An inflatable sleeping surface designed to fit within the confines of a vehicle’s rear seating area, primarily intended for pickup trucks or larger cars, provides a portable and temporary bed. These mattresses offer a solution for rest or sleep while traveling, camping, or during situations where conventional accommodation is unavailable.

The utility of such a product lies in its ability to convert unused space into a comfortable resting area. This enhances the practicality of vehicle-based travel, affording convenience and potentially reducing expenses associated with lodging. Historically, improvised sleeping arrangements in vehicles have been uncomfortable; these mattresses offer a dedicated and more ergonomic alternative, promoting better rest and recovery during journeys.

The ensuing discussion will delve into various aspects of these vehicle accessories, including material composition, inflation methods, considerations for vehicle compatibility, and factors influencing overall user experience. Key features that differentiate products in this category and inform purchasing decisions will also be examined.

Essential Considerations for Vehicle Sleeping Platforms

Prior to procuring an inflatable rear seating area bed for a truck, a series of factors should be thoroughly evaluated to ensure optimal suitability and functionality.

Tip 1: Measure Interior Dimensions: Precise measurements of the available space in the rear seating area are paramount. Account for contours, obstructions, and the distance between seatbacks to ensure the selected inflatable mattress fits appropriately. An ill-fitting mattress compromises comfort and safety.

Tip 2: Evaluate Material Durability: The composition of the mattress material directly influences its resistance to punctures, tears, and general wear. Opt for models constructed from reinforced PVC or similar durable materials capable of withstanding repeated use and varying temperatures.

Tip 3: Assess Inflation Mechanism: Inflation methods vary across different models. Consider the convenience and efficiency of the inflation system. Integrated electric pumps are often preferable for ease of use, while manual pumps offer a backup solution in situations where electricity is unavailable. Ensure the pump’s power source is compatible with the vehicle’s electrical system.

Tip 4: Consider Surface Texture and Comfort: The surface texture of the mattress impacts user comfort. Flocked surfaces tend to provide a softer and more comfortable sleeping experience compared to plain PVC. Examine the surface finish to determine its suitability for prolonged use.

Tip 5: Inspect Weight Capacity: Determine the weight capacity of the inflatable mattress and ensure it adequately supports the intended users. Exceeding the weight limit can lead to mattress failure and potential discomfort or injury.

Tip 6: Prioritize Leak Prevention: Check reviews regarding the air-tightness and leak resistance of the mattress. Examine valve design, seam construction, and material integrity to identify potential points of failure. A well-sealed mattress maintains inflation throughout the duration of use.

Tip 7: Verify Storage and Portability: Consider the deflated size and weight of the mattress for ease of storage and transportation. A compact and lightweight design facilitates convenient packing and carrying when not in use.

Careful consideration of these elements ensures the chosen product aligns with specific needs and vehicle characteristics, resulting in a more comfortable and dependable solution for mobile resting.

The subsequent section will address the benefits and drawbacks associated with specific models and features of these rear vehicle sleeping accommodations.

1. Size and Fit

The dimensional compatibility between a vehicle’s rear seating area and an inflatable mattress is paramount for safety, comfort, and effective utilization. A mismatch in size compromises the functionality and can create hazardous conditions.

- Vehicle Model Specificity

Trucks exhibit considerable variation in rear seating area dimensions, contingent upon the make, model, and cab configuration (e.g., regular cab, extended cab, crew cab). Mattresses marketed as universally compatible may exhibit suboptimal fitment in certain vehicles. The physical dimensions of the target vehicle must be measured and compared with the mattress specifications before purchase.

- Contour Conformity

Rear seats are often contoured and not perfectly flat. The mattress design must account for these irregularities to ensure even weight distribution and prevent localized stress points that could lead to material failure or discomfort. Mattresses specifically designed to conform to common seat contours offer improved stability and support.

- Obstruction Clearance

Seatbelts, center consoles, and other protrusions within the rear seating area can impede the proper inflation and positioning of the mattress. The mattress design may incorporate cutouts or allowances for such obstructions. Consideration must be given to these features to avoid interference and ensure a flush and stable sleeping surface.

- Safety Implications

An improperly sized mattress can shift during vehicle movement, potentially interfering with the driver’s visibility or control. Furthermore, a mattress that extends beyond the rear seating area could obstruct access to emergency exits or create a projectile hazard in the event of a sudden stop or collision. Adherence to dimensional compatibility guidelines is crucial for minimizing safety risks.

Therefore, careful measurement and consideration of the vehicle’s internal dimensions and features are essential when selecting an inflatable mattress. A tailored fit optimizes comfort, safety, and the overall utility of the “back seat air mattress for truck.”

2. Material Durability

The longevity and performance of an inflatable mattress intended for use in a truck’s rear seating area are directly contingent upon the durability of its constituent materials. The capacity to withstand repeated inflation/deflation cycles, temperature fluctuations, abrasion, and weight load determines the product’s overall lifespan and suitability for its intended purpose.

- Puncture Resistance

The materials used in the mattress construction must exhibit a high degree of resistance to punctures from sharp objects, such as keys, tools, or debris that may be present in the vehicle’s interior. Thicker gauge PVC or laminated fabrics are commonly employed to mitigate the risk of air leaks and maintain structural integrity. Failure to resist puncture leads to rapid deflation and renders the mattress unusable.

- Abrasion Resistance

Contact with the vehicle’s upholstery, seatbelt buckles, and other interior surfaces subjects the mattress to constant abrasion. Materials with low abrasion resistance degrade quickly, leading to thinning and eventual failure of the seams or surface. Reinforced coatings and durable fabrics are essential for prolonged use in this environment.

- Tensile Strength

The material’s tensile strength dictates its ability to withstand the internal pressure exerted during inflation and the external forces applied by the occupant’s weight. Insufficient tensile strength results in deformation, bulging, or rupture of the mattress. High-strength polymers and reinforced construction techniques are necessary to ensure structural stability under load.

- Environmental Resistance

The interior of a vehicle is subject to significant temperature variations and exposure to UV radiation. Materials used in the mattress must resist degradation from these environmental factors. Excessive heat can cause material softening and stretching, while UV exposure can lead to embrittlement and cracking. UV-stabilized polymers and temperature-resistant coatings are crucial for maintaining material integrity over time.

In summary, the selection of durable materials is of paramount importance in the design and manufacturing of an inflatable mattress for truck back seats. The ability to resist punctures, abrasion, tensile stress, and environmental degradation directly impacts the product’s longevity, reliability, and overall value proposition.

3. Inflation Method

The mechanism by which an inflatable mattress reaches its functional state is a critical determinant of user experience. Within the context of a vehicle’s rear seating area, the inflation method must balance convenience, efficiency, and power source availability.

- Integrated Electric Pumps

Many inflatable mattresses incorporate small electric pumps powered by the vehicle’s 12V DC outlet (cigarette lighter socket). These pumps offer ease of use, inflating the mattress at the push of a button. However, reliance on the vehicle’s electrical system is a limitation, and pump failure can render the mattress unusable. Examples include models with automatic shut-off to prevent over-inflation.

- External Electric Pumps

Separate electric pumps, either AC or DC powered, provide an alternative inflation method. This approach offers greater flexibility, allowing inflation outside the vehicle or from a standard wall outlet. However, it requires carrying an additional piece of equipment and ensuring compatibility with available power sources. An example is a portable air compressor with a nozzle adapter for the mattress valve.

- Manual Pumps

Foot pumps or hand pumps offer a low-tech inflation solution, independent of electrical power. While reliable, manual inflation requires physical exertion and can be time-consuming. This method serves as a backup option when electric pumps are unavailable or impractical. Double-action pumps, which inflate on both the upstroke and downstroke, increase efficiency.

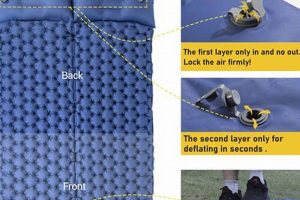

- Valve Design and Compatibility

The design of the inflation valve significantly impacts inflation speed and ease of use. Wide-mouth valves facilitate rapid inflation and deflation, while secure sealing mechanisms prevent air leakage. Compatibility with standard pump nozzles is essential for versatility. Boston valves, commonly found on inflatable mattresses, offer a balance between flow rate and sealing effectiveness.

The selection of an appropriate inflation method should align with the user’s anticipated use case and available resources. Considerations include the convenience of electric pumps, the reliability of manual pumps, and the compatibility of the valve design with readily available inflation devices. The chosen method directly impacts the practicality and overall satisfaction derived from a back seat air mattress for truck.

4. Comfort Level

The subjective experience of “Comfort Level” constitutes a primary consideration when evaluating an inflatable mattress designed for use in a truck’s rear seating area. Several factors contribute to the overall sense of comfort, influencing the suitability of the product for extended rest or sleep.

- Surface Texture and Material Properties

The tactile sensation of the mattress surface significantly affects comfort. Flocked surfaces, typically composed of short, raised fibers, provide a softer and less abrasive feel compared to bare PVC. The material’s breathability also impacts thermal regulation, influencing comfort in varying ambient temperatures. Mattresses with non-breathable surfaces may lead to perspiration and discomfort during prolonged use. An example is a flocked PVC mattress versus a standard PVC mattress in a hot climate.

- Support and Pressure Distribution

The mattress’s ability to distribute weight evenly and provide adequate support is crucial for preventing pressure points and promoting restful sleep. Internal baffling or coil structures contribute to uniform support and minimize sagging. Insufficient support can lead to discomfort, muscle strain, and disrupted sleep. A mattress with internal coils will generally provide better support than a simple air bladder design.

- Thickness and Inflation Level

The thickness of the inflated mattress impacts its cushioning effect and ability to isolate the occupant from the underlying seat structure. An adequately thick mattress provides greater insulation from bumps and uneven surfaces. Furthermore, the inflation level influences the firmness of the mattress, allowing users to customize the level of support to their preference. Over-inflation can result in excessive firmness, while under-inflation can lead to bottoming out and discomfort.

- Noise and Motion Transfer

The materials and construction of the mattress can influence noise levels during movement and the degree of motion transfer. Mattresses constructed from noisy materials can disrupt sleep, while those with high motion transfer can transmit disturbances from one occupant to another. Designs incorporating sound-dampening materials and independent support zones minimize these effects. A mattress with individually wrapped coils will typically exhibit lower motion transfer than a simple air mattress.

In summary, achieving an optimal “Comfort Level” in a “back seat air mattress for truck” necessitates careful consideration of surface texture, support characteristics, thickness, and noise-related properties. The relative importance of these factors will vary depending on individual preferences and the intended duration of use, ultimately influencing the suitability of a given mattress for providing a comfortable and restful experience within the confines of a vehicle.

5. Weight Capacity

The designated maximum weight capacity of an inflatable rear seat mattress for trucks constitutes a critical performance parameter, directly impacting safety, du

rability, and user comfort. Exceeding the specified weight limit induces disproportionate stress on the mattress materials, potentially leading to structural failure, air leaks, and compromised support. The relationship between weight capacity and product longevity is inverse; exceeding the stated limit accelerates wear and reduces the lifespan of the mattress. For example, a mattress rated for 300 pounds may experience premature seam separation or material fatigue if consistently loaded with 400 pounds. This is distinct from static load testing, which may represent an idealized scenario not reflective of real-world use conditions.

Weight capacity is not solely a matter of preventing catastrophic failure; it also affects the distribution of air pressure within the mattress. When overloaded, the mattress may deform, causing uneven support and localized pressure points. This can lead to discomfort, muscle strain, and disrupted sleep, negating the intended benefit of the product. Furthermore, the vehicle’s suspension system may be adversely affected by excessive weight concentrated in the rear seating area, impacting handling and stability. Real-world instances include cases where overloaded mattresses sag in the middle, creating an unstable and uncomfortable sleeping surface, or causing the mattress to press against the vehicle’s interior, potentially damaging upholstery.

In conclusion, adherence to the manufacturer’s stated weight capacity is paramount for ensuring the safe, effective, and prolonged use of a truck back seat air mattress. Exceeding this limit not only risks product failure and discomfort but may also compromise vehicle handling and safety. Understanding and respecting this parameter is therefore essential for maximizing the value and utility of the product while mitigating potential risks.

6. Storage Space

The compact storage of a deflated back seat air mattress for a truck directly influences its practicality and versatility. A reduced storage footprint facilitates ease of transport and minimizes the encroachment on available space within the vehicle when the mattress is not in use. The design and materials employed in mattress construction dictate its collapsibility, subsequently determining the volume occupied during storage. For instance, mattresses constructed from thinner, more pliable materials generally compress to a smaller size than those made from thicker, more rigid polymers. The inclusion of a dedicated storage bag or carrying case further enhances portability and protects the deflated mattress from damage. Examples include situations where limited cab space necessitates a mattress that can be easily stowed under a seat or behind the driver, or scenarios where the mattress must be transported in conjunction with other camping gear.

Efficient storage also mitigates the risk of damage to the air mattress. A properly stored mattress is less susceptible to punctures, abrasions, and exposure to extreme temperatures, all of which can compromise its integrity and reduce its lifespan. The storage environment should be dry, clean, and protected from direct sunlight and sharp objects. Real-world applications include preventing the mattress from being crushed by heavier items in the truck bed or shielding it from the elements during outdoor activities. Mattresses designed with integrated straps or buckles to maintain a compact folded configuration further contribute to damage prevention.

In summary, the efficient management of storage space is an indispensable aspect of back seat air mattress design and usage. A mattress that can be compactly and securely stored not only maximizes available space within the vehicle but also extends the product’s lifespan by minimizing the potential for damage. The interplay between material selection, design features, and user storage practices ultimately determines the practicality and long-term value of these vehicular sleeping solutions.

Frequently Asked Questions

The following addresses common inquiries concerning inflatable mattresses designed for use in the rear seating area of trucks, with the aim of providing clear and factual information.

Question 1: Are all “back seat air mattress for truck” models universally compatible across different truck makes and models?

No. While some mattresses are marketed as “universal fit,” variations in rear seat dimensions and configurations necessitate careful measurement and comparison of product specifications with the target vehicle’s interior dimensions.

Question 2: What is the typical lifespan of a “back seat air mattress for truck” under regular usage?

Lifespan varies based on material quality, usage frequency, and adherence to weight capacity limitations. Higher-quality materials and responsible use extend the product’s longevity. Expect a range from one to several years with appropriate care.

Question 3: What constitutes proper maintenance for a “back seat air mattress for truck” to maximize its lifespan?

Proper maintenance includes regular cleaning with mild soap and water, avoiding over-inflation, storing the mattress in a cool, dry place when not in use, and protecting it from sharp objects and extreme temperatures.

Question 4: What are the primary safety concerns associated with using a “back seat air mattress for truck?”

Safety concerns include obstructed visibility, interference with vehicle controls in the event of mattress shifting, and potential blockage of emergency exits. Selecting a correctly sized mattress and securing it properly mitigates these risks.

Question 5: Can a “back seat air mattress for truck” be used in other types of vehicles besides trucks?

Potentially, but fit and safety should be carefully evaluated. The mattress is specifically designed for the rear seating area of trucks, and use in other vehicles may result in an improper fit, compromising safety and comfort.

Question 6: What are the advantages of an integrated electric pump versus a manual pump for inflating a “back seat air mattress for truck?”

Integrated electric pumps offer convenience and ease of use but rely on a power source. Manual pumps provide a reliable backup option when electricity is unavailable, although they require more physical exertion.

In summary, informed selection, proper usage, and diligent maintenance are crucial for maximizing the value and lifespan of a back seat air mattress for trucks.

The concluding section will provide purchasing guidance and considerations for acquiring these products.

Conclusion

The preceding discussion has explored various facets of the back seat air mattress for truck, encompassing its definition, benefits, material considerations, inflation methods, safety concerns, and storage requirements. Careful evaluation of these factors is crucial for selecting a product that aligns with individual needs and vehicle specifications.

The decision to acquire a back seat air mattress for truck warrants thoughtful deliberation, considering the potential enhancements to travel convenience against the inherent limitations and safety considerations. Prudent purchasing decisions, coupled with responsible usage, maximize the utility and minimize the risks associated with this vehicular accessory. Future advancements may address current limitations, potentially leading to more versatile and safer iterations of the back seat air mattress for truck.

![Best Jeep Wrangler Air Mattress [Guide] On Road! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Jeep Wrangler Air Mattress [Guide] On Road! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-6718-300x200.jpg)