The structural foundation designed to support a viscoelastic foam sleeping surface plays a critical role in the overall sleep experience. These foundations come in various materials and constructions, each offering distinct advantages and disadvantages in terms of support, ventilation, and longevity of the foam sleeping surface. For instance, a slatted foundation may promote airflow, while a solid platform may provide enhanced support.

Selecting a suitable foundation is paramount because it directly impacts the lifespan of the foam material and the quality of rest. Proper support prevents sagging, ensures even weight distribution, and maintains the integrity of the foam over time. The right choice can also influence temperature regulation during sleep, a crucial factor for individuals sensitive to heat. Historically, a range of materials from wood to metal has been employed in their construction, reflecting evolving preferences in aesthetics and functionality.

This article will explore several key factors in selecting a suitable foundation, including material types, construction methods, ventilation considerations, and weight capacity. Furthermore, it will delve into the impact of foundation choice on sleep quality and the long-term health of the viscoelastic foam sleeping surface.

Selection Guidance

The appropriate foundation selection is crucial for optimizing the lifespan and performance of viscoelastic foam sleeping surfaces. Consider the following guidelines to ensure compatibility and maximize benefits.

Tip 1: Assess Support Requirements: Evaluate the density and thickness of the viscoelastic foam. Thicker, denser materials require more robust support to prevent sagging and maintain even weight distribution.

Tip 2: Prioritize Ventilation: Viscoelastic foam tends to retain heat. Opt for foundations with slats or mesh surfaces to promote airflow and dissipate heat, thereby improving sleep comfort.

Tip 3: Consider Weight Capacity: Ensure the foundation’s weight capacity is sufficient for both the viscoelastic foam sleeping surface and the occupants. Exceeding the weight limit can compromise the foundation’s structural integrity and lead to premature wear.

Tip 4: Evaluate Material Durability: Choose a foundation constructed from durable materials such as solid wood or reinforced steel. These materials offer superior stability and resistance to wear and tear.

Tip 5: Check for Slat Spacing: If selecting a slatted foundation, ensure that the slats are spaced closely enough to provide adequate support. Excessive spacing can create pressure points and diminish the benefits of the viscoelastic foam.

Tip 6: Measure Foundation Height: Account for the foundation’s height when determining the overall bed height. An excessively high or low bed can impact ease of access and ergonomic comfort.

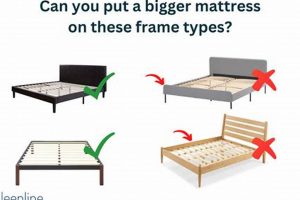

Tip 7: Verify Compatibility with Existing Frames: If the foundation is intended for use with an existing frame, confirm that the dimensions and attachment mechanisms are compatible. Incompatible components can compromise stability and safety.

Adhering to these guidelines facilitates the selection of a foundation that supports, ventilates, and preserves the viscoelastic foam, leading to an improved sleep experience and extended product lifespan.

The subsequent sections of this article will delve into specific foundation types and their suitability for different viscoelastic foam characteristics and user preferences.

1. Support Adequacy

Support adequacy is a critical determinant in evaluating foundations for viscoelastic foam sleeping surfaces. The primary function of a foundation is to provide uniform support, preventing sagging and ensuring even weight distribution across the entire surface. Inadequate support leads to localized compression, which can accelerate the degradation of the foam material. This degradation manifests as permanent indentations or a loss of resilience, thereby diminishing the lifespan of the sleeping surface and impacting the quality of rest. For example, a lightweight metal frame with widely spaced slats used beneath a high-density memory foam mattress is likely to exhibit insufficient support, resulting in premature sagging in areas of concentrated weight.

The selection of a foundation with appropriate support characteristics directly affects the biomechanical properties of the sleeping surface. A foundation that provides adequate support helps maintain proper spinal alignment and reduces pressure points, contributing to improved sleep posture and reduced musculoskeletal strain. Conversely, a sagging or uneven surface caused by inadequate support can exacerbate existing back pain or contribute to the development of new discomfort. Furthermore, the type of foundation influences the perceived firmness of the viscoelastic foam. A solid platform foundation generally provides a firmer feel compared to a slatted foundation, allowing for customization based on individual comfort preferences.

In summary, support adequacy is an indispensable component of a foundation suitable for viscoelastic foam sleeping surfaces. The ability of the foundation to provide uniform support is directly correlated with the lifespan, performance, and comfort characteristics of the foam material. Selecting a foundation that meets or exceeds the recommended support requirements is essential for maximizing the value of the sleeping surface and promoting optimal sleep health. Failure to prioritize support adequacy can result in premature wear, compromised comfort, and potential musculoskeletal issues.

2. Ventilation Capability

Ventilation capability is a critical, yet often overlooked, attribute of foundation structures designed to support viscoelastic foam sleeping surfaces. Due to the inherent properties of viscoelastic foam, which tends to retain heat, the ability of a foundation to promote airflow is paramount to maintaining a comfortable sleeping environment. The following details outline key facets of ventilation and its relevance to foundation selection.

- Heat Dissipation

Viscoelastic foam is known for its ability to conform to the body, which can limit airflow and trap heat. A foundation that facilitates heat dissipation helps regulate sleeping temperature, preventing overheating and promoting restful sleep. Foundations with slatted designs or open structures allow for greater air circulation beneath the mattress, channeling away excess heat. Without sufficient ventilation, individuals may experience discomfort and disrupted sleep patterns, particularly in warmer climates or during warmer seasons.

- Moisture Management

In addition to heat retention, viscoelastic foam can also trap moisture. Perspiration and humidity can accumulate within the mattress, creating an environment conducive to mold and mildew growth. A well-ventilated foundation helps to wick away moisture, preventing the build-up of humidity and preserving the hygiene and longevity of the mattress. Platforms offering solid support, while generally more supportive, often lack sufficient breathability, making them less suitable in humid environments.

- Material Composition of the Foundation

The materials used in the construction of the foundation also play a significant role in its ventilation capabilities. Wood, for example, can absorb and release moisture, helping to regulate humidity levels. Metal foundations, particularly those with open designs, can promote airflow more effectively than solid wood platforms. The optimal choice depends on the climate and the individual’s specific needs regarding temperature and moisture regulation.

- Impact on Sleep Quality

The ability of a foundation to facilitate ventilation directly impacts sleep quality. Overheating and moisture accumulation can disrupt sleep cycles, leading to restlessness and reduced overall restfulness. Selecting a foundation with adequate ventilation is, therefore, crucial for creating a comfortable and hygienic sleeping environment. Proper ventilation contributes to consistent sleep temperature and a reduction in allergens, promoting deeper, more restorative sleep.

In conclusion, the ventilation capability of a foundation is an essential consideration when choosing a support structure for viscoelastic foam sleeping surfaces. A well-ventilated foundation helps regulate temperature, manage moisture, and promote a comfortable and hygienic sleeping environment, ultimately contributing to improved sleep quality and an extended mattress lifespan. Prioritizing ventilation can mitigate common issues associated with memory foam mattresses, such as overheating and moisture build-up.

3. Material Durability

Material durability is a paramount consideration in the selection of a support structure for viscoelastic foam sleeping surfaces. The longevity and stability of the foundation directly influence the long-term performance and user satisfaction with the entire sleep system.

- Frame Construction Materials

The selection of materials used in the frame’s construction dictates its ability to withstand long-term use. Solid wood, particularly hardwoods like oak or maple, offers superior strength and resistance to warping or cracking compared to softer woods or engineered wood products. Steel frames, especially those with reinforced joints and a powder-coated finish, provide excellent structural integrity and corrosion resistance. The choice between wood and steel often depends on aesthetic preferences and budget considerations, but prioritizing high-quality materials ensures longevity.

- Joint Reinforcement Techniques

The manner in which the frame’s components are joined together significantly impacts its overall durability. Dovetail joints, mortise-and-tenon joints, and metal-to-metal bolted connections are examples of robust joining techniques that enhance structural stability and prevent loosening over time. In contrast, frames that rely solely on screws or staples are more susceptible to failure under sustained weight and pressure. Careful examination of the joint construction reveals the level of attention to detail and the expected lifespan of the foundation.

- Weight Capacity and Load Distribution

The material durability of a foundation is directly correlated with its weight capacity and ability to distribute load evenly. A frame constructed from low-quality materials or with inadequate reinforcement may exhibit premature sagging or structural failure under the combined weight of the viscoelastic foam mattress and the occupants. Exceeding the recommended weight limit can compromise the frame’s integrity and lead to discomfort and potential safety hazards. It’s crucial to select a foundation with a weight capacity that accommodates the intended use and provides a safety margin for added assurance.

- Resistance to Environmental Factors

Material durability also encompasses the frame’s resistance to environmental factors, such as humidity, temperature fluctuations, and pest infestations. Solid wood frames, if properly sealed and finished, can withstand moderate humidity levels and resist insect damage. Steel frames, particularly those with a powder-coated finish, are less susceptible to corrosion and moisture-related issues. In environments with high humidity or susceptibility to pests, selecting materials with inherent resistance is essential for preserving the foundation’s structural integrity and appearance.

In summation, material durability is a non-negotiable aspect of a suitable foundation for viscoelastic foam sleeping surfaces. Careful consideration of frame construction materials, joint reinforcement techniques, weight capacity, and resistance to environmental factors ensures that the foundation provides reliable support and maintains its structural integrity over an extended period, contributing to a better sleep experience and a worthwhile investment.

4. Weight Capacity

The designated weight capacity of a bed frame is a critical factor directly influencing its suitability for supporting a memory foam mattress and its occupants. Overlooking this specification can compromise structural integrity, leading to premature wear, instability, and potential safety hazards. Rigorous adherence to weight capacity guidelines is, therefore, essential for optimal performance and longevity.

- Structural Integrity

Exceeding the specified weight capacity places undue stress on the frame’s structural components, including the side rails, crossbars, and support legs. This excessive load can result in bending, warping, or even breakage of these components, compromising the overall stability of the bed. For example, a metal frame rated for 500 pounds that is consistently subjected to 700 pounds of weight will likely experience deformation over time, leading to a sagging mattress and reduced support.

- Mattress Longevity

Inadequate support due to exceeding weight limits can negatively impact the lifespan of the memory foam mattress itself. Uneven weight distribution can cause localized compression and premature wear in areas of concentrated pressure. This can lead to permanent indentations, reduced comfort, and a decreased overall lifespan of the mattress. A bed frame with an insufficient weight capacity will not effectively distribute the weight of the mattress and occupants, resulting in accelerated degradation of the memory foam.

- Safety Implications

Failure to adhere to weight capacity guidelines poses significant safety risks to the occupants. A structurally compromised bed frame can collapse unexpectedly, resulting in potential injuries. This risk is particularly pronounced with platform beds, where a failure of the support structure can lead to a sudden and complete collapse of the entire bed. Ensuring that the selected frame has a weight capacity that comfortably accommodates the combined weight of the mattress and occupants is paramount for preventing such incidents.

- Warranty Considerations

Exceeding the weight capacity of a bed frame often voids the manufacturer’s warranty, leaving the owner responsible for any repair or replacement costs. Manufacturers establish weight limits based on extensive testing and engineering analysis, and exceeding these limits is considered misuse of the product. Understanding and adhering to the weight capacity specification is, therefore, essential for maintaining warranty coverage and protecting the investment in both the bed frame and the memory foam mattress.

Therefore, the weight-bearing limitations of a bed frame must align with the combined mass of the memory foam sleeping surface and its users to maintain structural soundness, prolong the life of the mattress, and safeguard against potential harm. Neglecting this crucial aspect not only diminishes comfort but could also lead to hazardous situations, reinforcing the importance of meticulous assessment of weight specifications prior to purchase.

5. Slat Spacing

Slat spacing within a bed frame designed for a viscoelastic foam mattress is a critical determinant of mattress support, longevity, and overall sleep quality. The distance between individual slats directly impacts the distribution of weight and the prevention of sagging, necessitating careful consideration during bed frame selection.

- Support Distribution

Excessive slat spacing can lead to uneven weight distribution across the mattress surface. Memory foam, being highly conforming, will tend to sink between widely spaced slats, creating pressure points and reducing support in critical areas. Conversely, closely spaced slats provide more uniform support, preventing sagging and maintaining the mattress’s intended shape and comfort. The ideal slat spacing balances support and ventilation.

- Mattress Longevity

Inadequate support due to improper slat spacing can significantly shorten the lifespan of a viscoelastic foam mattress. Sagging caused by wide slat gaps leads to localized compression and accelerated wear of the foam material. This, in turn, results in permanent indentations and a loss of the mattress’s original resilience. A bed frame with appropriate slat spacing ensures even support, thereby prolonging the mattress’s lifespan and maintaining its performance characteristics.

- Ventilation Considerations

While close slat spacing provides superior support, it can also impede airflow and ventilation beneath the mattress. Viscoelastic foam tends to retain heat, making ventilation a crucial factor in maintaining a comfortable sleeping temperature. A balance must be struck between providing sufficient support and allowing adequate airflow to dissipate heat and prevent moisture buildup. Some bed frame designs incorporate ventilation channels or strategically spaced slats to address this concern.

- Industry Guidelines and Standards

Industry standards typically recommend a maximum slat spacing of 2-3 inches for bed frames intended for use with memory foam mattresses. This spacing is generally considered optimal for providing adequate support while maintaining sufficient ventilation. Deviation from these guidelines can compromise mattress performance and longevity. Consulting manufacturer recommendations and product specifications is essential in determining the appropriate slat spacing for a given mattress type.

Therefore, the optimal slat spacing for a bed frame supporting a viscoelastic foam mattress is a compromise between providing adequate support to prevent sagging and allowing sufficient ventilation to regulate temperature and moisture. Consideration of these factors, along with adherence to industry guidelines, is essential for maximizing mattress performance, longevity, and overall sleep quality.

Frequently Asked Questions

The following elucidates critical aspects concerning suitable bed frames for use with viscoelastic foam mattresses, addressing prevalent concerns and misconceptions.

Question 1: Does a memory foam mattress require a specific type of bed frame?

While memory foam mattresses can be used with various bed frame types, optimal performance necessitates adequate support. Slatted, platform, or adjustable frames are generally suitable, provided they offer sufficient structural integrity and proper slat spacing to prevent sagging.

Question 2: What slat spacing is recommended for a bed frame supporting a memory foam mattress?

Industry consensus recommends a maximum slat spacing of 2-3 inches. Exceeding this spacing can lead to uneven weight distribution, premature mattress wear, and compromised support.

Question 3: Are metal bed frames suitable for memory foam mattresses?

Metal bed frames can provide adequate support, contingent upon their construction and weight capacity. Frames with reinforced joints and a sufficient number of cross supports are preferable. Powder-coated finishes enhance durability and corrosion resistance.

Question 4: Do platform beds require a box spring when used with a memory foam mattress?

Platform beds generally eliminate the necessity for a box spring, as their solid or closely-spaced slatted surface provides direct support for the mattress. However, ensure the platform surface is smooth and free of sharp edges that could damage the mattress.

Question 5: How does bed frame material influence temperature regulation with a memory foam mattress?

Certain materials, such as wood, can absorb and release moisture, potentially aiding in temperature regulation. Open-slatted designs, regardless of material, promote airflow and heat dissipation, counteracting the heat retention properties of memory foam.

Question 6: What weight capacity should a bed frame possess to adequately support a memory foam mattress?

The bed frame’s weight capacity must exceed the combined weight of the mattress and its occupants. Exceeding the specified weight limit can compromise structural integrity, void warranties, and pose safety risks.

In summation, judicious selection of a bed frame involves careful consideration of slat spacing, material durability, ventilation capabilities, and weight capacity to ensure optimal support, longevity, and user safety.

The subsequent article section will explore specific bed frame models and their suitability for various types of viscoelastic foam sleeping surfaces.

Conclusion

The preceding analysis underscores the importance of informed decision-making in selecting the most appropriate bed frame. Key considerations include structural support, ventilation capabilities, and material durability to ensure the longevity and performance of the viscoelastic foam sleeping surface. Slat spacing and adherence to weight capacity guidelines are also crucial factors that impact both mattress integrity and user safety.

Future research and development should focus on innovative materials and designs that further optimize support, ventilation, and durability. Diligent evaluation of individual needs and preferences, coupled with a thorough understanding of product specifications, is essential for selecting the best foundation to enhance sleep quality and overall well-being. Prioritizing these critical factors ensures a sound investment in lasting comfort and support.