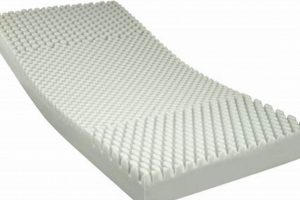

An overlay designed to mitigate concentrated force against the body during sleep can enhance comfort and potentially alleviate pain. These products, typically composed of materials like memory foam or latex, distribute weight more evenly across the sleep surface. For example, a five-centimeter thick memory foam addition placed atop a standard innerspring mattress can provide a significant reduction in pressure points at the hips and shoulders.

The significance of such an addition lies in its ability to improve sleep quality and promote overall well-being. Reduced pressure minimizes tossing and turning, leading to more restful sleep. Historically, individuals have sought solutions to uncomfortable sleep surfaces, evolving from rudimentary padding to sophisticated, engineered materials designed specifically for pressure reduction. This evolution reflects a growing awareness of the link between sleep surface and physical health.

The subsequent sections will examine the various materials used in constructing these items, their relative effectiveness in alleviating pressure, and factors to consider when selecting a suitable product to meet individual needs. Furthermore, lifespan, maintenance, and potential drawbacks will be discussed to provide a comprehensive overview.

Guidance on Selecting a Pressure-Reducing Mattress Overlay

The following recommendations are intended to provide guidance when choosing an appropriate mattress overlay designed to alleviate pressure points and enhance sleep comfort.

Tip 1: Material Density Assessment: Evaluate the density of the material, particularly memory foam. Higher density typically correlates with greater support and durability, resulting in more effective and long-lasting pressure relief. As a guide, consider a density of 4 to 5 pounds per cubic foot for memory foam options.

Tip 2: Thickness Considerations: Select an appropriate thickness based on individual body weight and the firmness of the existing mattress. A thicker overlay generally provides more substantial cushioning. A minimum of three inches is often recommended, but heavier individuals may require four inches or more.

Tip 3: Identify Targeted Pressure Zones: Determine specific areas where pressure relief is most critical, such as the shoulders, hips, or lower back. Consider overlays with zoned support, featuring varying densities or textures in different areas to address these specific needs.

Tip 4: Temperature Regulation Properties: Certain materials, like open-cell memory foam or latex, offer improved breathability compared to traditional memory foam. These options can help regulate body temperature and prevent overheating during sleep, particularly beneficial for individuals who tend to sleep hot.

Tip 5: Consider Latex Alternatives: Explore latex as an alternative to memory foam. Latex offers natural resilience and responsiveness, providing excellent pressure relief while maintaining a supportive feel. It is also naturally hypoallergenic and resistant to dust mites.

Tip 6: Review Independent Testing Data: Consult independent product reviews and testing data to assess the performance and durability of different mattress overlays. Look for objective measurements of pressure distribution and long-term comfort.

Tip 7: Check for Certifications: Prioritize products with certifications like CertiPUR-US, indicating that the foam has been tested for harmful substances and meets stringent emissions standards. This ensures product safety and quality.

Proper selection, based on these tips, leads to improved sleep quality, reduced pain, and enhanced physical well-being. Investing time to properly analyze these aspects will yield best outcomes.

Following sections will cover material comparison and long-term maintenance.

1. Material Density

Material density plays a critical role in determining the effectiveness of a mattress overlay intended for pressure relief. Density, measured in pounds per cubic foot (lbs/ft), directly impacts the support, durability, and overall comfort provided by the overlay. Higher density materials generally offer superior pressure redistribution and longevity compared to lower density alternatives.

- Support and Conformity

Increased material density allows the overlay to conform more precisely to the body’s contours, distributing weight evenly and minimizing concentrated pressure points. For example, a 5lb/ft memory foam overlay will provide greater support and conformity compared to a 3lb/ft option, reducing pressure on areas such as the hips and shoulders.

- Durability and Longevity

Higher density materials exhibit greater resistance to compression and deformation over time. A denser overlay is less likely to sag or develop indentations, maintaining its pressure-relieving properties for a longer period. This is particularly important for individuals who require consistent and reliable support.

- Pressure Redistribution Efficiency

A dense material can more effectively spread weight across the surface of the overlay, minimizing the concentration of force on specific areas. This reduces the likelihood of pressure sores and discomfort, especially for individuals who spend extended periods in bed. Effective pressure redistribution is crucial for promoting healthy circulation and preventing tissue damage.

- Temperature Sensitivity

The density of certain materials, particularly memory foam, can influence its temperature sensitivity. Higher density memory foam may retain more heat compared to lower density options. Consideration should be given to breathability and cooling properties to prevent overheating during sleep.

In conclusion, material density represents a fundamental parameter in evaluating the suitability of a mattress overlay designed for pressure relief. Selecting an overlay with appropriate density, based on individual needs and preferences, is essential for achieving optimal comfort, support, and long-term durability. Failure to address material density compromises on health of body and sleep quality.

2. Thickness and Support

The relationship between thickness and support is paramount in assessing the efficacy of a mattress overlay designed for pressure relief. Adequate thickness, in conjunction with appropriate material density, directly determines the level of cushioning and weight distribution provided, influencing overall comfort and the minimization of pressure points.

- Load Distribution Capacity

Increased overlay thickness enhances the capacity to distribute weight across a broader surface area. This reduces the concentration of force on specific pressure points, such as the hips, shoulders, and sp

ine. For example, a four-inch overlay will generally provide greater load distribution than a two-inch counterpart, particularly for individuals with higher body mass. - Responsiveness to Body Contours

A thicker overlay allows for deeper compression and conformity to the body’s natural curves. This ensures that the overlay adequately fills the gaps between the body and the underlying mattress, providing consistent support and preventing localized pressure build-up. Insufficient thickness may result in inadequate contouring, leading to pressure points and discomfort.

- Impact of Existing Mattress Firmness

The optimal thickness of an overlay is influenced by the firmness of the underlying mattress. A firmer mattress may require a thicker overlay to achieve adequate pressure relief, while a softer mattress may necessitate a thinner option to prevent excessive sinking and loss of support. Careful consideration of the existing mattress firmness is crucial for selecting an overlay with appropriate thickness.

- Material Composition and Firmness

The relationship between overlay thickness and its firmness is important. High-density foam, though firm and pressure relieving when thick, will lead to a harsh sleeping experience in a thin profile. Therefore, the material must complement the thickness for optimal pressure reduction.

In conclusion, the selection of a mattress overlay requires careful consideration of both thickness and support characteristics. The interplay between these factors determines the overlay’s ability to effectively redistribute weight, conform to body contours, and mitigate pressure points. A properly selected overlay contributes significantly to improved sleep quality and the prevention of discomfort.

3. Zoned Construction

Zoned construction, in the context of a mattress overlay designed for pressure relief, refers to the strategic variation of material density or firmness across different sections of the product. The objective is to provide targeted support and cushioning to specific areas of the body, thereby optimizing pressure redistribution and minimizing discomfort. This design approach acknowledges the uneven distribution of weight and pressure that occurs during sleep, tailoring the overlay to address the unique needs of different anatomical regions. Its importance stems from its ability to more effectively contour to the body, providing tailored support where it is needed most. Failure to provide proper zoning increases the risk of pressure points, discomfort, and disrupted sleep patterns.For example, an overlay may feature a softer zone in the shoulder region to accommodate side sleeping, while incorporating a firmer zone in the lumbar area to provide support for the lower back.

The practical application of zoned construction involves identifying key pressure points and designing the overlay to specifically address these areas. Pressure mapping technology is often employed during the design phase to identify regions of high pressure concentration. Based on this data, the overlay is then constructed with varying densities or firmness levels to redistribute weight and alleviate pressure.Such an approach offers notable advantage over uniform construction. By tailoring support to the body’s unique contours, zoned construction reduces the potential for pressure build-up and improves overall sleep comfort. Real-world testing has demonstrated that mattress overlays with zoned construction can significantly decrease pressure point discomfort in individuals with conditions such as fibromyalgia or arthritis.

In summary, zoned construction represents a significant advancement in the design of mattress overlays for pressure relief. By strategically varying material properties across different zones, these overlays offer targeted support and cushioning to critical areas of the body. The design strategy optimizes pressure redistribution and enhances sleep comfort. However, it is essential to recognize that the effectiveness of zoned construction depends on accurate pressure mapping and appropriate material selection. Overlays with poorly designed zoning may offer limited benefits and even exacerbate pressure point discomfort.

4. Temperature Regulation

Effective thermal management constitutes a crucial element in evaluating mattress overlays designed for pressure reduction. Elevated skin temperature can disrupt sleep cycles and exacerbate discomfort, particularly in individuals prone to overheating. Therefore, the ability of a mattress overlay to dissipate heat and promote airflow directly influences sleep quality and the perceived effectiveness of its pressure-relieving properties. A pressure-relieving overlay that traps heat can negate its intended benefits, leading to restlessness and discomfort. For instance, a memory foam overlay lacking adequate ventilation may conform well to the body, reducing pressure points, but simultaneously retain heat, causing the sleeper to wake frequently due to thermal discomfort.

Materials and construction techniques play a pivotal role in determining the thermal performance of these overlays. Open-cell memory foam, as opposed to traditional closed-cell varieties, allows for increased airflow and improved heat dissipation. Similarly, the incorporation of cooling gels or phase-change materials can further enhance thermal regulation. Latex, with its inherent breathability, presents another viable option for individuals seeking temperature-neutral sleep surfaces. The practical application of this understanding involves selecting overlays with documented thermal performance characteristics, such as independent testing data on breathability and heat retention. Consumers might also look for certifications indicating that the product meets specific thermal comfort standards.

In summary, temperature regulation is inextricably linked to the overall effectiveness of a pressure-reducing mattress overlay. The overlay’s ability to dissipate heat and promote airflow significantly impacts sleep quality and perceived comfort. While pressure relief addresses the physical aspects of sleep, thermal regulation ensures a comfortable sleep environment, preventing overheating and promoting restful sleep. The selection of an appropriate overlay necessitates careful consideration of material properties, construction techniques, and individual thermal preferences. Failure to address temperature regulation can compromise the benefits of pressure relief, leading to a suboptimal sleep experience.

5. Material Composition

Material composition forms a foundational element in determining the efficacy of a mattress overlay designed to alleviate pressure. The specific materials employed, along with their inherent properties, directly influence the overlay’s ability to conform to the body, distribute weight evenly, and minimize pressure points. The consideration of material composition should be considered vital in selecting a pressure-relieving product.

- Memory Foam Variants

Memory foam, a commonly utilized material, exists in various formulations, each exhibiting distinct characteristics. Traditional memory foam, while offering sign

ificant pressure relief, may exhibit limited breathability, potentially leading to heat retention. Open-cell memory foam mitigates this issue through enhanced airflow. Gel-infused memory foam further enhances thermal regulation. The specific memory foam variant dictates the overlay’s capacity to balance pressure relief with temperature control. - Latex Options

Latex, derived from either natural rubber or synthetic sources, presents an alternative to memory foam. Natural latex possesses inherent resilience and responsiveness, providing a supportive yet conforming surface. Synthetic latex, while more cost-effective, may lack the durability and breathability of its natural counterpart. The choice between natural and synthetic latex impacts the overlay’s longevity and overall comfort.

- Polyurethane Foam Considerations

Polyurethane foam, often used as a base layer or support core, offers varying degrees of firmness and density. High-density polyurethane foam provides robust support, while lower-density options offer increased cushioning. The selection of polyurethane foam density influences the overlay’s overall structural integrity and ability to maintain its shape over time.

- Specialized Material Infusions

Manufacturers may incorporate specialized materials, such as copper or graphite, into mattress overlays to enhance specific properties. Copper infusions are purported to offer antimicrobial benefits, while graphite infusions contribute to improved thermal conductivity. The presence and concentration of these specialized materials can affect the overlay’s hygiene and temperature regulation capabilities.

The interplay of these material properties dictates the suitability of a particular mattress overlay for individual needs. An informed decision necessitates a thorough understanding of the characteristics and limitations associated with each material, thereby optimizing pressure relief, comfort, and long-term durability.

6. Durability & Lifespan

The longevity of a mattress overlay intended for pressure relief represents a critical factor in evaluating its overall value proposition. While initial comfort and pressure reduction may be satisfactory, the sustained performance and structural integrity of the overlay over an extended period directly impact its long-term effectiveness and cost-efficiency. A product exhibiting premature degradation or loss of support compromises its pressure-relieving capabilities and necessitates replacement, negating the initial investment.

- Material Degradation Resistance

The inherent resistance of the overlay’s constituent materials to degradation, such as compression set, oxidation, and ultraviolet light exposure, significantly influences its lifespan. High-density memory foam and natural latex generally exhibit greater resistance to these factors compared to lower-density polyurethane foams. The selection of materials with superior degradation resistance translates directly into extended product life and sustained performance.

- Construction Integrity and Resilience

The method of construction, including seam strength, adhesive quality, and overall structural design, contributes to the overlay’s ability to withstand repeated use and maintain its shape over time. Reinforced seams and robust bonding techniques enhance the overlay’s resistance to tearing, stretching, and separation. A well-constructed overlay will exhibit greater resilience and a reduced likelihood of premature failure.

- Weight Load and Usage Patterns

The weight load placed on the overlay and the frequency of use impact its rate of wear and tear. Overlays subjected to excessive weight or continuous use will experience accelerated degradation compared to those used under lighter loads or intermittently. Consideration of anticipated weight load and usage patterns is essential for selecting an overlay with appropriate durability characteristics.

- Maintenance and Care Protocols

Adherence to recommended maintenance and care protocols, such as regular cleaning, rotation, and protection from direct sunlight, can significantly extend the lifespan of a mattress overlay. Proper maintenance minimizes the accumulation of dust, allergens, and moisture, thereby preventing material degradation and preserving the overlay’s structural integrity. Consistent care contributes directly to prolonging the overlay’s functional lifespan.

The interplay of these factors determines the true value of a mattress overlay designed for pressure relief. While initial cost may be a primary consideration, the long-term cost-effectiveness is contingent upon the overlay’s durability and lifespan. Investing in a product constructed from high-quality materials, exhibiting robust construction integrity, and properly maintained will yield superior value over time, providing sustained pressure relief and minimizing the need for premature replacement. The investment of the “best pressure relief mattress topper” should be durable and long-lasting to provide greater relief.

Frequently Asked Questions About Pressure-Reducing Mattress Overlays

The following questions address common concerns and misconceptions regarding the selection and use of mattress overlays designed for pressure relief.

Question 1: How does the density of memory foam impact the effectiveness of a pressure-reducing mattress overlay?

Material density, measured in pounds per cubic foot (lbs/ft), directly correlates with the support and longevity of a memory foam overlay. Higher density foams generally offer superior pressure redistribution and resistance to compression, leading to more effective and durable pressure relief.

Question 2: What is the optimal thickness for a mattress overlay intended to minimize pressure points?

The appropriate thickness depends on individual body weight, the firmness of the existing mattress, and preferred sleeping position. A minimum of three inches is often recommended, but heavier individuals or those with firmer mattresses may require four inches or more to achieve adequate pressure relief.

Question 3: Are mattress overlays with zoned construction more effective than those with uniform density?

Zoned construction, featuring varying densities or firmness levels across different areas of the overlay, can provide tailored support to specific body regions. This approach optimizes pressure redistribution and may be particularly beneficial for individuals with specific pressure point concerns. However, the effectiveness depends on accurate pressure mapping and appropriate material selection.

Question 4: How does temperature regulation influence the overall effectiveness of a pressure-reducing mattress overlay?

Excessive heat retention can disrupt sleep cycles and exacerbate discomfort, negating the intended benefits of pressure relief. Overlays with improved breathability, such as open-cell memory foam or latex, promote airflow and help regulate body temperature, enhancing overall sleep quality.

Question 5: What are the key differences between natural latex and memory foam mattress overlays?

Natural latex offers inherent resilience, responsiveness, and breathability, providing a supportive yet conforming surface. Memory foam excels at contouring to the body and minimizing pressure points but may exhibit limited breathability. The choice depends on individual preference

s regarding firmness, support, and temperature regulation.

Question 6: How can the lifespan of a pressure-reducing mattress overlay be extended?

Adherence to recommended maintenance and care protocols, such as regular cleaning, rotation, and protection from direct sunlight, can significantly prolong the lifespan of a mattress overlay. Proper care minimizes material degradation and preserves the overlay’s structural integrity.

Key takeaways include the importance of material density, thickness, and temperature regulation in selecting an effective pressure-reducing mattress overlay. Understanding these factors allows for informed decision-making and optimized sleep comfort.

The subsequent section will explore case studies illustrating the practical application of these principles in real-world scenarios.

Conclusion

The preceding analysis has explored critical aspects of selecting a mattress overlay designed for optimal pressure reduction. Evaluation of material density, thickness, zoned construction, temperature regulation, material composition, and potential lifespan represents a comprehensive approach to determining product suitability. Each element contributes to the overall effectiveness of a “best pressure relief mattress topper” in mitigating pressure points and promoting restorative sleep.

Ultimately, the informed selection of a pressure-reducing mattress overlay necessitates a thorough understanding of individual needs and preferences, coupled with a rigorous assessment of product characteristics. While objective data and expert opinions provide valuable guidance, individual experimentation and careful consideration of long-term performance remain paramount. Individuals who prioritize sustained comfort and well-being should diligently apply the principles outlined to ensure a judicious and beneficial investment in their sleep environment.

![Top-Rated Best Mattress for Slipped Disc Relief [2024] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Top-Rated Best Mattress for Slipped Disc Relief [2024] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-7776-300x200.jpg)

![Top-Rated Best Double Sided Mattress Review [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Top-Rated Best Double Sided Mattress Review [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-7772-300x200.jpg)