Protective encasements designed for healthcare facility mattresses offer a crucial barrier against fluids, pathogens, and allergens. These specialized coverings are typically constructed from durable, impermeable materials like vinyl or polyurethane, ensuring easy cleaning and disinfection between patients. A typical example would be a fitted, zippered encasement protecting a medical-grade mattress from spills and microbial growth.

The use of these coverings is paramount in maintaining hygiene and preventing the spread of healthcare-associated infections (HAIs). They contribute significantly to patient safety by minimizing the risk of cross-contamination. Historically, less effective methods were employed, highlighting the advancements in material science and infection control that have led to the development and widespread adoption of these essential healthcare products.

Subsequent sections will delve into the specific types of materials used in their construction, the different closure mechanisms available, and the regulatory standards that govern their use in healthcare settings. Furthermore, the economic impact and the best practices for cleaning and maintenance will be examined to provide a comprehensive understanding of their role in modern healthcare.

Guidance on Healthcare Mattress Protection

The following provides practical advice on the selection, utilization, and maintenance of protective mattress encasements within a medical environment, ensuring optimal hygiene and longevity of equipment.

Tip 1: Material Selection: Prioritize encasements constructed from fluid-impermeable, antimicrobial materials such as vinyl or polyurethane. These materials prevent liquid penetration and inhibit microbial growth, vital for infection control.

Tip 2: Seam Integrity: Inspect seams meticulously. Welded or sonically sealed seams are preferable to sewn seams, minimizing potential breaches where contaminants can accumulate.

Tip 3: Zippered Closure Systems: Opt for zippered closures with a concealed or protected zipper track. This feature prevents fluid ingress and protects the zipper mechanism from damage during cleaning.

Tip 4: Cleaning Protocol Adherence: Strictly adhere to the manufacturer’s recommended cleaning protocols. Utilize approved disinfectants and cleaning agents to effectively eliminate pathogens without degrading the encasement material.

Tip 5: Regular Inspection: Implement a routine inspection schedule to identify any signs of damage, such as tears, punctures, or seam separation. Promptly replace compromised encasements to maintain barrier integrity.

Tip 6: Proper Storage: When not in use, store encasements in a clean, dry environment to prevent mold growth and material degradation. Avoid stacking heavy items on top of stored encasements, as this can cause deformation.

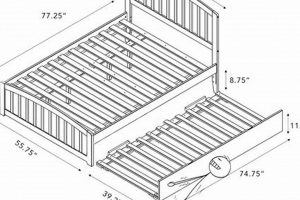

Tip 7: Compatibility Verification: Ensure the selected encasement is appropriately sized for the specific mattress dimensions. An ill-fitting encasement can compromise its protective function and reduce its lifespan.

Implementing these measures will significantly enhance infection control efforts, extend the life of medical mattresses, and ultimately contribute to a safer patient environment.

The subsequent section will address advanced cleaning techniques and emerging technologies in mattress protection.

1. Impermeability

Impermeability stands as a foundational attribute of effective healthcare mattress coverings. The primary purpose of these encasements is to prevent the ingress of fluids, including bodily fluids, cleaning agents, and other contaminants. Should these substances penetrate the covering, they can saturate the mattress core, creating a breeding ground for bacteria, fungi, and viruses. This compromises the hygiene of the medical environment, elevating the risk of healthcare-associated infections (HAIs). For example, a covering lacking sufficient impermeability may allow blood or urine to seep into the mattress following an incident, necessitating costly mattress replacement and posing a potential health hazard to subsequent patients.

The materials used in manufacturing these coverings directly determine their level of impermeability. Polyurethane-coated fabrics and vinyl are commonly employed due to their inherent fluid resistance. However, the integrity of the seams and closures also plays a crucial role. Seams must be welded or sonically sealed rather than stitched to prevent fluid passage. Similarly, zippers, if present, require a protective flap or waterproof design to maintain a complete barrier. The selection process should prioritize materials that meet stringent impermeability standards, often measured through hydrostatic resistance testing. An example of a practical application is selecting coverings rated to withstand a certain pressure level, ensuring they remain impermeable even under the weight and movement of a patient.

In summary, impermeability is not merely a desirable feature; it is an indispensable characteristic of healthcare mattress coverings. Its effectiveness directly influences infection control, patient safety, and the longevity of the mattress itself. The challenge lies in maintaining impermeability over time, as repeated cleaning and disinfection can degrade certain materials. Therefore, a comprehensive strategy, encompassing material selection, proper maintenance protocols, and regular inspection, is essential to ensure sustained performance and protection.

2. Antimicrobial properties

Antimicrobial properties in medical mattress encasements serve as a critical defense against the proliferation of microorganisms. The presence of such properties inhibits the growth of bacteria, fungi, and viruses on the surface of the covering. This is especially crucial in healthcare settings where patients may be immunocompromised or susceptible to infection. The cause-and-effect relationship is straightforward: the introduction of antimicrobial agents into the encasement material leads to a reduction in microbial load on the surface, thereby minimizing the risk of transmission. An example of this is the incorporation of silver ions into the fabric of the covering, which disrupt the metabolic processes of bacteria, leading to their inactivation.

The importance of antimicrobial properties lies in their contribution to infection control efforts. While regular cleaning and disinfection are essential, antimicrobial properties provide an additional layer of protection, particularly between cleaning cycles or in areas that are difficult to reach. Consider a situation where a small amount of fluid contaminates the covering. Even if the area is not immediately cleaned, the antimicrobial agents present will begin to inhibit the growth of any microorganisms present in the fluid. This active protection helps to reduce the risk of c

ross-contamination and the spread of healthcare-associated infections (HAIs). Some encasements also incorporate copper or other metallic compounds with inherent antimicrobial benefits.

In summary, the integration of antimicrobial properties into healthcare mattress coverings is a vital component of modern infection prevention strategies. It provides a proactive defense against microbial growth, complementing routine cleaning practices. The long-term challenge involves maintaining the efficacy of these properties, as some microorganisms may develop resistance over time. Future research should focus on developing new antimicrobial agents and delivery methods to ensure the continued effectiveness of these protective encasements, contributing to a safer environment for both patients and healthcare professionals.

3. Seam Integrity

Seam integrity is a paramount consideration in the performance of medical mattress encasements. The seams, where different sections of the material are joined, represent potential vulnerabilities in the barrier against fluids and microorganisms. Compromised seam integrity can negate the protective functions of the entire covering, leading to contamination and increased infection risks.

- Types of Seam Construction

Various seam construction techniques exist, each offering different levels of durability and impermeability. Sewn seams, while common in textiles, are generally less suitable for medical environments due to the needle perforations creating pathways for fluid ingress. Welded seams, achieved through thermal or ultrasonic bonding, fuse the material together, creating a continuous, impermeable barrier. Sonically sealed seams offer a similar benefit by using high-frequency sound waves to fuse the material at a molecular level. The choice of seam construction significantly impacts the overall performance and longevity of the covering.

- Resistance to Stress and Wear

Medical mattress encasements are subjected to repeated stress from patient movement, cleaning procedures, and disinfection protocols. Seams must withstand these stresses without separating or weakening. The tensile strength of the seam is a critical indicator of its ability to resist tearing or splitting. Additionally, the seam must resist degradation from chemical exposure during cleaning and disinfection. For example, repeated exposure to harsh disinfectants can weaken sewn seams over time, while welded seams tend to maintain their integrity under similar conditions.

- Impact on Infection Control

The primary function of a mattress encasement is to prevent fluids and microorganisms from reaching the mattress core. A breach in seam integrity creates a direct pathway for contaminants, compromising the infection control measures in place. Even microscopic openings can harbor bacteria and fungi, leading to the potential for cross-contamination between patients. Regular inspection of seams is essential to identify any signs of damage, such as fraying, separation, or discoloration, which may indicate a loss of integrity. Damaged coverings must be promptly replaced to maintain a safe and hygienic environment.

- Regulatory Compliance

Healthcare facilities are subject to stringent regulations regarding infection control and patient safety. These regulations often specify requirements for mattress coverings, including standards for impermeability and seam strength. Compliance with these regulations necessitates careful selection of coverings that meet or exceed the established benchmarks. Manufacturers typically provide technical specifications and testing data to demonstrate compliance with relevant standards. Regular audits and inspections may be conducted to ensure ongoing adherence to these requirements.

The interconnectedness of seam integrity with overall hygiene makes it a crucial factor in the selection and maintenance of medical mattress coverings. The combination of appropriate seam construction, resistance to stress and wear, and its direct impact on infection control underscores its importance in preventing contamination. Attention to these facets results in a more effective barrier system, promoting patient safety and regulatory compliance.

4. Durability

Durability, in the context of medical mattress encasements, refers to the ability of the material and construction to withstand repeated use, cleaning, disinfection, and potential exposure to a range of fluids and chemicals over an extended period. This characteristic is crucial for maintaining the integrity and protective function of the covering, ultimately impacting patient safety and cost-effectiveness for healthcare facilities.

- Material Resistance to Degradation

The inherent properties of the materials used in encasement construction directly influence durability. Vinyl and polyurethane, commonly employed, exhibit varying degrees of resistance to tearing, abrasion, and chemical degradation. For example, a high-grade polyurethane encasement may withstand hundreds of cleaning cycles with harsh disinfectants before showing signs of wear, while a lower-quality vinyl covering might crack or delaminate after significantly fewer exposures. The selection of materials with demonstrated resistance to degradation is essential for long-term performance.

- Seam Strength and Construction Integrity

As previously addressed, the seams of an encasement represent potential weak points. Durability hinges on the seam’s ability to withstand stress and maintain its integrity throughout the covering’s lifespan. Welded or sonically sealed seams generally exhibit superior durability compared to sewn seams, as they eliminate stitch holes that can weaken over time. An example would be a welded seam maintaining its fluid-proof seal even after repeated flexing and stretching, whereas a sewn seam might begin to fray and allow fluid penetration under similar conditions.

- Resistance to Puncture and Tearing

Medical mattress encasements are susceptible to accidental punctures or tears from sharp objects or patient movement. The material’s resistance to these types of damage is a critical factor in its overall durability. For instance, a thicker, reinforced material may resist tearing if snagged, while a thinner, less robust material might tear easily, compromising its protective function. Similarly, the presence of a zipper requires robust construction around the zipper track to prevent it from separating or tearing away from the encasement.

- Long-Term Cost-Effectiveness

While initial cost is a consideration, the long-term cost-effectiveness of a medical mattress encasement is directly tied to its durability. A more durable covering may have a higher upfront cost but can provide significant savings over time by reducing the frequency of replacements. For example, a facility that invests in high-quality, durable encasements may avoid the costs associated with replacing damaged or compromised coverings, as well as the potential expenses related to infection control breaches resulting from ineffective coverings. This makes durability a vital element in the total cost of ownership for these healthcare products.

In conclusion, the durability of medical mattress encasements encompasses multiple facets, from material resistance to seam strength and puncture resistance. Considering these fa

ctors in the selection process ensures that the chosen coverings provide long-lasting protection, contribute to a safer patient environment, and represent a sound investment for healthcare facilities. The importance of the right hospital bed covers for the mattress can also increase profitability.

5. Cleanability

Cleanability is a primary determinant in the selection and maintenance of mattress coverings within healthcare settings. The ease and effectiveness with which these coverings can be cleaned and disinfected directly impacts infection control, patient safety, and operational efficiency. Imperfect cleanability can compromise the integrity of the covering and contribute to the spread of healthcare-associated infections (HAIs).

- Material Compatibility with Disinfectants

The ability of a covering material to withstand repeated exposure to hospital-grade disinfectants without degradation is crucial. Some materials may react negatively with certain chemicals, leading to cracking, discoloration, or loss of impermeability. Testing the material’s compatibility with commonly used disinfectants ensures its long-term effectiveness. For instance, a covering that becomes brittle after repeated cleaning with bleach is unsuitable for a healthcare environment.

- Surface Texture and Smoothness

A smooth, non-porous surface facilitates easier and more thorough cleaning. Textured or porous surfaces can trap contaminants, making complete disinfection challenging. A smooth surface allows cleaning agents to make full contact with the material, effectively removing dirt and pathogens. An example is a comparison between a smooth vinyl covering, which can be wiped clean with a single pass, and a textured fabric covering, which may require more rigorous scrubbing and multiple passes to achieve adequate disinfection.

- Seam Construction and Cleanability

Seams represent potential areas for contaminant accumulation, and their design directly impacts cleanability. Welded or sonically sealed seams minimize crevices where pathogens can hide, facilitating easier disinfection. Sewn seams, with their stitch holes, can trap debris and make thorough cleaning more difficult. The advantage of a welded seam is its seamless surface, which allows for effortless wiping and disinfection, compared to the crevices associated with a sewn seam.

- Resistance to Staining and Residue

The ability of a covering to resist staining from bodily fluids, medications, and other substances contributes to its cleanability and aesthetic appeal. Materials that readily stain require more aggressive cleaning methods, potentially damaging the covering. Additionally, some cleaning agents may leave behind a residue that can attract dirt and pathogens. A covering that remains stain-free after routine cleaning not only enhances its appearance but also simplifies the disinfection process, ensuring a cleaner and safer environment.

Collectively, these facets of cleanability underscore its central role in the selection and maintenance of healthcare mattress coverings. Cleanability is a crucial aspect of the hospital bed covers for the mattress. Prioritizing materials and construction techniques that facilitate easy and effective cleaning directly contributes to infection control efforts, patient safety, and the longevity of the investment in these essential healthcare products.

6. Fit

The term “fit,” when applied to medical mattress coverings, denotes the degree to which the encasement conforms to the dimensions and contours of the mattress. An accurate fit is not merely a matter of aesthetics; it is a fundamental requirement for ensuring the covering’s protective capabilities. A poorly fitting encasement, whether too loose or too tight, can compromise its primary functions of fluid impermeability, antimicrobial protection, and overall hygiene. An ill-fitting cover will not perform its protection tasks.

A loose-fitting cover creates folds and creases that can trap fluids and debris, rendering effective cleaning and disinfection nearly impossible. These crevices provide a breeding ground for microorganisms, increasing the risk of healthcare-associated infections. Conversely, an overly tight cover can stretch the material beyond its intended limits, compromising its structural integrity and potentially leading to tears or seam failure. A properly fitted cover, in contrast, provides a smooth, taut surface that is easily cleaned and disinfected, while maintaining its barrier properties. For instance, a properly sized, zippered encasement will completely enclose the mattress, leaving no exposed areas or loose fabric, thus minimizing the risk of contamination.

The practical significance of understanding the critical role of fit lies in its direct impact on patient safety and the overall cost-effectiveness of healthcare operations. A properly fitted and well-maintained mattress covering extends the lifespan of the mattress, reduces the need for frequent replacements, and minimizes the risk of infection-related complications. While the initial cost of a high-quality, properly sized encasement may be higher, the long-term savings in terms of reduced infection rates and equipment replacement costs make it a worthwhile investment. Ensuring the correct size and type are selected is the most important step.

Frequently Asked Questions

The following addresses common inquiries regarding mattress coverings used in healthcare environments, providing clarity on selection, usage, and maintenance.

Question 1: What materials are most suitable for hospital mattress encasements?

Acceptable materials include fluid-impermeable options such as vinyl or polyurethane-coated fabrics. These materials must withstand repeated cleaning and disinfection without degradation.

Question 2: How frequently should medical mattress coverings be cleaned?

Coverings should be cleaned and disinfected between each patient use and immediately following any fluid contamination. Adherence to the manufacturer’s recommended cleaning protocols is essential.

Question 3: How can seam integrity be assessed in a hospital mattress cover?

Inspect seams visually for any signs of separation, fraying, or damage. Welded or sonically sealed seams are preferable to sewn seams, which are more prone to failure.

Question 4: What are the key features to consider when selecting a zippered mattress encasement?

Zippered encasements should feature a concealed or protected zipper track to prevent fluid ingress. The zipper material should be durable and resistant to corrosion from cleaning agents.

Question 5: How does the fit of a mattress covering impact its effectiveness?

A properly fitting covering provides a taut, smooth surface that is easy to clean and disinfect. Loose-fitting covers can trap fluids and debris, compromising hygiene.

Question 6: What is the typical lifespan of a medical mattress encasement?

The lifespan varies depending on the material, usage, and maintenance practices. Regular inspection and prompt replacement of damaged coverings are crucial for maintaining barrier integrity.

Proper implementation of these principles ensures the ongoing safety and hygiene of patient care environments

.

The subsequent section will explore advancements and emerging technologies related to mattress protection.

Conclusion

This exploration of hospital bed covers for mattresses has underscored their critical role in healthcare settings. Key attributes such as impermeability, antimicrobial properties, seam integrity, durability, cleanability, and proper fit have been examined in detail, highlighting their individual and collective contributions to infection control and patient safety. The selection and maintenance of these protective encasements are not merely procedural tasks, but essential components of a comprehensive strategy to mitigate risks associated with healthcare-acquired infections.

The continued vigilance in adopting and adhering to best practices concerning hospital bed covers for mattresses remains paramount. The implementation of stringent protocols, coupled with ongoing research into advanced materials and technologies, will further enhance the effectiveness of these protective barriers, contributing to a safer and more hygienic healthcare environment for both patients and providers. The appropriate selection is essential.