A manually operated device designed to inflate air mattresses through the repeated action of a foot pressing down on a bellows or similar mechanism. This portable tool eliminates the need for electrical power, offering a convenient solution for inflating mattresses in locations without outlets. Examples include compact models easily stored for camping and larger, more efficient designs suitable for home use.

The significance of such devices lies in their portability and independence from external power sources. Their utility spans recreational activities like camping and travel, as well as providing a practical solution for temporary bedding needs at home. Historically, these manual inflation devices represent a simplified, readily accessible alternative to electrically powered pumps, addressing inflation needs in a cost-effective and reliable manner.

The subsequent sections will delve into the operational principles, diverse types available, selection criteria, and maintenance practices associated with these inflation solutions, providing a comprehensive overview of their application and suitability for various scenarios.

Operational Tips for Manual Inflation Devices

The following guidelines are intended to optimize the use and extend the lifespan of manual inflation devices, ensuring efficient performance and preventing potential damage.

Tip 1: Secure Placement: Before commencing inflation, position the device on a stable, level surface to prevent slippage and ensure consistent operation.

Tip 2: Proper Nozzle Attachment: Verify that the nozzle is securely attached to both the device and the air mattress valve. A loose connection results in air leakage and prolonged inflation time.

Tip 3: Controlled Pumping Action: Apply consistent, moderate pressure when pressing down on the pump. Avoid forceful or rapid pumping, which can overstress the mechanism.

Tip 4: Monitor Mattress Pressure: Periodically check the firmness of the air mattress during inflation. Overinflation can lead to seam damage or bursting.

Tip 5: Gradual Deflation: When deflating, use the devices deflation port or a dedicated deflation tool to release air gradually. This minimizes stress on the mattress material.

Tip 6: Cleanliness and Storage: After each use, wipe down the device to remove dirt or debris. Store it in a dry, protected location to prevent damage from moisture or physical impact.

Tip 7: Inspect for Damage: Regularly examine the device for signs of wear or damage, such as cracks in the bellows or leaks in the hose. Address any issues promptly to maintain functionality.

Adhering to these guidelines ensures efficient inflation and deflation, prolongs the device’s operational life, and maximizes the air mattress’s utility.

The subsequent sections will explore troubleshooting common issues and further optimize the use of these devices in diverse scenarios.

1. Portability

Portability is a fundamental characteristic influencing the utility and appeal of manual inflation devices for air mattresses. The compact size and lightweight design of many models facilitate transportation and storage, enabling their use in environments where space is limited or external power is unavailable. The absence of electrical components contributes significantly to a devices portability, allowing for deployment in remote locations such as campsites, hiking trails, or areas affected by power outages. For example, backpackers often favor smaller, manually operated pumps to minimize weight and bulk in their gear, prioritizing portability over inflation speed.

The connection between portability and the functional utility of the pump is direct: a more portable device expands the range of situations in which an air mattress can be conveniently deployed. This portability translates into practical advantages for various user groups. Travelers can easily pack a manual pump in luggage, families can store one in a car for emergency bedding needs, and outdoor enthusiasts can carry one on extended wilderness excursions. In each scenario, the device’s portability ensures that a comfortable sleeping surface can be readily available regardless of location or circumstance.

Ultimately, the portability of manual inflation devices enhances the versatility and accessibility of air mattresses, bridging the gap between comfort and convenience in diverse settings. Overcoming challenges related to size and weight without compromising efficiency remains a key design consideration, solidifying portability as a critical attribute for the widespread adoption and continued relevance of manual inflation devices.

2. Manual Operation

Manual operation, in the context of air mattress inflation, represents a direct, user-controlled means of increasing air pressure within a mattress. This method forgoes reliance on external power sources, positioning it as a robust alternative for varied environments.

- Mechanical Action

Manual operation inherently relies on mechanical force generated by the user, typically through foot or hand actuation. The compression of bellows or a similar mechanism forces air into the mattress. This design simplifies construction and reduces potential failure points linked to electrical components.

- Power Source Independence

A key attribute of manual operation is its self-sufficiency. Without the requirement of electricity or batteries, these inflation devices can function in remote or underdeveloped areas. This independence is advantageous during camping, travel, or in emergency situations where power access is limited.

- Operational Control and Feedback

Manual operation provides tactile feedback, enabling the user to gauge mattress firmness during inflation. This allows for precise control over air pressure, reducing the risk of overinflation and potential damage to the mattress.

- Maintenance and Longevity

The simplicity of manual inflation devices contributes to their durability and ease of maintenance. Fewer components translate to a lower probability of mechanical failure and simplified repair processes, potentially extending the device’s operational lifespan.

These facets of manual operation underscore its significance in the context of air mattress inflation. The method’s self-reliance, user control, and simplified design provide a reliable and versatile alternative to electrically powered inflation solutions, particularly in scenarios where power accessibility is a concern.

3. Inflation Efficiency

Inflation efficiency, re

garding foot-operated air mattress pumps, denotes the rate at which air is transferred into the mattress relative to the user’s effort expended. It is a critical performance metric influencing user satisfaction and the practical applicability of these devices. Several factors determine this efficiency, ranging from pump design to user technique.

- Pump Volume and Stroke Rate

The volume of air displaced per pump stroke, combined with the achievable stroke rate, directly impacts inflation time. Larger pump volumes translate to faster inflation, provided the user can maintain a consistent stroke rate. For instance, a pump displacing 0.5 liters per stroke at a rate of 60 strokes per minute will inflate a mattress faster than one displacing 0.3 liters at the same rate. Inefficient pumps require increased user effort and extended inflation durations.

- Air Leakage and Seal Integrity

Air leakage, whether from the pump itself or the valve connection, reduces the effective inflation rate. Compromised seals around the bellows or faulty valve adapters diminish the quantity of air delivered to the mattress per stroke, necessitating more pumping cycles. Users may experience this as a perceptible hissing sound or a prolonged inflation process, indicating a reduction in efficiency.

- User Technique and Ergonomics

The manner in which the pump is operated significantly influences its output. Consistent, full-stroke compressions maximize air displacement, whereas partial or erratic pumping reduces efficiency. Ergonomic designs, incorporating features such as stable bases and comfortable footpads, promote efficient pumping by minimizing user fatigue and maximizing force transfer.

- Valve Compatibility and Airway Resistance

The compatibility between the pump nozzle and the air mattress valve affects airflow efficiency. Mismatched connections or constricted airways increase resistance, reducing the volume of air entering the mattress per stroke. Adapters that provide a secure, unobstructed pathway optimize airflow and enhance inflation efficiency. Airway resistance, therefore, dictates the amount of air that is able to enter the mattress and therefore affects the rate it can be inflated.

These factors collectively influence the overall inflation efficiency of air mattress pumps. Optimizing pump design, minimizing air leakage, promoting proper user technique, and ensuring valve compatibility are crucial for enhancing performance and reducing the effort required to inflate an air mattress.

4. Durability

Durability is a primary consideration in assessing the utility of a manual air mattress pump. The capacity of the device to withstand repeated use and environmental stressors directly influences its operational lifespan and cost-effectiveness. Construction materials, component design, and manufacturing processes determine the pump’s resistance to wear, impact, and degradation, collectively shaping its overall reliability. An unreliable pump requires frequent replacement, offsetting initial cost savings. Camping, for example, demands robust equipment able to endure transport and exposure to variable weather conditions; a fragile pump risks failure when relied upon for essential inflation. The correlation between pump durability and its functional longevity is therefore a crucial factor in purchase decisions.

The choice of materials significantly impacts durability. High-density plastics offer impact resistance and protection against deformation, while reinforced bellows designs mitigate stress fractures and air leaks. Metal components, appropriately treated to prevent corrosion, enhance structural integrity and resist wear in critical areas. The integration of these durable elements ensures consistent performance under typical usage conditions. Consider a pump constructed from brittle plastic; its susceptibility to cracking under pressure renders it unsuitable for demanding applications. Conversely, a pump with reinforced construction can sustain repeated use without compromising its functionality.

In summary, durability directly affects the long-term value and practical utility of manual air mattress pumps. The ability of the device to withstand the rigors of regular use, resist environmental damage, and maintain consistent performance is paramount. Investments in pumps designed with durable materials and robust construction translate to enhanced reliability and extended operational lifespan, providing a cost-effective solution for air mattress inflation needs. Understanding the interplay between materials, design, and longevity is essential for selecting a pump that reliably fulfills its intended purpose.

5. Ease of Use

Ease of use is a crucial attribute in the design and functionality of air mattress foot pumps, directly impacting user satisfaction and the frequency of their employment. A complex or cumbersome pump discourages use, even if it is otherwise efficient and durable. The intuitive nature of a well-designed foot pump reduces the physical and cognitive burden on the user, making it more likely to be chosen over alternative, potentially more sophisticated, inflation methods. For instance, an elderly individual or someone with limited mobility may find a foot pump with a large, stable base and a smooth pumping action significantly easier to operate than a compact model requiring greater physical exertion.

The practical implications of ease of use extend beyond mere convenience. A user-friendly foot pump streamlines the process of preparing an air mattress for use, allowing for faster setup and reducing the risk of user error. Clear instructions, easily attachable nozzles, and a readily accessible deflation port further contribute to a positive user experience. In emergency situations, such as providing temporary bedding during a power outage, a pump that is quick and simple to operate becomes particularly valuable. Consider a scenario where multiple air mattresses need to be inflated rapidly; a cumbersome or difficult-to-use pump would significantly impede the process, delaying the provision of comfortable sleeping arrangements.

In conclusion, ease of use is not merely a desirable feature, but an essential component of a successful air mattress foot pump design. It directly influences user acceptance, encourages frequent use, and enhances the overall practicality of the device. Addressing the ergonomic and cognitive aspects of pump operation is crucial for maximizing user satisfaction and ensuring that the pump effectively fulfills its intended purpose. Ultimately, a user-friendly foot pump transforms the often tedious task of inflating an air mattress into a quick and effortless process.

6. Valve Compatibility

Valve compatibility represents a critical interface between a manual inflation device and an air mattress, determining the effectiveness and feasibility of inflation. Mismatched valve types render a pump unusable, underscoring the importance of standardized or adaptable connection mechanisms.

- Universal Adapters and Nozzle Design

The inclusion of multiple adapters or a universal nozzle design expands the range of air mattresses a single pump can inflate. Ad

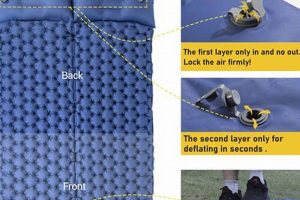

apters bridge the gap between differing valve sizes and thread patterns, providing versatility across various mattress brands and models. A pump equipped with such features ensures compatibility, minimizing the need for multiple inflation devices. An example is a stepped nozzle design that fits both small and large valve openings. - Valve Types and Inflation Efficiency

Different valve types, such as Boston valves, pinch valves, and stem valves, exhibit varying levels of airflow efficiency when connected to a manual inflation device. Boston valves, characterized by their wide openings, typically allow for faster inflation compared to smaller pinch valves. The pump’s nozzle design must accommodate these variations to optimize airflow and minimize inflation time. A poorly matched nozzle can restrict airflow, prolonging the inflation process.

- Secure Connection Mechanisms

A secure connection between the pump nozzle and the air mattress valve is essential to prevent air leakage during inflation. Threaded connections, bayonet fittings, or tight friction fits ensure a sealed pathway for air transfer. A loose or incompatible connection results in wasted effort and incomplete inflation, highlighting the importance of a well-designed and properly fitting interface. This secure connection means faster inflation because none of the effort is wasted as escaping air.

- Material Compatibility and Durability

The materials used in the pump nozzle and valve adapter must be compatible with the valve material to prevent degradation or damage over time. Incompatible materials can lead to chemical reactions or physical wear, compromising the seal and reducing the pump’s effectiveness. Durable materials that resist wear and deformation ensure a long-lasting and reliable connection. Using a plastic adapter on a metal valve, for instance, might result in premature wear of the plastic component.

These considerations demonstrate the pivotal role of valve compatibility in the overall performance of a manual inflation device. A pump designed with versatile adapters, optimized airflow, secure connections, and compatible materials ensures efficient and reliable inflation across a range of air mattress types.

7. Storage Requirements

The storage demands of a manual air mattress pump constitute a significant factor in its practicality and overall utility. Pump dimensions directly influence storage space requirements, with compact designs facilitating easier integration into limited storage environments. Cumbersome or bulky pumps necessitate dedicated storage areas, potentially diminishing their convenience, particularly in settings such as camping or apartment living. Therefore, a pump’s physical size directly correlates with its ease of storage, affecting its suitability for diverse applications and user preferences. A pump’s design directly influences user adoption: a small and easy to store foot pump will be far more appealing than one that is a hassle to store.

Storage considerations extend beyond mere physical size to encompass protective measures. Proper storage safeguards the pump against damage from environmental factors such as moisture, dust, or extreme temperatures. A pump left exposed to these conditions can experience accelerated degradation of its components, reducing its lifespan and operational effectiveness. Consequently, appropriate storage protocols, including the use of protective cases or storage bags, contribute significantly to preserving the pump’s functionality over extended periods. In situations where space is a premium, storage is often neglected, however, it can drastically shorten the life of your foot pump.

In summary, the interplay between a manual air mattress pump and its storage requirements is integral to its overall practicality and longevity. Compact designs, coupled with appropriate storage practices, ensure the pump remains readily accessible and functional when needed. Neglecting storage considerations can diminish the pump’s utility and shorten its lifespan, thereby undermining its value as a portable inflation solution. Understanding the relationship between storage requirements and the pump’s design, functionality, and material composition is essential for maximizing its benefits.

Frequently Asked Questions About Air Mattress Foot Pumps

The following section addresses common inquiries regarding the functionality, maintenance, and selection of foot-operated air mattress inflation devices.

Question 1: What is the average inflation time using an air mattress foot pump?

Inflation time varies depending on the mattress size, pump volume, and user effort. Smaller mattresses may inflate within 5-10 minutes, while larger mattresses could require 15-20 minutes or longer.

Question 2: How does one maintain an air mattress foot pump to extend its lifespan?

Regular cleaning of the pump’s exterior and nozzle is recommended. Storing the pump in a dry environment prevents corrosion and material degradation. Periodic inspection for leaks or damage ensures optimal performance.

Question 3: Are air mattress foot pumps compatible with all air mattress valve types?

Compatibility depends on the pump’s nozzle design and included adapters. Many pumps come with multiple adapters to accommodate various valve types, such as Boston valves, stem valves, and pinch valves. Confirming compatibility before purchase is advisable.

Question 4: What factors contribute to the efficiency of an air mattress foot pump?

Pump volume, stroke rate, air leakage, and user technique significantly impact efficiency. Larger pump volumes, minimal air leakage, and consistent, full-stroke compressions optimize inflation speed.

Question 5: What materials are commonly used in the construction of air mattress foot pumps?

Common materials include high-density plastics for the pump body, reinforced bellows for air displacement, and rubber or silicone for seals and connectors. Material quality influences the pump’s durability and resistance to wear.

Question 6: How does one troubleshoot air leakage in an air mattress foot pump?

Inspect the pump’s seals and connectors for cracks or damage. Ensure a secure connection between the nozzle and the mattress valve. Applying a small amount of lubricant to the seals may improve their effectiveness. Replacement parts may be necessary for irreparable damage.

Air mattress foot pumps offer a reliable and portable solution for inflating air mattresses, provided they are selected, maintained, and operated properly. Addressing common concerns and following best practices ensures optimal performance and extended pump longevity.

The subsequent article section will discuss scenarios where these inflation solutions are best employed.

Conclusion

This article has explored the multifaceted nature of the air mattress foot pump, detailing its operational principles, diverse types, selection criteria, maintenance practices, and common queries. The portability, independence from external power, and simplicity of operation constitute its primary advantages. Factors such as pump volume, valve compatibility, material durability, and storage requirements significantly influence its performance and lifespan.

Understanding the characteristics and limitations of the air mattress foot pump empowers users to make informed decisions regarding its suitability for specific applications. While technological a

dvancements may offer alternative inflation solutions, the fundamental reliability and accessibility of this manual device ensure its continued relevance in diverse scenarios. Users are encouraged to apply the insights presented herein to optimize the utilization and longevity of their inflation devices.

![Best Jeep Wrangler Air Mattress [Guide] On Road! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Jeep Wrangler Air Mattress [Guide] On Road! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-6718-300x200.jpg)