The process of compactly storing an inflatable sleeping surface manufactured by Intex involves specific deflation and folding techniques. This procedure is essential for minimizing storage space and protecting the material from potential damage. Proper execution of this process ensures the item remains in good condition for future use. For instance, a deflated and neatly packaged air mattress can be stored easily in a closet or vehicle trunk.

Correctly preparing the inflatable for storage offers several advantages. It reduces the risk of punctures and tears, prolonging the lifespan of the product. Furthermore, a well-folded item occupies less space, optimizing storage efficiency. The practice of compacting inflatable mattresses dates back to the increased popularity of camping and outdoor recreation, where portability and minimal space consumption are highly valued.

The subsequent sections will provide a detailed guide to achieving effective deflation and folding for Intex air mattresses, encompassing steps for maximizing compactness and safeguarding the item against potential harm during storage.

Effective Compaction Strategies

Employing these strategies will facilitate the efficient storage of Intex air mattresses, minimizing space occupancy and maximizing product longevity.

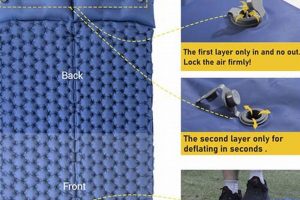

Tip 1: Ensure Complete Deflation: Prior to folding, verify all air has been expelled from the mattress. Utilize the built-in pump (if equipped) in reverse, or manually depress the valve to release any remaining air. Incomplete deflation hinders compact folding.

Tip 2: Fold Along Existing Seams: Intex air mattresses often feature raised seams. Use these as guides for initial folds. Folding along these lines promotes a more uniform and tighter package.

Tip 3: Expel Air During Folding: As each fold is made, apply pressure to the mattress to force out any trapped air. This step is critical for achieving maximum compression and minimizing the final folded size.

Tip 4: Secure with Straps or Bands: Once folded, utilize straps, bungee cords, or large rubber bands to secure the mattress in its compressed form. This prevents unfolding and maintains the compact shape during storage.

Tip 5: Protect the Valve: Exercise caution to avoid placing undue stress or pressure on the air valve during folding and storage. A damaged valve can lead to air leaks and render the mattress unusable.

Tip 6: Store in a Climate-Controlled Environment: Extreme temperatures can affect the integrity of the vinyl material. Store the folded mattress in a cool, dry location away from direct sunlight to prevent degradation.

Tip 7: Use the Original Packaging (If Available): The original carrying bag provides a protective layer against dust and abrasion during storage. If unavailable, consider using a durable storage container.

These strategies enhance the ease of storage and safeguard the Intex air mattress from potential damage. Adhering to these guidelines ensures the product remains in optimal condition for subsequent use.

The concluding section will summarize the complete procedure for compact storage and offer final recommendations for maintaining the inflatable mattress.

1. Deflation Thoroughness

The extent to which an Intex air mattress is deflated directly influences its subsequent foldability and storage efficiency. Achieving complete deflation is not merely a preliminary step, but an integral component of effectively preparing the mattress for compact storage.

- Volume Reduction

Residual air within the mattress significantly increases its volume. Imperfect deflation impedes tight folding, resulting in a larger, less manageable package. For example, an air mattress with trapped air might occupy twice the storage space of a fully deflated one, limiting storage options.

- Folding Uniformity

Uneven distribution of air during folding leads to irregular shapes and creases. These inconsistencies can stress the mattress material, increasing the risk of tears and punctures. A properly deflated mattress allows for even, predictable folds, minimizing potential damage.

- Valve Integrity

Attempting to force-fold an incompletely deflated mattress places undue stress on the inflation valve. This pressure can damage the valve mechanism, leading to leaks and rendering the mattress unusable. Complete deflation alleviates this stress, preserving the valve’s functionality.

- Long-Term Storage

Over time, trapped air can expand and contract with temperature fluctuations, potentially weakening the mattress seams. Furthermore, moisture can accumulate within the air pockets, fostering mold growth. Thorough deflation eliminates these issues, promoting long-term storage integrity.

In summary, achieving complete deflation is paramount for effective folding and secure storage of an Intex air mattress. Neglecting this initial step compromises the compactness of the folded mattress, increases the risk of material damage, and can negatively impact the product’s lifespan. Prioritizing thorough deflation ensures optimal storage efficiency and preservation of the air mattress.

2. Seam Alignment

The alignment of seams is critical in the effective folding of Intex air mattresses. These seams serve as natural guidelines, dictating the direction and uniformity of folds. Deviations from this alignment lead to uneven stress distribution across the mattress material, potentially causing tears or weakening the welded seams over time. For example, a misaligned fold might concentrate pressure on a single point, increasing the likelihood of a puncture during storage.

Correct seam alignment contributes significantly to a more compact and manageable package. When folds are precisely aligned with existing seams, the air mattress conforms to a more predictable shape, facilitating compression and secure binding with straps or bands. Consider the scenario where the mattress is folded without regard for seam alignment; the resulting shape will likely be bulky and irregular, making storage challenging. In contrast, following seam guidelines results in a flatter, more rectangular form, optimizing storage space. From a practical standpoint, aligning seams reduces the risk of damage to the mattress material, resulting in product longevity and performance.

In conclusion, the deliberate alignment of seams is not merely an aesthetic consideration but a functional necessity for the effective folding and storage of Intex air mattresses. This practice promotes uniform stress distribution, facilitates compaction, and ultimately contributes to the extended lifespan of the inflatable sleeping surface. Prioritizing seam alignment is therefore an essential component of proper air mattress maintenance a

nd storage.

3. Air Expulsion

Effective air expulsion is a prerequisite for properly preparing an Intex air mattress for storage. Incomplete removal of air hinders the folding process, increases the overall storage volume, and can compromise the integrity of the mattress material. Therefore, understanding and implementing thorough air expulsion techniques is crucial.

- Volume Minimization

The primary goal of air expulsion is to reduce the mattress’s volume to a minimum. Trapped air prevents tight folding, resulting in a bulky and unmanageable storage item. Effective air expulsion, achieved through manual compression or the use of integrated deflation pumps, allows for a more compact and space-saving package. For instance, a fully deflated twin-size air mattress occupies significantly less storage area compared to one only partially deflated.

- Material Stress Reduction

Air trapped within the mattress creates internal pressure points during folding. These localized stresses can lead to material fatigue, seam separation, and ultimately, punctures. Comprehensive air expulsion distributes pressure more evenly across the mattress surface, minimizing the risk of material damage. Imagine attempting to fold a partially inflated balloon; the uneven pressure would concentrate stress at the fold points, potentially causing it to burst. Similarly, a poorly deflated air mattress is more susceptible to damage during folding and storage.

- Folding Ease and Consistency

Thorough air expulsion facilitates easier and more consistent folding. A fully deflated mattress is more pliable and conforms readily to the desired shape. This promotes uniform folds, reducing the likelihood of irregular creases and bulges. In contrast, attempting to fold a partially inflated mattress often results in awkward and unstable configurations, making secure fastening difficult.

- Long-Term Storage Protection

Residual air can contribute to moisture accumulation within the mattress during storage. This moisture can foster mold growth and material degradation, particularly in humid environments. Complete air expulsion minimizes the potential for moisture buildup, preserving the mattress’s integrity over extended storage periods. For example, air mattresses stored in damp basements are particularly vulnerable to moisture damage if not thoroughly deflated beforehand.

In summary, air expulsion is not merely a preparatory step but a fundamental element in the proper folding and storage of Intex air mattresses. Through volume minimization, material stress reduction, enhanced folding ease, and long-term storage protection, thorough air expulsion contributes significantly to the longevity and usability of the inflatable sleeping surface. Prioritizing this stage of the folding process ensures optimal storage efficiency and safeguards the mattress against potential damage.

4. Secure Fastening

Secure fastening represents a critical phase in the storage of Intex air mattresses. Once an air mattress has undergone deflation and folding, the application of secure fastening techniques ensures that the compressed form is maintained, optimizing storage space and preventing potential damage that can result from unfolding.

- Maintaining Compactness

Secure fastening methods, such as straps or bands, prevent the air mattress from expanding after it has been folded. Without such measures, the tightly rolled or folded mattress can revert to a larger, less manageable size, negating the efforts of thorough deflation and precise folding. For example, neglecting to secure a folded queen-size air mattress may result in it partially unfurling, consuming significantly more storage area than intended.

- Protection Against Damage

A securely fastened air mattress is less susceptible to damage during storage and transportation. Unsecured mattresses may unfold and rub against other objects, increasing the risk of punctures, tears, or abrasions. Securing the folded mattress minimizes movement and friction, protecting the material from environmental hazards. An unsecured mattress transported in a vehicle, for instance, is far more likely to sustain damage compared to one that is properly fastened.

- Facilitating Handling

Secure fastening enhances the ease of handling and transporting the folded air mattress. A securely bound mattress is more compact and stable, making it easier to lift, carry, and maneuver in storage spaces. An unsecured mattress, in contrast, can be unwieldy and difficult to manage, increasing the risk of dropping or bumping it against other objects. Imagine the difference between carrying a neatly bundled package versus a loose, unfolding one.

- Extending Product Lifespan

Consistent use of secure fastening techniques contributes to the long-term preservation of Intex air mattresses. By preventing unfolding and minimizing friction, secure fastening reduces the strain on the mattress material, prolonging its overall lifespan. An air mattress that is consistently stored in a tightly secured and compact form is less prone to wear and tear compared to one that is allowed to unfold and expand freely. The application of secure fastening is, therefore, an investment in the durability of the product.

In summary, secure fastening is an indispensable step in the process of folding and storing Intex air mattresses. It is not merely a final touch but a functional necessity that ensures compactness, protects against damage, facilitates handling, and extends the products lifespan. Integrating secure fastening methods into the standard procedure for storing air mattresses is, therefore, highly recommended for maximizing storage efficiency and preserving the integrity of the inflatable sleeping surface.

5. Valve Protection

Valve protection is an integral consideration within the procedure for folding Intex air mattresses. The valve, as the primary point for inflation and deflation, is a vulnerable component susceptible to damage during handling and storage. Consequently, techniques employed in folding the mattress must account for the valve’s fragility to ensure the product’s longevity and continued functionality.

- Minimizing Stress Concentration

Folding processes that create pressure points directly on or adjacent to the valve can lead to its deformation or cracking. Improper folding can force the valve against hard surfaces or adjacent sections of the mattress, resulting in structural weakening. Valve protection necessitates folding techniques that distribute pressure evenly, avoiding concentrated force on the valve mechanism. For example, positioning the valve on an exterior fold, away from inward pressure, minimizes this risk.

- Preventing Accidental Activation

The folding process must preclude unintentional opening or damage to the valve cap. Accidental activation during storage can result in slow air leakage, rendering the mattress partially deflated and unsuitable for immediate use. Inadvertent damage to the valve cap compromises its seal,

leading to similar leakage problems. Folding strategies should incorporate measures to shield the valve cap from direct contact or pressure, such as tucking it inside a fold or using a protective covering. - Avoiding Abrasive Contact

During both folding and storage, abrasive contact between the valve and surrounding surfaces should be avoided. Dragging the mattress across rough surfaces or storing it in close proximity to abrasive materials can scratch or damage the valve, impairing its functionality. Protective measures include using a storage bag or ensuring the valve is positioned away from potentially abrasive elements. This consideration is particularly relevant when transporting or storing the folded mattress in environments where it may be subject to movement or friction.

- Ensuring Proper Valve Closure

Before commencing the folding process, verification of the valve’s secure closure is essential. A partially open or improperly sealed valve will result in air leakage, undermining the effectiveness of the deflation process and hindering compact folding. Ensuring the valve is fully closed and sealed prior to folding minimizes the risk of subsequent air loss and promotes optimal storage conditions. This verification step should be a standard element of the pre-folding procedure.

These aspects of valve protection demonstrate a direct correlation between the folding method and the preservation of the Intex air mattress’s functionality. Implementing folding techniques that address these considerations is crucial for safeguarding the valve, mitigating the risk of damage, and ensuring the product remains in optimal condition for subsequent use. Failure to prioritize valve protection during folding can lead to premature product failure and necessitate costly repairs or replacements.

6. Appropriate Environment

The environmental conditions under which an Intex air mattress is stored significantly impact its structural integrity and longevity, influencing the effectiveness of even the most meticulous folding techniques. An unsuitable storage environment can negate the benefits of proper deflation, seam alignment, and secure fastening, leading to premature material degradation and product failure.

- Temperature Regulation

Extreme temperatures, both high and low, pose a threat to the vinyl composition of Intex air mattresses. Elevated temperatures can cause the vinyl to soften and become more susceptible to stretching and tearing. Conversely, low temperatures can render the material brittle and prone to cracking. A climate-controlled environment, maintained at a moderate temperature, mitigates these risks and preserves the elasticity and strength of the vinyl. For example, storing an air mattress in an uninsulated attic or garage, where temperatures fluctuate significantly, is likely to accelerate material degradation, regardless of how carefully the mattress is folded.

- Humidity Control

Elevated humidity levels promote the growth of mold and mildew, which can damage the air mattress material and create unpleasant odors. Trapped moisture within the folded mattress, combined with high humidity, provides an ideal environment for microbial proliferation. Storing the air mattress in a dry environment, or using a dehumidifier in the storage area, inhibits mold and mildew growth, safeguarding the material integrity. An air mattress stored in a damp basement, for instance, is at a higher risk of mold infestation than one stored in a dry closet.

- Protection from Direct Sunlight

Prolonged exposure to direct sunlight can cause the vinyl material to fade, become brittle, and lose its elasticity. Ultraviolet (UV) radiation degrades the plasticizers within the vinyl, leading to structural weakening. Storing the folded air mattress in a dark or shaded location prevents UV damage and preserves the material’s flexibility. Placing an air mattress near a window, where it is exposed to direct sunlight for extended periods, is likely to accelerate the aging process, even when the mattress is properly folded.

- Physical Protection

The storage environment should also provide physical protection against sharp objects, abrasive surfaces, and potential pests. Punctures, tears, and rodent damage can compromise the air mattress’s functionality, regardless of its storage conditions. Storing the folded air mattress in a protective bag or container shields it from these hazards. Leaving an unfolded or poorly protected air mattress on the floor of a garage, for example, increases the risk of damage from sharp tools, heavy objects, or rodents.

Therefore, selecting an appropriate storage environment is a crucial adjunct to proper folding techniques. A climate-controlled, dry, dark, and physically protected location maximizes the benefits of careful deflation, folding, and fastening, ensuring the Intex air mattress remains in optimal condition for future use. Neglecting these environmental factors can undermine even the most diligent folding efforts, leading to premature product degradation and diminished lifespan.

Frequently Asked Questions

This section addresses common inquiries regarding the proper methods for folding Intex air mattresses, providing concise and informative answers to ensure optimal storage and product longevity.

Question 1: What constitutes “complete deflation” when preparing an Intex air mattress for storage?

Complete deflation entails the removal of all discernible air from the mattress chambers. This process requires utilizing the integrated pump (if equipped) in reverse, or manually depressing the valve while applying pressure to the mattress surface. The objective is to minimize the volume of the deflated mattress, facilitating a compact fold.

Question 2: Why is seam alignment considered a critical factor in the folding process?

Seam alignment ensures uniform distribution of stress across the mattress material during folding. By adhering to the natural fold lines established by the seams, users can prevent localized pressure points that could lead to tears or seam separation. Correct alignment also contributes to a more compact and manageable folded form.

Question 3: What are the recommended methods for expelling residual air during the folding procedure?

Residual air expulsion is achieved through a combination of manual compression and strategic folding techniques. As each fold is made, firm pressure should be applied to the mattress surface to force out any trapped air. This process is iterative, requiring repeated application of pressure with each successive fold.

Question 4: What types of fastening mechanisms are suitable for securing a folded Intex air mattress?

Appropriate fastening mechanisms include durable straps, bungee cords, or heavy-duty rubber bands. The chosen method should provide sufficient tension to maintain the compressed form of the folded mattress, preventing it from unfolding during storage or transport. Avoid using materials that could damage the mattress surface or valve.

Question 5: What are the key considerations for protecting the air valve during folding and storage?

Valve protection involves minimizing stress on the valve mechanism and preventing accidental activation or damage to the valve cap. During folding, ensure the valve is positioned away from pressure points. Consider using a protective covering for the valve cap to prev

ent abrasion or accidental opening. Inspect the valve for proper closure before commencing the folding process.

Question 6: What environmental conditions are conducive to long-term storage of Intex air mattresses?

Optimal storage conditions include a climate-controlled environment with moderate temperatures and low humidity. Avoid exposure to direct sunlight or extreme temperature fluctuations, as these can degrade the mattress material. Physical protection from sharp objects and pests is also essential for preserving the mattress’s integrity during storage.

Adherence to these guidelines promotes effective storage, extending the lifespan of the inflatable product.

The concluding section summarizes the complete storage procedure and provides recommendations for maintaining the inflatable mattress.

Conclusion

This exploration of how to fold Intex air mattress has detailed the critical aspects of proper storage for these inflatable products. The procedures outlined encompass thorough deflation, precise seam alignment, effective air expulsion, secure fastening techniques, vigilant valve protection, and selection of an appropriate storage environment. Adherence to these guidelines promotes optimal compactness and safeguards the mattress against potential damage during storage.

Implementing these best practices extends the lifespan of the Intex air mattress, preserving its functionality and ensuring reliable performance for future use. Proper folding, therefore, is not merely a matter of convenience, but a crucial aspect of responsible product stewardship. Consistent application of these principles will contribute to the enduring value and utility of the air mattress investment.