A portable, inflatable sleeping surface designed for use within the interior of a vehicle defines a specific product category. These mattresses transform the back seat or cargo area into a comfortable sleeping space. An example includes an inflatable platform custom-fit for a specific car model, allowing occupants to rest during travel.

The availability of such a product offers several advantages, most notably enhanced comfort during road trips and camping excursions. Historically, individuals seeking rest during travel relied on less convenient options such as sleeping in seats or using traditional ground tents. These inflatable car solutions provide a more practical and readily available alternative, increasing travel convenience and potentially reducing accommodation costs.

The following sections will delve into the various types available, their construction materials, inflation methods, essential features to consider during purchase, and tips for optimal use and maintenance, providing a comprehensive guide for potential users.

Essential Usage Considerations

This section provides critical information regarding the correct and safe utilization of vehicular inflatable sleeping platforms. Adherence to these recommendations will maximize product lifespan and ensure user safety.

Tip 1: Measure Vehicle Interior Dimensions: Prior to purchase, carefully measure the available space within the vehicle’s rear seating or cargo area. Ensure the inflated dimensions are compatible to prevent overcrowding or potential damage to the vehicle’s interior.

Tip 2: Use Appropriate Inflation Methods: Employ the pump specifically designed for the model. Over-inflation can lead to seam rupture, while under-inflation compromises support and comfort.

Tip 3: Distribute Weight Evenly: Position occupants to distribute weight evenly across the surface. Concentrated pressure on one area can accelerate wear and tear or cause structural failure.

Tip 4: Protect Against Sharp Objects: Remove or cover any sharp or protruding objects within the vehicle’s interior. Punctures can render the product unusable and create a safety hazard.

Tip 5: Avoid Extreme Temperatures: Refrain from leaving the inflated platform in direct sunlight or extreme heat for extended periods. Elevated temperatures can cause expansion, leading to seam failure. Similarly, avoid using in sub-freezing temperatures as the material may become brittle.

Tip 6: Clean and Store Properly: Following use, thoroughly clean the surface with a mild detergent and water. Ensure the platform is completely dry before deflation and storage in its designated bag, in a cool, dry place.

Adhering to these guidelines will enhance the lifespan of the inflatable platform, guaranteeing comfort and convenience on subsequent trips.

The final section will summarize the key considerations for selecting the optimal vehicular inflatable sleeping platform and reinforce the benefits of responsible usage.

1. Vehicle Compatibility

Vehicle compatibility represents a fundamental consideration when selecting an inflatable sleeping platform for automotive use. The physical dimensions and structural design of these mattresses must align precisely with the available space within a given vehicle’s interior to ensure both functionality and safety.

- Dimensional Accuracy

Dimensional accuracy refers to the degree to which the inflated mattress conforms to the specific contours and measurements of the vehicle’s rear seating or cargo area. An ill-fitting platform can obstruct access to seatbelts, interfere with safety features, and create an unstable sleeping surface. For example, a mattress designed for a full-size SUV may be unsuitable for a compact sedan due to insufficient space. This necessitates careful measurement and matching of product specifications to the target vehicle.

- Vehicle Type Specificity

Vehicle type specificity recognizes that different categories of vehicles (e.g., sedans, SUVs, minivans, trucks) possess vastly different interior layouts. Some manufacturers offer models specifically tailored to certain vehicle types, accounting for variations in seat configurations, wheel well intrusions, and overall space constraints. The absence of vehicle type specificity can lead to compromised comfort and increased risk of product damage due to improper fitment.

- Inflation Dynamics and Space Constraints

Inflation dynamics describe how the mattress expands when filled with air and how this expansion interacts with the vehicle’s interior. Even if a mattress appears to fit when deflated, full inflation can cause it to press against vehicle components, potentially damaging both the mattress and the vehicle’s interior. Furthermore, over-inflation in a confined space can create an unsafe situation. Products must be designed to accommodate these dynamics within the intended vehicle.

- Safety Feature Accessibility

Maintaining accessibility to essential safety features, such as seatbelts and emergency exits, is paramount. An incompatible mattress can impede access to these features, potentially compromising passenger safety in the event of an accident. Product designs should prioritize safety by ensuring that these features remain readily accessible even when the platform is fully deployed.

The interplay of dimensional accuracy, vehicle type specificity, inflation dynamics, and safety feature accessibility underscores the critical role of vehicle compatibility in the selection of an inflatable vehicular sleeping platform. Failure to adequately address these factors can result in a product that is not only uncomfortable but also potentially unsafe for use. Thorough evaluation of these aspects is essential for ensuring a positive and secure experience.

2. Material Durability

Material durability directly impacts the longevity, safety, and overall value of vehicular inflatable sleeping platforms. The materials used in construction must withstand the rigors of automotive environments, frequent use, and varying temperature conditions.

- Puncture Resistance

Puncture resistance is the material’s capacity to resist penetration from sharp objects commonly found within vehicles, such as keys, tools, or debris. High-denier PVC, reinforced nylon, or laminated fabrics are often employed to enhance puncture resistance. The consequences of a puncture include rapid deflation, rendering the mattress unusable and potentially creating a hazard if it occurs during use. For example, a mattress constructed from thin, unreinforced vinyl is significantly more susceptible to punctures than one fabricated from multi-layered PVC.

- Abrasion Resistance

Abrasion resistance denotes the material’s ability to withsta

nd surface wear caused by friction against vehicle interiors, bedding, or occupants’ clothing. Prolonged abrasion can lead to material thinning, seam weakening, and eventual failure. Materials with a tightly woven structure and a protective coating typically exhibit superior abrasion resistance. An instance of poor abrasion resistance is demonstrated when a mattress’s surface deteriorates rapidly due to contact with rough carpet or repeated sliding, leading to discomfort and reduced lifespan. - Seam Strength

Seam strength represents the material’s ability to maintain structural integrity at the points where separate pieces are joined. Weak seams are a common failure point, particularly under stress caused by inflation pressure or occupant weight. Radio frequency welding, heat sealing, or reinforced stitching are techniques used to enhance seam strength. For example, a mattress with poorly welded seams may develop leaks or burst at the seams when fully inflated or when subjected to the weight of one or more occupants.

- Temperature Stability

Temperature stability describes the material’s capacity to retain its physical properties and structural integrity across a range of temperatures encountered within a vehicle. Extreme heat can cause expansion and weakening, while extreme cold can lead to brittleness and cracking. Materials with a low coefficient of thermal expansion and resistance to degradation at high and low temperatures are preferred. If the mattress is left inside the car in direct sunlight for long period, this can cause permanent damage to seam.

These four facets collectively define the material durability of vehicular inflatable sleeping platforms. A robust and long-lasting product requires a material that excels in puncture resistance, abrasion resistance, seam strength, and temperature stability. The selection of appropriate materials directly correlates with the overall performance, safety, and value proposition of the product.

3. Inflation Mechanism

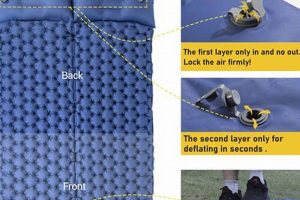

The inflation mechanism represents a critical functional component in the category of vehicular inflatable sleeping platforms. This mechanism dictates the ease, speed, and efficiency with which the mattress is inflated to its operational state, directly affecting user convenience and the overall practicality of the product. The relationship can be viewed as follows: the effectiveness of the mechanism determines the accessibility and usability of the sleeping platform. A deficient mechanism can render an otherwise well-designed mattress impractical for regular use. Consider, for example, a mattress that requires an extensive manual inflation process; the effort and time involved might discourage its use for short rest stops or overnight stays.

Several distinct inflation mechanisms are prevalent in this market segment. Manual pumps, typically foot-operated or hand-operated, offer a cost-effective solution but demand physical exertion and can be time-consuming. Electric pumps, often powered by a vehicle’s 12V outlet, provide a more convenient and rapid inflation method. However, reliance on an external power source can be a limitation in certain scenarios, such as remote camping locations without access to a vehicle. Integrated inflation systems, featuring self-contained air reservoirs and automated inflation processes, represent the most advanced approach but often come at a higher price point. A practical application of a well-designed mechanism is its ability to quickly inflate the mattress to the appropriate firmness level, providing optimal support and comfort for the user. The mechanism must also ensure a secure seal to prevent air leakage during use.

The selection of an appropriate inflation mechanism should align with the intended use case and user preferences. For frequent users or those prioritizing convenience, an electric or integrated system is often the optimal choice. For occasional use or budget-conscious consumers, a manual pump may suffice. Understanding the cause-and-effect relationship between mechanism effectiveness and user experience is vital. The challenge lies in balancing convenience, cost, and reliability. Ultimately, the inflation mechanism is more than simply a means of inflating the mattress; it is a key determinant of its overall utility and user satisfaction.

4. Storage Footprint

Storage footprint, referring to the volume occupied by a deflated vehicular inflatable sleeping platform, significantly influences its practicality and suitability for various travel scenarios. A reduced storage footprint enhances portability and minimizes space constraints within the vehicle.

- Material Compressibility

The inherent compressibility of the mattress material directly affects the final packed size. Materials such as thin-gauge PVC or lightweight nylon are inherently more compressible than thicker, multi-layered fabrics. A highly compressible material enables tighter folding and reduced volume, facilitating storage in confined spaces. For instance, a mattress constructed from heavy-duty PVC may offer superior durability but requires significantly more storage space than a similar design using ripstop nylon.

- Folding Design Efficiency

The design of the folding pattern impacts the efficiency with which the mattress can be compacted for storage. Intricate folding patterns can reduce the overall packed size, but may also increase the complexity of the folding process. Simpler designs prioritize ease of folding, potentially at the expense of a slightly larger storage footprint. An example of efficient design are mattresses that incorporate integrated straps or clips to secure the folded package, further minimizing its volume.

- Integrated Storage Solutions

Some manufacturers incorporate integrated storage solutions into the design of the mattress, such as attached storage bags or compression straps. These solutions facilitate organized packing and minimize the potential for damage during transport. The absence of an integrated storage solution can lead to haphazard packing and increased storage space requirements. Mattresses with dedicated storage bags often include instructions for proper folding techniques, ensuring optimal compactness.

- Impact on Vehicle Cargo Capacity

The storage footprint of the mattress directly affects the vehicle’s available cargo capacity. A bulky mattress can consume a significant portion of the vehicle’s storage space, limiting the ability to transport other essential items. Conversely, a compact mattress preserves valuable cargo space, making it ideal for situations where storage space is limited. For example, users undertaking extended road trips with multiple passengers may prioritize a mattress with a minimal storage footprint to maximize cargo capacity.

The interplay of material compressibility, folding design efficiency, integrated storage solutions, and impact on vehicle cargo capacity collectively defines the importance of storage footprint for vehicular inflatable sleeping platforms. A well-designed product balances comfort and durability with a compact storage profile, optimizing its usability and convenience for a wide range of travel applications.

5. Comfort Level

Comfort level represents a primary determinant of user satisfaction with vehicular inflatable sleeping platforms. The utility of these mattresses hinges on their ability to provide a restful and supportive sleeping surface within the confined space of a vehicle. A low comfort level negates the benefits of portability and convenience, rendering the product ineffective. The absence of adequate comfort directly impacts sleep quality, which, in turn, affects driver alertness and passenger well-being during travel. For example, an uneven or inadequately cushioned surface can lead to discomfort, restlessness, and ultimately, a degraded travel experience. The significance of this understanding lies in the fact that comfort is not merely a luxury but a functional requirement for maximizing the product’s value and ensuring safe and enjoyable travel.

Several factors contribute to the perceived comfort level of these products. These include the mattress material, surface texture, internal support structure, and overall thickness. A plush, non-slip surface enhances tactile comfort, while an internal support system prevents sagging and ensures even weight distribution. Material choices impact both the feel of the mattress and its thermal properties. For instance, a flocked surface can improve airflow and reduce sweating. The practical application of this understanding is evident in the design and marketing of high-end vehicular mattresses, which often incorporate advanced materials and ergonomic designs to optimize comfort. The implementation of contoured designs that mimic the shape of the human body or incorporate zonal support features are other examples.

The ultimate goal in optimizing the comfort level of vehicular inflatable sleeping platforms is to provide a sleep experience that approximates that of a conventional bed. Achieving this requires careful consideration of material selection, design elements, and user feedback. While challenges such as space constraints and portability requirements pose limitations, continuous innovation in materials science and engineering holds the potential to further enhance the comfort level of these products. Understanding the connection between comfort level and the overall value proposition remains crucial for both manufacturers and consumers, ensuring that these mattresses serve their intended purpose effectively.

Frequently Asked Questions

This section addresses prevalent inquiries and concerns regarding inflatable sleeping platforms designed for automotive use, providing concise and objective answers.

Question 1: What criteria determine the suitability of a specific platform for a particular vehicle model?

Suitability is predicated upon dimensional compatibility between the inflated mattress and the vehicle’s interior space, factoring in seat configurations, wheel well intrusions, and safety feature accessibility. Mismatching dimensions may compromise usability and safety.

Question 2: How is the durability of these platforms assessed?

Durability is evaluated based on material puncture resistance, abrasion resistance, seam strength, and temperature stability. Products constructed from robust materials such as reinforced PVC or nylon are generally more durable.

Question 3: Which inflation mechanism offers the greatest convenience?

Electric pumps, powered by a vehicle’s 12V outlet, typically provide the most convenient inflation method, offering rapid and effortless inflation. However, manual pumps provide a backup option when electrical power is unavailable.

Question 4: What is the recommended method for cleaning and storing the platform?

Following use, the surface should be cleaned with a mild detergent and water. The platform must be thoroughly dried before deflation and storage in its designated bag, in a cool, dry environment.

Question 5: What safety precautions should be observed during use?

Sharp objects should be removed from the vehicle’s interior, and weight should be distributed evenly across the mattress surface. Over-inflation and exposure to extreme temperatures should be avoided.

Question 6: How does mattress thickness influence comfort?

Increased thickness generally enhances comfort by providing greater cushioning and support. However, excessive thickness may compromise available headroom within the vehicle.

These answers provide a foundational understanding of critical aspects related to vehicular inflatable sleeping platforms. Understanding these aspects facilitates informed purchasing decisions and responsible product utilization.

The subsequent section will delve into best practices for selecting a vehicular inflatable sleeping platform, reinforcing key considerations for maximizing user satisfaction and product longevity.

air mattress for car

The preceding sections have comprehensively examined vehicular inflatable sleeping platforms, addressing vehicle compatibility, material durability, inflation mechanisms, storage footprint, and comfort levels. Understanding these factors enables informed purchasing decisions tailored to individual needs and vehicle specifications. The selection of a suitable air mattress for car depends on a thorough assessment of intended usage scenarios and prioritization of desired attributes.

The responsible use and proper maintenance of these platforms are essential for maximizing product lifespan and ensuring user safety. As material science and design innovation advance, vehicular inflatable sleeping platforms are poised to offer increasingly enhanced comfort and convenience for travelers. Continued adherence to safety guidelines and informed purchasing practices will ensure that these products effectively serve their intended purpose and contribute to enhanced travel experiences.

![Best Jeep Wrangler Air Mattress [Guide] On Road! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Jeep Wrangler Air Mattress [Guide] On Road! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-6718-300x200.jpg)