The process of locating perforations in inflatable sleeping pads involves a systematic approach to identify where air is escaping. This typically entails a combination of visual inspection, auditory detection, and the application of soapy water to pinpoint the source of the air loss. Success hinges on careful observation and methodical coverage of the mattress surface.

Identifying and repairing punctures extends the lifespan of the air mattress, preventing premature disposal and saving resources. Addressing leaks promptly ensures continued comfort and support during use, whether for camping or as a temporary bed at home. Historically, techniques for leak detection have evolved from simple visual cues to incorporating modern cleaning and listening technologies.

The following sections detail common methods employed to achieve successful detection, including preparation steps, specific testing procedures, and considerations for various mattress materials and sizes.

Essential Leak Detection Techniques

The following guidelines offer a structured approach to identifying sources of air loss in inflatable mattresses, maximizing efficiency and accuracy during the inspection process.

Tip 1: Initial Visual Examination: Before proceeding with more involved methods, conduct a thorough visual scan of the entire mattress surface. Pay particular attention to seams, valves, and areas that may have experienced abrasion or stress.

Tip 2: Auditory Assessment: Inflate the mattress fully in a quiet environment and listen closely for hissing sounds. Slowly move around the perimeter and across the surface, concentrating near potential weak points.

Tip 3: Soapy Water Application: Mix a mild dish soap with water in a spray bottle or bucket. Apply the solution liberally to small sections of the inflated mattress. Air escaping will create visible bubbles at the location of the perforation.

Tip 4: Submersion Technique (for smaller mattresses): If feasible based on size, deflate the mattress slightly and submerge it section by section in a tub or pool of water. Observe for streams of air bubbles indicating the leak’s location.

Tip 5: Sectional Isolation: For larger mattresses, divide the surface into quadrants using tape or markers. Test each section independently to narrow down the search area and improve focus.

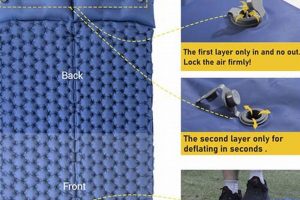

Tip 6: Valve Inspection: Carefully examine the valve for tightness and proper sealing. Apply soapy water around the valve stem and base to determine if air is escaping from the valve mechanism itself.

Tip 7: Targeted Pressure Application: Once a potential leak area is identified, apply gentle pressure around the suspected point. This can help to force air through the hole and make it easier to detect using auditory or soapy water methods.

These steps provide a methodical framework for locating punctures in air mattresses, optimizing the chances of a successful repair and extending the useful life of the product.

Following successful leak detection, consider appropriate repair techniques to restore functionality to the air mattress.

1. Inflation Level

The inflation level of an air mattress directly impacts the efficiency of leak detection. Insufficient inflation provides minimal pressure differential, resulting in a weak or nonexistent airflow through perforations. Consequently, auditory and soapy water tests become less effective. Conversely, excessive inflation can stretch the material, potentially enlarging existing leaks and creating new stress points, complicating accurate localization of the original breach.

The optimal inflation level balances sufficient pressure to force air through leaks for detection and minimizing material stress. As an example, a mattress inflated to its maximum recommended pressure allows for more audible hissing from small leaks, facilitating their discovery. However, if the source of leakage is a seam already under stress, over inflation could cause a more significant rupture, masking the initial problem. Proper inflation as a component of the detection process should involve gradual pressurization, frequent monitoring, and adherence to the manufacturers recommendations.

In summary, the connection between inflation level and effective leak identification hinges on controlled pressurization. The right level of inflation enables faster, more accurate identification of air loss without compromising mattress integrity. Challenges arise from differing material compositions and damage types. The controlled process of inflation is one part of effective testing protocols.

2. Ambient Noise

Ambient noise significantly impacts the effectiveness of auditory leak detection in inflatable mattresses. Elevated background sounds can obscure the subtle hissing sound emitted by escaping air, hindering the ability to pinpoint the source of the perforation. Minimizing surrounding noise is crucial for accurate leak identification.

- Masking Effect

External sounds, such as traffic, conversations, or appliances, compete with the sound of escaping air. This masking effect reduces the signal-to-noise ratio, making it difficult to discern the leak. The presence of a running air conditioner, for instance, can completely drown out the sound of a slow leak, rendering auditory detection nearly impossible.

- Frequency Interference

Different sources of noise emit sound at various frequencies. If ambient noise contains frequencies similar to those produced by escaping air, it creates interference. High-pitched sounds from machinery or electronic devices can overlap with the hissing sound of a leak, making it harder to isolate.

- Subjective Perception

Human auditory perception is influenced by the surrounding environment. In a noisy setting, the brain tends to filter out quieter sounds, focusing on dominant signals. This cognitive bias can lead to missed leaks, especially if the escaping air generates only a faint sound.

- Environmental Acoustics

The acoustic properties of the environment, such as room size, shape, and surface materials, affect how sound propagates. Reverberation and echoes in a large, empty room can distort the sound of a leak, making it difficult to determine the precise location. Conversely, sound-absorbing materials can dampen the leak sound, reducing its audibility.

The integration of effective noise reduction strategies, such as performing the leak detection procedure in a quiet room or using noise-canceling headphones, can significantly improve the efficacy of auditory methods for pinpointing perforations. The challenge remains mitigating unpredictable external disturbances to ensure an optimal acoustic environment.

3. Soapy Solution

The application of a soapy solution forms a cornerstone of leak detection procedures for inflatable mattresses. This technique relies on the principle that escaping air, forced through a liquid film, generates visible bubbles at the point of egress. The efficacy of this method stems from the soap’s ability to reduce surface tension, allowing for the formation of stable, easily observable bubbles even with minimal airflow. The method’s success depends on factors such as solution concentration and thorough surface coverage.

The procedure involves mixing a mild detergent with water, then applying this solution to the inflated mattress surface. When air escapes through a perforation, it passes through the soapy film, creating bubbles that visually identify the leak’s location. For instance, a slow leak may produce only a small, slowly expanding bubble, while a larger breach results in a rapid formation of larger bubbles. The advantage of this technique lies in its simplicity and effectiveness in identifying even minute perforations that might be missed by visual or auditory inspection alone. The solution should be applied with a sponge or spray bottle to saturate the material, paying particular attention to seams and areas suspected of damage.

Effective use of a soapy solution allows for precise leak localization, enabling targeted repairs and extending the mattress’s lifespan. The limitations lie in the necessity for thorough application and the potential for false positives from residual moisture. Despite these challenges, the soapy solution method remains an essential component of diagnostic processes, offering a simple, reliable means of pinpointing air loss and preventing further damage.

4. Visual Inspection

Visual inspection constitutes the initial and a fundamentally important step in the process of detecting air leaks in inflatable mattresses. The approach involves a meticulous examination of the mattress surface, seams, and valve components, aiming to identify physical indicators of potential air escape. Damage such as abrasions, punctures, cuts, or seam separations often provide direct clues to the location of a leak, obviating the need for more complex testing methods.

The effectiveness of visual inspection depends on careful attention to detail and adequate lighting. Surface imperfections, such as discoloration or residue buildup, can indicate areas of past or present stress that may be compromising the mattress’s air retention. For example, a small puncture caused by a sharp object may not be immediately obvious, but the surrounding material may exhibit a slight distortion or change in texture. Seams, particularly those located along the edges of the mattress, are prone to separation due to repeated stress from inflation and deflation cycles; close observation of these areas can reveal minute gaps or tears. Additionally, the valve mechanism should be visually checked for cracks, deformation, or improper sealing, as these can also lead to air loss. A thorough visual inspection can often prevent the need for more cumbersome methods, by identifying the source of air loss efficiently.

In conclusion, visual inspection serves as an indispensable component in the procedures for identifying leaks. The method’s simplicity and non-destructive nature make it an ideal starting point, frequently providing sufficient information to locate and address the issue promptly. While not always conclusive, a diligent visual assessment significantly increases the chances of effective leak detection and subsequent repair, thereby extending the usable lifespan of the inflatable mattress.

5. Valve Integrity

Valve integrity is a critical aspect of maintaining air retention in inflatable mattresses. A compromised valve presents a direct pathway for air leakage, thereby necessitating a thorough assessment of its condition during leak detection efforts. Evaluation should encompass the valve’s sealing mechanism, physical structure, and secure attachment to the mattress material.

- Sealing Mechanism Functionality

The valve’s primary function is to create an airtight seal, preventing air from escaping once the mattress is inflated. The sealing mechanism, typically a stopper, flapper valve, or threaded cap, must engage completely and maintain consistent pressure. Deterioration of the sealing material, such as rubber or silicone, can lead to air seepage. For example, a worn-out rubber stopper may not create a tight seal against the valve seat, resulting in a slow, continuous leak. Leak detection should always involve testing the valve’s seal by applying pressure and listening for escaping air.

- Physical Structure Integrity

Cracks, fractures, or deformation in the valve body can compromise its ability to maintain an airtight seal. Physical damage may arise from impact, excessive force during inflation or deflation, or material degradation over time. For instance, a plastic valve body exposed to extreme temperatures can become brittle and develop cracks, providing pathways for air leakage. Visual inspection should include examining the valve for any signs of structural compromise. Subtle hairline cracks, although difficult to detect, can contribute to significant air loss.

- Attachment Security

The valve’s secure attachment to the mattress material is essential for preventing air leaks around the valve perimeter. The attachment point, often involving adhesive bonding or mechanical fastening, must remain intact to maintain an airtight seal. Separation or loosening of the valve from the mattress creates a direct pathway for air to escape. The process of applying a soapy water solution can confirm this failure point, where air bubbles form around the valve perimeter. A loosened or poorly sealed valve necessitates repair of the bonding agent, or complete valve replacement.

In summation, assessing valve integrity forms a vital component of effective leak identification in air mattresses. A faulty valve can negate the effectiveness of patching other leaks in the mattress body, necessitating targeted inspection and repair. Comprehensive evaluation encompasses the sealing mechanism, structural integrity, and attachment security, ensuring all potential leak points are addressed.

6. Material Flex

Material flex, the capacity of an air mattress’s fabric to bend or deform under pressure, directly impacts the process of detecting leaks. The flexibility of the material influences the size and shape of a perforation under differing inflation levels and applied stresses, thus affecting air escape patterns and detectability. Increased material flex allows for potential elongation of small punctures during inflation, potentially increasing air loss and making the leak more readily identifiable. Conversely, rigid materials may conceal minute perforations by resisting deformation and limiting airflow, complicating the detection process.

The application of force during leak detection, such as pressing down on the inflated mattress duri

ng a soapy water test, demonstrates the practical significance of material flex. This action causes the material to bend, opening a potential leak site that may be otherwise undetectable under static conditions. The increased stress from flexing the material can force air through the perforation, leading to more pronounced bubble formation in the soapy solution. Similarly, repeated folding or rolling of the mattress during storage can induce material fatigue, creating small tears along fold lines. These tears may remain closed under normal inflation but open under the stress of lying on the mattress, resulting in an intermittent and difficult-to-locate leak. Testing under simulated use conditions, including the application of pressure and weight, helps to replicate these real-world scenarios and improve leak detection accuracy.

Understanding the role of material flex in leak detection highlights the importance of considering dynamic testing methods. Relying solely on static visual inspection or auditory tests may prove insufficient in identifying leaks that only manifest under stress. By incorporating techniques that mimic actual usage conditions, detection efforts can better account for the influence of material flex on air leakage patterns. This comprehensive approach improves the likelihood of identifying and repairing punctures, ensuring prolonged mattress performance and utility.

Frequently Asked Questions About Locating Air Mattress Leaks

The following addresses common inquiries concerning the procedures for pinpointing air loss in inflatable sleeping pads. The answers provided aim to offer practical guidance and clarity on best practices.

Question 1: Is it possible to locate a very small leak?

Extremely small leaks can present detection challenges. Employing a highly concentrated soapy solution and conducting the test in a quiet environment can enhance the likelihood of identifying minute perforations.

Question 2: How can the valve be tested for leaks?

Apply a soapy solution around the valve stem and base while the mattress is inflated. The formation of bubbles indicates a leak within the valve mechanism or its seal.

Question 3: What if a leak cannot be found?

If the source of air loss remains elusive, consider that the leak may be intermittent or located in an inaccessible area, such as within internal baffles. Repeated testing, varying inflation levels, and applying targeted pressure may assist in revealing the perforation.

Question 4: Can the type of material affect leak detection?

Yes, the material composition influences the effectiveness of certain detection methods. Thicker materials may mask the sound of escaping air, while porous materials can complicate the application of soapy solutions.

Question 5: Should the mattress be fully inflated for testing?

Full inflation generally aids in leak detection by increasing the pressure differential, which forces air through perforations. However, excessive inflation can overstress the material and potentially enlarge existing leaks. A balanced inflation level is recommended.

Question 6: What is the most reliable method for leak detection?

No single method guarantees success in all situations. A combination of visual inspection, auditory assessment, and soapy water application generally provides the most comprehensive approach.

Effective leak identification necessitates a systematic approach, incorporating multiple techniques and careful observation. Persistence and attention to detail are crucial for success.

Following leak identification, appropriate repair techniques should be implemented to restore the air mattress to functional condition.

Conclusion

The preceding exploration has outlined a systematic approach to identify air loss points in inflatable mattresses. The effective execution of leak detection protocols, incorporating visual, auditory, and tactile methods, directly correlates with the ability to extend the serviceable life of such products. The detailed breakdown of individual techniques, from soapy water application to valve integrity assessments, provides a foundation for accurate diagnosis.

Continued diligence in applying these investigative measures ensures both the sustained functionality of air mattresses and a reduction in unnecessary waste. Further refinement of these techniques, coupled with advancements in materials science, may lead to enhanced preventative measures and more robust product designs, ultimately minimizing instances of air leakage and improving the overall user experience.