A large, airtight enclosure designed for the storage and transportation of oversized bedding. These enclosures utilize vacuum technology to compress the contents, significantly reducing volume. For instance, a bulky bed covering can be flattened to a more manageable form, facilitating easier handling.

Such compression offers several advantages. It minimizes storage space requirements, protecting against dust mites, moisture, and other environmental factors that can degrade fabric quality. Historically, methods for managing bulky textiles were cumbersome; the introduction of these vacuum-sealed solutions represented a significant advancement in storage efficiency and preservation.

The following sections will detail the construction materials, optimal usage techniques, and considerations for selecting an appropriate vacuum-sealed storage solution for oversized bedding items.

Maximizing the Utility of Vacuum-Sealed Bedding Storage

The subsequent guidelines aim to optimize the use of compression enclosures for oversized mattresses and bedding, ensuring effective storage and prolonged material integrity.

Tip 1: Selection of Appropriate Dimensions: Prior to purchase, accurately measure the mattress or bedding. An enclosure of insufficient size will compromise the sealing process, negating its protective benefits.

Tip 2: Thorough Cleaning and Drying: Bedding should be meticulously cleaned and completely dried before sealing. Residual moisture encourages mold and mildew growth, potentially damaging the stored materials.

Tip 3: Proper Folding and Placement: Fold items neatly to minimize wrinkles and ensure uniform compression. Distribute weight evenly within the enclosure to prevent stress points that could lead to tears.

Tip 4: Adherence to Sealing Instructions: Carefully follow the manufacturer’s instructions for sealing. Incorrect sealing compromises airtight integrity, rendering the protective function ineffective.

Tip 5: Controlled Vacuum Application: Utilize a vacuum cleaner with appropriate suction power. Excessive suction can damage delicate materials; gradual compression is recommended.

Tip 6: Periodic Inspection and Re-Sealing: Routinely inspect the enclosure for leaks or tears. Over time, minor punctures may occur. Promptly re-seal or replace damaged enclosures to maintain optimal protection.

Tip 7: Strategic Storage Location: Store sealed enclosures in a cool, dry environment, away from direct sunlight and extreme temperature fluctuations. These conditions can degrade the materials of both the enclosure and its contents.

Adherence to these guidelines promotes efficient storage, safeguarding against environmental damage and maximizing space utilization. Proper execution extends the lifespan of stored bedding, preserving its quality and hygiene.

The concluding section will address common issues encountered during vacuum-sealed storage and provide troubleshooting strategies.

1. Dimensions

The dimensions of a mattress vacuum bag are critical to its successful utilization for king-size mattresses. Precise measurements dictate whether the mattress can be adequately enclosed and effectively compressed, impacting storage efficiency and protection.

- Length and Width Compatibility

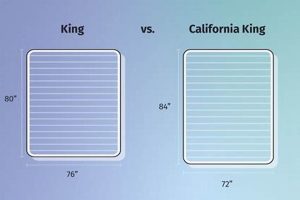

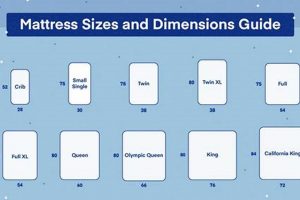

The bag’s internal length and width must accommodate the full dimensions of a standard king-size mattress (typically 76 inches wide by 80 inches long). Insufficient dimensions prevent complete enclosure, rendering the vacuum seal ineffective and leaving portions of the mattress exposed to environmental elements. Excessively large dimensions may lead to inefficient compression and wasted space.

- Gusset and Depth Considerations

The bag’s gusset, or depth, is another vital dimension. It determines the bag’s capacity to accommodate the mattress’s thickness. A bag with insufficient depth will struggle to fully encapsulate thicker mattresses, hindering the vacuum sealing process. Manufacturers often specify a maximum mattress thickness for their bags, which should be carefully considered.

- Impact on Vacuum Sealing Efficiency

Dimensional discrepancies between the bag and the mattress affect the vacuum sealing process. A bag that is too small creates excessive stress on the seams, increasing the risk of tearing during vacuuming. Conversely, a bag that is too large introduces excess air volume, prolonging the vacuuming process and potentially reducing the overall compression achieved.

- Influence on Storage Space Optimization

Appropriate dimensions directly correlate to optimized storage space. A properly sized bag, when vacuum-sealed, minimizes the mattress’s overall volume, allowing for more efficient storage in closets, storage units, or other confined spaces. In contrast, an improperly sized bag may not achieve adequate compression, negating the space-saving benefits.

Therefore, meticulous attention to the dimensions of the bag in relation to the specific measurements of the king-size mattress is paramount. Selecting a bag with compatible dimensions ensures effective vacuum sealing, optimal storage space utilization, and enhanced protection of the mattress from environmental factors.

2. Material Strength

The material strength of a mattress vacuum bag is intrinsically linked to its performance and longevity. This characteristic determines the bag’s ability to withstand the stresses inherent in the vacuum compression process and subsequent storage. A bag constructed from weak or substandard material is susceptible to tearing or puncturing under the pressure of a vacuum, negating its intended purpose of compression and protection. For example, a bag made from thin polyethylene may readily tear at the seams or develop holes when subjected to the edges or corners of a mattress, rendering it useless and exposing the mattress to potential damage. Consequently, material strength directly influences the effectiveness of the product.

The practical significance of understanding material strength is threefold. First, it informs purchasing decisions, enabling consumers to select bags with sufficient durability to meet their storage needs. Second, it impacts handling practices; users are more likely to exercise caution when handling a bag known to be less robust. Third, it influences expectations regarding the bag’s lifespan; a bag constructed from high-strength material is reasonably expected to provide extended service compared to one made from a thinner, more fragile material. For instance, bags utilizing multiple layers of reinforced nylon or polyethylene offer greater resistance to puncture and tearing, ensuring the long-term integrity of the vacuum seal and the protection of the mattress within.

In conclusion, the material strength of a mattress

vacuum bag is a crucial determinant of its overall utility and reliability. Selecting a bag with appropriate material strength ensures effective compression, safeguards against environmental factors, and extends the lifespan of both the bag and the stored mattress. While higher material strength typically correlates with a higher initial cost, the investment is often justified by the increased protection and extended durability afforded. The challenge lies in accurately assessing material strength based on product specifications and user reviews, necessitating a discerning approach to selection.

3. Sealing Mechanism

The sealing mechanism constitutes a critical component of a vacuum bag designed for storing king-size mattresses. It directly influences the bag’s ability to maintain a vacuum, safeguarding the mattress from environmental factors and maximizing space efficiency. The integrity of the seal dictates the overall effectiveness of the storage solution.

- Zipper Closure Systems

Many vacuum bags incorporate zipper closures, often augmented with a slider to facilitate secure sealing. These zippers typically feature interlocking teeth that, when properly engaged, create an airtight barrier. However, the effectiveness of zipper closures is contingent on the quality of the zipper material, the precision of the teeth alignment, and the user’s diligence in ensuring complete closure. A compromised zipper closure can lead to gradual air leakage, diminishing the vacuum and potentially exposing the mattress to moisture, dust, and pests. Examples include double-zipper systems that enhance security and durability.

- Valve Design and Functionality

The valve serves as the interface for vacuuming the air out of the bag. Its design directly impacts the ease and efficiency of the vacuuming process and the long-term maintenance of the vacuum seal. A well-designed valve allows for rapid evacuation of air without permitting backflow. Common valve types include single-way valves with caps or integrated flaps that prevent air reentry. The valve material must be durable and resistant to deformation to ensure consistent sealing performance. Valve failures are a primary cause of vacuum loss in these storage bags.

- Material Compatibility and Seal Integrity

The material used in the bag’s construction must be compatible with the sealing mechanism to ensure a reliable and lasting seal. If the material is too rigid or too prone to stretching, it may not conform adequately to the sealing surfaces, resulting in air gaps and vacuum leakage. The seal integrity is also influenced by the pressure applied during the sealing process; insufficient pressure may result in an incomplete seal, while excessive pressure could damage the bag material or the sealing mechanism itself. High-quality bags often utilize multi-layered materials that provide both flexibility and strength, optimizing seal integrity.

- Testing and Quality Control Standards

The reliability of the sealing mechanism is dependent on rigorous testing and adherence to quality control standards during the manufacturing process. These standards often involve subjecting the bags to pressure tests, leak tests, and durability tests to ensure that they can withstand the stresses of repeated use and long-term storage. Bags that have undergone thorough testing and certification are more likely to provide consistent and reliable sealing performance. Independent certification marks can offer assurance of product quality and adherence to industry standards.

In summary, the sealing mechanism is a critical determinant of a vacuum bag’s suitability for king-size mattress storage. The selection of a bag with a robust and well-designed sealing mechanism, coupled with careful adherence to sealing instructions, is essential for maximizing the benefits of vacuum compression and protecting the mattress from environmental damage. Compromises in sealing integrity will undermine the entire storage strategy.

4. Vacuum Compatibility

Vacuum compatibility, in the context of a king size mattress vacuum bag, refers to the design features and material properties that enable the bag to be effectively evacuated of air using standard vacuum cleaner equipment. This compatibility is crucial for achieving the desired compression and airtight seal, thereby maximizing storage space and protecting the mattress from environmental contaminants.

- Valve Design and Adaptability

The valve is the primary interface between the bag and the vacuum cleaner. Its design must accommodate common vacuum cleaner hose attachments, ensuring a secure and airtight connection. Universal valve designs are preferable, as they eliminate the need for specialized adapters. The valve material should also be robust enough to withstand repeated vacuuming without cracking or deforming, which could compromise the seal. An example is a two-way valve allowing quick air extraction without backflow.

- Material Permeability and Airflow

The bag material itself must exhibit minimal air permeability to maintain the vacuum seal once established. However, it should also allow for efficient airflow during the vacuuming process to facilitate rapid compression. Balancing these two properties requires careful selection of materials with appropriate porosity and thickness. Bags constructed from multi-layered polyethylene blends often strike this balance effectively, offering both durability and efficient air evacuation. A bag constructed from high-density material should also offer the advantage of increased strength.

- Bag Size and Volume Considerations

The overall size and volume of a king size mattress vacuum bag directly influence the vacuuming time and the required suction power. Larger bags necessitate more powerful vacuum cleaners to achieve adequate compression. The bag’s design should also minimize internal pockets or folds that could trap air, hindering the vacuuming process. The design must allow the user to easily extract large volumes of air as a result of its larger size.

- Sealing Mechanism and Vacuum Retention

The sealing mechanism, typically a zipper or clamp system, plays a critical role in maintaining the vacuum after the air has been evacuated. The sealing mechanism must create an airtight barrier to prevent air from seeping back into the bag. The design also must be durable and designed to withstand the constant forces exerted by the vacuum. Vacuum cleaner designs must be compatible with these types of mechanisms, ensuring they do not damage the material.

These considerations collectively underscore the importance of vacuum compatibility in ensuring the effectiveness of a king size mattress vacuum bag. A bag that is not designed with these factors in mind will likely fail to achieve the desired compression or maintain a long-lasting seal, thereby negating its primary benefits. In order to maximize savings, proper research should be conducted prior to purchase.

5. Storage Space

The relationship between storage space and a king size mattress vacuum bag is fundamenta

lly one of optimization. The primary function of such a bag is to minimize the volume occupied by a large mattress, thereby freeing up storage space. This is achieved through the evacuation of air, compressing the mattress into a significantly smaller and more manageable form. The bag’s effectiveness is directly proportional to the reduction in volume it can achieve. For example, a standard king-size mattress, uncompressed, may require substantial floor area in a storage unit or be impossible to fit in a standard closet. When vacuum-sealed, its dimensions are considerably reduced, enabling it to be stored in smaller, more accessible spaces.

The importance of storage space optimization is particularly evident in urban environments or smaller homes where living space is at a premium. The ability to store a spare mattress efficiently, without sacrificing valuable square footage, is a significant benefit. Furthermore, the vacuum-sealed environment protects the mattress from dust, moisture, and pests, preserving its condition during storage. Consider the scenario of a homeowner downsizing or needing to temporarily store a mattress during renovations. A vacuum bag enables them to retain the mattress without the burden of finding and paying for a large storage unit. A real-life example would include students storing mattresses over the summer between semesters.

In summary, a king-size mattress vacuum bag directly addresses the challenge of limited storage space. Its successful application results in a tangible reduction in volume, facilitating easier storage and protecting the mattress from environmental damage. The efficiency of this space-saving solution is contingent on factors such as bag quality, sealing mechanism effectiveness, and adherence to proper usage techniques. While the initial cost of the bag may be a consideration, the long-term benefits of space optimization and mattress preservation often outweigh the expense.

6. Protective Qualities

The protective attributes of a vacuum bag designed for king-size mattresses are central to its utility and value proposition. These qualities directly determine the bag’s capacity to shield the enclosed mattress from environmental factors that can degrade its condition over time. Foremost among these factors are moisture, dust mites, allergens, and physical damage during handling or storage. The effectiveness of the bag in mitigating these threats directly correlates to the longevity and hygiene of the stored mattress. For instance, a mattress stored unprotected in a damp environment is prone to mold and mildew growth, rendering it unusable; a properly sealed vacuum bag mitigates this risk significantly.

The material composition and sealing mechanism of the vacuum bag are critical determinants of its protective capabilities. High-quality bags utilize durable, puncture-resistant materials that create an airtight barrier against external elements. A robust sealing mechanism, such as a double-zipper closure coupled with a reliable valve system, is essential for maintaining the vacuum and preventing air ingress. Consider a scenario where a family is relocating and needs to store their king-size mattress for an extended period; a vacuum bag with superior protective qualities ensures that the mattress arrives at its destination in the same condition as when it was stored. Moreover, many bags incorporate antimicrobial agents to further inhibit the growth of mold and bacteria, providing an additional layer of protection.

In summary, the protective qualities of a king-size mattress vacuum bag are paramount to its functionality and economic value. These attributes safeguard the mattress from moisture, dust mites, allergens, and physical damage, extending its lifespan and preserving its hygienic condition. The selection of a bag with superior materials and a robust sealing mechanism is a critical investment in the long-term care of the mattress. While no bag can provide absolute protection against all potential threats, a well-designed and properly used vacuum bag offers a significant degree of protection, making it a valuable tool for storage and relocation. The main challenge is selecting a product that truly offers quality protection since many on the market offer little if any.

Frequently Asked Questions

The following addresses common inquiries regarding the use, benefits, and limitations of vacuum storage solutions for king-size mattresses.

Question 1: What is the expected lifespan of a king-size mattress vacuum bag?

The lifespan of a mattress vacuum bag is contingent on the quality of materials and the frequency of use. High-grade bags, constructed from durable polymers, may last for several years with proper handling. However, repeated use and exposure to abrasive surfaces can shorten their lifespan. Periodic inspection for tears or punctures is recommended.

Question 2: Can a mattress be permanently damaged by long-term vacuum compression?

While vacuum compression reduces the volume of a mattress, extended periods in this state may affect its structural integrity. Some mattress types, particularly those with innerspring systems, may experience a degree of deformation. Rotating or periodically decompressing the mattress is advised to mitigate potential long-term damage.

Question 3: Is a specialized vacuum cleaner required for use with these bags?

A specialized vacuum cleaner is generally not required. Most standard vacuum cleaners with a hose attachment are compatible with the valve systems found on mattress vacuum bags. However, the vacuum cleaner should possess sufficient suction power to effectively evacuate the air from the bag in a reasonable timeframe.

Question 4: How can mold or mildew growth be prevented inside the vacuum bag?

To prevent mold or mildew growth, the mattress must be thoroughly cleaned and completely dried before being placed inside the vacuum bag. The inclusion of desiccant packets within the bag can further absorb any residual moisture. Regular inspection for signs of moisture is also recommended.

Question 5: What is the recommended method for folding a king-size mattress before sealing?

Folding a king-size mattress is generally not recommended, as it can cause permanent creases or damage to the internal structure. Instead, the mattress should be carefully rolled to reduce its width, then placed inside the vacuum bag. Uniform compression is crucial to prevent uneven stress on the mattress components.

Question 6: Are these bags effective against bed bug infestations?

A properly sealed mattress vacuum bag can be an effective tool in containing a bed bug infestation. The airtight environment prevents bed bugs from escaping and accessing a food source. However, it is essential to ensure that all bed bugs are eradicated from the mattress before sealing it in the bag, as they can survive for extended periods without feeding.

These answers provide a foundational understanding of king-size mattress vacuum bags. Proper usage and maintenance are essential for maximizing their benefits and minimizing potential risks.

The subsequent section will explore customer reviews and testimonials related to various mattress vacuum bag products.

King Size Mattress Vacuum Bag

This exposition has detailed the multifaceted nature of the king size mattress vacuum bag. Key elements reviewed encompassed dimensions, material strength, sealing mechanisms, vacuum compatibility, storage efficiency, and protective attributes. Successful applicatio

n hinges upon judicious selection, appropriate usage, and diligent maintenance. Compromises in any of these areas will diminish the utility and longevity of this storage solution.

Ultimately, the king size mattress vacuum bag represents a strategic investment in space optimization and mattress preservation. Prudent evaluation of individual needs, coupled with a discerning approach to product selection, remains paramount for maximizing the benefits derived from this increasingly prevalent storage methodology. Further research into evolving materials and sealing technologies is warranted to enhance the efficacy and sustainability of these systems.

![Best King Size Split Mattress [Guide] For Couples! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best King Size Split Mattress [Guide] For Couples! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-8339-300x200.jpg)