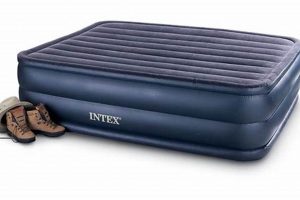

An inflatable sleeping surface characterized by interconnected air chambers, often spherical or pill-shaped in appearance, provides support and cushioning. These sleeping surfaces are commonly employed for temporary bedding solutions, such as camping or accommodating overnight guests. Their design focuses on even weight distribution through interconnected air pockets.

The utility of these items lies in their portability and convenience. Deflated, they occupy minimal space, making them ideal for situations where storage is limited. Historically, similar designs have been utilized in medical settings to prevent bedsores by alleviating pressure points. Modern iterations offer enhanced comfort and durability through improved materials and construction techniques.

The following sections will explore the construction materials, inflation methods, maintenance procedures, and common applications of this type of sleeping arrangement. Further discussion will delve into the advantages and disadvantages of this design compared to alternative bedding options, alongside considerations for selecting a suitable model for specific needs.

Essential Usage Guidelines

The following guidelines aim to optimize the lifespan and performance of an inflatable, chambered sleeping surface, ensuring user satisfaction and minimizing potential issues.

Tip 1: Select a Suitable Location: Prior to inflation, ensure the placement area is free from sharp objects, debris, or uneven surfaces. This minimizes the risk of punctures or structural stress.

Tip 2: Follow Inflation Instructions: Adhere strictly to the manufacturer’s instructions regarding inflation pressure. Over-inflation can lead to seam rupture, while under-inflation compromises support.

Tip 3: Use a Protective Layer: Place a fitted sheet or thin blanket atop the surface. This serves as a barrier against abrasion and facilitates easier cleaning.

Tip 4: Maintain Consistent Temperature: Avoid exposing the item to extreme temperature fluctuations. Excessive heat or cold can affect the material’s elasticity and durability.

Tip 5: Distribute Weight Evenly: While designed for individual or dual occupancy, avoid concentrated pressure on specific areas. Distribute weight evenly to prevent localized stress.

Tip 6: Store Properly When Not in Use: Deflate completely and fold neatly according to the manufacturer’s recommendations. Store in a cool, dry location, away from direct sunlight.

Tip 7: Address Minor Leaks Promptly: Regularly inspect for small punctures or leaks. Utilize a repair kit designed for inflatable materials to address these issues immediately.

By adhering to these usage guidelines, users can significantly extend the lifespan and maintain the performance of an inflatable, chambered sleeping surface, ensuring continued comfort and utility.

The subsequent sections will explore common issues, troubleshooting methods, and advanced maintenance techniques to address more complex challenges.

1. Inflatable support structure

The term “inflatable support structure” directly defines the core functionality of the air mattress design. The structural integrity and ability to provide a sleeping surface derive entirely from the contained air. Without a robust and properly inflated structure, the item is rendered unusable for its intended purpose. For example, a puncture compromises the support, resulting in deflation and a lack of cushioning. The arrangement of individual, interconnected chambers contributes to the overall structural stability by distributing weight and minimizing the impact of localized pressure points.

A practical example of the importance of the inflatable structure can be observed in different mattress designs. Models employing vertical internal beams exhibit greater resistance to deformation compared to those relying solely on interconnected chambers. Furthermore, the material’s tensile strength dictates the maximum inflation pressure and, consequently, the firmness of the sleeping surface. The structure’s design influences its suitability for various user weights and sleeping positions. Individuals exceeding the weight capacity can experience bottoming out, while those requiring firmer support might find certain designs inadequate.

In summary, the inflatable support structure represents the defining characteristic. Understanding its design, limitations, and material properties is critical for selecting a product that meets specific needs and ensuring its long-term performance. Challenges often stem from material fatigue, seam weakness, or improper inflation practices, all of which directly impact the structural integrity. Optimizing these factors ensures the user experience and extends the product lifespan.

2. Interconnected air chambers

The functionality and comfort level of a “bubble air mattress” are intrinsically linked to its network of interconnected air chambers. This design feature dictates the mattress’s ability to distribute weight, conform to the body, and provide a stable sleeping surface. The integrity and configuration of these chambers are paramount to the overall performance and longevity of the product.

- Weight Distribution and Support

The interconnected nature of the chambers allows for the even distribution of body weight across the entire mattress surface. This minimizes pressure points and contributes to a more comfortable and supportive sleeping experience. Without this interconnection, weight would be concentrated on individual chambers, leading to uneven support and potential discomfort. Consider, for instance, a mattress with a ruptured connection between chambers; the surrounding areas would become overstressed while the damaged area would lack proper inflation and support.

- Contour and Conformity

The interconnected air chamber design enables the “bubble air mattress” to conform to the sleeper’s body contours. As the individual adjusts position, air is displaced between the chambers, allowing the surface to adapt and maintain support. This adaptability enhances comfort and reduces the likelihood of pressure-related discomfort. A mattress lacking interconnected chambers would provide a rigid, unyielding surface, unable to accommodate the natural curves of the body.

- Stability and Motion Isolation

Interconnected chambers contribute to the overall stability of the “bubble air mattress”. While not providing the same level of motion isolation as a traditional innerspring mattress, the interconnected design mitigates the impact of movement on one side of the mattress to the other. This can be particularly beneficial for couples sharing the sleeping surface. Conversely, a mattress with poorly designed or damaged interconnections would transmit movement more readily, disrupting the s

leep of a partner. - Inflation and Deflation Dynamics

The interconnected chambers simplify the inflation and deflation process. Air introduced into one chamber distributes throughout the entire network, ensuring uniform inflation. Similarly, when deflating, air is expelled from all chambers simultaneously. This efficient process contributes to the convenience and ease of use associated with “bubble air mattresses”. A system with faulty or blocked interconnections would result in uneven inflation or difficulty in deflation.

In essence, the “bubble air mattress” relies on the interconnected nature of its air chambers to achieve its core functions. The effectiveness of weight distribution, body contouring, stability, and inflation/deflation processes are all directly dependent on the integrity and design of this interconnected system. Therefore, these chambers represent a fundamental and indispensable feature of these mattresses.

3. Portability and storage

The inherent design of the “bubble air mattress” prioritizes portability and ease of storage, rendering it a practical choice for temporary sleeping arrangements and situations where space is limited. These characteristics stem directly from the inflatable nature of the product, allowing it to be collapsed and compacted significantly when not in use. The ability to deflate and store the mattress in a small volume constitutes a key advantage over traditional mattresses. For instance, apartment dwellers with minimal storage capacity or campers seeking lightweight bedding find this feature invaluable.

The cause-and-effect relationship between the “bubble air mattress” design and its portability is evident. The absence of bulky internal components found in conventional mattresses allows for complete deflation and folding. This contrasts sharply with spring or foam mattresses, which retain their full dimensions regardless of use. Real-life examples highlight the practical significance: Disaster relief organizations utilize these mattresses for emergency shelter due to their ease of transport and deployment. Similarly, individuals relocating frequently appreciate the convenience of transporting a deflated mattress rather than a bulky alternative. The materiality also contributes to its portability, being constructed out of a lightweight material compared to standard mattress options. It is often stored inside a bag or folded in a box when deflated.

In conclusion, the connection between portability, storage, and the “bubble air mattress” is inextricably linked. The design explicitly addresses the need for a compact and easily transportable sleeping solution. Understanding this connection allows consumers to make informed purchasing decisions based on their specific spatial constraints and travel requirements. Challenges may arise from improper storage techniques, potentially damaging the material and compromising future use. Proper deflation, folding, and storage in a dry environment are essential for maintaining the integrity of the mattress and maximizing its lifespan.

4. Comfort and pressure relief

The ability of a “bubble air mattress” to provide comfort and pressure relief is a critical factor influencing its suitability as a sleeping surface. The design and materials directly impact the degree of comfort and the effectiveness of pressure redistribution, which are paramount considerations for users seeking a restful and pain-free sleep experience.

- Air Distribution and Support Zones

The interconnected air chambers of a “bubble air mattress” facilitate the distribution of weight across the entire surface, creating distinct support zones tailored to different areas of the body. This even distribution minimizes concentrated pressure points, particularly around the hips, shoulders, and spine. For example, individuals with back pain often benefit from the ability of the mattress to conform to their spinal curvature, providing targeted support and alleviating discomfort. The effectiveness of these support zones relies on the integrity of the air chambers and the uniformity of inflation.

- Surface Conformity and Responsiveness

The flexible nature of the air-filled chambers allows the surface to conform to the sleeper’s body shape, providing a customized level of support. This responsiveness reduces pressure on bony prominences and enhances overall comfort. Consider the experience of a side sleeper; the mattress yields to the contours of the shoulder and hip, preventing excessive pressure build-up. The material’s elasticity and the air pressure within the chambers influence the degree of conformity and the perceived softness of the surface.

- Impact of Material Composition

The type of material used in the construction of a “bubble air mattress” significantly impacts its comfort and pressure-relieving properties. Softer, more pliable materials provide a greater degree of cushioning and conformity compared to stiffer, less yielding alternatives. For example, mattresses made with flocked surfaces offer a softer touch and improved breathability, enhancing the overall sleeping experience. The material’s durability and resistance to stretching also influence its long-term comfort performance.

- Regulation of Air Pressure and Firmness

The ability to adjust the air pressure within the “bubble air mattress” allows users to customize the firmness level to their individual preferences and needs. Lowering the air pressure creates a softer, more yielding surface, while increasing the pressure provides a firmer, more supportive feel. This adjustability can be particularly beneficial for individuals with varying pain sensitivities or those who prefer different sleeping positions. Over-inflation, however, can compromise comfort by creating an overly rigid surface that lacks conformity.

In conclusion, the “bubble air mattress” aims to deliver comfort and pressure relief through its interconnected air chambers, surface conformity, material composition, and adjustable firmness. The effectiveness of these factors is contingent upon the quality of materials, the integrity of the air chamber design, and the user’s ability to properly inflate and maintain the mattress. Addressing these elements effectively can contribute to a more comfortable and restful sleep experience.

5. Durability and material

The longevity and performance of any “bubble air mattress” are inextricably linked to the inherent durability of its constituent materials. Material selection dictates resistance to puncture, abrasion, and degradation, ultimately influencing the product’s lifespan and suitability for intended use cases. Understanding the correlation between material properties and overall durability is therefore paramount.

- Tensile Strength of Outer Shell

The outer shell of a “bubble air mattress” bears the brunt of physical stress during inflation, use, and storage. Materials with high tensile strength, such as reinforced PVC or polyester laminates, exhibit greater resistance to tearing and stretching. For instance, a mattress constructed fro

m a lower-grade, thin PVC is more susceptible to punctures from sharp objects or seam failures under pressure, drastically reducing its lifespan. The tensile strength directly impacts the mattress’s ability to withstand repeated inflation and deflation cycles. - Seam Construction and Integrity

Weak points often arise at the seams joining different sections of the “bubble air mattress”. The method of seam construction, such as welding or stitching, and the type of adhesive used, significantly influence the seam’s resistance to stress and air leakage. High-frequency welding, for example, creates a more robust bond compared to simple gluing. Failures at the seams are a common cause of deflation and represent a significant factor in determining overall durability. Consequently, reinforced seam designs are essential for extending the useful life of the mattress.

- Resistance to Environmental Factors

Exposure to environmental factors such as UV radiation, temperature fluctuations, and moisture can degrade the materials used in “bubble air mattresses”. UV radiation can cause PVC to become brittle and crack, while extreme temperatures can affect the elasticity and integrity of the material. Resistance to these factors is crucial, particularly for mattresses intended for outdoor use. Materials treated with UV inhibitors or designed for high-temperature environments exhibit improved durability in challenging conditions.

- Puncture and Abrasion Resistance

The ability to withstand punctures from sharp objects and abrasion from rough surfaces is a primary determinant of durability. Thicker materials and those with specialized coatings offer enhanced protection against these hazards. For example, a mattress designed for camping requires a higher level of puncture resistance than one intended for indoor guest use. Failure to consider this aspect can lead to rapid degradation and loss of functionality. Materials incorporating ripstop technology further enhance puncture resistance by preventing tears from propagating.

The interplay between material properties and construction techniques directly dictates the durability and longevity of a “bubble air mattress.” By understanding these factors, consumers can make informed decisions and select products that align with their intended use and expected lifespan. Neglecting the importance of material selection often results in premature failure and a diminished return on investment. The integration of robust materials and sound construction practices is therefore essential for ensuring a reliable and durable sleeping surface.

6. Inflation/deflation mechanisms

The operational effectiveness and user convenience of any “bubble air mattress” are fundamentally determined by its inflation/deflation mechanisms. These mechanisms facilitate the introduction and expulsion of air, directly affecting the mattress’s firmness, usability, and storage efficiency. The design and functionality of these mechanisms significantly influence the overall user experience.

- Valve Design and Airflow Efficiency

The valve design directly impacts the speed and ease of inflation and deflation. Valves with larger openings and efficient sealing mechanisms allow for rapid airflow, minimizing the time required to inflate or deflate the mattress. Conversely, valves with small openings or poorly designed seals can restrict airflow, prolonging the process and potentially leading to air leakage. For example, a valve utilizing a one-way flap design prevents backflow during inflation, while a secure cap ensures airtight closure. Inefficient valve designs can lead to user frustration and reduced convenience.

- Pump Integration and Automation

Many “bubble air mattresses” incorporate integrated pumps, either manual or electric, to streamline the inflation process. Electric pumps offer automated inflation, requiring minimal user effort, while manual pumps provide a portable solution for situations where electricity is unavailable. The power and efficiency of the pump directly affect the inflation time and the degree of firmness achievable. For instance, a high-powered electric pump can inflate a queen-sized mattress in minutes, while a small manual pump may require significantly more time and physical exertion. The presence and functionality of an integrated pump are critical factors in user satisfaction.

- Durability and Reliability of Components

The longevity and dependability of the inflation/deflation mechanisms are crucial for the overall lifespan of the “bubble air mattress.” The components, including the valve, pump, and connecting hoses, must be constructed from durable materials capable of withstanding repeated use and exposure to air pressure. A valve made from brittle plastic is prone to cracking or breaking, leading to air leakage and rendering the mattress unusable. Similarly, a pump with a weak motor or faulty components can fail prematurely, requiring replacement or repair. The reliability of these mechanisms directly impacts the long-term value and usability of the product.

- Safety Features and Leak Prevention

Safety features incorporated into the inflation/deflation mechanisms are essential for preventing over-inflation and ensuring user safety. Pressure relief valves, for example, automatically release excess air when the internal pressure exceeds a safe limit, preventing the mattress from bursting. Similarly, secure locking mechanisms on the valve prevent accidental opening and deflation during use. These safety features are particularly important for mattresses used by children or individuals unfamiliar with inflatable products. The presence of robust safety mechanisms enhances user confidence and minimizes the risk of accidents.

The design and functionality of the inflation/deflation mechanisms are integral to the usability, convenience, and safety of the “bubble air mattress”. Efficient valve designs, integrated pumps, durable components, and robust safety features contribute to a positive user experience and extend the lifespan of the product. Neglecting these aspects can lead to frustration, inconvenience, and potential safety hazards, diminishing the overall value and desirability of the mattress.

7. Maintenance and repair

The operational longevity and sustained comfort of a “bubble air mattress” are contingent upon diligent maintenance practices and the availability of effective repair solutions. Regular maintenance mitigates potential issues, while readily accessible repair options extend the usable lifespan, preserving the initial investment.

- Preventative Cleaning Procedures

The accumulation of dirt, debris, and moisture on the mattress surface can degrade the material and compromise hygiene. Regular cleaning with mild detergents and appropriate cleaning agents prevents material breakdown and inhibits the growth of mold or mildew. For instance, wiping down the surface after each use removes perspiration and prevents staining. Neglecting preventative cleaning can lead to irreversible damage and necessitate premature replacement.

- Leak Detection and Sealing Techniques

Air leakage is a common issue affecting “bubble air mattresses,” diminishing support and comfort. Regular inspection for leaks, fol

lowed by prompt and effective sealing, is crucial. Utilizing commercially available repair kits specifically designed for inflatable materials, coupled with careful adherence to instructions, can effectively seal punctures and prevent further air loss. Delaying leak repair results in progressive deflation and eventual unusable. Examples of leak detection method is listening for hissing sound or apply soapy water on the surface. - Proper Storage Protocols

Incorrect storage practices can induce material degradation and structural damage. Deflating the mattress completely, folding it neatly according to manufacturer’s instructions, and storing it in a cool, dry location away from direct sunlight minimizes the risk of material breakdown. Storing a damp or partially inflated mattress can lead to mold growth and compromise the integrity of the air chambers. Correct storage prolongs the lifespan and maintains the functionality of the “bubble air mattress”.

- Valve Maintenance and Replacement

The inflation/deflation valve is a critical component prone to wear and tear. Regular inspection and cleaning of the valve mechanism ensure proper sealing and prevent air leakage. Over time, the valve may become damaged or develop leaks, requiring replacement. Sourcing compatible replacement valves and following the manufacturer’s instructions for installation restores functionality and extends the usability of the “bubble air mattress”. The valve functionality influences ease of use and overall performance.

Effective maintenance and repair protocols are integral to maximizing the value and lifespan of a “bubble air mattress.” Consistent adherence to preventative measures and proactive repair strategies safeguards the investment and ensures continued comfort and utility. These practices represent a cost-effective alternative to frequent replacement, contributing to both economic and environmental sustainability.

Frequently Asked Questions

The following questions address common concerns and inquiries regarding the utilization, maintenance, and characteristics of inflatable chambered sleeping surfaces, providing objective and informative responses.

Question 1: What is the typical lifespan of a “bubble air mattress”?

The lifespan varies depending on usage frequency, material quality, and maintenance practices. Under typical usage conditions and with proper care, a quality model can last for several years. Neglecting maintenance or subjecting it to harsh conditions will significantly reduce its lifespan.

Question 2: How does “bubble air mattress” support compare to that of a traditional mattress?

Support characteristics differ significantly. Traditional mattresses offer consistent, uniform support derived from springs or foam. “Bubble air mattress” support is dependent on air pressure and distribution, potentially resulting in a less stable or uniform sleeping surface, especially for individuals requiring firm support.

Question 3: Can a “bubble air mattress” be used as a primary sleeping surface on a long-term basis?

While possible, it is not generally recommended. Prolonged use may lead to discomfort due to inconsistent support and potential air leakage. Traditional mattresses are typically more suitable for consistent, long-term use.

Question 4: What measures should be taken to prevent punctures in a “bubble air mattress”?

Prior to inflation, ensure the sleeping surface is free of sharp objects. Consider using a protective layer, such as a fitted sheet or thin blanket, to minimize abrasion. Avoid placing the mattress on rough or uneven surfaces.

Question 5: Is it possible to repair a “bubble air mattress” with a significant puncture?

Minor punctures can often be repaired using commercially available repair kits designed for inflatable materials. However, larger tears or damage to seams may be irreparable, necessitating replacement.

Question 6: What are the environmental considerations regarding the disposal of a “bubble air mattress”?

Many “bubble air mattresses” are constructed from PVC or similar materials that are not readily biodegradable. Explore recycling options if available, or dispose of responsibly in accordance with local regulations. Consider the environmental impact of material choices when purchasing.

Understanding these common questions and their corresponding answers will aid in making informed decisions regarding the purchase, use, and maintenance of inflatable chambered sleeping surfaces.

The subsequent section will provide a comparative analysis of inflatable chambered sleeping surfaces and alternative bedding solutions, highlighting their respective advantages and disadvantages.

Concluding Remarks on Inflatable Chambered Mattresses

This exploration has examined the inflatable chambered mattress design, encompassing its operational principles, construction materials, maintenance needs, and comparative advantages. Key elements, including the interconnected air chambers, portability, material durability, and inflation mechanisms, contribute to the overall utility and lifespan of this specific bedding solution.

Careful consideration of the information presented herein is crucial for prospective purchasers seeking a cost-effective and portable sleeping arrangement. While this type of mattress offers advantages in specific contexts, its limitations must be weighed against alternative bedding solutions to ensure optimal suitability for individual needs and anticipated usage scenarios. Responsible disposal and mindful consumption contribute to a more sustainable approach to bedding choices.