A sleeping surface specifically designed for use within a wall bed frame represents a key element in maximizing both space and comfort. These surfaces must meet particular requirements to ensure seamless operation and long-term durability of the wall bed mechanism. A critical aspect is often the thickness and weight of the product to allow the bed to fold up and down smoothly.

The suitability of this sleeping surface for a wall-mounted bed offers numerous advantages, including optimized floor space, particularly beneficial in apartments or smaller living areas. Historically, these specialized mattresses have evolved alongside innovations in space-saving furniture, becoming increasingly sophisticated in terms of materials and construction, providing both support and longevity. Selecting a compatible sleeping surface safeguards the functionality of the folding mechanism while contributing to a comfortable night’s rest.

The following sections will delve into the different types of these sleeping surfaces available, essential considerations when selecting one, and guidelines for maintenance to prolong its lifespan and ensure continued optimal performance within a wall bed system.

Essential Considerations for a Wall Bed Sleeping Surface

The following tips provide guidance on selecting and maintaining a sleeping surface optimized for wall bed systems, ensuring both longevity and user satisfaction.

Tip 1: Assess Weight and Thickness Restrictions: Examine the wall bed frame’s specifications to identify maximum weight and thickness limits. Exceeding these limits may impair the folding mechanism and pose a safety risk.

Tip 2: Prioritize Spring System Compatibility: Innerspring, memory foam, and latex models each exhibit varying levels of compressibility. Verify that the selected spring system conforms to the wall bed’s operational requirements, ensuring smooth folding and unfolding.

Tip 3: Evaluate Edge Support: Adequate edge support is crucial for preventing sagging and ensuring consistent comfort across the entire surface. Strengthened edges are particularly important given the unique stresses placed upon a wall bed sleeping surface when folded.

Tip 4: Consider Breathability and Temperature Regulation: Opt for materials that promote airflow to prevent heat buildup during sleep. Breathable fabrics and open-cell foam structures can significantly enhance comfort, particularly in enclosed spaces.

Tip 5: Investigate Durability and Warranty: A robust construction and comprehensive warranty indicate a commitment to long-term performance. Scrutinize the materials used, seam construction, and warranty terms to assess the overall value and reliability.

Tip 6: Evaluate Firmness and Support Levels: Sleeping surfaces are available in various firmness levels to accommodate individual preferences and sleep styles. Consider factors such as body weight, preferred sleeping position, and any existing orthopedic concerns when selecting a firmness level.

These considerations are vital for maximizing the comfort, functionality, and lifespan of a wall bed system, ensuring that the sleeping surface complements the space-saving design and provides optimal sleep support.

The next section will explore the implications of these considerations on the overall user experience and long-term value of the wall bed investment.

1. Weight limitations

Weight limitations are a critical factor in the selection of a sleeping surface for wall-mounted beds. The operating mechanisms of these beds are engineered to manage specific weight ranges. Exceeding the designated weight threshold can compromise the folding system, potentially leading to operational failures, structural damage to the frame, and safety hazards. For instance, if a wall bed frame is designed to accommodate a sleeping surface up to 70 pounds, exceeding this limit by using a heavier model could strain the springs, hinges, or other components responsible for smooth opening and closing. Over time, this added stress accelerates wear and tear, increasing the risk of malfunction.

The relationship between weight and operational integrity directly impacts the longevity and safe use of the wall bed. Manufacturers typically provide detailed specifications outlining the weight restrictions for each model. Compliance with these specifications is not merely a suggestion but a fundamental requirement for maintaining warranty validity and ensuring reliable performance. Ignoring the weight limitations can invalidate the warranty, leaving the owner responsible for repair or replacement costs arising from weight-related damage. For example, if the folding mechanism fails due to using a sleeping surface that exceeds the specified weight, the manufacturer may deny coverage for the repairs.

In summary, understanding and adhering to the weight limitations of a wall bed frame is essential for safe and reliable operation. Selecting a sleeping surface that falls within the prescribed weight range mitigates the risk of mechanical failure, extends the lifespan of the system, and preserves the warranty coverage. This is a primary consideration for individuals seeking a space-saving sleeping solution without compromising on safety and long-term functionality.

2. Thickness constraints

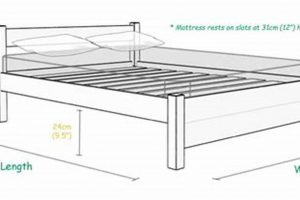

Thickness constraints are a primary consideration when selecting a sleeping surface for a wall-mounted bed. The design of these beds necessitates a specific thickness profile to allow for proper folding and storage within the cabinet or wall recess. Deviation from these prescribed dimensions can impede functionality and potentially damage the bed frame.

- Operational Clearance

The primary role of thickness constraints is to ensure adequate operational clearance within the wall bed frame. If the sleeping surface is too thick, the bed may not fully close, preventing secure latching and creating a safety hazard. For example, a frame designed for a 10-inch thick sleeping surface will likely encounter operational issues if paired with a 12-inch model. This can manifest as difficulty in closing, undue stress on the hinges, or even an inability to lock the bed in the closed position. Consequently, observing the specified maximum thickness is crucial for the smooth and safe operation of the wall bed.

- Cabinet Depth Limitations

Wall beds are typically housed within a cabinet or recess, the depth of which dictates the maximum allowable thickness of the sleeping surface. Using a thicker product than the cabinet’s depth allows results in protrusion, preventing the cabinet doors from closing properly. This can affect the aesthetic appeal of the furniture and potentially expose the sleeping surface to dust and damage when not in use. A common example is a wall bed cabinet designed with a limited depth to maximize floor space. Selecting a thinner sle

eping surface becomes necessary to maintain the streamlined profile of the closed cabinet. - Folding Mechanism Stress

An excessively thick sleeping surface places undue stress on the folding mechanism of a wall bed. This added stress can accelerate wear and tear on the hinges, springs, and other moving parts, leading to premature failure and costly repairs. For instance, if a folding mechanism is engineered for a sleeping surface of a specific weight and thickness, exceeding these parameters creates a mechanical disadvantage, increasing the force required for operation. Over time, this increased force weakens the structural integrity of the mechanism, potentially resulting in breakage or malfunction.

- Mattress Retention Systems

Many wall bed systems incorporate retention straps or other mechanisms to secure the sleeping surface during folding and storage. These retention systems are designed to accommodate a specific range of thicknesses. Using a product that is too thick can prevent the retention system from functioning effectively, allowing the product to shift or become dislodged during folding. This can not only damage the surface itself but also pose a risk of injury if it falls out of the frame during operation. Therefore, compatibility with the retention system is a crucial aspect of thickness constraints.

In conclusion, thickness constraints are an integral design consideration in the context of sleeping surfaces for wall-mounted beds. Adhering to the manufacturer’s specifications regarding thickness ensures smooth operation, prevents damage to the frame, maintains the aesthetic integrity of the furniture, and promotes the long-term durability and safety of the entire wall bed system. Ignoring these constraints can lead to operational difficulties, increased maintenance costs, and potential safety hazards.

3. Folding mechanism compatibility

The functional efficacy of a wall-mounted bed is intrinsically linked to the compatibility between its folding mechanism and the selected sleeping surface. The intricate interplay between these components dictates the ease of operation, longevity, and overall performance of the system. Selecting an unsuitable product can lead to operational difficulties, accelerated wear, and potential safety concerns.

- Weight Distribution and Balance

The folding mechanism is designed to manage a specific weight distribution. A product that concentrates weight unevenly can create imbalances, leading to jerky or strained operation. For instance, a hybrid model with a dense innerspring core and a lightweight foam layer may place undue stress on certain points of the mechanism, particularly during the initial stages of folding or unfolding. Even weight distribution across the surface ensures smooth and controlled movement, minimizing strain and extending the lifespan of the system.

- Compression and Flexibility

The ability of the sleeping surface to compress and flex during the folding process is critical. Overly rigid models can resist bending, potentially damaging the frame or hindering complete closure. Conversely, a model that is too flexible may buckle or sag, interfering with the mechanism’s functionality. An optimal model exhibits a balance of compressibility and support, allowing it to conform to the folding arc without compromising its structural integrity. For example, a memory foam model with moderate density can offer the necessary flexibility without sacrificing support, ensuring seamless operation.

- Profile Consistency

The consistency of the sleeping surface profile across its entire area is crucial for smooth interaction with the locking and support structures of the folding mechanism. Variations in thickness or density can create uneven contact points, leading to instability or difficulty in securing the bed in either the open or closed position. A model with a uniform profile ensures consistent engagement with the frame, promoting stability and preventing unwanted movement or shifting. This is particularly important for wall beds that rely on locking mechanisms to maintain their position during use or storage.

- Material Resilience and Durability

The material composition and overall durability of the sleeping surface directly impact its ability to withstand the repeated stresses associated with folding and unfolding. Models constructed from substandard materials may degrade rapidly, losing their shape and support over time. This degradation can compromise the folding mechanism by creating slack or interfering with its alignment. A model built with high-quality, resilient materials ensures long-term performance and minimizes the risk of operational issues. For example, a latex model with reinforced edges is more likely to maintain its structural integrity and support the folding mechanism effectively over years of use.

The interplay between these factors underscores the importance of selecting a sleeping surface that is specifically designed for use within a wall-mounted bed system. Careful consideration of weight distribution, compression characteristics, profile consistency, and material durability ensures seamless folding mechanism compatibility, maximizing the longevity, safety, and overall performance of the wall bed.

4. Support and Comfort

The selection of a sleeping surface for a wall-mounted bed necessitates a meticulous evaluation of both support and comfort characteristics. These attributes are not mutually exclusive but rather intertwined elements that contribute to the overall quality of sleep and the long-term viability of the system.

- Firmness and Spinal Alignment

The firmness of a sleeping surface directly impacts spinal alignment, a crucial factor in preventing back pain and promoting restful sleep. A model that is too soft may allow the spine to sag, while one that is too firm may create pressure points. The ideal firmness level provides adequate support to maintain the natural curvature of the spine, regardless of sleeping position. For example, a medium-firm model often strikes a balance, accommodating both back and side sleepers. The impact of firmness on spinal alignment is amplified in a wall bed setting, where space constraints may limit the user’s ability to adjust their sleeping position throughout the night.

- Pressure Relief and Circulation

Effective pressure relief minimizes stress on joints and promotes healthy blood circulation. Areas such as the shoulders, hips, and knees are particularly susceptible to pressure buildup, especially during prolonged periods of rest. Materials like memory foam and latex conform to the body’s contours, distributing weight more evenly and reducing pressure points. For instance, a latex model’s responsiveness can prevent the “numbness” or discomfort that may arise from prolonged pressure on a particular area. This attribute is particularly important in a wall bed, where the user may be more likely to maintain a single sleeping position due to the confined space.

- Material Breathability and Temperature Regulation

The breathability of the sleeping surface material plays a pivotal role in temperature regulation, preventing overheating and promoting a comfortable sleep environment. Materials like open-cell foam a

nd natural fibers allow for increased airflow, dissipating heat and moisture. Conversely, synthetic materials with poor breathability can trap heat, leading to discomfort and restlessness. A model with enhanced breathability, such as one incorporating a gel-infused memory foam layer, can significantly improve sleep quality, especially in warmer climates or for individuals prone to night sweats. Given the often-enclosed nature of wall bed systems, prioritizing breathability is essential. - Edge Support and Usable Surface Area

Adequate edge support maximizes the usable sleeping surface area and prevents the sensation of rolling off the bed. Reinforced edges provide stability and prevent sagging, ensuring consistent comfort across the entire surface. This is particularly important in wall beds, where space is often at a premium, and users may rely on the full width of the surface. A model with robust edge support, such as one featuring reinforced coils or a high-density foam border, provides a more secure and comfortable sleeping experience.

The integration of these support and comfort elements is paramount in optimizing the sleep experience within a wall-mounted bed system. Selecting a model that addresses these considerations ensures not only a comfortable night’s rest but also contributes to the long-term health and well-being of the user. The choice of the sleeping surface, therefore, represents a critical investment in both space-saving functionality and restful sleep.

5. Durability and Longevity

The durability and longevity of a sleeping surface designed for use in a wall-mounted bed represent critical determinants of its long-term value and performance. These characteristics directly influence the lifespan of the product and its ability to withstand the unique stresses associated with regular folding and unfolding.

- Material Composition and Resilience

The inherent properties of the materials used in construction significantly impact resistance to wear and tear. High-density foams, robust innerspring systems, and tightly woven fabrics contribute to a product’s ability to withstand repeated compression and flexing without degradation. For instance, a sleeping surface incorporating high-density latex exhibits greater resistance to compression set compared to a model utilizing lower-density polyurethane foam. In the context of wall beds, where the sleeping surface is subjected to frequent folding, material resilience is paramount for maintaining its original shape and support over time. Compromised material integrity translates directly to diminished comfort and increased susceptibility to sagging.

- Construction Techniques and Reinforcement

The methods employed in assembling the sleeping surface play a crucial role in enhancing its structural integrity and resistance to deformation. Reinforced seams, robust edge supports, and strategically placed quilting patterns distribute stress and prevent premature wear. As an example, a model featuring a perimeter edge support system is better equipped to resist sagging along the edges, a common point of failure in wall bed systems. These construction details contribute to the overall dimensional stability, ensuring that the product retains its shape and support characteristics despite repeated folding and unfolding cycles. Inferior construction techniques can lead to seam failures, material shifting, and a shortened lifespan.

- Resistance to Compression and Sagging

The ability of a sleeping surface to resist compression and sagging under repeated use is essential for maintaining consistent comfort and support. Models with superior resistance to compression retain their loft and firmness over time, preventing the formation of body impressions and ensuring proper spinal alignment. For instance, an innerspring model with individually wrapped coils is more effective at distributing weight and minimizing localized compression compared to a traditional open-coil system. The consequences of sagging extend beyond mere discomfort; they can compromise spinal alignment, exacerbate back pain, and necessitate premature replacement.

- Warranty Coverage and Performance Guarantees

The terms and duration of a sleeping surface warranty serve as an indicator of the manufacturer’s confidence in its durability and longevity. Comprehensive warranties that cover sagging, structural defects, and material degradation provide consumers with assurance and recourse in the event of premature failure. A warranty that specifically addresses the unique stresses associated with wall bed usage demonstrates a commitment to performance in this particular application. Conversely, limited warranties or exclusions for wall bed usage may signal concerns regarding the product’s suitability for such applications. A thorough review of warranty terms is essential for making an informed purchasing decision.

In summation, the durability and longevity of a wall-mounted bed sleeping surface are multifaceted attributes governed by material selection, construction techniques, resistance to compression, and warranty provisions. Prioritizing these factors during the selection process is crucial for ensuring a long-lasting, comfortable, and supportive sleep experience within the confines of a space-saving wall bed system.

Frequently Asked Questions

The following section addresses common inquiries regarding the selection, usage, and maintenance of sleeping surfaces designed specifically for wall-mounted bed systems. These questions are intended to provide clarity and assist in making informed decisions.

Question 1: Are standard sleeping surfaces suitable for use in wall-mounted bed frames?

Standard sleeping surfaces may not be optimal for wall bed use due to weight and thickness constraints. Compatibility hinges on adhering to the frame manufacturer’s specifications. Using a standard model without verification can compromise the folding mechanism.

Question 2: What sleeping surface types are generally recommended for wall bed applications?

Sleeping surfaces utilizing memory foam, latex, or hybrid constructions with moderate profile heights are often recommended. These materials offer a balance of support, compressibility, and weight, facilitating smooth operation of the wall bed.

Question 3: How does sleeping surface thickness affect the functionality of a wall bed system?

Excessive thickness can impede the folding and closure of the wall bed, potentially damaging the frame or preventing secure latching. Always adhere to the maximum thickness specified by the wall bed manufacturer.

Question 4: Is it necessary to use specific straps or retention systems to secure the sleeping surface within a wall bed frame?

Retention straps or similar systems are often essential for preventing the sleeping surface from shifting or dislodging during folding and storage. Verify that the retention system is compatible with the selected model.

Question 5: How can the lifespan of a wall bed sleeping surface be maximized?

Regular rotation, proper support within the frame, and adherence to weight limits contribute to extended longevity. Avoiding excessive stress on the surface during folding and storage is also recommended.

Question 6: Are there specific warranty considerations for sleeping surfaces used in wall bed systems?

Some warranties may exclude coverage for sleeping surfaces used in wall beds. Th

oroughly review the warranty terms to ascertain whether the product is suitable for this application and what specific issues are covered.

In summary, careful consideration of weight, thickness, material composition, and warranty provisions is crucial for selecting a suitable sleeping surface for a wall bed. Adherence to manufacturer specifications is paramount for ensuring optimal performance and longevity.

The next section will explore the impact of sleeping surface selection on the overall user experience of a wall bed system.

Concluding Remarks on Sleeping Surfaces for Wall Beds

The preceding analysis underscores the critical nature of selecting an appropriate “mattress for murphy bed.” Key considerations include adherence to weight and thickness constraints, compatibility with the folding mechanism, and a focus on both support and durability. Neglecting these factors can result in operational impairments, compromised comfort, and a reduced lifespan for the entire wall bed system.

The investment in a compatible sleeping surface translates directly to enhanced functionality, improved user experience, and long-term cost savings. Prudent selection, guided by manufacturer specifications and an understanding of material properties, ensures that the wall bed serves as a reliable and comfortable space-saving solution for years to come. Continued adherence to maintenance guidelines further safeguards this investment.