A self-contained inflation device, operating on electrical energy stored in portable cells, serves the specific function of introducing air into inflatable sleeping surfaces. For example, this type of device facilitates the rapid setup of temporary bedding in camping or guest accommodations, obviating the need for manual or mains-powered alternatives.

The significance of these devices lies in their portability and convenience. Their historical context emerges from the need for easily deployable inflation solutions in settings where access to mains electricity is limited or unavailable. These devices offer users greater autonomy and efficiency in preparing inflatable bedding for immediate use.

The following sections will delve into aspects such as the operational mechanisms, different types available, key performance metrics, considerations for maintenance and longevity, and comparative analysis with other inflation methods.

Optimizing the Use of Portable Inflation Devices

This section provides guidance on maximizing the utility and lifespan of these devices used for inflating air mattresses. Adherence to these recommendations will enhance operational efficiency and minimize potential issues.

Tip 1: Select the Appropriate Device: Evaluate power output and battery capacity relative to the mattress size. Larger mattresses require higher output for efficient inflation.

Tip 2: Charge Batteries Fully Before Use: Ensure a complete charge prior to each inflation cycle to maximize performance and prevent premature battery depletion during operation.

Tip 3: Avoid Over-Inflation: Utilize integrated pressure gauges where available, or carefully monitor the mattress firmness, to prevent over-inflation and potential seam damage.

Tip 4: Store the Device Properly: Store in a cool, dry location, away from direct sunlight and extreme temperatures. This helps preserve battery integrity and prevent plastic component degradation.

Tip 5: Clean the Device Regularly: Remove dust and debris from the intake and exhaust ports. A clean device operates more efficiently and reduces the risk of motor overheating.

Tip 6: Use the Correct Nozzle Attachment: Ensure the nozzle is securely fitted to the mattress valve to prevent air leakage during inflation, optimizing the inflation process.

Tip 7: Inspect for Damage Before Each Use: Check the casing, power cord (if applicable), and nozzle for cracks or damage. Using a damaged device could lead to malfunction or injury.

Following these guidelines ensures efficient operation, extends the device’s service life, and contributes to a reliable and convenient inflation process for air mattresses.

The subsequent section will summarize the key considerations covered and offer final recommendations.

1. Portability

Portability represents a critical attribute in the context of self-powered air mattress inflation devices. Its influence extends to usage scenarios, design considerations, and overall utility of such equipment.

- Weight and Size Optimization

The inherent design of these devices prioritizes minimized weight and dimensions. Lighter units are easier to transport and store, essential for activities such as camping, where minimizing payload is crucial. Compact designs allow for storage in confined spaces, such as car trunks or storage lockers. The physical ergonomics are directly linked to user convenience during transport and handling.

- Cordless Operation

The elimination of external power cords enhances portability by removing dependency on mains electricity. This allows operation in remote locations without access to power outlets. Devices with rechargeable batteries or compatibility with common battery types further promote independent operation and ease of use in varied environments. A lack of cords also contributes to safety by mitigating tripping hazards.

- Integrated Components and Carrying Cases

Many models incorporate features like integrated nozzles or storage compartments for accessories. This consolidation of components reduces the need for separate parts and simplifies packing. Inclusion of dedicated carrying cases further enhances portability by protecting the device during transport and consolidating all necessary items into a single, easily manageable package. The design helps to prevent loss of components and damage during transit.

- Application Versatility

Portability dictates the range of application scenarios. Easily transportable devices are suitable for camping, travel, guest accommodations, and emergency situations. The ability to rapidly deploy an air mattress in diverse settings enhances preparedness and responsiveness. Furthermore, portable designs facilitate usage in situations where space is limited, making them well-suited for smaller tents or confined living spaces.

The facets of weight, cordless design, integrated components, and versatility are interconnected elements which establish the value of these devices. A portable inflation device provides independence and convenience in locations where traditional power sources and manual methods are impractical.

2. Inflation Speed

The rate at which a self-powered air mattress pump fills an inflatable sleeping surface constitutes a critical performance parameter. The relationship between the device’s power source and its ability to rapidly introduce air into the mattress directly affects user satisfaction and the practicality of the device in various scenarios. Factors such as motor efficiency, pump design, and battery capacity collectively determine the overall inflation speed. Slower inflation times can be inconvenient, especially in situations demanding quick setup, such as late-night arrivals at campsites or unexpected guest visits. Conversely, faster inflation speeds enhance user convenience and contribute to a more positive user experience.

For example, a low-powered pump with a small battery may require a significantly longer inflation time, potentially exceeding 10-15 minutes for a queen-sized air mattress. In contrast, a higher-powered model with an optimized pump design could achieve full inflation in under 5 minutes. Consider the scenario of an individual arriving at a campsite during inclement weather; a faster inflation time minimizes exposure to the elements and allows for quicker shelter setup. In another instance, a homeowner preparing for overnight guests would benefit from a device that swiftly inflates the air mattress, reducing the preparation time and minimizing disruption.

Ultimately, inflation speed functions as a key differentiator among portable air mattress pumps. Recognizing the trade-offs between battery life, motor power, and pump efficiency is essential for selecting a devi

ce that aligns with specific usage needs. While extended battery life is advantageous for prolonged use, it should not come at the expense of unacceptably slow inflation times. The optimal balance between these factors contributes to a more versatile and user-friendly product.

3. Battery Capacity

The operational effectiveness of a self-powered air mattress inflation device is intrinsically linked to its stored electrical energy. The amount of electrical energy the device can hold, expressed in units such as amp-hours (Ah) or watt-hours (Wh), determines the duration and intensity of its performance. Understanding this connection is crucial for selecting an appropriate device.

- Number of Inflations Per Charge

The capacity dictates the quantity of full mattress inflations achievable on a single charge cycle. A higher capacity generally allows for multiple inflations of a standard-sized air mattress without requiring a recharge. This is particularly relevant in situations where access to a power source is limited, such as camping or extended travel. For instance, a device with a 2 Ah battery might inflate a twin-sized mattress three times, while a 4 Ah battery could inflate the same mattress six times before needing a recharge.

- Inflation Speed Maintenance

Battery performance influences the consistency of inflation speed throughout the discharge cycle. As the battery depletes, some devices may exhibit a gradual decrease in motor power, resulting in slower inflation times. Advanced power management systems and battery chemistries can mitigate this effect, maintaining a more consistent inflation rate until the battery is nearly depleted. Devices employing lithium-ion batteries, for example, often demonstrate better sustained performance compared to those using older nickel-cadmium technologies.

- Standby Duration and Self-Discharge Rate

The capacity also affects how long a device can remain unused while retaining a usable charge. Self-discharge, a natural phenomenon in batteries, causes a gradual loss of stored energy over time. Lower self-discharge rates are desirable, as they ensure the device is ready for use even after extended periods of storage. Premium battery technologies and optimized internal circuitry contribute to minimizing self-discharge. This becomes relevant for users who only require the device sporadically, such as for occasional guest accommodations.

- Overall Device Lifespan

The design and construction of the battery contribute to the overall lifespan of the self-powered inflation device. Batteries are consumables; their capacity degrades over time and repeated charge/discharge cycles. Batteries constructed with higher quality materials tend to exhibit slower degradation rates and can endure a greater number of charge cycles before significant capacity loss occurs. This represents an important consideration for users seeking a long-term inflation solution.

The factors of the quantity of inflation per charge, maintaining inflation speed, standby duration, and lifespan of battery design and construction all have an interdependent relationship that can effect the success of a battery operated air mattress pump. The interplay between these factors determines the practicality and utility of the device in various usage contexts, making battery considerations paramount for effective product selection.

4. Nozzle Compatibility

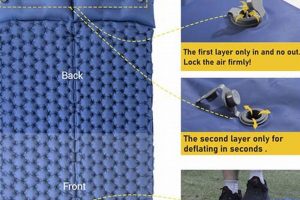

Nozzle compatibility directly dictates the usable range of a self-powered air mattress inflation device. Incompatible nozzles render the device useless for inflating specific air mattresses, irrespective of its battery capacity or inflation speed. Different air mattress manufacturers employ varying valve designs, necessitating a range of nozzle types to ensure a secure and airtight connection. For instance, certain mattresses may utilize a standard pinch valve, while others require a Boston valve or a double-lock valve. A device lacking the appropriate nozzle for a given valve cannot effectively inflate the mattress, leading to air leakage and an inability to achieve the desired firmness. This highlights the importance of a comprehensive nozzle set or a universal nozzle design.

The practical significance of nozzle compatibility extends to situations where users own multiple air mattresses with differing valve types. Consider a family with an older air mattress using a standard valve and a newer model employing a double-lock valve. An inflation device lacking both nozzle types would necessitate the purchase of separate pumps or adapters, increasing cost and complexity. Some manufacturers address this issue by including a multi-nozzle adapter set with their self-powered pumps, enhancing versatility and eliminating the need for additional purchases. Conversely, a universal nozzle design that automatically adjusts to different valve sizes provides a streamlined and convenient solution. This adaptability is particularly valuable for users who frequently encounter different air mattress types, such as those involved in camping or emergency relief efforts.

In conclusion, nozzle compatibility is a non-negotiable aspect of a functional self-powered air mattress inflation system. The ability to interface seamlessly with various valve designs directly impacts the device’s utility and user satisfaction. Challenges remain in standardizing valve designs across the industry, but manufacturers can mitigate these issues by providing comprehensive nozzle sets or implementing universal nozzle solutions. Understanding the implications of nozzle compatibility ensures informed purchasing decisions and contributes to a more reliable and versatile inflation experience.

5. Durability

The operational lifespan and reliable performance of a self-powered air mattress inflation device are fundamentally linked to its robustness. Device longevity hinges on withstanding operational stresses, environmental factors, and the rigors of storage and transport. This interrelation warrants a detailed examination of key durability facets.

- Component Quality and Material Selection

The composition of critical internal components, such as the motor, impeller, and battery housing, directly influences overall durability. Utilizing high-grade plastics, corrosion-resistant metals, and robust electronic components ensures resilience against wear, impact, and temperature fluctuations. For example, a pump employing a brushless motor and a housing constructed from impact-resistant ABS plastic will exhibit greater longevity than a device with a brushed motor and a housing made from brittle polypropylene. These material selections translate directly into enhanced resistance to damage during use and transit.

- Sealed Construction and Environmental Resistance

The extent to which a device is sealed against the intrusion of dust, moisture, and other environmental contaminants dictates its performance consistency and lifespan. A well-sealed unit prevents particulate matter from entering the motor and damaging sensitive components, while moisture resistance mitigates the risk of corrosion and electrical short circuits. Devices designed for outdoor use

, such as camping, should prioritize ingress protection (IP) ratings, indicating the level of protection against solid objects and liquids. Sealed construction ensures reliable operation in diverse environmental conditions. - Battery Longevity and Cycle Life

The battery represents a critical point of failure in self-powered inflation devices. Battery chemistry, construction, and charging circuitry influence the number of charge-discharge cycles the battery can endure before experiencing significant capacity degradation. Lithium-ion batteries, commonly used in these devices, offer a higher energy density and longer cycle life compared to older battery technologies. However, even high-quality lithium-ion batteries degrade over time, necessitating periodic replacement. Robust battery management systems that prevent overcharging and deep discharging can extend battery lifespan and enhance overall device durability.

- Impact Resistance and Structural Integrity

The device’s ability to withstand accidental drops and impacts is paramount for maintaining its functionality. Reinforced housings, internal bracing, and shock-absorbing materials contribute to improved impact resistance. Devices designed for rugged use often incorporate rubberized coatings or reinforced corners to mitigate damage from falls. A structurally sound design minimizes the risk of component displacement or breakage during transport and handling, ensuring continued operation even after experiencing minor impacts.

In summation, the robustness of a self-powered air mattress pump arises from the interplay of material selection, environmental protection, and battery resilience. Prioritizing durability during the design and manufacturing processes results in a more reliable and long-lasting device, ultimately enhancing user satisfaction and reducing the need for frequent replacements.

6. Power Output

The rate at which a self-powered air mattress inflation device can perform its function, directly influenced by its electrical discharge capacity, is a critical determinant of its utility. The device’s efficacy is largely contingent on this parameter.

- Motor Torque and Airflow Volume

The energy delivered to the motor translates directly into torque, which drives the impeller or piston responsible for generating airflow. Higher power output enables the motor to sustain greater torque, resulting in a larger volume of air being displaced per unit of time. For example, a device with a low power rating might struggle to inflate a queen-sized air mattress fully, or may require an extended inflation period, while a higher-powered unit can achieve full inflation more rapidly and efficiently. This parameter correlates directly with the practical effectiveness of the device, particularly for larger mattresses.

- Inflation Time and Battery Drain Relationship

The power delivered influences the duration required to fully inflate a mattress. Higher power delivery typically results in a shorter inflation time. However, this benefit is often counterbalanced by increased battery drain. A device operating at maximum energy expenditure will deplete its stored energy more quickly than a device operating at a lower energy level. Therefore, there is a trade-off between inflation speed and overall run time, requiring a careful balance in design and usage. Users must consider their specific needs and prioritize either rapid inflation or extended usage depending on the application scenario.

- Suitability for Mattress Size and Type

The demands vary depending on the dimensions and construction of the air mattress. Larger mattresses require greater energy to achieve the same level of inflation as smaller ones. Similarly, mattresses with more complex internal structures or thicker materials may require more forceful air displacement to achieve adequate firmness. A device with insufficient electrical discharge capacity may be unable to fully inflate a larger or more robust mattress, rendering it unsuitable for that particular application. Therefore, matching the device’s rating to the specific requirements of the air mattress is crucial for optimal performance.

- Impact on Device Lifespan and Component Stress

Operating a self-powered air mattress inflation device at or near its maximum energy level can place significant stress on its internal components, particularly the motor and battery. Prolonged operation under high stress conditions can accelerate wear and tear, potentially reducing the device’s overall lifespan. Conversely, operating the device within its recommended range minimizes stress on the components, contributing to greater longevity and reliability. Users should adhere to manufacturer guidelines regarding operating parameters to maximize the device’s service life.

The considerations of motor and airflow, time-to-drain ratio, mattress compatibility, and service lifespan are all aspects of operating the device that need to be assessed. Considering both advantages and drawbacks associated with varying energy capabilities, users can make informed choices that align with their requirements and maximize the value of self-powered air mattress inflation devices.

7. Operating Noise

Acoustic emissions during operation represent a significant factor in the overall user experience associated with self-powered air mattress inflation devices. The decibel level and tonal characteristics of the noise generated can impact user satisfaction and influence the appropriateness of the device in various settings. This section examines the key aspects contributing to operational sound levels.

- Motor Design and Sound Dampening

The type of motor employed directly influences the noise profile. Brushless motors, while generally more efficient, can produce a high-frequency whine. Brushed motors tend to generate a lower-pitched hum but may also exhibit rattling noises due to brush contact. The integration of sound-dampening materials within the motor housing and device casing can mitigate these acoustic emissions. For instance, some models utilize foam insulation or vibration-isolating mounts to reduce noise transmission. In a bedroom setting, a quieter device minimizes disturbance to sleeping individuals.

- Impeller/Piston Mechanism and Airflow Turbulence

The design and rotational speed of the impeller or the reciprocating motion of the piston contribute to the overall sound level. Aerodynamic inefficiencies and turbulent airflow generate broadband noise. Devices incorporating optimized blade designs or smoothed airflow pathways can reduce turbulence and thereby minimize noise. An example includes pumps with angled impeller blades to reduce air resistance, thus making them quieter than simple flat blades. This consideration is particularly relevant in noise-sensitive environments such as libraries or campgrounds.

- Casing Material and Acoustic Resonance

The properties of the outer casing material influence the device’s susceptibility to acoustic resonance. Thin, lightweight plastic casings tend to amplify internal noise, while thicker, denser materials offer better sound absorption. Internal ribs or baffles can also disrupt sound wave propagation and reduce resonance. A device with a sturdy, well-damped casing will generally produce less noise than on

e with a flimsy or poorly designed enclosure. The selection of housing material directly affects the acoustic signature of the device and, consequently, the user’s perception of its quality. - Vibration and Surface Coupling

Vibrations generated by the motor and pump mechanism can transmit through the device’s housing and couple with the supporting surface, amplifying the perceived noise level. Rubber feet or vibration-isolating pads can decouple the device from the surface, reducing noise transmission. The effectiveness of these measures depends on the frequency and amplitude of the vibrations. A device placed directly on a hard surface, such as a wooden floor, will typically produce more noise than one placed on a carpeted surface due to increased vibration transmission. Proper vibration isolation is critical for minimizing noise pollution.

These elements are key to the value of battery power air mattress pumps. Minimizing noise, whether through motor design, airflow management, material selection, or vibration control, is essential for enhancing the user experience and broadening the applicability of self-powered air mattress inflation devices in diverse environments.

Frequently Asked Questions

This section addresses common inquiries regarding portable, cell-operated air mattress pumps. The information aims to clarify operational aspects, performance metrics, and best practices for use.

Question 1: What factors govern the inflation speed of a cell-operated air mattress pump?

Inflation speed is primarily determined by the motor’s electrical discharge capacity, the impeller’s design, and the seal integrity between the nozzle and the mattress valve. Higher wattage motors and efficient impeller designs facilitate faster air displacement. Air leaks at the connection points diminish the overall efficiency and extend inflation times.

Question 2: How does battery capacity relate to the number of inflations achievable?

The number of full mattress inflations possible on a single charge cycle correlates directly with the battery’s storage capacity, typically measured in amp-hours (Ah) or watt-hours (Wh). Larger capacity batteries facilitate more inflations before requiring a recharge. However, the precise number also depends on the mattress size and the inflation pressure desired.

Question 3: What are the primary advantages of lithium-ion batteries in these devices?

Lithium-ion batteries offer a superior energy density, lower self-discharge rate, and longer cycle life compared to older battery chemistries. They also maintain a more consistent voltage output during discharge, resulting in more sustained performance and reduced performance degradation during use.

Question 4: Why is nozzle compatibility a crucial consideration?

Different air mattress manufacturers employ varying valve designs. A device lacking the appropriate nozzle adapter for a specific valve cannot effectively inflate the mattress, leading to air leakage and preventing the attainment of the desired firmness. A comprehensive nozzle set or a universal nozzle design enhances versatility.

Question 5: What maintenance practices contribute to extending the lifespan of these devices?

Regularly cleaning the air intake and exhaust ports to remove dust and debris prevents motor overheating and maintains airflow efficiency. Storing the device in a cool, dry environment minimizes battery degradation and prevents plastic component embrittlement. Adhering to manufacturer-recommended charging practices further extends battery life.

Question 6: What factors influence the noise level produced during operation?

Motor design, impeller/piston mechanism, casing material, and vibration transmission all contribute to the overall noise level. Brushless motors, aerodynamic inefficiencies, thin plastic casings, and direct surface coupling amplify acoustic emissions. Sound dampening materials and vibration-isolating mounts can mitigate these effects.

These answers provide a foundation for understanding the practical aspects of operating a cell-powered air mattress device. Considering these factors ensures informed purchasing decisions and optimized utilization.

The following section will offer comparative analyses of different devices and explore emerging technologies in this product category.

Conclusion

The preceding analysis has detailed critical facets of battery power air mattress pump technology, encompassing portability, inflation speed, battery capacity, nozzle compatibility, durability, power output, and operational noise. These elements collectively dictate the performance envelope and suitability of such devices for diverse applications.

Effective utilization of self-powered inflation systems requires careful consideration of user needs and operational constraints. Continued advancements in battery technology and motor design promise further refinements in efficiency and performance. The informed selection and proper maintenance of battery power air mattress pump systems will ensure reliable and convenient inflation solutions for years to come.

![Best Toyota Tacoma Air Mattress [Sleep Easy!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Toyota Tacoma Air Mattress [Sleep Easy!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-6744-300x200.jpg)