A portable, electrically-powered device designed to inflate air mattresses is frequently powered by batteries. This mechanism offers a convenient solution for inflating mattresses in locations where access to mains electricity is limited or unavailable. Common examples include camping trips or temporary guest accommodations where traditional electrical outlets are not readily accessible.

The utility of these devices lies in their portability and ease of use. They eliminate the need for manual inflation, saving time and effort. Historically, alternatives involved foot pumps or hand pumps, which required considerable physical exertion. Battery-operated models provide a more efficient and user-friendly approach, contributing to enhanced comfort and convenience in diverse settings. Their development reflects a broader trend toward portable and readily accessible power solutions.

The subsequent sections will delve into the various types of battery-operated inflation devices, their operational characteristics, factors to consider when selecting a suitable model, and best practices for maintenance and long-term usage. Further discussion will address safety considerations and potential environmental impacts.

Optimizing Usage and Longevity

Maximizing the performance and lifespan of portable inflation devices requires adherence to specific guidelines. The following recommendations are intended to ensure reliable operation and prevent premature failure.

Tip 1: Battery Selection: Utilize high-quality batteries of the correct voltage and type as specified by the manufacturer. Avoid mixing different battery brands or types within the device, as this can lead to reduced performance and potential damage.

Tip 2: Pre-Inflation Inspection: Before each use, examine the inflation device for any signs of damage, such as cracks, loose connections, or frayed wires. If damage is detected, discontinue use until repairs are completed.

Tip 3: Nozzle Compatibility: Ensure that the nozzle of the inflation device is securely attached to the air mattress valve. An improper seal can result in air leakage and inefficient inflation.

Tip 4: Inflation Monitoring: Avoid over-inflation of the air mattress. Consult the mattress manufacturer’s recommendations for optimal pressure. Over-inflation can compromise the mattress’s integrity and lead to premature failure.

Tip 5: Storage Practices: Store the device in a dry, cool location away from direct sunlight and extreme temperatures. Remove batteries if the device will not be used for an extended period, to prevent corrosion.

Tip 6: Cleaning Procedures: Periodically clean the exterior of the device with a soft, damp cloth. Avoid using harsh chemicals or abrasive cleaners that could damage the plastic casing.

Tip 7: Operational Environment: Refrain from using the inflation device in wet or humid environments, as moisture can damage the electrical components and compromise its functionality.

Following these practices will contribute to enhanced performance, prolonged lifespan, and safe operation. Adherence to these guidelines is crucial for reliable inflation whenever and wherever needed.

The subsequent section will provide a comparative analysis of different models, highlighting their features, performance characteristics, and suitability for various applications.

1. Portability

The concept of portability is intrinsically linked to the utility and appeal of battery-operated air inflation devices designed for air mattresses. The absence of reliance on mains electricity dictates the suitability of these devices for various applications where convenience and accessibility are paramount.

- Weight and Dimensions

The weight and physical dimensions of the device directly impact its ease of transport. Lighter and more compact models are more conducive to inclusion in travel luggage or camping gear. The ability to minimize bulk is a primary driver in device design, balancing functionality with space constraints. Excessively large or heavy units diminish the core advantage of on-the-go inflation.

- Cordless Operation

Eliminating the necessity for a power cord enhances operational flexibility. Cordless designs facilitate use in diverse environments where electrical outlets are unavailable or inconveniently located. This feature is particularly advantageous for outdoor activities or temporary accommodations lacking reliable power sources. The independence from cord constraints translates to greater user mobility and deployment options.

- Self-Contained Power Source

The integration of a battery as a self-contained power source distinguishes these devices from their corded counterparts. This independence from external power infrastructure broadens the scope of potential applications. A fully charged battery enables repeated inflation cycles without requiring access to electrical networks, crucial for remote locations or emergency situations. Battery capacity directly influences the number of inflations achievable per charge, a key performance metric.

- Storage Considerations

Portability extends beyond operational use to encompass storage efficiency. Compact storage facilitates easy packing and minimizes the space occupied when the device is not in use. Many models incorporate design features that optimize storage space, such as retractable cords or detachable nozzles. The ability to stow the device conveniently enhances its overall practicality and user experience.

These considerations collectively define the degree to which a battery-operated air inflation device embodies the principle of portability. Manufacturers prioritize these aspects to create products that effectively address the needs of users seeking convenient and readily deployable inflation solutions. The convergence of lightweight design, cordless operation, self-contained power, and storage efficiency ultimately determines the device’s suitability for a wide range of mobile applications.

2. Inflation Speed

Inflation speed, in the context of battery-operated air inflation devices for air mattresses, denotes the rate at which the device can introduce air into the mattress, typically measured in cubic feet per minute (CFM) or liters per minute (LPM). A higher inflation speed translates to a shorter time required to fully inflate the air mattress. This parameter is directly influenced by the device’s motor power, impeller design, and the efficiency of the air delivery system. Slower inflation can lead to user frustration and inconvenience, particularly when time is a constraint. Real-world examples include situations such as quickly preparing guest accommodations or inflating a mattress at a campsite after a long journey, where r

apid inflation is highly desirable. Understanding the device’s inflation speed is crucial for selecting a product that aligns with specific user needs and expectations. A discrepancy between advertised and actual inflation speed can significantly impact user satisfaction.

The practical significance of inflation speed extends beyond mere convenience. In emergency situations, such as inflating an air mattress for temporary shelter, a faster inflation rate can provide critical time savings. Furthermore, individuals with physical limitations or those who find manual inflation challenging will greatly benefit from a device that offers rapid inflation. Conversely, lower-powered devices with slower inflation speeds may be more energy-efficient, extending battery life, a factor to consider in situations where access to recharging facilities is limited. The trade-off between inflation speed and battery consumption is a significant design consideration for manufacturers.

In summary, inflation speed represents a core performance characteristic of a battery-powered air inflation device, directly affecting user experience and practical utility. Challenges remain in accurately communicating and measuring inflation speeds under real-world conditions, as external factors such as ambient temperature and battery charge level can influence performance. Future advancements may focus on optimizing motor technology and impeller designs to achieve higher inflation speeds while maintaining energy efficiency and portability, ultimately enhancing the value proposition of these devices.

3. Battery Lifespan

Battery lifespan directly influences the utility and practicality of a battery-powered air pump for air mattresses. The capacity of the battery, measured in amp-hours (Ah) or watt-hours (Wh), dictates the duration for which the pump can operate before requiring a recharge or battery replacement. A longer battery lifespan enables the inflation of multiple air mattresses, or the maintenance of a single mattress’s pressure over an extended period, without interruption. Conversely, a short battery lifespan limits the device’s functionality and necessitates frequent recharging, rendering it less convenient, particularly in environments lacking readily available power sources. For example, a pump with a short battery lifespan would be unsuitable for a multi-day camping trip where multiple inflations are required, whereas a model with a longer lifespan would provide greater utility.

The type of battery employed also plays a significant role. Lithium-ion (Li-ion) batteries generally offer a higher energy density and longer lifespan compared to Nickel-Metal Hydride (NiMH) or traditional alkaline batteries. Li-ion batteries also exhibit a lower self-discharge rate, meaning they retain their charge for longer periods when not in use. The performance of the pump is intrinsically linked to the battery’s health; as the battery degrades over time, its capacity diminishes, leading to reduced inflation speed and duration. Manufacturers often specify the battery’s cycle life, indicating the number of charge-discharge cycles it can withstand before significant performance degradation occurs. Proper battery maintenance, such as avoiding complete discharge and storing the pump in a cool, dry environment, can help prolong battery lifespan.

In summary, battery lifespan is a critical determinant of a battery-operated air pump’s effectiveness and user satisfaction. Selection of a pump with an adequate battery capacity and a robust battery technology, coupled with appropriate maintenance practices, ensures reliable performance and extended usability. The challenge lies in balancing battery lifespan with other factors such as pump size, weight, and cost. Future advancements in battery technology are likely to further enhance the capabilities and convenience of these devices, solidifying their role as essential tools for portable inflation needs.

4. Nozzle Compatibility

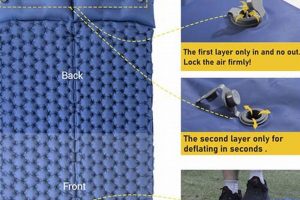

Nozzle compatibility represents a critical factor in the effective and efficient operation of any battery-operated air pump designed for air mattress inflation. The interface between the pump’s output and the mattress’s valve dictates the integrity of the airflow and the ability to achieve the desired inflation level. Mismatched or poorly designed interfaces can result in air leakage, inefficient inflation, and potential damage to either the pump or the mattress valve. Therefore, a thorough understanding of nozzle compatibility is essential for selecting and utilizing these devices effectively.

- Valve Type Standardization

Air mattresses employ various valve types, including Boston valves, pinch valves, and stem valves. The degree of standardization across different mattress manufacturers is limited, leading to potential compatibility issues. A pump designed with multiple nozzle attachments, or a universal adapter, addresses this variability, ensuring compatibility with a broader range of air mattresses. The absence of such adaptability restricts the pump’s usability to specific mattress types and necessitates the acquisition of additional adapters.

- Secure Connection Mechanisms

The method by which the nozzle attaches to the valve directly affects the airtightness of the connection. Threaded connections, for instance, offer a more secure and reliable seal compared to simple press-fit designs. However, threaded connections may require more time and effort to engage properly. Quick-connect mechanisms provide speed and convenience, but may be more susceptible to leakage if not properly aligned. The selection of a secure connection mechanism is crucial for preventing air loss during inflation and maintaining consistent pressure within the mattress.

- Material Composition and Durability

The materials used in the construction of the nozzle and valve interface impact the longevity and resistance to wear and tear. Nozzles fabricated from robust materials, such as reinforced plastics or metals, are less prone to cracking or deformation under pressure. The sealing surfaces must be smooth and free from imperfections to ensure an airtight seal. Repeated use of a poorly designed or damaged nozzle can lead to valve damage on the air mattress, necessitating costly repairs or replacements.

- Airflow Efficiency

Nozzle design influences the efficiency of airflow from the pump into the mattress. A well-designed nozzle minimizes turbulence and restrictions, allowing for a smooth and unimpeded flow of air. Conversely, a poorly designed nozzle can create backpressure and reduce the pump’s overall performance. The internal diameter of the nozzle and the geometry of the airflow path are critical factors in optimizing airflow efficiency. Maximizing airflow efficiency translates to faster inflation times and reduced strain on the pump’s motor.

In conclusion, nozzle compatibility is an indispensable consideration in the context of battery air pumps for air mattresses. These facets highlight its pervasive influence on performance, durability, and user satisfaction. By selecting pumps with versatile nozzle options, secure connection mechanisms, robust materials, and efficient airflow designs, users can ensure optimal inflation and prolonged operational lifespan.

5. Pressure control

Pressure control, as it pertains to battery-operated air pumps designed for air mattresses, is a critical feature influencing both user comfort and the longevity of the air mattress itself. The ability to regulate the internal pressure of the mattress allows users to customize the firmness and support level to their preference. Inadequate pressure control can lead to either under-inflation, resulting in a sagging and uncomfortable sleep surface, or over-inflation, increasing the risk of seam rupture and material damage. Consequently, effective pressure control is not merely a convenience but a necessary component for maximizing the functional lifespan and user satisfaction associated with the air mattress.

Several mechanisms can facilitate pressure control in these devices. Some models incorporate a pressure gauge, providing a visual indication of the current internal pressure. This allows users to monitor the inflation process and avoid over-inflation. More sophisticated models feature automatic shut-off mechanisms, which halt inflation once a pre-set pressure threshold is reached. This functionality is particularly beneficial, as it eliminates the risk of over-inflation due to user error. The absence of either a gauge or automatic shut-off necessitates a more cautious approach to inflation, relying on tactile feedback and user judgment, which may be less precise and more prone to error. For example, without proper pressure control, an air mattress used for camping in fluctuating temperatures might be over-inflated during the day (due to heat expansion) and become uncomfortably firm, only to be under-inflated and saggy at night as temperatures drop.

In summary, pressure control represents a pivotal aspect of battery-operated air pump functionality. Its integration allows for optimized user comfort, minimizes the risk of damage to the air mattress, and enhances the overall user experience. The absence of effective pressure control introduces a significant risk of both discomfort and premature product failure, thereby diminishing the value proposition of the air mattress and its associated inflation device. Future advancements may focus on integrating more precise pressure sensors and automated control systems to further refine this capability.

6. Durability

The durability of a battery air pump for air mattresses is a critical attribute determining its longevity, reliability, and overall value proposition. A robust design and high-quality materials contribute to a longer operational lifespan and reduced risk of failure under normal operating conditions. The device’s ability to withstand physical stresses, environmental factors, and frequent use directly impacts its cost-effectiveness and user satisfaction.

- Material Selection and Construction Integrity

The materials employed in the construction of the pump casing, internal components, and connectors significantly influence its resistance to damage. High-impact plastics, reinforced polymers, and corrosion-resistant metals enhance the pump’s ability to withstand shocks, vibrations, and exposure to moisture. Poorly constructed pumps with flimsy materials are more susceptible to cracking, breakage, and internal component failure, particularly under conditions of frequent use or storage in harsh environments. Examples include pumps used for camping or travel, where they may be exposed to rough handling and varying weather conditions.

- Motor and Component Reliability

The motor is the core component of the air pump, and its reliability directly impacts the device’s overall lifespan. High-quality motors with robust bearings and efficient cooling systems are less prone to overheating and premature failure. Similarly, the durability of other internal components, such as the impeller, valves, and electrical connections, is crucial for maintaining consistent performance over time. Devices incorporating substandard components are more likely to experience reduced inflation speed, increased noise levels, or complete operational failure. For instance, an air pump with a poorly constructed motor may overheat and shut down during prolonged inflation, rendering it useless.

- Resistance to Environmental Factors

Battery air pumps for air mattresses are often used in outdoor settings, exposing them to a range of environmental factors, including moisture, dust, and temperature extremes. Durable pumps are designed to withstand these conditions without experiencing performance degradation or component damage. Sealed casings, corrosion-resistant coatings, and robust seals protect internal components from moisture and dust intrusion. Temperature-resistant materials prevent cracking or deformation under extreme heat or cold. Pumps that are not adequately protected against environmental factors are more likely to experience corrosion, electrical shorts, or mechanical failures. A pump used at a beach, for example, without adequate sealing, might suck in sand and cease to function.

- Stress Testing and Quality Assurance

Manufacturers of durable air pumps subject their products to rigorous stress testing and quality assurance procedures. These tests simulate real-world usage conditions and evaluate the pump’s ability to withstand repeated inflation cycles, temperature variations, and physical impacts. Pumps that pass these tests are more likely to provide reliable performance and a longer operational lifespan. Consumers can assess durability by reviewing product specifications, reading user reviews, and considering the manufacturer’s warranty. A longer warranty period often indicates a higher level of confidence in the product’s durability. Pumps without adequate stress testing may be more prone to unexpected failures and shorter lifespans.

In conclusion, the durability of a battery air pump for air mattresses is a multifaceted attribute encompassing material selection, component reliability, environmental resistance, and rigorous testing. Prioritizing durability when selecting a pump ensures a longer lifespan, reduced risk of failure, and enhanced user satisfaction, ultimately providing a more cost-effective and reliable solution for air mattress inflation.

7. Noise Level

The operational noise level of a battery air pump for air mattresses represents a significant consideration impacting user experience and suitability for various environments. Excessive noise can be disruptive, particularly during nighttime use or in shared living spaces, potentially negating the convenience and portability advantages offered by these devices. Therefore, understanding the factors contributing to noise generation and strategies for mitigation is essential for informed product selection and responsible usage.

- Motor Operation and Design

The primary source of noise stems from the pump’s electric motor. Motor design, rotational speed, and the presence of internal vibrations directly influence the acoustic output. Cheaper pumps often utilize less refined motors, resulting in higher noise levels due to increased mechanical vibration and less efficient energy conversion. Conversely, premium models typically incorporate noise-dampening features, such as insulated motor mounts and optimized impeller designs, to minimize acoustic emissions. A practical example is the use of a pump in a campground setting, where a quieter motor

is less likely to disturb other campers during late-night inflation. - Airflow Dynamics and Turbulence

The movement of air through the pump’s internal channels and nozzle also contributes to noise generation. Turbulent airflow creates a hissing or whistling sound that can be particularly noticeable at higher inflation pressures. Pump designs that incorporate smooth, streamlined airflow pathways minimize turbulence and reduce acoustic output. Nozzle design also plays a role; a poorly designed nozzle can create additional turbulence and amplify noise levels. For example, a pump with a narrow or obstructed nozzle may produce a higher-pitched, more irritating sound compared to a model with a wider, more open nozzle design.

- Housing Material and Vibration Dampening

The material composition and structural integrity of the pump housing affect its ability to dampen vibrations and contain noise. Housings constructed from rigid, dense materials, such as high-impact plastics or composites, tend to be more effective at absorbing vibrations and reducing noise transmission compared to flimsy or lightweight housings. The inclusion of vibration-dampening pads or rubber feet can further minimize noise propagation by isolating the pump from its surroundings. Using a pump on a hard surface without proper dampening can significantly amplify its noise output.

- Operational Context and Mitigation Strategies

The perceived impact of noise level depends on the operational context. Using a pump in a secluded outdoor environment may be less problematic than using it in a shared apartment or a quiet bedroom. Mitigation strategies include placing the pump on a soft surface to absorb vibrations, using earplugs, or selecting a model specifically designed for low noise operation. Furthermore, awareness of inflation timing can minimize disruption; inflating the mattress during daylight hours, rather than late at night, is considerate of others in shared spaces. A consumer should be aware of decibel levels if noise level is a consideration.

In conclusion, the noise level of a battery air pump for air mattresses is a multifaceted characteristic influenced by motor design, airflow dynamics, housing material, and operational context. Recognizing these contributing factors allows users to make informed purchasing decisions and implement mitigation strategies to minimize noise pollution, ensuring a more pleasant and considerate user experience. Future advancements may focus on developing even quieter pump technologies, further enhancing the appeal of these devices in noise-sensitive environments.

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding battery-operated air pumps designed for air mattress inflation. The information provided aims to offer clarity and facilitate informed decision-making.

Question 1: What is the typical lifespan of a battery-operated air pump for air mattresses?

The lifespan of a battery-operated air pump varies significantly depending on factors such as build quality, motor type, battery chemistry, and usage frequency. Higher-quality models, employing robust motors and lithium-ion batteries, can last for several years with proper maintenance. Conversely, budget-friendly pumps with less durable components may only last for a season or two of regular use. Adherence to manufacturer-recommended maintenance procedures, such as proper storage and battery care, can prolong the device’s operational lifespan.

Question 2: Are battery-operated air pumps suitable for inflating large air mattresses?

The suitability of a battery-operated air pump for inflating large air mattresses depends on the pump’s capacity and the mattress’s volume. High-volume pumps, designed to deliver a greater airflow rate, are better suited for inflating larger mattresses in a reasonable timeframe. Lower-capacity pumps may struggle to fully inflate a large mattress or may require an extended period to do so, potentially draining the battery prematurely. Careful consideration of the pump’s specifications and the mattress’s size is essential.

Question 3: What types of batteries are commonly used in these air pumps, and what are their respective advantages?

Common battery types include alkaline, nickel-metal hydride (NiMH), and lithium-ion (Li-ion). Alkaline batteries offer affordability but typically have a shorter lifespan and lower energy density. NiMH batteries are rechargeable and offer a longer lifespan than alkaline batteries, but they exhibit a higher self-discharge rate. Lithium-ion batteries provide the highest energy density, longest lifespan, and lowest self-discharge rate, making them the preferred choice for high-performance pumps, but they are generally more expensive. The selection of battery type represents a trade-off between cost, performance, and environmental considerations.

Question 4: Is it possible to over-inflate an air mattress using a battery-operated air pump?

Over-inflation is a potential risk when using any air pump, including battery-operated models. Over-inflating an air mattress can stretch the material beyond its limits, leading to seam rupture and irreparable damage. Some pumps incorporate pressure gauges or automatic shut-off mechanisms to prevent over-inflation. In the absence of such features, careful monitoring of the mattress’s firmness and adherence to the manufacturer’s recommended pressure levels are crucial.

Question 5: How should a battery-operated air pump be stored when not in use?

Proper storage is essential for maintaining the performance and longevity of a battery-operated air pump. The device should be stored in a cool, dry location away from direct sunlight and extreme temperatures. Batteries should be removed if the pump will not be used for an extended period to prevent corrosion and potential damage. The pump should be cleaned periodically to remove dust and debris, ensuring optimal performance.

Question 6: Are there any safety precautions to consider when using a battery-operated air pump?

Several safety precautions should be observed when using a battery-operated air pump. The pump should never be used in or near water, as this poses a risk of electric shock. The device should be inspected for any signs of damage before each use. Overheating during prolonged operation should be avoided. The pump should be kept out of reach of children. Adherence to these precautions minimizes the risk of accidents and ensures safe operation.

In summary, understanding the capabilities, limitations, and proper usage of battery-operated air pumps is vital for maximizing their utility and ensuring a positive user experience. Careful consideration of the factors outlined above facilitates informed decision-making and promotes safe and effective operation.

The subsequent section will delve into troubleshooting common issues encountered with these devices.

Conclusion

The preceding sections have detailed the multifaceted aspects of the battery air pump for air mattress, ranging from operational characteristics and selection criteria to maintenance practices and safety considerations. Emphasis has been placed on factors influencing performance, durability, and user satisfaction, underscoring the significance of informed purchasing decisions and responsible usage protocols. The exploration has encompassed the importance of battery selection, nozzle compatibility, pressure control, and noise level, among other critical attributes.

The utility of the battery air pump for air mattress is undeniable in scenarios demanding portability and convenience. Continued advancements in battery technology, motor efficiency, and material sc

ience promise to further enhance the capabilities and longevity of these devices. Responsible consumption practices, including proper disposal of batteries and adherence to manufacturer guidelines, are essential for mitigating environmental impact and maximizing product lifespan. The discerning consumer will prioritize informed selection and diligent maintenance to ensure optimal performance and enduring value.