A safety action, initiated either voluntarily by a manufacturer or mandated by a regulatory body, concerning a specific baby product designed for sleep is the central subject. This action follows the determination that the item presents a potential hazard to infants, necessitating its removal from the market and subsequent remediation. A hypothetical example would involve discovering a design flaw in a sleeping surface that poses a suffocation risk.

Such actions are vital for protecting vulnerable populations, specifically infants. Historically, they have served as critical interventions, preventing potential injuries or fatalities related to unsafe product designs or manufacturing defects. These interventions provide assurance to caregivers and reinforce the importance of rigorous safety standards within the juvenile product industry.

The following sections will delve into the specifics of identifying affected products, understanding the reasons behind the action, and navigating the steps involved in obtaining a remedy.

This section provides essential guidance for individuals potentially affected by a safety action concerning a specific sleep surface for infants. Careful adherence to these recommendations is paramount for ensuring infant safety and resolving any related concerns.

Tip 1: Verify Product Identification. Scrutinize the product label, model number, and manufacturing date. Compare this information against official recall announcements released by the manufacturer and regulatory agencies like the Consumer Product Safety Commission (CPSC). Mismatched information indicates the product is not part of the safety action.

Tip 2: Cease Product Use Immediately. Upon confirming that the product is subject to the action, discontinue its use immediately. Continuing to use the item places the infant at potential risk.

Tip 3: Retain All Documentation. Keep all purchase receipts, warranty information, and product packaging. This documentation may be required to facilitate the remedy process.

Tip 4: Contact the Manufacturer. Reach out to the manufacturer directly using the contact information provided in the safety action notice. Inquire about the available remedies, such as refunds, replacements, or repairs, and understand the required steps to participate.

Tip 5: Register with the Manufacturer. Many manufacturers require affected consumers to register through a dedicated website or hotline to receive updates, instructions, and to facilitate the remedy process.

Tip 6: Follow Instructions Precisely. Adhere strictly to the instructions provided by the manufacturer regarding product disposal or return. Failure to follow instructions may invalidate eligibility for compensation or remediation.

Tip 7: Monitor Official Announcements. Stay informed by regularly checking the manufacturer’s website and the CPSC website for updates or clarifications regarding the safety action.

Diligent application of these steps is crucial for safeguarding infants from potential hazards and ensuring a swift and equitable resolution to the situation. Prompt action minimizes risk and facilitates access to available remedies.

The subsequent section will explore the legal and regulatory landscape surrounding such product safety actions.

1. Product Identification

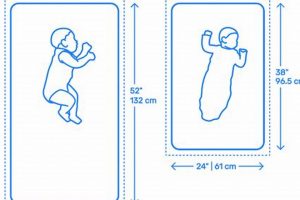

Accurate product identification constitutes a critical initial step in addressing a product safety action. In scenarios involving infant sleep surfaces, such as hypothetical situations, pinpointing the affected models is paramount. This process involves verifying the model number, manufacturing date, and any unique identifiers against official announcements. A failure in this initial stage compromises the entire subsequent process, potentially leaving at-risk infants exposed to identified hazards. The product label provides detailed information, but it’s only as useful as the person utilizing it. Disregarding or misinterpreting the information printed on the label results in the purchase of a product under recall.

The connection between the ability to accurately identify a product and the effectiveness of a recall is direct. Consider a scenario where an infant sleeping surface has a latent defect in the flame retardant materials used. If purchasers cannot correctly identify their model against the official listing, they will remain unaware of the hazard and fail to avail themselves of the necessary remediation. This demonstrates the cause-and-effect relationship: inaccurate identification directly causes continued exposure to potential harm. It follows from that, if the purchasers are diligent and identify the labels clearly, then all can seek the remediations required to prevent harm to the infant.

In summary, accurate product identification is not merely a preliminary step but an essential component of a product safety action. Its absence nullifies the protective intent of a recall, leaving infants potentially exposed to preventable hazards. Addressing this aspect through enhanced labeling clarity, widespread consumer education, and streamlined verification processes remains crucial for enhancing the efficacy of product safety actions.

2. Hazard Assessment

Hazard assessment forms a critical cornerstone of any product safety action concerning infant sleep surfaces. For illustrative purposes, consider a hypothetical instance related to a specific model. The assessment process meticulously identifies potential dangers associated with the product’s design, materials, or manufacturing. This assessment is not merely theoretical; it entails rigorous testing and analysis to determine the nature and severity of any risks posed to infants. For example, an assessment may reveal that certain components of a sleeping surface contain volatile organic compounds (VOCs) exceeding safe levels, potentially impacting infant respiratory health. Or it may discover a design flaw leading to collapse, creating a suffocation hazard. The reliability of the data from the hazard assessment determines the effectiveness of the ensuing safety action and protects the children.

The link between hazard assessment and any product safety action involving infant sleep surfaces is direct and consequential. The identification of a hazard, such as the presence of unsafe levels of flame retardants, triggers the subsequent decision-making process. This leads to the implementation of recall procedures, remedial actions, and public warnings. Consider a case where a sleeping surface’s support structure is prone to failure. The consequence is a dangerous sleeping environment for the infant. Without the assessment to pinpoint this structural weakness, consumers remain unaware of the latent danger, thus highlighting the assessment’s essential role. The consumer is directly affected by the accuracy of the original assessment.

In summary, hazard assessment acts as the critical foundation upon which all safety actions are built. It determines the nature and scope of the risks associated with infant sleep products. Its thoroughness and accuracy dictate the effectiveness of subsequent remedial actions and, ultimately, safeguard infant well-being. Challenges remain in refining assessment methodologies to account for long-term health impacts and evolving manufacturing techniques. Nevertheless, robust hazard assessment is a non-negotiable element in upholding product safety standards and protecting vulnerable infants.

3. Remedy Options

Following a product safety action, the availability of viable remedy options becomes paramount for affected consumers. This directly pertains to situations where a potentially hazardous infant sleep surface has been identified. The scope and nature of these options influence the resolution of safety concerns and provide redress to purchasers.

- Full Refund

The provision of a complete reimbursement of the original purchase price represents one potential remedy. This is particularly relevant when the manufacturer deems the product irredeemable or when a suitable replacement is unavailable. The refund serves to restore the consumer to their pre-purchase financial state, mitigating financial loss incurred due to the acquisition of a substandard or unsafe item. For instance, if the sleeping surface presents an irreparable structural flaw, a full refund may be the most equitable resolution.

- Product Replacement

Offering a direct replacement with a newer, safer model constitutes an alternative remedy. This option involves exchanging the recalled item for a redesigned or re-engineered version that addresses the identified safety concerns. The replacement product must meet or exceed current safety standards. A product replacement ensures that the consumer receives a functional and safe infant sleep surface, fulfilling the original intended purpose of the purchase. The replacement strategy should be carefully considered, because it provides the consumer with the security that the product that they purchase has been checked for safety and will prevent them from having to deal with any dangers.

- Repair Program

In certain scenarios, a manufacturer may offer a repair program. The program allows the affected product to have all of its defects repaired and then the consumer can use the product safely. This approach may entail modifications or component replacements designed to mitigate the identified hazard. A carefully executed repair program restores the product to a safe and usable condition, avoiding the need for complete replacement or disposal. The execution of the program requires clear instructions, readily available repair services, and verifiable quality control measures.

- Partial Refund

In some cases, a partial refund, in conjunction with retaining the original product, may be offered. This scenario typically arises when the identified hazard does not render the product entirely unusable but necessitates specific precautions or modifications. The partial refund compensates for the diminished value or inconvenience associated with the product’s limitations. However, this remedy is generally less desirable than a full refund or replacement, as it leaves the consumer with a compromised item.

The precise remedy options available depend on various factors. The factors include the nature and severity of the hazard, the cost-effectiveness of different solutions, and regulatory requirements. These elements are critical for determining the appropriate course of action. Transparency in the remedy process is essential. Clear communication between the manufacturer and the consumer facilitates efficient resolution and reinforces confidence in the product safety system.

4. Reporting Procedures

Effective reporting procedures serve as a critical component of product safety actions, specifically concerning infant sleep surfaces. Standardized reporting channels ensure that relevant information regarding potential hazards or defects reaches manufacturers and regulatory agencies in a timely and efficient manner. This allows for prompt investigation, risk assessment, and subsequent remediation efforts.

- Consumer Reporting to Manufacturers

Consumers play a crucial role in the initial detection and reporting of potential product defects. Direct communication with the manufacturer, often through designated hotlines or online portals, enables the swift relay of information regarding malfunctions, safety concerns, or observed irregularities. For example, if a caregiver discovers a tear in the sleeping surface’s fabric, creating a potential entrapment hazard, this should be reported immediately. Manufacturers are then obligated to investigate these claims, analyze trends, and initiate corrective actions if warranted. This first contact can serve as the starting point for improving the quality and safety of future products.

- Manufacturer Reporting to Regulatory Agencies

Manufacturers have a legal and ethical obligation to report significant safety issues to relevant regulatory bodies, such as the Consumer Product Safety Commission (CPSC) in the United States. This reporting is typically triggered when a manufacturer becomes aware of a defect that could create a substantial risk of injury or death. The CPSC then conducts its own independent investigation, assesses the severity of the risk, and determines whether a recall or other corrective action is necessary. This two-tiered reporting system ensures that safety concerns are thoroughly vetted by both the manufacturer and an independent regulatory authority.

- Healthcare Provider Reporting

Healthcare providers, particularly pediatricians and emergency room physicians, may encounter cases involving injuries or adverse health effects potentially linked to defective infant products. These professionals have a responsibility to report such incidents to the appropriate public health agencies or directly to the manufacturer. Such reporting provides valuable insights into the real-world impact of product defects and can help identify previously unrecognized safety hazards. The information gathered from healthcare providers can be critical in assessing the overall risk posed by a specific product.

- Public Databases and Complaint Systems

Several public databases and online complaint systems, often maintained by regulatory agencies or consumer advocacy groups, provide a centralized repository for reports related to product safety concerns. Consumers can submit complaints directly through these channels, and the information is then made available to the public and to relevant regulatory authorities. These databases serve as a valuable resource for identifying emerging trends, tracking product safety issues, and informing consumer decision-making. Before purchasing a product, purchasers should check the databases to ensure that they are not purchasing an item that has a history of complaints about it.

In summary, effective reporting procedures are essential for mitigating the risks associated with potentially hazardous infant sleep surfaces. By ensuring clear, accessible, and reliable channels for reporting safety concerns, manufacturers and regulators can promptly identify and address potential defects, ultimately safeguarding infant health and well-being. The effectiveness of these procedures hinges on collaboration and transparency among all stakeholders.

5. Prevention Strategies

Proactive measures to prevent future product safety issues, specifically those necessitating actions similar to a hypothetical infant sleep surface matter, are paramount. Effective prevention strategies aim to eliminate potential hazards before products reach consumers, thereby minimizing the risk of injuries and recalls.

- Enhanced Design Review Processes

Rigorous design review processes, incorporating comprehensive risk assessments and failure mode analyses, are essential. These processes identify potential weaknesses or hazards early in the development phase. Consider a scenario where a sleeping surface’s design includes small, detachable parts. A thorough design review would flag this as a potential choking hazard, prompting a redesign before the product enters production. Implementing standardized checklists and incorporating feedback from independent safety experts strengthens design reviews.

- Stricter Quality Control Measures

Stringent quality control measures throughout the manufacturing process are critical for ensuring product conformity to safety standards. This includes meticulous inspection of raw materials, continuous monitoring of production processes, and rigorous testing of finished products. For instance, regular testing of materials for harmful chemicals, such as phthalates or lead, prevents the introduction of hazardous substances into the infant sleep environment. Robust quality control systems detect and rectify deviations from safety specifications, minimizing the likelihood of defective products reaching consumers.

- Supplier Audits and Certification

Manufacturers should conduct thorough audits of their suppliers’ facilities and processes to ensure compliance with established safety standards. Requiring suppliers to obtain independent certifications, such as ISO 9001 or similar quality management systems, provides an additional layer of assurance. Regular audits identify potential deficiencies in supplier operations. Manufacturers can take corrective action to improve quality control and prevent the use of substandard or unsafe materials. By ensuring the integrity of the supply chain, manufacturers reduce the risk of safety-related issues arising from component defects or non-compliant materials.

- Post-Market Surveillance and Data Analysis

Vigilant post-market surveillance, involving the continuous monitoring of consumer feedback, incident reports, and regulatory data, is vital for identifying potential safety concerns that may emerge after a product has been released to market. Analysis of this data can reveal previously unrecognized hazards or patterns of failure. For instance, tracking consumer complaints regarding collapsing sleeping surfaces, even if isolated, may indicate a systemic design flaw or manufacturing defect. Prompt investigation and corrective action, based on post-market surveillance data, prevents widespread safety issues and mitigates potential harm to infants.

These prevention strategies, when implemented comprehensively, significantly reduce the likelihood of future safety actions involving infant sleep surfaces. By prioritizing proactive risk management and continuous improvement, manufacturers can ensure the safety and well-being of infants while fostering consumer trust and confidence in their products.

Frequently Asked Questions

The following addresses common queries regarding the safety action concerning specific infant sleep surfaces.

Question 1: How is an affected infant sleep surface identified?

Verification involves checking the product label, model number, and manufacturing date against official recall announcements from the manufacturer and regulatory agencies.

Question 2: What immediate steps should be taken upon confirming a product is subject to a safety action?

Product use should be discontinued immediately. All purchase receipts, warranty information, and product packaging should be retained.

Question 3: How does one obtain information about available remedies?

The manufacturer should be contacted directly, utilizing the contact information provided in the official safety action notice.

Question 4: Are there reporting requirements for discovering a defect?

Consumers should report any malfunctions, safety concerns, or observed irregularities directly to the manufacturer through designated channels.

Question 5: What are the key prevention strategies to minimize the need for future safety actions?

Implementing enhanced design review processes, stricter quality control measures, and supplier audits are essential preventive steps.

Question 6: Where can additional information on infant product safety actions be found?

Regulatory agency websites, such as the Consumer Product Safety Commission (CPSC), provide resources and updates on product safety actions.

Prompt and informed action in response to a safety action ensures infant safety and facilitates access to available remedies.

The succeeding section will cover available resources.

Conclusion

This exploration of the “bubble bear crib mattress recall” underscores the critical importance of product safety within the juvenile product sector. The analysis highlighted essential procedures for identifying affected products, understanding available remedies, and recognizing the preventative measures necessary to minimize future risks. The rigorous investigation of a product safety action should be a collaborative commitment between manufacturers, regulatory bodies, and consumers.

Ongoing diligence in product design, manufacturing, and surveillance remains paramount. The imperative to safeguard infant well-being necessitates unwavering adherence to safety standards and proactive engagement in product safety initiatives. The industry’s sustained dedication towards safety can ensure a safer environment for infants.