The selection of appropriate bedding for an adjustable medical frame is crucial in providing comfort and support to individuals requiring long-term care or recuperation. This specialized bedding aims to alleviate pressure points, promote proper spinal alignment, and enhance overall well-being for patients spending extended periods in a recumbent position. As an illustration, consider a pressure redistribution foam model designed to minimize the risk of pressure ulcers in bedridden patients.

Proper bedding offers numerous advantages, including improved sleep quality, reduced pain, and enhanced circulation. Its significance stems from the potential to prevent complications associated with immobility, such as pressure sores and discomfort. Historically, advancements in materials and designs have led to increasingly sophisticated options, tailored to address specific medical needs and improve patient outcomes.

The following discussion will delve into the various types of suitable bedding options available, critical factors to consider when making a purchase, and maintenance guidelines to ensure longevity and hygiene. Further examination will explore the relationship between specific features and their impact on patient comfort and therapeutic value.

Selecting Appropriate Bedding

The selection of appropriate bedding for an adjustable medical frame requires careful consideration of patient needs and therapeutic objectives. The following guidelines offer essential considerations to inform the decision-making process.

Tip 1: Prioritize Pressure Redistribution: Models designed to minimize pressure points are crucial for preventing pressure ulcers, particularly for individuals with limited mobility. Options include foam, air, and gel-infused designs. Evaluate the pressure redistribution capabilities based on clinical recommendations and patient risk factors.

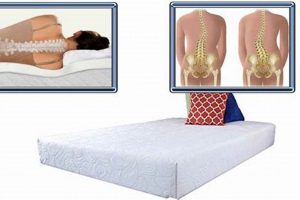

Tip 2: Assess Support and Alignment: Bedding should offer adequate support to maintain proper spinal alignment and reduce musculoskeletal strain. Consider the firmness and contouring properties of different materials to ensure appropriate support for the patient’s specific needs and body type.

Tip 3: Evaluate Cleanability and Hygiene: Infection control is paramount. Select options with waterproof and antimicrobial covers that are easily cleaned and disinfected. Consider models with removable and washable covers to facilitate regular hygiene maintenance.

Tip 4: Determine Compatibility with Frame Adjustments: Ensure the chosen bedding is compatible with the adjustable features of the medical frame. It should be flexible enough to conform to different positions without compromising support or comfort. Consider models specifically designed for use with adjustable frames.

Tip 5: Consider Patient Weight Capacity: Verify that the bedding’s weight capacity is appropriate for the patient’s weight to ensure safety and effectiveness. Exceeding the weight limit can compromise the product’s performance and durability.

Tip 6: Examine Material Composition: Research the materials used in the bedding’s construction. Look for hypoallergenic and breathable materials to minimize the risk of allergic reactions and promote airflow, which can enhance comfort and reduce moisture buildup.

These guidelines highlight the importance of considering pressure redistribution, support, hygiene, compatibility, weight capacity, and material composition when selecting bedding. A thorough evaluation of these factors will contribute to a comfortable, safe, and therapeutically beneficial environment for the patient.

The subsequent sections of this article will provide further details on specific types of bedding and address common questions regarding their selection and maintenance.

1. Pressure Redistribution

Pressure redistribution is a critical factor in selecting appropriate bedding for an adjustable medical frame. Prolonged pressure on bony prominences, such as the sacrum, heels, and hips, can lead to pressure ulcers, a serious complication for individuals with limited mobility. Bedding that effectively redistributes pressure minimizes the concentration of force on these vulnerable areas, reducing the risk of tissue damage.

The effectiveness of pressure redistribution directly impacts patient outcomes. For example, a randomized controlled trial demonstrated that individuals utilizing a specialized air mattress designed for pressure redistribution experienced a significantly lower incidence of pressure ulcers compared to those using a standard hospital mattress. Different materials, such as foam, gel, and air, offer varying degrees of pressure redistribution. Foam conforms to the body’s contours, distributing weight more evenly. Gel provides a cooler surface and can further reduce pressure. Air mattresses offer adjustable pressure settings to cater to individual needs. The selection of the most suitable material depends on the patient’s specific risk factors, weight, and medical condition.

Understanding the principles of pressure redistribution is essential for caregivers and healthcare professionals. By selecting appropriate bedding that minimizes pressure concentration, the risk of pressure ulcers can be significantly reduced, leading to improved patient comfort, reduced healthcare costs, and enhanced quality of life. Failure to adequately address pressure redistribution can result in preventable complications, underscoring the importance of informed decision-making in bedding selection.

2. Support and Alignment

Optimal support and spinal alignment are fundamental considerations when selecting bedding for an adjustable medical frame. Inadequate support can exacerbate existing musculoskeletal conditions, impede recovery, and contribute to discomfort. Proper bedding provides a stable and even surface, minimizing pressure points and promoting natural spinal curvature. The relationship between bedding characteristics and patient well-being is direct: insufficient support can lead to pain, while appropriate alignment facilitates healing and improves sleep quality. For instance, individuals recovering from spinal surgery require bedding that maintains spinal stability, preventing further injury and aiding in the rehabilitation process. Choosing the best mattress for hospital bed, therefore, hinges on understanding its support and alignment capabilities.

Various materials offer differing degrees of support. High-density foam, for example, provides a firm and stable surface, minimizing sinkage and promoting proper alignment. In contrast, softer materials may conform more closely to the body’s contours but may lack the necessary support for individuals with specific medical needs. Air-filled bedding allows for adjustable support levels, catering to individual preferences and requirements. The effectiveness of support and ali

gnment is often assessed through clinical evaluations, where healthcare professionals assess the patient’s posture and comfort while lying on different surfaces. This assessment informs bedding selection, ensuring it meets the individual’s unique needs.

In summary, the selection of bedding for an adjustable medical frame must prioritize support and alignment. This ensures the patient’s comfort and directly contributes to their physical well-being and recovery. Challenges may arise in identifying the optimal balance between comfort and support, requiring careful consideration of individual needs and the advice of healthcare professionals. Ultimately, bedding that effectively supports spinal alignment minimizes discomfort, promotes healing, and enhances the overall quality of life for individuals requiring long-term care or recuperation within an adjustable medical frame.

3. Cleanability/Hygiene

Maintaining stringent cleanability and hygiene standards is of paramount importance when selecting bedding for adjustable medical frames. The hospital environment and long-term care settings inherently present a higher risk of infection. The presence of bodily fluids, potential contaminants, and the susceptibility of patients with compromised immune systems necessitate bedding materials and designs that facilitate thorough and effective cleaning procedures.

- Waterproof and Antimicrobial Covers

The utilization of waterproof and antimicrobial covers is critical in preventing the penetration of liquids and inhibiting the growth of bacteria, fungi, and viruses. These covers act as a barrier, protecting the inner core of the mattress from contamination. For example, polyurethane-coated fabrics are commonly employed due to their durability, impermeability, and ease of disinfection. The implication is a reduction in the risk of cross-contamination and the spread of infection among patients.

- Removable and Washable Components

Bedding options that incorporate removable and washable covers enhance hygiene maintenance. This feature allows for regular laundering, effectively removing accumulated debris, allergens, and microorganisms. Zippered enclosures facilitate the easy removal and replacement of covers. A practical application is the ability to quickly address spills or soiling incidents, minimizing the potential for bacterial growth and odor development.

- Material Resistance to Cleaning Agents

The selection of bedding materials should consider their resistance to commonly used cleaning agents and disinfectants. Harsh chemicals can degrade certain materials, compromising their structural integrity and reducing their lifespan. Materials such as vinyl and specific types of treated fabrics exhibit a higher tolerance to disinfection procedures. Selecting cleaning-agent-resistant materials ensures effective hygiene without damaging the bedding, preserving its functional properties over time.

- Seam Construction and Design

The design and construction of seams influence the ease and effectiveness of cleaning. Recessed or hidden seams minimize the accumulation of dirt and debris, preventing the formation of microbial reservoirs. Welded seams, as opposed to sewn seams, offer a seamless and impermeable surface, further reducing the risk of contamination. Attention to seam details contributes to a more hygienic bedding environment and facilitates more efficient cleaning processes.

In conclusion, prioritizing cleanability and hygiene in the selection of bedding for adjustable medical frames is crucial for infection control and patient safety. The incorporation of waterproof and antimicrobial covers, removable and washable components, material resistance to cleaning agents, and thoughtful seam construction collectively contributes to a more hygienic environment. This comprehensive approach ensures that the chosen bedding not only provides comfort and support but also minimizes the risk of infection, promoting overall patient well-being.

4. Frame Compatibility

Frame compatibility is a critical determinant in selecting appropriate bedding for adjustable medical frames. The functionality of an adjustable bed relies on the seamless integration of the frame and bedding. Incompatibility can negate the therapeutic benefits of the frame, compromise patient safety, and reduce the lifespan of both the frame and the bedding. Proper alignment and movement synchronization are essential for optimal performance. The selection of a medical bedding should never occur without considering its compatibility with the intended adjustable frame.

- Flexibility and Conformance

Bedding must possess sufficient flexibility to conform to the various positions achievable by the adjustable frame. Rigidity can impede movement, create pressure points, and potentially damage the frame’s mechanics. Consider a scenario where a high-density, non-flexible surface is used on an adjustable frame designed to elevate the head and foot sections. The lack of conformance could result in the surface buckling, placing undue stress on the frame’s joints and compromising patient comfort. Bedding materials should be chosen based on their ability to bend and flex without losing structural integrity.

- Dimensions and Fit

Precise dimensional compatibility is essential. Overly large bedding can bunch up, hindering frame movement and creating uneven surfaces. Conversely, bedding that is too small may shift, exposing the frame and compromising support. Manufacturers typically provide specific dimensional recommendations for their frames. Compliance with these specifications ensures proper fit and function. For instance, selecting a standard residential size for a specialized medical frame may lead to suboptimal performance and increased risk of injury.

- Weight Distribution and Support

The interaction between the bedding and the frames support structure is crucial. Uneven weight distribution can strain the frame’s mechanisms, leading to premature wear or failure. Bedding should provide consistent support across its surface, preventing concentrated pressure points that could overload specific sections of the frame. Examples of poor weight distribution include bedding that sags in the center or lacks adequate edge support, both of which can negatively impact the frame’s stability and longevity.

- Material Durability and Resistance to Friction

The materials used in the bedding’s construction should be durable and resistant to friction. Repeated adjustments of the frame can cause friction between the bedding and the frame’s surface, leading to wear and tear. Durable materials, such as reinforced fabrics and high-density foams, are better equipped to withstand this friction. For instance, a bedding surface made of a delicate or loosely woven material may quickly deteriorate with frequent adjustments, compromising its integrity and potentially creating safety hazards.

The preceding discussion highlights the multifaceted nature of frame compatibility. The best mattress for hospital bed choice must incorporate factors such as flexibility, dimensions, weight distribution, and material durability to ensure optimal performance and patient safety. Choosing the incorrect bedding can nullify the benefits of an adjustable medical frame, potentially leading to d

iscomfort, injury, and costly repairs. Therefore, meticulous attention to frame compatibility is essential for achieving the desired therapeutic outcomes.

5. Weight Capacity

Weight capacity represents a critical specification in the selection of appropriate bedding for adjustable medical frames. Exceeding the designated weight limit can compromise the structural integrity of the bedding, diminish its therapeutic effectiveness, and jeopardize patient safety. The following considerations highlight the significance of weight capacity in relation to the selection of medical bedding.

- Structural Integrity and Durability

The specified weight capacity directly correlates with the bedding’s ability to withstand applied loads without deformation or failure. Overloading can lead to sagging, uneven support, and premature wear of materials. For instance, a foam bedding with a rated capacity of 300 lbs subjected to a sustained load of 400 lbs may exhibit compression and loss of support over time, rendering it ineffective and potentially unsafe. This is particularly critical for long-term care scenarios.

- Pressure Redistribution Performance

Adequate pressure redistribution depends on the bedding’s ability to conform to the patient’s body while maintaining its structural form. Exceeding the weight capacity can compromise this function, concentrating pressure on bony prominences and increasing the risk of pressure ulcers. A gel-infused bedding designed to evenly distribute weight may fail to do so effectively if overloaded, negating its therapeutic benefits.

- Adjustable Frame Mechanism Strain

The weight applied to the bedding directly impacts the load on the adjustable frame’s lifting mechanisms. Exceeding the bedding’s rated weight capacity can strain these mechanisms, leading to accelerated wear, reduced functionality, and potential mechanical failure. This can create safety hazards for the patient and necessitate costly repairs or replacements of the adjustable frame.

- Warranty and Liability Considerations

Manufacturers’ warranties typically stipulate adherence to specified weight limits. Exceeding these limits can void the warranty, leaving the purchaser liable for any resulting damage or injuries. Adhering to the stated weight capacity is essential for maintaining warranty coverage and minimizing potential legal liabilities.

In summary, weight capacity is a non-negotiable parameter in the bedding selection process for adjustable medical frames. Neglecting this specification can have significant consequences, ranging from compromised therapeutic effectiveness to safety hazards and financial liabilities. Careful consideration of the patient’s weight and adherence to the bedding’s stated weight capacity are essential for ensuring optimal performance, safety, and longevity.

6. Material Composition

The material composition of bedding intended for adjustable medical frames holds a pivotal role in determining its suitability for patient care. The selection of materials directly impacts critical factors such as pressure redistribution, support, hygiene, and durability, thereby influencing the overall therapeutic effectiveness and longevity of the product. The composition of the bedding’s core, cover, and any intermediate layers contributes significantly to its performance characteristics. For example, a core constructed from high-density memory foam can provide superior pressure relief compared to a standard polyurethane foam core, resulting in a reduced risk of pressure ulcer development.

The choice of cover materials also warrants careful consideration. Waterproof and antimicrobial covers are essential for maintaining hygiene and preventing the proliferation of harmful microorganisms. Materials such as vinyl or treated polyester offer resistance to fluid penetration and can be easily cleaned and disinfected. Breathability is another key attribute, as it promotes airflow and reduces moisture accumulation, contributing to patient comfort and minimizing the risk of skin irritation. Examples include covers incorporating specialized fabrics designed to wick away moisture and dissipate heat. Furthermore, the durability of the cover material is critical to withstand the rigors of frequent cleaning and prolonged use.

In conclusion, a comprehensive understanding of material composition is paramount when selecting bedding for adjustable medical frames. The properties of the constituent materials directly impact key performance characteristics, influencing patient comfort, safety, and the long-term value of the product. A diligent assessment of material specifications, informed by clinical needs and hygiene protocols, is essential for optimizing patient outcomes and ensuring a cost-effective investment. Failure to consider the relationship between materials and performance can lead to suboptimal bedding choices and potentially compromise patient well-being.

7. Durability

Durability, in the context of bedding for adjustable medical frames, is a paramount characteristic dictating its long-term cost-effectiveness and suitability for continuous use within demanding healthcare environments. Bedding experiencing frequent use and stringent hygiene protocols requires resilience to maintain structural integrity and performance over an extended period. The selection of durable bedding minimizes the frequency of replacements, thereby reducing long-term costs and ensuring consistent patient support. Its absence will render the bed unusable and can be unsafe for patients.

- Material Resistance to Degradation

The inherent resistance of bedding materials to degradation, including compression, tearing, and chemical exposure, is a primary indicator of durability. Materials such as high-density foam, reinforced fabrics, and specialized coatings exhibit superior resistance to wear and tear compared to standard materials. A foam core that retains its shape and supportiveness after repeated compression cycles demonstrates greater durability. Likewise, a cover fabric resistant to abrasion and degradation from cleaning agents ensures long-term hygiene and aesthetic appeal. Selection must consider materials designed to withstand the stresses of continuous use and stringent sanitation protocols.

- Construction Quality and Reinforcement

The quality of construction techniques and the presence of reinforcement features significantly influence the bedding’s overall durability. Reinforced seams, robust stitching, and strategically placed support structures enhance its ability to withstand stress and prevent premature failure. For example, a bed with reinforced edges is less likely to sag or deform over time, maintaining its structural integrity and providing consistent support. Careful consideration of construction details ensures that the bedding can withstand the demanding conditions of a healthcare setting.

- Resistance to Fluid Penetration and Microbial Growth

Durability extends to the bedding’s ability to resist fluid penetration and inhibit microbial growth. Waterproof covers with sealed seams prevent fluids from seeping into

the core, mitigating the risk of contamination and prolonging the bedding’s lifespan. Antimicrobial treatments further enhance durability by inhibiting the growth of bacteria, fungi, and other microorganisms, reducing the likelihood of odors and material degradation. A durable product effectively resists the damaging effects of fluids and microbial activity, ensuring long-term hygiene and performance. - Compliance with Industry Standards and Testing

Compliance with relevant industry standards and rigorous testing protocols provides an objective measure of durability. Standards such as those established by organizations like the American Society for Testing and Materials (ASTM) specify minimum performance requirements for bedding materials and construction. Testing methods, including compression tests, tear resistance tests, and chemical resistance tests, provide quantifiable data on the product’s ability to withstand demanding conditions. Adherence to these standards and successful completion of testing procedures demonstrate a commitment to durability and quality.

Considering these factors collectively ensures that the selected bedding possesses the requisite durability to withstand the demands of adjustable medical frames. Durable and best mattress for hospital bed choice that minimize the need for frequent replacements and provide consistent support and hygiene over their intended lifespan, contributing to both cost-effectiveness and enhanced patient care.

Frequently Asked Questions

This section addresses common inquiries concerning bedding options for adjustable medical frames, providing concise and authoritative answers to guide informed decision-making.

Question 1: What types of bedding materials are most suitable for individuals at high risk for pressure ulcers?

Bedding materials specifically designed for pressure redistribution are recommended. Options include viscoelastic foam, gel-infused foam, and air-filled mattresses. The selection should be based on a patient-specific risk assessment, considering factors such as immobility, skin condition, and nutritional status.

Question 2: How frequently should bedding covers be cleaned in a healthcare setting?

Bedding covers should be cleaned and disinfected after each patient use and whenever visibly soiled. Adherence to established infection control protocols is essential to minimize the risk of cross-contamination. Specific cleaning agents should be selected based on the cover material and manufacturer recommendations.

Question 3: What is the recommended firmness level for optimal support and spinal alignment?

The optimal firmness level varies based on individual patient needs and preferences. Generally, a medium-firm surface is recommended to provide adequate support while maintaining comfort. Consultation with a healthcare professional is advisable to determine the most appropriate firmness level for specific medical conditions.

Question 4: How can I ensure that the bedding is compatible with the adjustable frame’s range of motion?

Verify the bedding’s flexibility and conformance to ensure it can accommodate the full range of positions offered by the adjustable frame. The bedding should bend and flex without bunching or creating pressure points. Consult the frame manufacturer’s specifications for recommended bedding dimensions and materials.

Question 5: What features should be considered when selecting bedding for patients with incontinence?

Bedding for incontinent patients should feature a waterproof cover with sealed seams to prevent fluid penetration. The cover material should be resistant to staining and odor retention. Removable and washable covers are highly recommended to facilitate regular cleaning and hygiene maintenance.

Question 6: How does bedding weight capacity affect the longevity and performance of the product?

Exceeding the stated weight capacity can compromise the bedding’s structural integrity, diminish its pressure redistribution capabilities, and accelerate wear. Adherence to the weight limit is essential to ensure optimal performance, prevent premature failure, and maintain warranty coverage.

In summary, the selection of suitable bedding for adjustable medical frames necessitates careful consideration of material properties, hygiene protocols, compatibility factors, and individual patient needs. Prioritizing these factors contributes to a safe, comfortable, and therapeutically beneficial environment.

The following section will provide a guide to selecting bedding in more simple terms.

Selecting Suitable Bedding

The preceding discourse has elucidated the critical factors involved in selecting the best mattress for hospital bed, encompassing pressure redistribution, support, hygiene, compatibility, weight capacity, material composition, and durability. These elements directly impact patient comfort, safety, and therapeutic outcomes. A comprehensive understanding of these considerations enables informed decision-making.

Therefore, the careful evaluation of bedding options based on individual patient needs and the specific requirements of the adjustable medical frame is paramount. Prioritizing these factors will contribute to improved patient well-being and a more effective healthcare environment. This approach reflects a commitment to providing optimal care and maximizing the benefits of medical bedding technology.

![Find Your Best Cheap King Mattress [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Find Your Best Cheap King Mattress [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-7824-300x200.jpg)