The lifespan of inflatable sleeping surfaces is a common consideration for consumers. Expected usability can vary greatly depending on factors such as material quality, frequency of use, care practices, and storage conditions. For example, a model used nightly will likely have a shorter functional period than one employed only for occasional guests.

Understanding the duration of service from such products is important for budgetary planning and responsible consumption. Historically, these items were seen as temporary solutions. However, advancements in manufacturing have led to increased durability in some models, potentially offering extended utility and a reduction in replacement frequency. This contributes to resource conservation and waste minimization.

The subsequent sections will detail specific factors influencing the serviceable timeframe, including material composition, usage patterns, maintenance protocols, and potential failure modes. This analysis aims to provide a realistic assessment of probable operational timeframes under various conditions.

Extending the Usability of Inflatable Sleeping Surfaces

The following guidelines are designed to maximize the functional period of inflatable sleeping surfaces, ensuring optimal value and minimizing premature replacement.

Tip 1: Select a High-Quality Model: Invest in models constructed from durable materials, such as reinforced PVC or laminated fabrics. Higher-quality materials exhibit greater resistance to punctures and air leakage, directly impacting its longevity.

Tip 2: Utilize a Protective Layer: Always place a fitted sheet or mattress topper on the surface. This barrier minimizes direct friction, reducing the likelihood of abrasion and potential damage to the inflatable material.

Tip 3: Avoid Over-Inflation: Overfilling can stress the seams and internal structure, accelerating wear. Inflate to the manufacturer’s recommended pressure only, ensuring the surface remains firm yet pliable.

Tip 4: Conduct Regular Inspections: Periodically examine the surface for signs of wear, punctures, or leaks. Early detection allows for timely repairs, preventing minor issues from escalating into major failures.

Tip 5: Employ Proper Storage Techniques: When not in use, deflate completely, fold neatly, and store in a cool, dry location away from direct sunlight and sharp objects. This minimizes material degradation and potential puncture hazards.

Tip 6: Keep Away From Extreme Temperatures: Avoid exposing to extreme heat or cold. Such conditions can compromise the material’s integrity, leading to deformation, brittleness, or seam failures.

Tip 7: Promptly Repair Minor Damage: Use repair kits designed for inflatable products to address small punctures or leaks as soon as they are detected. Timely repairs can prevent further air loss and extend the product’s usability.

Adhering to these practices will contribute significantly to an extended period of service, providing enhanced value and reducing the need for frequent replacements. Prioritizing preventative measures and consistent maintenance are key to maximizing the investment.

The subsequent section will address common issues associated with inflatable sleeping surfaces and provide troubleshooting strategies.

1. Material Composition

The material from which an inflatable mattress is constructed is a primary determinant of its lifespan. Lower-grade polyvinyl chloride (PVC) is susceptible to stretching, punctures, and seam failures, resulting in reduced durability. In contrast, higher-denier PVC, often reinforced with nylon or polyester mesh, exhibits increased resistance to these common failure modes. For example, models employing laminated PVC, where multiple layers are bonded together, can withstand greater stress and abrasion, extending the product’s serviceable period.

The type of coating or surface treatment applied to the material also plays a significant role. Flocked surfaces, while providing a comfortable sleeping surface, can be prone to wear and tear, leading to eventual separation from the underlying PVC. Textured surfaces, designed to improve grip and prevent slippage of bedding, can also contribute to increased abrasion resistance. The gauge or thickness of the material directly correlates with puncture resistance; a thicker gauge inherently offers greater protection against sharp objects and prolonged use.

In summary, the selection of materials directly influences its potential longevity. Investing in a mattress constructed with durable, reinforced materials, alongside a protective coating, can significantly extend the usable lifespan and maximize the return on investment. Inferior material composition will invariably lead to premature failure, regardless of other care practices.

2. Usage Frequency

The frequency with which an inflatable mattress is utilized exerts a substantial influence on its overall lifespan. Regular, consistent use leads to accelerated wear and tear on the material, seams, and internal components. Conversely, infrequent or occasional use typically results in a significantly longer operational period. Consider the scenario of a mattress employed daily as a primary sleeping surface versus one reserved exclusively for infrequent overnight guests; the former will invariably exhibit a shorter lifespan due to the cumulative effects of constant inflation, deflation, and physical stress.

The impact of usage frequency is further amplified by factors such as the weight of the user and the types of activities performed on the mattress. Heavier individuals place greater stress on the seams and internal baffling, potentially leading to premature failure. Activities such as sitting on the edge of the mattress or engaging in rigorous movements can also contribute to localized stress concentrations, shortening its usable life. For instance, a mattress used in a child’s playroom may experience more frequent and intense stress compared to one used solely for adult sleep. In order to reduce the effects of daily use, consumers may want to consider a mattress that has reinforced seams, such as double-welded or a higher-quality material.

In conclusion, understanding the correlation between usage frequency and its probable duration of service is crucial for realistic expectations and proactive maintenance. Individuals anticipating frequent utilization should invest in more robust models designed for sustained use, implement preventative measures such as the use of protective coverings, and adhere to recommended inflation and storage practices to mitigate the accelerated wear associated with regular use. Failure to account for this factor can result in disappointment and premature replacement of the product.

3. Inflation Practices

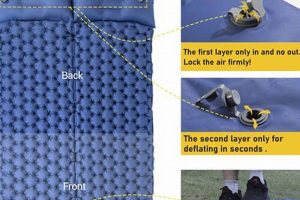

Inflation practices exert a direct and significant influence on the overall lifespan of an inflatable mattress. Improper inflation techniques can lead to premature wear, material stress, and eventual failure. Over-inflation, for example, increases internal pressure beyond the design specifications of the mattress, placing undue strain on seams and internal baffling. This excessive pressure weakens the structural integrity of the product, rendering it more susceptible to punctures and air leaks. Conversely, under-inflation provides inadequate support, causing the material to flex and distort under weight, which can also accelerate wear and tear. Consider a scenario where a mattress is consistently inflated beyond its recommended pressure; the seams may eventually separate, resulting in irreparable damage and a drastically reduced lifespan.

The method of inflation also contributes to its durability. Utilizing an air compressor designed for this purpose, and equipped with an automatic shut-off feature prevents over-inflation and applies pressure evenly. The use of manual pumps provides greater control but can be more prone to inconsistencies. Furthermore, inflation in extreme temperatures affects pressure. Inflating a mattress in a cold environment and then bringing it into a warm room will cause the internal pressure to increase, potentially leading to over-inflation if not properly monitored. In situations where the mattress is inflated within a tent, it is necessary to monitor its pressure in tandem with outside temperature fluctuation.

Adherence to the manufacturer’s recommended inflation guidelines is crucial for maximizing the product’s serviceable lifespan. This encompasses both the recommended pressure and the proper inflation tools. Employing appropriate inflation practices mitigates the risk of material stress and structural damage, ultimately contributing to the extended and reliable performance of the inflatable mattress. Failure to observe these recommendations can lead to significantly shortened usability and necessitate premature replacement.

4. Storage Environment

The environment in which an inflatable mattress is stored directly impacts its serviceable lifespan. Exposure to extreme temperatures, humidity, and direct sunlight can accelerate material degradation and shorten the product’s usability. For instance, prolonged storage in a hot attic or garage can cause the PVC to become brittle and lose its elasticity, increasing the risk of punctures and air leaks. Similarly, a damp basement promotes mold and mildew growth, compromising the structural integrity of the material and leading to unpleasant odors. Therefore, the conditions of storage become a crucial element in determining how long it remains functional.

Proper storage techniques can mitigate these adverse effects. Deflating the mattress completely, folding it neatly, and storing it in a designated bag or container protects the material from physical damage and environmental exposure. Choosing a cool, dry, and well-ventilated storage location minimizes the risk of temperature-induced degradation and moisture accumulation. Additionally, ensuring that the storage area is free from sharp objects or pests prevents accidental punctures or infestations that could compromise the integrity of the inflatable structure. Examples of ideal locations include a closet, a spare room, or a storage unit with climate control, whereas examples of less-suitable locations are attics, damp basements, or outside storage sheds.

In conclusion, the storage environment is a critical determinant of the duration of service. By understanding the detrimental effects of adverse conditions and implementing appropriate storage practices, individuals can significantly extend the life of their inflatable mattress. Ignoring this factor leads to premature material degradation and an earlier need for replacement. Proper storage practices are paramount to ensure the investment in such a product is protected and maximized.

5. Repair Procedures

The effectiveness of repair procedures directly correlates with its functional life. Timely and appropriate repairs can significantly extend the usable lifespan by addressing minor damage before it escalates into irreparable failures. Conversely, neglected or poorly executed repairs can exacerbate existing problems, leading to premature disposal.

- Puncture Identification and Sealing

Accurate identification of punctures is crucial for effective repair. Employing soapy water or leak detection solutions allows for precise pinpointing of air leaks. Utilizing appropriate sealing materials, such as PVC patches and specialized adhesives, creates a durable bond that restores the integrity of the inflatable structure. Improper patch application or the use of unsuitable adhesives can result in incomplete seals, leading to continued air loss and eventual failure.

- Seam Repair Techniques

Seam failures often present a more complex repair challenge. Depending on the extent of the damage, seam repairs may involve applying reinforcing patches or using specialized seam sealants designed to bond with PVC or similar materials. The success of seam repairs hinges on proper surface preparation and the use of adhesives compatible with the mattress material. Incorrect techniques can lead to weak or incomplete seals, resulting in recurring leaks along the seam.

- Valve Replacement Protocols

Defective or damaged valves can render an inflatable mattress unusable. Valve replacement requires careful removal of the old valve without damaging the surrounding material. The new valve must be compatible with the mattress and securely sealed to prevent air leakage. Improper installation of the replacement valve can result in air loss or damage to the mattress structure.

- Preventative Maintenance After Repair

After the repair is completed, a comprehensive inspection should be performed. Check and ensure that the patch is sealed, and there is no air leakage. When storing the mattress, avoid sharp object, and protect it from moisture to prevent any potential damage to the patched area. This is a proactive step in prolonging its use after it has been repaired.

The proficiency with which repairs are conducted directly influences its prolonged usability. Proper identification of damage, utilization of appropriate repair materials, and adherence to established repair protocols maximizes the likelihood of a successful and durable repair. Neglecting minor damage or employing inadequate repair techniques invariably shortens its serviceable period and necessitates earlier replacement.

6. Weight Capacity

Weight capacity serves as a critical factor influencing the expected lifespan of inflatable mattresses. Adherence to specified weight limits is essential for maintaining structural integrity and preventing premature failure. Exceeding the designated load places undue stress on materials and construction, leading to accelerated wear and reduced operation

al duration.

- Material Stress and Seam Integrity

Exceeding weight limits causes excessive stretching of the PVC or other material components. This overextension weakens the material over time, increasing the susceptibility to punctures and tears. Seams, often the weakest points in the construction, are particularly vulnerable to stress-induced failure when the mattress is overloaded. For example, a mattress rated for 300 lbs experiencing a 400 lb load will likely exhibit accelerated seam degradation.

- Internal Baffle System Strain

Inflatable mattresses utilize internal baffle systems to distribute weight evenly and maintain structural support. Exceeding weight limits places undue strain on these baffles, causing them to stretch, deform, or even rupture. Damaged baffles compromise the mattress’s ability to provide uniform support, leading to sagging and uneven weight distribution. An overloaded mattress may develop noticeable bulges or depressions, indicative of baffle system failure.

- Accelerated Material Fatigue

Repeatedly subjecting an inflatable mattress to loads exceeding its weight capacity accelerates material fatigue. The constant stress weakens the polymer structure, making it more prone to cracking and air leaks. This fatigue process reduces the material’s elasticity and its ability to withstand normal usage pressures. A mattress consistently used above its weight limit will degrade more rapidly than one used within its specifications, regardless of other maintenance practices.

- Compromised Inflation and Deflation Mechanisms

Overloading an inflatable mattress can also negatively impact the inflation and deflation mechanisms. Excessive pressure can damage valves, pumps, or internal seals, leading to air leakage and difficulty maintaining proper inflation. Damaged valves may require replacement, adding to the overall cost and inconvenience. In severe cases, an overloaded mattress may experience catastrophic failure of the inflation system, rendering it unusable.

The connection between weight capacity and its durability is undeniable. Adhering to the manufacturer’s specified weight limits protects the structural integrity, minimizes material stress, and prolongs its usability. Consistently exceeding weight limits accelerates wear and increases the risk of premature failure, thereby shortening its operational lifespan. Appropriate weight management is therefore a fundamental factor in maximizing the value and extending the useful period of an inflatable mattress. In cases of doubt, it is always best to choose a higher weight capacity model to ensure long-term reliability.

7. Environmental Conditions

Environmental conditions represent a significant determinant of the functional lifespan of inflatable mattresses. Extreme temperatures, humidity levels, and exposure to ultraviolet radiation exert detrimental effects on the materials used in their construction, thereby influencing overall durability. Fluctuations in temperature cause expansion and contraction of the PVC or other synthetic materials, leading to stress on seams and internal baffling. High humidity promotes the growth of mold and mildew, which can weaken the material and compromise its structural integrity. Direct sunlight, with its high ultraviolet (UV) content, degrades the polymer chains in the PVC, resulting in brittleness and increased susceptibility to punctures. For example, a mattress stored in an uninsulated garage during the summer months will experience significantly higher temperatures, accelerating the degradation process compared to a mattress stored in a climate-controlled environment.

The impact of environmental conditions is further amplified by usage patterns. Inflatable mattresses used for outdoor camping are exposed to a wider range of temperature and humidity fluctuations, as well as direct sunlight and abrasive surfaces. This increased exposure accelerates wear and tear, potentially shortening the mattress’s lifespan compared to one used primarily indoors. Coastal environments, with their high salt content in the air, also present unique challenges. Salt can corrode zippers, valves, and other metallic components, while also contributing to the breakdown of the PVC material. The interaction of these environmental factors creates a synergistic effect, where the combined impact is greater than the sum of individual effects. Proper mitigation strategies, such as using a protective cover, storing the mattress in a temperature-controlled environment, and avoiding prolonged exposure to direct sunlight, can significantly extend the functional life.

In summary, awareness of environmental conditions and the implementation of appropriate preventative measures are crucial for maximizing its potential operational period. Environmental stressors can severely degrade the integrity of the mattress materials and construction. By understanding the specific environmental factors that impact lifespan and taking proactive steps to minimize their influence, consumers can ensure that their investment in an inflatable mattress provides extended and reliable performance. This understanding is essential for both indoor and outdoor use, and the implementation of preventative measures will invariably extend the usability period.

Frequently Asked Questions

The following addresses common inquiries regarding the factors influencing the serviceable duration of inflatable mattresses. These questions provide insight into maximizing value and understanding realistic expectations.

Question 1: How long, on average, can an inflatable mattress be expected to last?

The average lifespan varies significantly based on material quality, usage frequency, and care practices. Models used infrequently and maintained properly can last several years. Those subjected to daily use or harsh conditions may only last one to two years.

Question 2: What are the primary indicators of an inflatable mattress reaching the end of its usable life?

Common signs include persistent air leaks that cannot be repaired effectively, significant material degradation (such as cracking or excessive stretching), and failure of internal baffling systems leading to uneven support.

Question 3: Does the price of an inflatable mattress directly correlate with its lifespan?

Generally, higher-priced models incorporate more durable materials and construction techniques, potentially extending their lifespan. However, price alone is not a guarantee of longevity; proper care and maintenance remain crucial.

Question 4: Can inflatable mattresses be repaired, and does repairability significantly extend their usability?

Minor punctures and leaks can often be repaired using readily available repair kits. Successful repairs can extend the mattress’s life, but extensive damage or seam failures may not be effectively addressed, limiting the potential for long-term recovery.

Question 5: How does the intended use of an inflatable mattress affect its lifespan expectations?

Inflatable mattresses designed for occasional use, such as camping or accommodating guests, typically have longer lifespans than those used as primary sleeping surfaces. Daily use places greater stress on the materials and internal components, accelerating wear.

Question 6: Are there specific storage practices that can significantly impact the longevity of an inflatable mattress?

Yes. Proper storage involves completely deflating the mattress, fol

ding it neatly, and storing it in a cool, dry environment away from direct sunlight and sharp objects. This minimizes material degradation and reduces the risk of punctures, extending its useful life.

In summary, the duration that an inflatable mattress remains serviceable is contingent upon multiple factors. Proper care, appropriate usage, and informed purchasing decisions contribute to maximizing the investment.

The subsequent section will provide a comprehensive checklist for evaluating the condition and potential lifespan of an inflatable mattress.

Determining Inflatable Mattress Longevity

The preceding analysis explored the multifaceted factors influencing the serviceable lifespan of inflatable mattresses. Material composition, usage patterns, inflation practices, storage conditions, repair effectiveness, weight adherence, and environmental exposure collectively determine how long an air mattress last. Careful consideration of these elements is crucial for informed purchasing decisions and realistic expectations regarding product duration.

Ultimately, understanding these determinants allows for proactive management and optimized investment. Prioritizing appropriate usage, meticulous maintenance, and mindful storage practices can substantially extend the functional period. Consumers are therefore encouraged to apply the outlined principles to maximize value and minimize premature replacement, promoting responsible consumption and resource efficiency.