The phenomenon of gradual air loss from inflatable mattresses during the course of a night is a common occurrence. This results in a noticeable reduction in firmness and support, impacting the user’s sleep quality. The degree of deflation can vary, ranging from a slight softening to near-complete flatness.

Understanding why inflatable mattresses lose air is crucial for maintaining comfort and extending the lifespan of the product. Investigating the potential causes, which can include leaks, temperature fluctuations, and valve malfunctions, enables preventative measures and informed purchasing decisions. Addressing this issue prevents discomfort and ensures a restful sleep experience.

The following sections will delve into specific reasons for air loss, methods for identifying leaks, repair techniques, and best practices for maintaining inflatable mattresses to minimize the probability of air escaping during use.

Mitigating Air Loss in Inflatable Mattresses

Addressing the problem of gradual air expulsion from inflatable mattresses requires a systematic approach. Proactive measures and diligent maintenance are critical for preserving firmness and maximizing product longevity.

Tip 1: Inspect Valve Integrity: The valve is a primary point of potential leakage. Ensure the valve is properly sealed and free from debris that could compromise the airtight seal. Periodically check for tightness and replace the valve if necessary.

Tip 2: Conduct Regular Leak Tests: Submerge the inflated mattress in water, section by section, observing for air bubbles. Alternatively, apply a soapy water solution and look for bubble formation. Mark any leaks identified for subsequent repair.

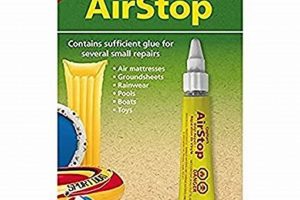

Tip 3: Utilize a Patch Kit: Small punctures can be effectively repaired using a dedicated patch kit. Clean and dry the affected area thoroughly before applying the patch, ensuring a secure bond to prevent further air escape.

Tip 4: Control Ambient Temperature: Fluctuations in temperature cause the air within the mattress to contract and expand. Avoid placing the mattress in direct sunlight or near sources of heat, as this can exacerbate air loss. Maintain a consistent room temperature to minimize pressure changes.

Tip 5: Distribute Weight Evenly: Uneven weight distribution places undue stress on certain areas of the mattress, increasing the likelihood of seam failure and subsequent air leaks. Encourage users to distribute weight evenly across the surface.

Tip 6: Store Properly When Not in Use: When deflated and stored, ensure the mattress is clean, dry, and folded loosely. Avoid storing it in a compressed or tightly packed state, as this can damage the material and weaken seams. Keep it away from sharp objects and extreme temperatures.

Implementing these preventative measures will significantly reduce the rate of air loss, enhancing the comfort and extending the lifespan of the inflatable mattress. Consistent attention to valve integrity, leak detection, and environmental factors are essential for optimal performance.

The subsequent section will explore advanced repair techniques and discuss the benefits of investing in higher-quality inflatable mattresses designed with enhanced air retention capabilities.

1. Leak Location

The position of an air leak is a primary determinant of the rate and severity of deflation observed in inflatable mattresses. The location directly influences the pressure exerted upon the compromised area, impacting the volume of air escaping over time. Identifying and understanding the characteristics of various leak locations is essential for effective repair and preventative maintenance.

- Seam Leaks

Leaks occurring along the seams of the mattress represent a common failure point. These areas are subject to stress from inflation, deflation, and weight distribution. Seam leaks often manifest as slow, gradual deflation, particularly when the mattress is under load. Their detection can be challenging due to the extended length of the seam and the potential for multiple, minute breaches. Seam leaks are often a result of manufacturing defects or material fatigue.

- Valve Leaks

The valve assembly is a critical component for maintaining airtight integrity. Leaks in this area can stem from a faulty valve seal, damaged threading, or foreign debris obstructing proper closure. Valve leaks typically result in a more rapid and noticeable deflation compared to pinhole leaks in the mattress body. Inspection of the valve for cracks, deformities, and proper seating is crucial for diagnosing and resolving this issue.

- Surface Puncture Leaks

Punctures to the main surface of the air mattress, often caused by sharp objects, create direct pathways for air to escape. The size and shape of the puncture dictate the deflation rate. Small pinhole leaks may be difficult to locate initially, requiring systematic testing methods. Larger punctures result in immediate and significant air loss. The material surrounding the puncture can influence the effectiveness of repair attempts.

- Internal Baffle Leaks

Some inflatable mattresses utilize internal baffles to distribute air and enhance structural support. Leaks within these baffles may not result in immediate, complete deflation, but can lead to uneven weight distribution and localized sagging. Diagnosing internal baffle leaks often requires specialized techniques, such as pressure testing individual compartments.

The specific location of the leak, whether at a seam, valve, surface, or internal baffle, plays a critical role in the manifestation of mattress deflation overnight. Addressing the identified location with appropriate repair techniques is essential for restoring the mattress’s functionality and ensuring a comfortable sleep experience. Failure to accurately locate and effectively repair leaks will perpetuate the problem of gradual air loss.

2. Valve Integrity

Valve integrity is paramount to maintaining the air pressure within an inflatable mattress. A compromised valve, characterized by defects in the sealing mechanism, structural damage, or the presence of foreign debris, directly facilitates air leakage. This leakage contributes significantly to the progressive deflation observed overnight, reducing mattress firmness and impacting user comfort. The valve functions as a critical barrier against air expulsion; any compromise directly undermines this function.

The impact of valve failure can range from subtle air loss, barely noticeable over a single night, to rapid deflation rendering the mattress unusable. Consider, for example, a valve with microscopic cracks in its plastic housing. While initially appearing secure, these cracks expand under pressure, allowing for a slow but persistent escape of air. Alternatively

, the accumulation of dust particles within the valve seat can prevent a complete seal, leading to continuous leakage, even when the valve is purportedly closed. These scenarios exemplify how seemingly minor valve imperfections directly result in significant overnight deflation.

Ensuring valve integrity is thus a crucial aspect of inflatable mattress maintenance and design. Regular inspection for damage, proper cleaning to remove obstructions, and the use of high-quality valve components are essential. Addressing valve-related issues promptly can mitigate air loss and preserve the intended function and lifespan of the inflatable mattress. Ultimately, the valve’s condition directly dictates the mattress’s ability to maintain its inflated state throughout the night.

3. Temperature effects

Ambient temperature exerts a significant influence on the air pressure within inflatable mattresses, thereby affecting their firmness and contributing to observed deflation overnight. The relationship is governed by basic thermodynamic principles, where air volume is directly proportional to temperature when pressure is constant. This dictates that lower temperatures result in decreased air volume, manifesting as reduced mattress firmness.

- Ideal Gas Law and Air Mattresses

The Ideal Gas Law (PV=nRT) provides a quantitative framework for understanding the link between temperature and air mattress deflation. A reduction in temperature (T) leads to a proportional decrease in pressure (P) within the fixed volume (V) of the mattress, assuming the number of moles of gas (n) and the gas constant (R) remain constant. This pressure reduction manifests as reduced firmness and a perception of deflation.

- Nocturnal Temperature Variations

Ambient temperature typically decreases during nighttime hours. This cooling effect causes the air inside the mattress to contract, resulting in a noticeable reduction in pressure and firmness. The magnitude of this effect depends on the initial inflation pressure, the insulation properties of the mattress material, and the extent of the temperature drop. A substantial temperature decrease can lead to perceived deflation, even in a leak-free mattress.

- Material Expansion and Contraction

The material comprising the air mattress itself can expand or contract with temperature changes. While less significant than the air volume change, this material property contributes to the overall deflation effect. Contraction of the mattress material can exacerbate any existing leaks by widening microscopic fissures or compromising valve seals.

- Practical Implications and Mitigation

Understanding the impact of temperature allows for practical mitigation strategies. Insulating the mattress by placing it on a carpeted surface or using a mattress topper can reduce heat loss. Maintaining a stable room temperature minimizes pressure fluctuations. Over-inflating the mattress slightly compensates for anticipated pressure drops due to cooling. These measures can enhance comfort and minimize perceived deflation overnight.

In summary, temperature effects are a primary driver of perceived and actual deflation in inflatable mattresses during nighttime use. Awareness of these effects, coupled with appropriate mitigation strategies, can significantly improve the user experience and reduce the frequency of re-inflation.

4. Material Porosity

Material porosity, defined as the presence of microscopic voids and channels within the substance of an inflatable mattress, is a critical factor influencing its air retention capability. Increased porosity allows air molecules to permeate the material over time, resulting in a gradual decrease in internal pressure. This phenomenon contributes directly to the observed deflation overnight, even in the absence of macroscopic leaks or valve malfunctions. The inherent porosity of the material, therefore, represents a baseline level of air loss that is unavoidable to some degree.

The type of material used in the construction of the air mattress significantly determines its porosity. Lower-grade polyvinyl chloride (PVC), for instance, often exhibits higher porosity than more advanced polymers or laminated fabrics. Manufacturing processes, such as the application of coatings or the use of specific inflation techniques, can either exacerbate or mitigate material porosity. For example, a thin or uneven coating layer may fail to adequately seal microscopic pores, while over-inflation can stretch the material and increase the size and connectivity of existing voids, accelerating air permeation. Similarly, repeated folding and storage can induce stress fractures, increasing porosity over time, which leads to air mattress deflates overnight.

Understanding the role of material porosity in air mattress deflation is crucial for both manufacturers and consumers. Manufacturers can improve air retention by selecting materials with inherently low porosity and optimizing manufacturing processes to minimize void formation. Consumers can mitigate the effects of material porosity by avoiding over-inflation, storing the mattress properly to prevent material degradation, and using supplementary measures such as mattress toppers to reduce direct pressure and slow the rate of air permeation. While material porosity cannot be entirely eliminated, its impact on air mattress deflation can be significantly managed through informed material selection, manufacturing practices, and usage patterns.

5. Seam Weakness

Seam weakness represents a significant vulnerability in inflatable mattresses, directly contributing to the phenomenon of overnight deflation. The seams, being points of connection between different material sections, are inherently susceptible to stress and potential failure. A compromise in seam integrity allows for air leakage, gradually reducing internal pressure and firmness.

- Manufacturing Defects

Substandard manufacturing processes, such as inadequate welding or insufficient adhesive application, can lead to initial seam weakness. These defects, often undetectable during initial inspection, compromise the structural integrity of the seam from the outset. Over time, pressure exerted during inflation and use causes these weak seams to separate, creating pathways for air to escape. The result is an accelerating rate of deflation as the mattress is used.

- Material Fatigue

Repeated inflation and deflation cycles subject the seam materials to stress and strain. This fatigue, particularly pronounced in lower-quality materials, weakens the bonds holding the seam together. Flexing and stretching during sleep exacerbate this process. Eventually, microscopic tears or fissures form in the seam, allowing air to seep out. The effect is cumulative, with each use further weakening the seam’s ability to maintain an airtight seal.

- Stress Concentration

Seams located in areas of high stress concentration, such as corners or around internal baffles, are more prone to failure. These areas experience greater tension and pressure during inflation and weight distribution. The increased stre

ss accelerates material fatigue and weakens the seam’s structural integrity. Even minor defects in these high-stress zones can lead to significant air leakage and rapid deflation. - Environmental Factors

Exposure to environmental factors, such as excessive heat or prolonged sunlight, can degrade the seam materials. Ultraviolet radiation weakens the adhesives and polymers used in seam construction, reducing their ability to maintain a secure bond. High temperatures can cause expansion and contraction, further stressing the seam and increasing the likelihood of separation. Such environmental degradation accelerates the process of seam weakening and contributes to overnight deflation.

Addressing seam weakness is crucial for improving the durability and longevity of inflatable mattresses. Implementing stringent quality control measures during manufacturing, selecting durable seam materials, and minimizing stress concentrations in design can mitigate the risk of seam failure. Consumers can also prolong mattress life by avoiding over-inflation, protecting the mattress from environmental extremes, and distributing weight evenly to reduce stress on vulnerable seams.

6. Weight distribution

Uneven weight distribution on an inflatable mattress significantly contributes to the phenomenon of overnight deflation. Excessive concentration of weight in specific areas of the mattress places undue stress on the internal structure, particularly the seams and baffles. This localized pressure weakens the material over time, leading to micro-tears or seam separation, thereby creating pathways for air leakage. For instance, a sleeper consistently positioned near the edge of the mattress exerts greater force on that perimeter, accelerating wear and increasing the likelihood of deflation along the edge seams. Similarly, prolonged periods of sitting in one location concentrates weight and can compromise the internal support structure, leading to localized sagging and increased pressure on surrounding areas.

The impact of improper weight distribution extends beyond immediate discomfort. Repeated stress on specific areas compromises the overall structural integrity of the mattress, shortening its lifespan. Consider the case of a couple sharing an inflatable mattress, where one individual is significantly heavier than the other. The heavier person’s side will experience greater and more concentrated pressure, increasing the risk of seam failure and resulting in uneven deflation. This uneven support can lead to discomfort and exacerbate any pre-existing back problems. Furthermore, the constant adjustments required to compensate for the uneven weight distribution disrupt sleep patterns and reduce the overall quality of rest.

Optimizing weight distribution is therefore crucial for prolonging the life of an inflatable mattress and ensuring a comfortable sleep experience. Rotating the mattress periodically can distribute wear more evenly. Encouraging occupants to utilize the entire surface area, rather than concentrating weight in one area, minimizes localized stress. Selecting a mattress with reinforced seams and robust internal baffling systems provides enhanced support and distributes weight more effectively. Addressing weight distribution concerns represents a proactive approach to preventing premature deflation and maximizing the long-term value of the inflatable mattress.

Frequently Asked Questions

The following addresses common inquiries regarding the issue of inflatable mattresses losing air pressure overnight. These questions and answers provide insights into the causes, prevention, and potential remedies.

Question 1: Is some degree of air loss normal in inflatable mattresses?

A minor reduction in air pressure is not uncommon, particularly with temperature fluctuations. However, significant or consistent deflation suggests an underlying problem requiring investigation. The material itself may exhibit inherent porosity, contributing to minimal air permeation.

Question 2: What are the primary causes of inflatable mattress deflation?

The most frequent causes include punctures, valve leaks, seam weaknesses, and temperature-induced pressure changes. Microscopic tears or abrasions in the material can also contribute to gradual air loss. A systematic inspection is recommended to identify the specific source.

Question 3: How can leaks be effectively located in an inflatable mattress?

One method involves submerging the inflated mattress in water, section by section, observing for air bubbles. Alternatively, a soapy water solution can be applied, and the formation of bubbles indicates the presence of a leak. Careful visual inspection under bright light may also reveal punctures or abrasions.

Question 4: What are the most effective methods for repairing leaks in inflatable mattresses?

Small punctures can often be repaired using a dedicated patch kit. Larger tears may require specialized adhesives and reinforcement materials. Cleaning and thoroughly drying the affected area prior to applying the patch is crucial for ensuring a secure and lasting bond. Valve replacements may be necessary for damaged or faulty valves.

Question 5: How does ambient temperature affect inflatable mattress pressure?

As temperature decreases, the air inside the mattress contracts, resulting in a reduction in pressure and perceived firmness. Conversely, increased temperatures cause expansion. Maintaining a stable room temperature can minimize these fluctuations and reduce the frequency of re-inflation.

Question 6: What steps can be taken to prevent inflatable mattress deflation?

Preventative measures include regular inspection for leaks, careful handling to avoid punctures, proper storage when not in use, and avoiding over-inflation. Utilizing a mattress topper can provide additional protection and distribute weight more evenly. Selecting a higher-quality mattress constructed from durable materials with reinforced seams can also enhance longevity.

Addressing the issue of air mattress deflation requires a multifaceted approach, encompassing preventative maintenance, prompt leak detection and repair, and an understanding of environmental factors.

The subsequent section will delve into the long-term care and maintenance strategies for inflatable mattresses to maximize their lifespan and minimize future deflation issues.

Conclusion

The consistent deflation of an air mattress during the night represents a multifaceted problem stemming from material properties, environmental factors, and usage patterns. This investigation has detailed the primary contributors to this phenomenon: leak location, valve integrity, temperature effects, material porosity, seam weakness, and weight distribution. Recognizing these factors allows for informed decisions regarding mattress selection, maintenance, and preventative measures.

Mitigation of the issue requires a proactive approach, encompassing regular inspection, appropriate repair techniques, and an awareness of environmental influences. While complete elimination of air loss may not be achievable, understanding and addressing the underlying causes will significantly improve product performance and user satisfaction. Continued diligence in these areas remains critical for optimizing the longevity and comfort provided by inflatable mattresses.