A protective encasement designed to accommodate a mattress of specified dimensions. These encasements provide a barrier against dust, moisture, and potential damage during storage or relocation. For example, a durable polyethylene sleeve can effectively shield a large bed component from the elements.

The use of such a covering is paramount for preserving the integrity and cleanliness of the contained item. It prevents the accumulation of allergens and safeguards against stains or tears. Historically, simpler versions of these covers have been utilized for generations to protect valuable textiles and furnishings during periods of inactivity or transport.

This article will now address the variety of materials, closure mechanisms, and purchasing considerations relevant to selecting an appropriate protective covering. Furthermore, it will examine proper usage techniques and long-term storage strategies.

Selecting a Protective Covering

The appropriate selection and utilization of a mattress encasement is crucial for preservation during relocation or extended storage. These tips will guide the user toward optimal results.

Tip 1: Material Durability is Paramount: Evaluate material thickness and resistance to tearing. Polyethylene plastic with a mil rating of 3 or higher is generally recommended for standard protection. For enhanced protection, consider woven polypropylene.

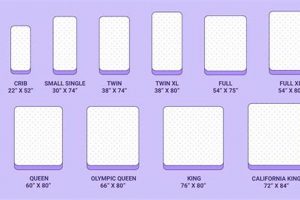

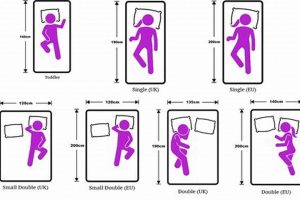

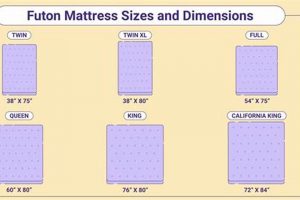

Tip 2: Ensure Adequate Dimensions: Precise measurement of the mattress is necessary. Select an encasement with sufficient room to avoid stress on the seams, which can lead to tearing. Account for extra depth due to pillow tops or mattress pads.

Tip 3: Prioritize a Secure Closure: A reliable sealing mechanism is vital to prevent ingress of dust and moisture. Heavy-duty zippers or adhesive closures offer a more secure seal than simple folding or taping.

Tip 4: Consider Ventilation Requirements: If storing long-term in a potentially humid environment, consider an encasement with small ventilation holes. These allow for air circulation, reducing the risk of mildew formation. However, balance this with protection from dust and insects.

Tip 5: Reinforce High-Stress Areas: Examine the seams and handles (if present) for reinforcement. Double-stitched seams and reinforced handles will increase the encasement’s lifespan and prevent failures during handling.

Tip 6: Verify Compatibility with Moving Equipment: If using a dolly or hand truck, ensure the encasement’s material is robust enough to withstand abrasion. Consider adding an additional layer of protection, such as moving blankets, to prevent damage.

The implementation of these guidelines ensures the longevity and cleanliness of the mattress during storage or relocation. Selecting the right encasement provides peace of mind and safeguards a significant investment.

The subsequent section will focus on appropriate storage locations and environmental considerations to further enhance mattress preservation.

1. Dimensions

Precise dimensions are a fundamental consideration when selecting a protective encasement for a queen-size mattress. The internal measurements of the bag must accurately accommodate the mattress to ensure proper protection and prevent damage.

- Length and Width Accommodation

The bag’s length and width must exceed the mattress’s corresponding measurements. A snug fit can stress the material, leading to tears, especially at seams and corners. An additional allowance of a few inches on each side is recommended to facilitate easy insertion and removal of the mattress.

- Depth Consideration

Mattress depth varies significantly, particularly with pillow-top or memory foam models. The bag’s depth must be sufficient to fully enclose the mattress’s vertical dimension. Underestimating depth can lead to incomplete closure and exposure to environmental elements.

- Tolerance for Irregularities

Minor dimensional variations in mattresses are common. The bag should have a slight tolerance to accommodate these irregularities without compromising its structural integrity. Rigid, perfectly sized bags are more susceptible to tearing if the mattress is slightly oversized.

- Impact on Sealing Mechanism

Incorrect dimensions directly impact the effectiveness of the bag’s sealing mechanism, such as zippers or adhesive closures. If the bag is too small, the closure may be strained or impossible to fully engage, leaving gaps that allow dust, moisture, and pests to enter.

The successful long-term protection of a queen-size mattress hinges on the careful selection of an encasement with appropriate dimensions. Accurate measurements, combined with a reasonable tolerance, ensure ease of use and prevent premature failure of the bag. Failure to properly account for dimensions can render the bag ineffective, negating its intended purpose.

2. Material Strength

The efficacy of a protective encasement for a queen-size mattress is fundamentally determined by the material’s inherent strength. This characteristic dictates the bag’s ability to withstand the rigors of handling, storage, and transportation, thereby directly impacting the mattress’s long-term condition. Insufficient material strength can lead to punctures, tears, and seam failures, compromising the barrier against dust, moisture, and pests. For example, a thin polyethylene bag, commonly used for short-term storage, offers limited protection against sharp objects encountered during moving, such as furniture legs or protruding nails. Conversely, a heavy-duty woven polypropylene bag provides a significantly more robust shield against such hazards, minimizing the risk of damage to the encased mattress.

The selection of appropriate material strength must also consider the intended environment and duration of storage. Mattresses stored in damp basements or garages require encasements constructed from water-resistant materials with high tensile strength to prevent moisture ingress and structural degradation. Similarly, mattresses transported over long distances necessitate bags capable of withstanding abrasion from contact with truck beds or other cargo. Material strength further influences the bag’s ability to support the weight of the mattress during lifting and carrying. Reinforced handles, securely attached to a durable bag material, facilitate safer and more efficient handling, reducing the likelihood of accidental drops or tears that could expose the mattress to damage.

In summary, material strength is a non-negotiable attribute of an effective mattress encasement. It serves as the primary line of defense against physical damage and environmental factors. Understanding the relationship between material properties and the intended application is crucial for selecting a bag that provides adequate protection, preserving the integrity and longevity of the enclosed queen-size mattress. The trade-off between cost and durability should be carefully considered, as a seemingly cheaper, weaker bag can ultimately lead to more significant expenses associated with mattress damage or replacement.

3. Closure Security

Closure security is a critical determinant of the effectiveness of a protective encasement, directly influencing its ability to safeguard a queen-size mattress from environmental contaminants and physical damage. A compromised closure negates the protective benefits of the encasement material itself, rendering the entire system vulnerable.

- Barrier Integrity

The primary function of a secure closure is to maintain an unbroken barrier against dust, moisture, allergens, and pests. Inadequate sealing allows these elements to penetrate the encasement, potentially causing staining, mold growth, or infestation of the mattress. Examples include zippered closures with gaps, adhesive strips that fail to adhere properly, or simple fold-over designs that provide minimal protection.

- Seal Reliability Under Stress

Closure mechanisms must maintain their integrity under the stresses of handling and transportation. A closure that easily disengages or tears under pressure is ineffective. Zippered closures with reinforced stitching and durable pulls, or robust adhesive strips with high shear strength, offer superior reliability. The impact of a failed seal under even moderate stress can expose the entire mattress to the elements.

- Closure Type and Longevity

Different closure types offer varying degrees of security and longevity. Zippered closures, while often providing a tight seal, can be susceptible to breakage or snagging. Adhesive closures, while simple to use, may lose their adhesive properties over time, especially in humid conditions. Fold-over closures, secured with tape, are generally the least reliable. Long-term storage necessitates a closure type designed for extended use and minimal degradation.

- Ease of Use vs. Security Trade-off

There often exists a trade-off between ease of use and closure security. Highly secure closures may be more difficult to engage and disengage, potentially requiring additional effort or specialized tools. Simple closures, while convenient, may lack the necessary robustness to provide adequate protection. The optimal closure design balances security with practicality, ensuring that the encasement can be effectively sealed and unsealed as needed without compromising its protective function.

The selection of a mattress encasement with a secure and reliable closure mechanism is paramount for preserving the cleanliness and integrity of a queen-size mattress during storage or relocation. Neglecting this aspect can undermine the effectiveness of the entire protective system, leading to potential damage and reduced mattress lifespan. Thus, a careful evaluation of closure types, materials, and construction is essential for ensuring long-term protection.

4. Ventilation

Ventilation, in the context of a mattress encasement, is a critical factor often overlooked, yet it plays a substantial role in preserving the integrity of a queen-size mattress during storage. The presence or absence of adequate ventilation directly impacts moisture management and the potential for mold or mildew growth within the enclosed environment. A lack of ventilation can create a conducive environment for microbial proliferation, even if the encasement material is nominally water-resistant.

- Moisture Control and Condensation Reduction

Ventilation facilitates the evaporation of moisture that may accumulate within the encasement, whether from residual dampness in the mattress or from fluctuations in ambient humidity. Without ventilation, this moisture can condense, creating a breeding ground for mold and mildew. For instance, a mattress stored in a non-climate-controlled garage during seasonal temperature swings is particularly susceptible to condensation-related damage if enclosed in a completely airtight bag.

- Air Circulation and Temperature Regulation

Ventilation promotes air circulation within the bag, helping to equalize temperature and prevent localized hotspots that could accelerate material degradation or microbial growth. Stagnant air can trap heat and humidity, creating an unfavorable environment. A bag with strategically placed ventilation openings allows for a more consistent and regulated internal environment, reducing the risk of localized damage.

- Material Compatibility and Degradation Prevention

Certain encasement materials, particularly those with a non-breathable composition like thick polyethylene, can exacerbate moisture-related problems if ventilation is absent. The material itself may be resistant to water penetration, but the trapped humidity inside can still damage the mattress. Ventilation mitigates this risk by allowing moisture to escape, prolonging the lifespan of both the mattress and the encasement itself. Some premium encasements feature breathable membranes that permit moisture vapor transmission while maintaining a barrier against liquids and pests.

- Balancing Protection and Airflow

The challenge lies in striking a balance between providing adequate ventilation and maintaining protection against dust, pests, and other external contaminants. Overly large or numerous ventilation openings can compromise the bag’s primary protective function. Ideally, ventilation should be achieved through the use of small, strategically positioned vents or through breathable materials that allow for limited airflow without sacrificing the barrier against larger particles and pests. A well-designed encasement will incorporate features that address both ventilation and protection simultaneously.

In conclusion, ventilation is a necessary, but often subtle, consideration when selecting an encasement. A balanced approach that prioritizes both moisture management and protection against external contaminants will contribute significantly to the long-term preservation of a queen-size mattress during storage or relocation. Failure to account for ventilation can negate the protective benefits of even the most durable and well-sealed encasement material.

5. Handle Reinforcement

Handle reinforcement is intrinsically linked to the functional utility and longevity of a mattress encasement. The implementation of robust handle reinforcement mitigates the risk of tearing or detachment during the lifting and transportation of a heavy queen-size mattress. Without such reinforcement, the handles become a critical point of failure, potentially leading to damage to the mattress or injury to the individuals handling it. The absence of reinforced handles can cause unbalanced weight distribution, increasing the likelihood of dropping the mattress, which compromises its structural integrity and cleanliness. For instance, imagine a thin, non-reinforced handle tearing while attempting to navigate a narrow staircase; the result would likely be a damaged mattress, a compromised encasement, and potential physical harm.

The method of handle reinforcement is a crucial aspect to consider. Simple stitching may suffice for lighter loads and short distances, but heavy-duty applications demand more robust techniques, such as cross-stitching, webbing, or the incorporation of metal grommets. The attachment point of the handle to the encasement material also requires specialized reinforcement to distribute the load effectively and prevent tearing. Furthermore, the handle material itself should possess high tensile strength and resistance to abrasion, ensuring that it can withstand repeated use without degradation. Examples of effective handle reinforcement include the use of wide, durable nylon webbing stitched through multiple layers of the encasement material, or the incorporation of reinforced leather or synthetic leather patches at the handle attachment points.

In summary, handle reinforcement is not merely an optional feature but a fundamental design consideration for a quality mattress encasement. It directly impacts the safety and ease of handling, as well as the long-term durability of the encasement. Choosing a mattress encasement with appropriately reinforced handles is essential for preventing damage to the mattress and ensuring the safety of those involved in its transport. While cost may be a factor, the investment in a well-reinforced encasement is justified by the reduction in potential damage and handling risks.

6. Abrasion Resistance

Abrasion resistance is a crucial material property that directly impacts the durability and protective capability of a mattress encasement. The encasement’s ability to withstand surface wear from friction is paramount, especially during relocation or storage scenarios involving movement and contact with other objects.

- Material Composition and Weave Density

The inherent abrasion resistance of a mattress encasement is directly tied to the composition of its constituent materials. Higher density materials, such as tightly woven polypropylene or canvas, exhibit superior resistance compared to thinner, loosely woven fabrics or low-density polyethylene. For example, a mattress encasement constructed from a durable, tightly woven canvas is less prone to tearing or developing holes when dragged across a rough surface, such as a concrete floor, compared to a bag made of thin plastic. The weave density, or the number of threads per unit area, also significantly contributes to abrasion resistance, with denser weaves providing greater protection against surface wear.

- Surface Coating and Treatments

The application of specialized surface coatings or treatments can enhance the abrasion resistance of a mattress encasement. These coatings, often composed of polymers or other durable materials, create a protective layer that shields the underlying fabric from direct contact with abrasive surfaces. For instance, a polyurethane coating applied to a woven polypropylene encasement can significantly increase its resistance to scuffing, tearing, and puncture. These treatments also improve the water resistance and overall durability of the encasement.

- Seam Construction and Reinforcement

Abrasion is not limited to the surface of the encasement; it can also occur along seams and edges, particularly during dragging or sliding. Reinforced seams, achieved through double-stitching or the addition of binding tape, enhance the overall abrasion resistance of the encasement. For example, a mattress encasement with double-stitched and taped seams is less likely to experience seam failure due to abrasion compared to one with simple, single-stitched seams. Reinforcing vulnerable areas minimizes the risk of the encasement splitting or tearing under stress.

- Friction Coefficient and Surface Smoothness

The friction coefficient of the encasement’s surface plays a role in determining its abrasion resistance. A lower friction coefficient allows the encasement to slide more easily across surfaces, reducing the amount of abrasive force applied to the material. For instance, a mattress encasement with a smooth, slick surface will experience less abrasion than one with a rough, textured surface when dragged across the same surface. The smoothness of the surface can be influenced by the material composition, surface coatings, and the manufacturing process.

In conclusion, the abrasion resistance of a mattress encasement is a multifaceted property determined by the interplay of material composition, surface treatments, seam construction, and surface characteristics. Selecting an encasement with adequate abrasion resistance is essential for preserving the integrity of the mattress during relocation, storage, and handling. Choosing the right encasement contributes to the longevity of the mattress and prevents costly damage.

7. Seam Integrity

Seam integrity is a critical attribute of any protective encasement. Its significance is heightened in the context of a mattress encasement, where a failure can compromise the entire protective function of the bag. This element dictates the bag’s capacity to withstand stress during handling and storage, preserving the cleanliness and structural soundness of the enclosed queen-size mattress.

- Stitch Type and Density

The type of stitch employed and its density directly influence the seam’s strength and resistance to tearing. Lockstitches, known for their secure interlocking, are preferable to chain stitches which can unravel if broken. A higher stitch density, meaning more stitches per inch, provides a more robust seam. For instance, a bag with double-stitched, high-density lockstitches is significantly more resistant to seam failure than one with single-stitched chain stitches.

- Thread Material and Strength

The material composition and tensile strength of the thread are paramount. High-tenacity threads, such as those made from polyester or nylon, offer greater resistance to breakage than cotton threads. The thread’s ability to withstand abrasion and UV degradation is also essential for long-term durability. Consider a scenario where a bag is stored in a partially exposed environment; a UV-resistant thread will maintain its integrity longer, preserving the seam’s strength.

- Seam Reinforcement Techniques

Various techniques can reinforce seams, enhancing their overall strength and durability. Binding the seam edges with tape or fabric strips provides additional support and prevents fraying. Incorporating gussets at stress points, such as corners or handle attachments, distributes the load more effectively. A bag with reinforced seams at critical stress points is less likely to experience seam failure under heavy loads or during rough handling.

- Seam Placement and Design

The placement and design of seams can influence their susceptibility to stress. Seams located along edges or in areas of high tension are more prone to failure. Designing seams to minimize stress concentration, such as using curved or offset seams, can enhance their overall integrity. For example, a bag with seams strategically placed away from the direct load-bearing points will exhibit greater seam longevity.

These facets collectively determine the long-term performance of the mattress encasement. Superior seam integrity translates directly into enhanced protection for the queen-size mattress during storage and relocation, mitigating the risk of damage from dust, moisture, and physical stress. Investing in a bag with robust seam construction ensures the preservation of the mattress’s cleanliness and structural integrity.

Frequently Asked Questions

The following addresses common inquiries regarding protective encasements for queen-size mattresses, clarifying appropriate usage and selection criteria.

Question 1: What material is most suitable for a mattress encasement intended for long-term storage?

Durable, water-resistant materials such as woven polypropylene or heavy-gauge polyethylene are recommended. These materials offer a balance of tear resistance and protection against moisture and pests.

Question 2: How should one properly seal a mattress encasement to ensure optimal protection?

Zippered closures with reinforced seams provide a secure seal. Alternatively, heavy-duty adhesive closures, properly applied, can offer effective protection. Avoid relying solely on tape, as it can degrade over time.

Question 3: Is ventilation necessary for a mattress encasement used in long-term storage?

Ventilation can be beneficial in minimizing moisture buildup and preventing mold growth. However, it must be balanced against the need for protection against dust and pests. Encasements with small, strategically placed ventilation ports are recommended.

Question 4: How does one determine the correct size encasement for a queen-size mattress?

Accurate measurement of the mattress’s length, width, and depth is essential. The encasement should provide a slightly larger fit to allow for easy insertion and removal without stressing the seams. Account for any pillow tops or mattress pads.

Question 5: What precautions should be taken when handling a mattress encased for storage or relocation?

Lift the mattress using the reinforced handles, if provided. Ensure a firm grip and avoid dragging the encasement across abrasive surfaces. Use a dolly or hand truck for long-distance transport.

Question 6: How often should a mattress encased in a protective bag be inspected during long-term storage?

Periodic inspection, ideally every six months, is recommended to check for signs of moisture, pest infestation, or damage to the encasement. Address any issues promptly to prevent further deterioration of the mattress.

The proper selection and utilization of a protective encasement are vital for preserving the condition of a queen-size mattress during storage and relocation. Prioritize durable materials, secure closures, and appropriate handling techniques to maximize protection.

The subsequent section will explore advanced storage strategies for mattresses, including environmental control and preventative maintenance.

Protective Mattress Encasements

This exploration has illuminated the multifaceted aspects of selecting and utilizing a protective encasement for queen-size mattresses. Considerations of material strength, closure security, ventilation, abrasion resistance, and seam integrity are critical to safeguarding the mattress from environmental factors and physical damage during storage or relocation. Failure to adequately address these elements compromises the encasement’s effectiveness, potentially leading to irreversible harm.

Therefore, judicious selection of a “bag for queen size mattress” grounded in a thorough understanding of its intended purpose and environmental conditions is paramount. Prudent investment in a high-quality encasement offers a tangible return through the prolonged lifespan and sustained cleanliness of a significant household asset. Diligence in this area represents a commitment to preserving value and ensuring long-term comfort.

![[Guide] What Size Mattress Do I Need? Find Your Fit! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions [Guide] What Size Mattress Do I Need? Find Your Fit! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-2304-300x200.jpg)