This type of sleeping arrangement involves a secondary bed frame and mattress that is stored beneath a primary bed. Designed for space efficiency, it typically rolls out from under the main bed when needed and can be pushed back for storage. An example would be a child’s bedroom where occasional sleepovers occur; this arrangement provides an extra bed without permanently occupying additional floor space.

The importance of this design lies in its ability to maximize usable space, particularly in smaller homes or apartments. Benefits include increased sleeping capacity without a dedicated guest room, simplified organization, and a potentially lower cost compared to purchasing a full-sized additional bed. Historically, similar space-saving bed designs have been utilized for centuries in situations where living space was limited.

The subsequent article will delve into various aspects, including available sizes, material options, mechanisms for extension and retraction, associated mattress types, and factors to consider when selecting the most appropriate option for a specific application.

Considerations for Purchasing a Trundle Bed with Mattress

The following are key considerations to ensure informed decisions regarding the acquisition of this type of sleeping solution.

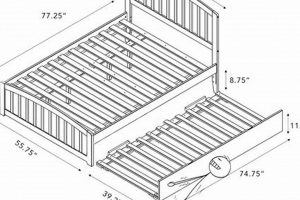

Tip 1: Measure Available Space. Prior to purchase, precisely measure the area where the primary bed and extended structure will reside. Account for clearance to ensure easy deployment and retraction, as well as sufficient space for movement around the extended bed.

Tip 2: Assess Mattress Compatibility. Verify that the mattress intended for use with the under-bed section is dimensionally appropriate and of a suitable thickness for the frame. Exceeding the recommended mattress height may impede smooth retraction.

Tip 3: Evaluate Frame Material and Construction. Examine the materials used in the frame construction. Solid wood or high-quality metal frames typically offer superior durability and longevity compared to less robust materials.

Tip 4: Consider Rolling Mechanism Quality. Inspect the wheels or gliding mechanism used to extend and retract the secondary bed. Smooth, quiet operation is indicative of a well-designed and durable system.

Tip 5: Determine Weight Capacity. Ascertain the weight capacity of the frame, especially if it will be used by adults. Exceeding the specified weight limit can compromise the structural integrity of the unit.

Tip 6: Review Safety Features. Consider models with locking mechanisms to prevent unintended rolling when deployed, particularly important in households with children.

Tip 7: Evaluate Style and Aesthetics. Select a model that complements the existing decor and furniture within the room. Consider factors such as finish, color, and overall design.

By carefully evaluating these factors, purchasers can optimize their investment in this type of sleeping solution and ensure long-term satisfaction.

The subsequent sections will provide a comprehensive overview of various types and applications, along with maintenance suggestions.

1. Space-saving design

The inherent function of this type of bed lies in its space-saving design. The inclusion of a secondary sleeping surface, storable beneath the primary bed frame, directly addresses space constraints common in apartments, smaller homes, or multi-purpose rooms. This design minimizes the footprint required for accommodating additional sleepers when a dedicated guest room is unavailable. A practical example involves a child’s bedroom; the primary bed serves daily use, while the lower bed emerges only during sleepovers, effectively doubling sleeping capacity without consuming permanent floor space.

The space-saving attribute is directly proportional to the selection considerations for the frame and mattress. A frame designed for maximum compression and minimal vertical space consumption is crucial. Similarly, the selected mattress must adhere to strict thickness limitations to ensure seamless retraction under the primary bed. Failure to adhere to these parameters negates the intended space-saving benefit, potentially rendering the unit impractical. For example, a frame with an inefficient rolling mechanism could obstruct walkways during deployment. Improper mattress selection may cause the frame to become stuck, eliminating the space efficiency.

In summary, the connection between space-saving design and the selection, installation, and utilization of this type of bed is paramount. Careful consideration of dimensions, rolling mechanisms, and mattress thickness is essential to realizing the intended spatial efficiency. Challenges may arise from inadequate planning or misinterpretations of product specifications, ultimately diminishing the practical advantages of this design. A thorough understanding facilitates informed purchasing decisions and maximizes the potential for effective space optimization.

2. Mattress thickness limits

The design of a trundle bed necessitates specific restrictions on mattress thickness for the retractable lower bed. These limitations directly stem from the physical space available beneath the primary bed frame. Exceeding the specified maximum thickness inhibits the proper storage and retraction of the secondary mattress. The cause-and-effect relationship is straightforward: an oversized mattress will prevent the under-bed section from fully sliding closed, obstructing functionality. The importance of adhering to thickness limits is paramount; it directly affects the usability and space-saving capabilities that define this type of bed.

Consider a practical scenario: a trundle bed frame designed for a maximum mattress thickness of eight inches. If a ten-inch mattress is used, the under-bed section will likely be unable to fully retract, possibly damaging the frame or preventing complete closure. This scenario eliminates the intended benefit, turning the bed into a partially extended, space-occupying obstacle. Manufacturers provide thickness specifications to ensure compatibility. Ignoring these specifications results in operational impairment. Correct mattress selection is therefore not an arbitrary detail but a functional requirement.

In summary, the connection between mattress thickness limits and the overall functionality of this type of bed is inextricable. Exceeding these limitations directly compromises the unit’s primary advantage: space-efficient storage. Challenges arise primarily from a lack of awareness or failure to adhere to manufacturer guidelines. Understanding and respecting mattress thickness requirements is critical for maximizing the utility and lifespan of the product, ensuring it functions as intended.

3. Frame material durability

The durability of the frame material directly impacts the lifespan and functionality of this type of bed. The frame, the primary structural component, supports both the upper and lower mattresses, along with the weight of individuals using the beds. Consequently, a frame constructed from inferior materials is prone to premature wear, warping, or even breakage. Such failures compromise the safety and usability of the entire unit. The importance of frame material durability is amplified by the retractable nature of the lower bed, as repeated extension and retraction place additional stress on the frame’s joints and mechanisms.

Consider two contrasting examples. A frame built from solid hardwood, such as oak or maple, can withstand considerable weight and repeated use for extended periods. This resilience minimizes the likelihood of structural failure and ensures smooth operation of the rolling mechanism. Conversely, a frame fabricated from low-density particleboard or weak metal alloys is susceptible to damage from routine use. For example, the wheels may detach, the frame may sag under weight, or the joints may crack, rendering the under-bed section unusable. The choice of frame material, therefore, is not merely an aesthetic consideration but a fundamental determinant of the bed’s longevity and performance.

In summary, the selection of a durable frame material is a critical factor in maximizing the long-term value and usability. Understanding the correlation between frame material and the overall functionality is essential for informed purchasing decisions. Challenges may arise from misleading marketing claims or insufficient product information. Prioritizing frame material durability translates directly into increased product lifespan, enhanced safety, and sustained satisfaction with this space-saving sleeping solution.

4. Rolling mechanism quality

The rolling mechanism in this type of bed is fundamental to its design and function, directly affecting ease of use, durability, and long-term reliability. The quality of this mechanism dictates how smoothly and effortlessly the under-bed section extends and retracts, which is crucial for maximizing the bed’s utility and minimizing user frustration.

- Wheel Material and Construction

The material and construction of the wheels are paramount. High-quality wheels, typically made of durable materials such as nylon or rubber, ensure smooth gliding and prevent damage to flooring. Inferior wheels, constructed of hard plastic, may create noise, scratch floors, and wear out quickly. For example, consider a model with rubberized wheels, which silently rolls on hardwood floors without leaving marks, versus a cheaper model with plastic wheels that squeak and scratch the same floor. The former enhances usability and preserves the floor, while the latter detracts from both.

- Bearing System

The type of bearing system within the wheels significantly impacts the smoothness of the rolling action. Ball bearings, in particular, allow for effortless movement with minimal friction. In contrast, wheels without bearings or with low-quality bearings require more force to move, leading to user strain and potential frame damage. A bed with sealed ball bearings would glide smoothly even when fully loaded, while one without bearings would require significant effort to pull out, especially on carpeted surfaces.

- Frame Integration and Support

The way the rolling mechanism is integrated into the frame also influences its performance and longevity. Robust attachment points and reinforced support structures prevent sagging or misalignment, ensuring consistent rolling performance over time. Conversely, a poorly integrated mechanism can become loose or detached, causing the under-bed section to drag or become stuck. A design where the wheels are securely bolted to a metal frame would offer superior stability compared to a design where the wheels are simply screwed into a wooden frame.

- Locking and Safety Features

High-quality rolling mechanisms often include locking features to prevent unintended movement when the bed is extended. These locking mechanisms enhance safety, particularly in households with children. Furthermore, durable locking systems ensure that the under-bed section remains securely in place when stored, preventing accidental roll-out. A model with a reliable locking mechanism offers peace of mind, knowing the bed will not unexpectedly move, while one without such features poses a potential safety risk.

The facets outlined contribute significantly to user experience and product reliability. Investing in a model with a well-designed rolling mechanism ensures seamless operation, reduces the risk of damage, and enhances the overall utility of the bed. This is especially crucial for those who frequently utilize the secondary bed.

5. Weight capacity importance

The weight capacity of a trundle bed with mattress is a critical specification that directly affects safety, durability, and long-term performance. Exceeding the stated weight limit can compromise structural integrity, leading to damage or potential injury. Therefore, understanding and adhering to weight capacity guidelines is essential for maximizing the lifespan and safe operation of this type of sleeping solution.

- Frame Material and Support Structure

The materials used in the frame and the design of the support structure are fundamental determinants of weight capacity. Frames constructed from solid hardwoods or reinforced steel are typically capable of supporting greater weight than those made from particleboard or thinner metals. Consider a scenario where a trundle bed with a frame made of solid oak can safely accommodate two adults, while a similar bed with a particleboard frame may only be suitable for children. The choice of materials directly impacts the bed’s ability to withstand weight and maintain structural integrity.

- Mattress Selection and Distribution

The type and thickness of the mattress also contribute to the overall weight load on the frame. Heavier mattresses, such as those with innerspring systems, exert more pressure on the frame compared to lighter foam mattresses. Uneven weight distribution can further exacerbate stress points. Imagine a situation where two individuals are positioned primarily on one side of the upper bed; this concentrated weight could strain the frame beyond its intended capacity, leading to warping or breakage. Proper mattress selection and even weight distribution are crucial for staying within the specified limits.

- Rolling Mechanism and Load-Bearing Capacity

The rolling mechanism of the under-bed section must be designed to support the combined weight of the frame, mattress, and occupant. High-quality wheels and robust support structures are necessary to prevent sagging or failure. For instance, a model with heavy-duty casters can smoothly roll even when fully loaded, whereas a model with lightweight wheels may struggle under the same conditions, potentially causing damage to the floor or the frame itself. The rolling mechanism’s load-bearing capacity is an integral aspect of the overall weight co

nsiderations. - Safety Considerations and User Guidelines

Adhering to the manufacturer’s weight capacity guidelines is essential for safety. Exceeding the limit can lead to structural failure, posing a risk of injury to the user. Clear communication of weight limits and responsible usage are paramount. Consider a scenario where a parent allows multiple children to jump on the bed, exceeding its weight capacity. This misuse could result in a broken frame and potential harm. Following user guidelines ensures safe and responsible operation.

These interconnected factors highlight the paramount importance of understanding and respecting weight capacity guidelines when selecting and using a trundle bed with mattress. Careful consideration of frame materials, mattress selection, rolling mechanism, and user guidelines will optimize safety and extend the lifespan of the unit.

6. Safety locking features

Safety locking features are an essential consideration in the design and selection of a trundle bed with mattress. These mechanisms prevent unintended movement of the under-bed section, contributing to user safety and stability, especially in environments with children or uneven surfaces.

- Prevention of Accidental Roll-Out

The primary function of safety locking mechanisms is to prevent the under-bed section from unintentionally rolling out. This is particularly important in households with young children who might inadvertently push or pull the bed, creating a tripping hazard or causing damage to the bed itself. An example would be a trundle bed positioned on a slightly inclined floor; without a locking mechanism, the under-bed section could gradually roll out, obstructing walkways.

- Enhanced Stability During Use

Locking features also enhance the stability of the extended under-bed during use. When locked in place, the under-bed section is less likely to shift or move, providing a more secure and comfortable sleeping surface. Consider a scenario where an individual is sleeping on the extended under-bed; a locking mechanism prevents the bed from rolling unexpectedly, which could disrupt sleep or cause injury.

- Types of Locking Mechanisms

Various types of locking mechanisms are available, including wheel locks, frame locks, and integrated latch systems. Wheel locks prevent the wheels from rotating, while frame locks secure the entire under-bed structure to the main frame. Integrated latch systems use a latch to hold the under-bed in place. The type of locking mechanism influences the ease of use and the level of security provided. A trundle bed with a robust frame lock offers a higher degree of stability compared to a model with simple wheel locks.

- Material Quality and Durability

The effectiveness of safety locking features depends on the quality of the materials used and the overall durability of the mechanism. Locking mechanisms constructed from high-strength materials are less prone to failure and provide a more secure lock. Regular inspection and maintenance are necessary to ensure the continued functionality of these safety features. A metal latch system, properly maintained, is more likely to provide long-term security compared to a plastic latch system subjected to frequent use.

The incorporation of effective safety locking features represents a significant enhancement to the overall design and functionality of a trundle bed with mattress. These mechanisms mitigate potential hazards, promote stability, and contribute to a more secure and comfortable sleeping environment. Understanding the different types of locking features and the importance of material quality is crucial for making informed purchasing decisions that prioritize safety and long-term reliability.

7. Aesthetic compatibility

The concept of aesthetic compatibility is a significant consideration when integrating a trundle bed with mattress into an existing living space. The visual harmony between the bed and the surrounding decor contributes to the overall ambiance and perceived comfort of the room. Neglecting aesthetic considerations can result in a visually dissonant environment, detracting from the room’s intended purpose.

- Color Palette Coordination

The color of the trundle bed frame and mattress should complement or contrast intentionally with the existing color scheme of the room. A clash in colors can create a jarring visual effect, while harmonious colors contribute to a cohesive and inviting atmosphere. For example, a room with neutral-toned walls might benefit from a trundle bed with a vibrant-colored frame and coordinated bedding to introduce visual interest.

- Style and Design Consistency

The style of the trundle bed should align with the overall design aesthetic of the room. A modern room would benefit from a trundle bed with clean lines and minimalist features, while a more traditional room might call for a bed with ornate details and classic styling. A mismatch in styles can disrupt the visual flow of the room. A Victorian-style room with an ultra-modern trundle bed would likely appear incongruous.

- Material Integration

The materials used in the construction of the trundle bed should be consistent with the existing materials in the room. Wood, metal, and fabric choices should complement the existing furniture and architectural elements. A room with predominantly wooden furniture would benefit from a trundle bed with a wooden frame. The texture and finish of the materials should also be carefully considered to maintain visual consistency.

- Scale and Proportion

The size and proportion of the trundle bed should be appropriate for the size of the room. A large trundle bed in a small room can overwhelm the space, while a small trundle bed in a large room might appear insignificant. The bed should be scaled to fit comfortably within the room without obstructing movement or creating a sense of imbalance. This requires careful consideration of the room’s dimensions and the bed’s overall footprint.

These facets of aesthetic compatibility highlight the importance of considering the visual impact of the trundle bed within its environment. By carefully coordinating color, style, materials, and scale, it’s possible to seamlessly integrate the trundle bed into the room, enhancing both its functionality and its aesthetic appeal. This careful consideration ensures that the trundle bed serves not only as a practical sleeping solution but also as a harmonious element within the overall design of the space.

Frequently Asked Questions

The following section addresses commonly encountered queries regarding this type of sleeping arrangement, providing clarity and essential information.

Question 1: What distinguishes a trundle bed from a standard bed?

A notable difference lies in the inclusion of a secondary bed frame and mattress concealed beneath the primary bed. Standard beds lack this space-saving attribute.

Question 2: Are specific mattress types required for the under-bed section?

Yes, the mattress must adhere to a specified thickness, typically thinner than standard mattresses, to ensure proper retraction and storage. Consult

the manufacturer’s specifications.

Question 3: Can a trundle bed support the weight of adults?

The weight capacity varies by model. Individuals should verify the manufacturer’s stated weight limit to ensure safe operation. Models constructed from robust materials are more likely to accommodate adult weights.

Question 4: How is the rolling mechanism maintained for optimal performance?

Regular cleaning of the wheels or glides is recommended to remove debris. Lubrication, as specified by the manufacturer, may also be necessary to ensure smooth operation.

Question 5: Are safety locking features essential?

Safety locking features, while not universally included, offer added security by preventing unintended roll-out, particularly relevant in households with children or uneven floors.

Question 6: What factors influence the overall durability?

Frame material, construction quality, and adherence to weight limits significantly impact durability. Solid wood or high-grade metal frames typically offer extended lifespans.

Understanding these aspects will assist in making informed decisions and ensuring satisfaction with this particular bed design.

The subsequent section will examine optimal usage scenarios and potential challenges.

Trundle Bed with Mattress

This exploration has illuminated the multifaceted aspects of a “trundle bed with mattress,” emphasizing its space-saving capabilities, material considerations, mechanical features, safety protocols, and aesthetic integration. Adherence to specified weight limits, careful evaluation of frame and mattress materials, and regular maintenance of the rolling mechanism are critical for optimizing the lifespan and safety of this bed design. Furthermore, understanding the significance of safety locking mechanisms and ensuring aesthetic compatibility within the existing decor are vital for maximizing user satisfaction.

In conclusion, the value proposition inherent in a “trundle bed with mattress” extends beyond simple space efficiency. It represents a strategic investment in adaptable living spaces, necessitating informed decision-making and responsible utilization. Future advancements in materials science and engineering will likely yield further improvements in the durability, functionality, and aesthetic versatility, thereby solidifying its position as a practical and increasingly sophisticated solution for maximizing sleeping capacity in constrained environments.