A portable, inflatable sleeping surface designed to fit within the cargo area of a pickup truck. These mattresses provide a comfortable and convenient option for rest and overnight stays during travel, camping, or work-related activities where traditional lodging is unavailable or impractical. Example: A camper using a product specifically shaped for their F-150’s bed length and wheel well cutouts.

The utility of such an accessory stems from its ability to transform the otherwise hard and often uneven truck bed into a comfortable sleeping space. This offers a practical solution for those seeking cost-effective accommodation on road trips, hunting excursions, or job sites. Historically, individuals camping from their vehicles have sought ways to optimize comfort and space; this product represents an evolution in providing a more refined and purpose-built sleep solution compared to generic air mattresses or sleeping bags alone.

The remainder of this article will explore key considerations when selecting an appropriate product, including dimensions, materials, inflation methods, and compatibility with different truck models. It will also address potential advantages and disadvantages compared to alternative camping and sleeping arrangements.

Essential Considerations for Selecting an Air Mattress for Pickup Truck Bed Use

This section outlines crucial factors to consider when choosing an inflatable mattress designed for use in a pickup truck bed, ensuring a comfortable and secure sleep experience.

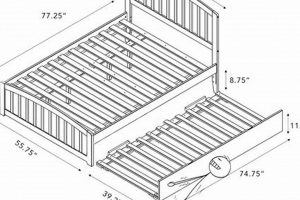

Tip 1: Measure Truck Bed Dimensions Accurately: Prior to purchase, precisely measure the length and width of the truck bed’s interior. Account for any obstructions such as wheel wells. Inaccurate measurements can result in an ill-fitting mattress, compromising comfort and safety.

Tip 2: Evaluate Material Durability: Opt for products constructed from heavy-duty PVC or similar puncture-resistant materials. The truck bed environment can be abrasive, and a durable material minimizes the risk of leaks and prolongs the mattress lifespan. Consider reinforced seams for added strength.

Tip 3: Assess Inflation and Deflation Mechanisms: Examine the type of inflation system offered. Integrated electric pumps offer convenience, while manual pumps require more physical effort. Quick deflation valves facilitate faster packing and storage. Ensure the pump is compatible with the truck’s power source if electric.

Tip 4: Verify Weight Capacity: Confirm the mattress’s maximum weight capacity to ensure it can safely support the intended occupants. Exceeding the weight limit can lead to mattress failure and potential discomfort or injury.

Tip 5: Consider Mattress Thickness and Comfort: Determine the desired level of comfort based on personal preference. Thicker mattresses generally provide more cushioning and support. Some models feature integrated pillow tops or flocked surfaces for enhanced comfort.

Tip 6: Evaluate Storage and Portability: Assess the packed size and weight of the deflated mattress. Compact storage is essential when space is limited in the truck cab or cargo area. A carrying bag can simplify transportation and protect the mattress from damage.

Tip 7: Check for Wheel Well Cutouts: Specific models are designed with cutouts to accommodate the truck’s wheel wells, maximizing usable space and ensuring a snug fit within the bed. Verify compatibility with the specific truck model.

Proper mattress selection based on these factors ensures a secure, comfortable, and practical sleeping solution when utilizing the truck bed for rest or overnight stays.

The following sections will delve into alternative sleeping arrangements and provide a concluding summary of the key considerations discussed.

1. Dimensions

The correlation between the dimensions of an air mattress and the inner dimensions of a pickup truck bed is fundamental to the functionality and usability of the product. Precise fit is not merely a matter of comfort; it directly affects the safety and stability of the sleeping surface. An air mattress that is too large will not fit within the confines of the truck bed, rendering it unusable. Conversely, a mattress that is too small will shift during use, potentially leading to discomfort or even creating a hazardous situation for the occupant. The presence of wheel wells further complicates dimensional considerations, necessitating either a custom-fit mattress with integrated cutouts or careful selection of a mattress size that avoids these obstructions.

Failure to accurately account for dimensions can manifest in several practical disadvantages. An ill-fitting mattress may require deflation to achieve closure of a truck bed cover or tonneau, compromising security and weather protection. It can also lead to uneven weight distribution, potentially accelerating wear and tear on the mattress material. Real-world examples include users reporting difficulty closing truck bed covers due to oversized mattresses, or experiencing sliding and shifting during sleep due to mattresses significantly smaller than the available space. Measuring the available sleeping area before making a purchase is therefore a critical step in ensuring a successful integration.

In summary, dimensional accuracy is paramount to the proper functioning of an air mattress within a pickup truck bed. Inaccurate measurements can result in discomfort, instability, and compromised security. The integration of custom cutouts to accommodate wheel wells adds complexity, requiring precise measurements. Adherence to dimensional precision ensures the air mattress can fulfill its purpose of providing a comfortable and secure sleeping surface within the confined space of the truck bed.

2. Material Durability

The correlation between material durability and the functional lifespan of an air mattress intended for pickup truck bed use is significant. The truck bed environment introduces stressors absent in typical indoor air mattress applications. Exposure to abrasive surfaces, temperature fluctuations, and potential contact with sharp objects necessitate robust material construction. Inadequate material durability precipitates premature failure, rendering the mattress unusable. This connection operates through a cause-and-effect mechanism: inadequate material selection (cause) leads to punctures, leaks, and eventual deflation (effect). The choice of materials is therefore not merely an aesthetic consideration but a determinant of the product’s utility and longevity.

Common materials include PVC (Polyvinyl Chloride) and TPU (Thermoplastic Polyurethane). PVC offers affordability and reasonable puncture resistance, while TPU provides superior durability and flexibility, particularly in cold temperatures. The denier rating of the material, indicating fabric weight and thread count, is a crucial metric. Higher denier values generally correl

ate with enhanced resistance to tearing and abrasion. Real-world scenarios underscore this: users report PVC mattresses failing quickly after contact with small rocks or imperfections in the truck bed liner, while TPU-based mattresses exhibit greater resistance in similar conditions. Reinforcement of seams and corners further contributes to overall durability, mitigating stress concentrations in vulnerable areas.

In summary, material durability is a critical determinant of the effectiveness and lifespan of an air mattress designed for pickup truck bed use. Selection of appropriate materials, such as high-denier PVC or TPU, coupled with reinforced construction, ensures the mattress can withstand the rigors of the truck bed environment. Failure to prioritize material durability leads to premature product failure, undermining the investment and negating the convenience the product is intended to provide.

3. Inflation Method

The means by which an air mattress is inflated directly impacts its practicality and ease of use within the context of a pickup truck bed. Considerations extend beyond mere convenience, encompassing factors such as power availability, inflation speed, and storage requirements.

- Integrated Electric Pumps

These pumps, built directly into the mattress, offer automated inflation at the touch of a button. They typically require connection to a 12V DC power source, often found in the truck’s cigarette lighter or auxiliary power outlet. While convenient, their reliance on a power source can be limiting in remote locations. Furthermore, the integrated pump adds to the overall weight and bulk of the deflated mattress. Examples include mattresses marketed for camping that emphasize ease of setup, often incorporating this feature.

- External Electric Pumps

These pumps are separate units that connect to the mattress via a valve. They offer greater flexibility in terms of power source, with some models operating on AC power, DC power, or even batteries. External pumps can be more powerful than integrated models, leading to faster inflation times. However, they require separate storage and can be easily misplaced. A practical application is seen with individuals using a standard household air pump adapted for use with a truck bed mattress using a DC adapter.

- Manual Pumps (Foot or Hand Operated)

These pumps rely on physical effort for inflation. They offer independence from power sources, making them suitable for off-grid use. However, manual inflation can be time-consuming and physically demanding, particularly for larger mattresses. Foot pumps offer a slightly more ergonomic approach than hand pumps. Campers seeking to minimize their reliance on technology often prefer manual pumps.

- Self-Inflating Valves

Certain mattresses employ a self-inflating design, incorporating open-cell foam. Upon opening the valve, the foam expands, drawing air into the mattress. While this method requires minimal effort, the inflation process can be slow, and the resulting firmness may be less adjustable compared to pumped systems. These are often favored by those prioritizing compact storage and ease of packing, even at the expense of inflation speed.

The choice of inflation method for a pickup truck bed mattress is a trade-off between convenience, power requirements, inflation speed, and portability. Understanding these trade-offs is crucial for selecting a system that aligns with the intended use and environment. For instance, overlanding expeditions may necessitate a manual pump for power independence, whereas weekend camping trips with readily available power might benefit from an integrated electric pump.

4. Weight Capacity

The weight capacity of an air mattress designed for pickup truck bed use directly impacts its safety and longevity. Weight capacity refers to the maximum amount of weight the mattress can support without risking damage or structural failure. Exceeding this limit can lead to seam ruptures, uneven inflation, and eventual deflation, rendering the mattress unusable and potentially causing discomfort or injury to the occupants. The relationship is causal: excessive weight load (cause) results in mattress degradation or failure (effect). The specific weight capacity is a critical specification of the product, determined by the manufacturer based on the mattress’s materials and construction techniques.

The significance of understanding weight capacity extends to practical scenarios. Consider a camping scenario involving two adults and gear. If the combined weight exceeds the mattress’s rated capacity, the mattress is prone to failure, resulting in an uncomfortable and potentially unsafe sleeping arrangement. Conversely, a mattress with a sufficient weight capacity ensures a stable and supportive sleep surface. Real-world examples include reported cases of air mattresses deflating during use due to exceeding the specified weight limit, often during family camping trips. A mattress with a higher stated weight capacity, even if not fully utilized, provides a margin of safety and typically indicates more robust construction. Furthermore, weight distribution also plays a role. Uneven weight distribution can create localized stress points, increasing the likelihood of failure even if the total weight is within the stated limit.

In summary, weight capacity is a fundamental attribute of an air mattress intended for truck bed use. It directly influences the mattress’s safety, durability, and overall performance. Understanding and adhering to the manufacturer’s specified weight capacity is paramount for ensuring a comfortable and safe sleep experience and preventing premature product failure. This understanding extends to considering not only the total weight but also the distribution of that weight across the mattress surface, which may require the use of supports.

5. Comfort Features

The integration of comfort features into an air mattress designed for pickup truck bed use significantly impacts user satisfaction and sleep quality. These features address the inherent challenges of sleeping in the potentially uneven and less forgiving environment of a truck bed, transforming it into a more comfortable resting space.

- Flocked Surfaces

Flocking, a process of adhering fine fibers to the mattress surface, creates a soft, velvety texture. This reduces friction between the sleeper and the mattress, minimizing noise and improving overall comfort. It also helps regulate temperature by absorbing moisture and preventing excessive sweating. Example: A sleeper using a flocked mattress experiences less skin irritation and reduced noise compared to a bare PVC surface.

- Integrated Pillow Tops

An integrated pillow top provides an additional layer of cushioning and support. This feature often utilizes memory foam or other padding materials to contour to the sleeper’s body, relieving pressure points and promoting spinal alignment. Example: Individuals with back pain may find significant relief from an air mattress featuring a built-in pillow top, compared to a standard air mattress lacking this extra layer of cushioning.

i>

- Zoned Support Systems

Zoned support systems incorporate varying levels of firmness across different sections of the mattress. This allows for targeted support to specific areas of the body, such as the lumbar region or shoulders. Example: A zoned support system might provide firmer support to the lower back while offering softer cushioning to the shoulders, promoting proper spinal alignment and reducing muscle strain.

- Adjustable Firmness

The ability to adjust the firmness of the air mattress allows users to customize their sleep experience to their individual preferences. This is typically achieved through variable inflation levels. Example: One individual might prefer a firmer mattress for back support, while another might prefer a softer mattress for pressure relief. Adjustable firmness allows both individuals to find a comfortable setting on the same mattress.

These comfort features, when effectively integrated into an air mattress designed for pickup truck bed use, elevate the sleeping experience from merely functional to genuinely comfortable. Selection of a mattress incorporating such features can significantly enhance the enjoyment and restorative quality of rest during camping, travel, or work-related activities requiring overnight stays in a pickup truck.

6. Storage Size

The storage size of an air mattress designed for pickup truck bed use is intrinsically linked to its practicality and overall utility. This connection arises from the constraints inherent in pickup truck environments, where cargo space is often limited and must accommodate a diverse range of equipment and supplies. The relationship between storage size and utility operates on a principle of inverse proportionality: larger deflated dimensions diminish available space for other essential items, thereby reducing the overall convenience and practicality of the product. The causal link manifests as follows: larger storage volume (cause) restricts space available for other gear (effect).

The importance of a compact storage profile is amplified in various real-world scenarios. Consider a camping trip where space is required for tents, cooking equipment, and personal belongings. A bulky, deflated mattress consumes valuable cargo capacity, potentially necessitating trade-offs or compromises in other areas. Conversely, a mattress that compresses into a relatively small package maximizes available space, allowing for a more comprehensive and organized packing strategy. Examples include instances where individuals have had to leave behind essential equipment due to the excessive space occupied by a large, deflated air mattress. The practical significance of this understanding lies in optimizing cargo management within the confined space of the truck bed, ensuring that the air mattress does not unduly compromise the ability to transport other necessary items.

In summary, storage size is a crucial attribute of an air mattress intended for pickup truck bed applications. Its minimization is directly proportional to maximizing the overall utility and practicality of the product. While comfort and durability are primary considerations, neglecting the storage dimensions can significantly detract from the user experience, particularly in situations where space is at a premium. Therefore, selecting an air mattress with a compact storage profile is a key element in optimizing cargo management and ensuring a successful and convenient truck bed camping experience.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, use, and maintenance of air mattresses specifically designed for use in pickup truck beds.

Question 1: Will any standard-sized air mattress fit within a pickup truck bed?

No. Standard air mattresses are generally not designed to conform to the dimensions of a pickup truck bed. Truck beds vary significantly in size and shape, particularly with regard to wheel well protrusions. A mattress specifically designed for truck bed use will typically feature cutouts or tapered edges to accommodate these features.

Question 2: What is the recommended air pressure for an air mattress in a pickup truck bed?

The appropriate air pressure is typically specified by the mattress manufacturer. Overinflation can lead to seam damage, particularly in fluctuating temperatures. Underinflation can result in inadequate support and reduced comfort. Adherence to the manufacturer’s recommendations is crucial for optimal performance and longevity.

Question 3: How does one prevent punctures to an air mattress within a pickup truck bed?

Preparation is paramount. The truck bed should be thoroughly cleaned and inspected for any sharp objects or debris. Consider using a truck bed liner or additional padding to provide a protective barrier between the mattress and the truck bed surface. Avoid placing the mattress near sharp objects or allowing pets with sharp claws to come into contact with the mattress.

Question 4: Can an air mattress for a pickup truck bed be used in other contexts, such as inside a tent?

While theoretically possible, the shape and dimensions of a truck bed mattress may not be ideal for use within a standard tent. The mattress might not fully utilize the available space and could be more prone to shifting. It is advisable to use a mattress specifically designed for tent camping.

Question 5: What is the best method for cleaning an air mattress used in a pickup truck bed?

A damp cloth with mild soap is generally sufficient for cleaning the surface. Avoid harsh chemicals or abrasive cleaners, as these can damage the mattress material. Ensure the mattress is completely dry before deflating and storing it to prevent mold and mildew growth.

Question 6: How should an air mattress for a pickup truck bed be stored when not in use?

The mattress should be completely deflated, cleaned, and dried before storage. It is advisable to fold or roll the mattress loosely to prevent creases and stress on the seams. Store the mattress in a cool, dry place away from direct sunlight and extreme temperatures. A dedicated storage bag can provide added protection.

Key takeaways include the importance of selecting a mattress specifically designed for truck bed dimensions, adhering to recommended inflation pressures, protecting against punctures, and employing proper cleaning and storage techniques.

The following sections will delve into alternative sleeping arrangements and provide a concluding summary of the key considerations discussed.

Air Mattress for Pickup Truck Bed

This exploration has elucidated the pivotal factors governing the selection and utilization of an air mattress for pickup truck bed applications. Dimensional accuracy, material robustness, inflation methodology, weight capacity, integrated comfort features, and deflated storage volume have been identified as critical determinants influencing the product’s practicality and user satisfaction. The preceding discussion underscores that the optimization of these attributes is not merely a matter of convenience but a necessity for ensuring a safe, comfortable, and functional sleeping arrangement within the confined space of a truck bed.

The diligent application of the outlined considerations will empower prospective purchasers to make informed decisions, mitigating the risks associated with suboptimal product selection. The inherent constraints of the pickup truck environment demand a judicious and discerni

ng approach to choosing an appropriate sleep solution. By prioritizing the factors discussed herein, users can effectively transform their truck bed into a viable and comfortable alternative to traditional lodging, enhancing the utility and versatility of their vehicles.