The process of inflating a specific brand of inflatable sleeping surface is the central topic. This involves introducing air into the mattress to achieve its functional form. The method used may vary depending on the presence of an integrated pump, the availability of an external pump, or the need to inflate it manually.

A properly inflated sleeping surface provides a comfortable and convenient alternative to traditional mattresses, especially for temporary accommodation or camping. The ability to quickly set up and deflate this type of mattress offers portability and ease of storage. Initially developed for camping and guest accommodations, these inflatable mattresses have become increasingly popular due to their affordability and adaptability.

The following sections will detail various methods for achieving optimal inflation, including utilizing built-in electric pumps, employing external air pumps, and using manual inflation techniques. Each approach presents unique considerations regarding speed, required equipment, and potential challenges.

Inflation Tips

Achieving optimal firmness and longevity requires careful attention to detail during the inflation process. These tips provide guidance for successfully preparing an inflatable sleeping surface for use.

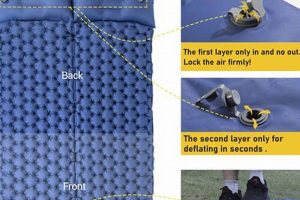

Tip 1: Inspect the Valve: Before commencing inflation, ensure the valve is clean and free of debris. A compromised valve may result in air leakage. Regularly check valve’s o-rings and seals.

Tip 2: Use the Correct Nozzle: Utilizing the appropriate nozzle for an external pump is essential for creating a secure seal. Avoid forcing an ill-fitting nozzle, as this can damage the valve.

Tip 3: Avoid Overinflation: Monitor the firmness of the sleeping surface throughout the inflation process. Overinflation can place undue stress on the seams and compromise its structural integrity, leading to bursting.

Tip 4: Inflate in a Temperature-Controlled Environment: Significant temperature variations can affect the air pressure within the mattress. Inflate in a stable environment to ensure consistent firmness.

Tip 5: Double-Check the Seal: After inflation, meticulously examine the valve to ensure it is securely closed and that no air is escaping. A soapy water solution can aid in detecting leaks.

Tip 6: Place on a Smooth Surface: To prevent punctures or tears, place the air mattress on a smooth, clean surface free from sharp objects. Consider using a protective layer, such as a blanket or tarp.

Adhering to these guidelines will assist in maximizing the lifespan and comfort of the sleeping surface.

The subsequent section will address common troubleshooting issues and maintenance practices.

1. Valve Integrity

Valve integrity is paramount to the successful inflation and sustained use of an inflatable sleeping surface. A compromised valve negates the utility of the mattress, irrespective of the inflation method employed. It directly impacts the ability to retain air and maintain the desired firmness. The valve serves as the primary interface for inflation and deflation; therefore, its condition is critical.

- Material Degradation

Over time, the valve material, often composed of plastic or rubber compounds, can degrade due to exposure to ultraviolet radiation, temperature fluctuations, or chemical cleaning agents. This degradation can lead to cracks, brittleness, or loss of elasticity, compromising the valve’s sealing capabilities. For example, prolonged exposure to direct sunlight can cause the plastic to become brittle and fracture during inflation or deflation, rendering the mattress unusable.

- Seal Imperfections

The valve’s seal, which prevents air leakage, can develop imperfections due to manufacturing defects, wear and tear, or improper maintenance. These imperfections may manifest as hairline cracks, deformities in the sealing surface, or the presence of foreign particles that obstruct a complete seal. Consequently, the mattress may slowly deflate over time, requiring frequent re-inflation.

- Thread Damage

Valves employing threaded closures are susceptible to thread damage resulting from cross-threading, over-tightening, or physical impact. Damaged threads impede the secure closure of the valve, creating air gaps and compromising the air-tight seal. This damage often necessitates valve replacement or renders the entire mattress unusable.

- Valve Core Issues

Some valves incorporate a core mechanism, similar to those found in vehicle tires. These cores can loosen, corrode, or become obstructed, leading to air leakage. Furthermore, the valve core tool is necessary for repair of the valve

In summary, maintaining valve integrity is essential for the proper function of any inflatable sleeping surface. Neglecting the condition of the valve can lead to inflation difficulties, air leakage, and premature failure of the mattress. Regular inspection, proper maintenance, and careful handling during inflation and deflation are crucial for preserving valve integrity and ensuring the long-term usability of these inflatable products.

2. Pump Compatibility

Proper inflation of this specific inflatable mattress hinges significantly on pump compatibility. The type of pump used, and its ability to interface correctly with the mattress valve, directly influences inflation speed, efficiency, and the potential for damage. Selecting a compatible pump is not merely a matter of convenience but one of ensuring the integrity and longevity of the inflatable structure.

- Valve Adapter Matching

A critical aspect of pump compatibility is the availability of appropriate valve adapters. These adapters bridge the gap between the pump nozzle and the mattress valve, creating a secure and airtight connection. Using an incorrect or ill-fitting adapter can lead to air leakage, prolonged inflation times, or even damage to the valve. For instance, attempting to force a standard bicycle pump nozzle into the air mattress valve will likely result in a poor seal and potential valve damage. The valve adapter’s ability to securely fit allows efficient air transfer.

- Airflow Capacity and Pressure Output

Pumps vary in their airflow capacity and pressure output, both of which are vital for effective inflation. A pump with insufficient airflow will result in a slow and laborious inflation process. Conversely, a pump with excessive pressure output can potentially overinflate the mattress, leading to seam stress and potential rupture. Selecting a pump with an appropriate balance of airflow and pressure ensures efficient and safe inflation. For example, a high-volume, low-pressure pump is generally more suitable for inflating large air mattresses than a h

igh-pressure, low-volume pump. A balanced pump allows inflation control and reduces risk to the mattress. - Power Source and Portability

The pump’s power source and portability are practical considerations that impact usability. Electric pumps offer convenience and speed but require access to a power outlet. Battery-powered pumps provide portability but may have limited run times. Manual pumps are entirely self-sufficient but require physical effort. The choice depends on the intended use case. If camping far from power sources, a manual or battery-powered pump would be preferable. Therefore, the power source impacts ease of use in different environments.

- Integrated vs. External Pumps

Some inflatable mattresses feature integrated electric pumps, while others require external pumps. Integrated pumps offer convenience and guarantee compatibility but can be more prone to failure and difficult to repair. External pumps provide greater flexibility in terms of power source and portability but require separate purchase and storage. The presence of an integrated pump streamlines the setup process, while external pumps offer versatility.

The discussed facets directly influence achieving successful inflation. Using compatible valves, understanding pressure capabilities, and understanding portable power impacts effective inflation. Integrated options offer greater accessibility and convenient control.

3. Inflation Pressure

Inflation pressure is a critical determinant in the functionality and lifespan of any inflatable sleeping surface. The process, therefore, directly dictates comfort, structural integrity, and overall user satisfaction. Consistent control over inflation levels is necessary for optimal performance.

- Comfort Level

The level of firmness is directly proportional to the internal pressure. Under-inflation results in a saggy, unstable surface, while over-inflation creates an unyielding and uncomfortable sleeping area. Optimal pressure is subjective but generally corresponds to a firm yet yielding surface that conforms to the body’s contours. For instance, individuals with back pain often prefer higher inflation levels for increased support. It is a key factor in comfort level.

- Structural Integrity

Maintaining appropriate pressure is crucial for preserving the structural integrity of the mattress. Over-inflation places excessive stress on the seams and internal baffles, increasing the risk of rupture, particularly under weight. Conversely, under-inflation can lead to excessive flexing and deformation of the material, potentially causing premature wear and tear. Maintaining pressure within the manufacturer’s recommended range safeguards against structural damage.

- Environmental Factors

Ambient temperature fluctuations significantly impact internal pressure. As temperature rises, air expands, increasing internal pressure. Conversely, as temperature falls, air contracts, reducing internal pressure. Failure to account for these fluctuations can lead to over- or under-inflation. For example, inflating a mattress indoors at room temperature and then moving it outdoors on a hot day can result in over-inflation and potential damage.

- Weight Capacity

The maximum weight capacity is directly correlated with inflation pressure. Under-inflating a mattress intended for multiple users can cause it to bottom out, negating its support and potentially damaging its structure. Adhering to the manufacturer’s pressure recommendations ensures that the mattress can adequately support the intended weight load. Using proper pressure and following weight recommendations extends the life.

Proper management of inflation pressure is paramount for achieving optimal comfort, preserving structural integrity, accounting for environmental factors, and accommodating weight capacity. Ignoring pressure recommendations significantly increases the risk of discomfort, damage, and premature failure, ultimately detracting from the intended utility of the sleeping surface.

4. Leak Detection

Leak detection is an integral element in the proper utilization of inflatable mattresses. This directly relates to the effort involved with inflation, as undetected leaks negate the purpose of the inflation process. Finding leaks quickly impacts longevity and efficient use.

- Identifying Leak Sources

The first step in leak detection involves a systematic examination of common points of failure. Seams, valves, and the main surface area are primary targets. Potential punctures or material weaknesses require identification. The presence of hissing sounds or the sensation of air movement near the mattress indicates a leak source. Systematic identification prevents wasted time with inflation.

- Soapy Water Test

The application of a soapy water solution is a widely employed method for pinpointing small leaks. A mixture of water and dish soap is applied to the mattress surface. The formation of bubbles indicates escaping air and reveals the leak’s location. This simple method facilitates precise leak detection. Soapy water solution reduces the difficulty of leak detection.

- Submersion Method

For larger inflatable products, partial or full submersion in water can be employed. Submerging sections and looking for streams of air bubbles identifies the leak. This method is effective for finding multiple leaks. Submersion is valuable for quick visualization of the leaks.

- Pressure Monitoring

After inflation, monitoring the air pressure can indicate the presence of slow leaks. Marking the inflated perimeter and observing for any changes over time can reveal gradual air loss. This technique detects slow air leaks. Pressure observation shows slow leak issues.

Employing these leak detection methods ensures that the effort expended during the inflation process is not negated by undetected air loss. Efficient leak detection, therefore, extends the useable life of the mattress and maintains comfort. Properly identified leaks prevent further effort and maintenance.

5. Surface Preparation

Surface preparation constitutes a foundational step inextricably linked to successful inflation and the subsequent use of an inflatable sleeping surface. The condition of the underlying surface directly influences the structural integrity of the mattress, affecting both its inflation effectiveness and its lifespan. Inadequate surface preparation can lead to premature failure, negating the effort invested in the inflation process. This highlights a critical cause-and-effect relationship: improper surface preparation causes preventable damage, undermining the intended benefits of a properly inflated mattress. For example, inflating an air mattress directly on a gravel surface will almost certainly result in punctures, rendering the inflation futile. Conversely, meticulous preparation safeguards the mattress, maximizing its utility.

The importance of proper surface preparation extends beyond simply preventing immedia

te damage. A clean, smooth surface evenly distributes the weight exerted on the mattress, reducing localized stress points that can weaken the material over time. Eliminating sharp objects and debris mitigates the risk of slow leaks that can gradually deflate the mattress, compromising comfort and support. Placing a protective barrier, such as a tarp or thick blanket, further minimizes abrasion and potential punctures, extending the mattress’s lifespan. Understanding this connection allows users to optimize the mattress’s performance and durability. For instance, in a camping scenario, thoroughly clearing a campsite of rocks and roots and placing a ground cloth before inflation significantly improves the mattress’s resilience.

In summary, surface preparation is not merely a preliminary task but an essential component integral to the effective utilization of an inflatable sleeping surface. It directly impacts the mattress’s inflation effectiveness, its structural integrity, and its overall longevity. By understanding and addressing the potential risks associated with inadequate surface preparation, users can significantly enhance the mattress’s performance and minimize the likelihood of premature failure. Ignoring this critical step represents a significant oversight, undermining the benefits of the inflation process and potentially leading to avoidable damage and discomfort.

Frequently Asked Questions

The following questions address common inquiries regarding the inflation of a specific brand of air mattress. Accurate procedures are important for mattress functionality.

Question 1: What is the optimal pressure for the inflatable mattress?

The optimal inflation pressure varies based on mattress size and user preference. It is imperative to consult the manufacturer’s instructions for specific pressure recommendations. Over-inflation can compromise structural integrity; under-inflation may yield inadequate support.

Question 2: Can an automotive air compressor be used for inflation?

While an automotive air compressor can technically be used, caution is advised. The high-pressure output of such compressors can easily lead to over-inflation and potential damage. Short bursts and careful monitoring are essential if this method is employed.

Question 3: What should be done if the built-in pump malfunctions?

If the built-in pump malfunctions, the mattress may require manual inflation using an external pump and appropriate nozzle adapter. Alternatively, contacting the manufacturer for warranty service or repair options is advised.

Question 4: What is the best method for detecting small leaks?

A solution of soapy water applied to the inflated surface is highly effective for detecting small leaks. The formation of bubbles indicates escaping air. Particular attention should be paid to seams and valve areas.

Question 5: How can over-inflation be avoided?

Over-inflation can be avoided by inflating in short intervals, regularly checking the firmness of the mattress, and consulting the manufacturer’s pressure recommendations. Avoid inflating to maximum capacity in environments with rising temperatures.

Question 6: Is it possible to inflate the mattress without a pump?

While not recommended for convenience, the mattress can be inflated manually using a hairdryer (on cool setting) or by repurposing a plastic bag to capture and transfer air into the valve. This method is labor-intensive and less efficient than using a pump.

Understanding proper inflation methods ensures optimal performance and longevity of this type of sleeping surface.

The subsequent section will focus on maintenance practices.

Conclusion

This exploration has detailed the procedural aspects associated with how to blow up intex air mattress, emphasizing critical factors. These encompass valve integrity, pump compatibility, inflation pressure management, leak detection strategies, and the imperative of adequate surface preparation. A thorough understanding of these elements is paramount for achieving optimal functionality and prolonging the lifespan of the inflatable structure.

Proper execution of these procedures directly influences the comfort, support, and overall durability of the air mattress. Consequently, adherence to these guidelines is not merely a matter of convenience, but a necessity for ensuring a satisfactory and enduring product experience. Continued application of these principles will promote responsible usage and maximize the value derived from this type of portable sleeping solution.

![Best Jeep Wrangler Air Mattress [Guide] On Road! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Jeep Wrangler Air Mattress [Guide] On Road! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-6718-300x200.jpg)