comfort, and longevity of the product. Understanding these elements is crucial for making an informed purchasing decision aligned with individual needs and preferences.

Ultimately, the selection and utilization of a 3 inch memory foam mattress topper queen represents an investment in sleep quality and well-being. It is incumbent upon the consumer to carefully evaluate product specifications, consider individual requirements, and adhere to recommended maintenance practices to maximize the benefits derived from this bedding enhancement. The impact of these considerations extends beyond mere comfort, potentially influencing long-term health and lifestyle quality.

![Best 8 Inch Twin Mattress [Review] & Buying Guide Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best 8 Inch Twin Mattress [Review] & Buying Guide | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3653-300x200.jpg)

![Best 8 Inch Queen Mattress [Guide + Deals] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best 8 Inch Queen Mattress [Guide + Deals] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3652-300x200.jpg)