Sleeping surfaces designed specifically for the upper sleeping quarters in recreational vehicles offer compact dimensions and often unique construction to accommodate space limitations. These sleeping platforms typically feature reduced thicknesses and specialized shapes to fit within the confined areas of camper bunks. Durable materials are used in their construction to withstand frequent use and potential environmental factors encountered during travel.

The selection of an appropriate RV sleeping solution significantly contributes to overall comfort and rest quality during travel. A well-chosen sleeping surface can alleviate pressure points, promote spinal alignment, and minimize motion transfer, all crucial for a restful experience in a mobile environment. The evolution of such sleeping solutions reflects a growing demand for comfortable and space-efficient options in recreational travel.

The following sections will detail considerations for selecting a suitable sleeping platform, including factors such as dimensions, material types, and construction methods. Furthermore, maintenance and care guidelines will be provided to ensure longevity and sustained performance. Lastly, potential upgrade options and alternatives will be discussed to cater to varied comfort preferences and budgetary considerations.

Tips for Selecting a Suitable Camper Bunk Bed Mattress

This section provides guidance on choosing the appropriate sleeping surface for recreational vehicle bunk beds. Careful consideration of these factors will enhance comfort and improve the overall travel experience.

Tip 1: Measure Accurately. Precise measurements of the bunk bed frame are crucial before purchase. Standard sizes may not apply, and custom sizes are often required. Measure the length, width, and depth to ensure a proper fit.

Tip 2: Consider Thickness Limitations. Bunk beds often have height restrictions. Select a sleeping platform with a thickness that allows adequate headroom for the occupant while adhering to safety guidelines. Thinner profiles are generally preferred.

Tip 3: Evaluate Material Composition. Foam density, coil count (if applicable), and fabric durability contribute to the sleeping surface’s longevity and comfort. High-density foam offers better support and resistance to compression over time.

Tip 4: Prioritize Support and Comfort. While space is a primary concern, support should not be compromised. Assess the sleeping platform’s ability to provide adequate spinal alignment and pressure relief. Consider individual sleeping preferences when making this determination.

Tip 5: Research Certifications and Standards. Look for certifications indicating the sleeping surface has been tested for harmful substances and meets flammability standards. This ensures a safer sleeping environment.

Tip 6: Account for Weight Capacity. Bunk beds have specified weight limits. Verify that the selected sleeping platform is capable of supporting the intended occupant’s weight. Exceeding the weight limit can compromise the structure’s integrity and safety.

Tip 7: Explore Options for Enhanced Airflow. In warmer climates, heat retention can be an issue. Consider options with breathable materials or ventilation channels to promote airflow and minimize discomfort.

Selecting the correct RV bunk sleeping surface involves carefully balancing space constraints with the need for comfortable and supportive rest. Adhering to these tips will assist in making an informed decision, resulting in a more enjoyable travel experience.

The next section will explore maintenance practices to extend the lifespan of the chosen RV bunk sleeping solution.

1. Dimensions

The physical size of a sleeping surface is paramount to its suitability for RV bunk beds. Due to the often limited and non-standardized dimensions of these spaces, precise dimensional considerations are crucial for a functional and comfortable fit. Failure to account for dimensions can result in either unusable sleeping space or structural compromises.

- Length and Width Specifications

Length and width measurements must correspond precisely to the interior dimensions of the bunk frame. Overestimation can prevent installation, while underestimation creates gaps that reduce usable space and compromise safety. For instance, a bunk bed frame measuring 74 inches by 28 inches requires a sleeping surface of identical or very slightly smaller dimensions.

- Thickness Constraints

The vertical space within a bunk bed is often limited, particularly in upper bunks. Excessive sleeping surface thickness can restrict headroom, creating an uncomfortable or even claustrophobic environment. Conversely, insufficient thickness may compromise support and comfort. Typically, thicknesses ranging from 4 to 6 inches are preferred to strike a balance between space utilization and comfort.

- Custom Shapes and Contours

Some RV bunk beds incorporate non-rectangular shapes to maximize space utilization. In such cases, standard rectangular mattresses are unsuitable. Custom-shaped sleeping platforms are necessary to conform to the specific contours of the bunk, ensuring full space utilization and eliminating uncomfortable gaps. These custom shapes must be accurately replicated in the sleeping platform’s design.

- Impact on Overall Weight

The dimensions of a sleeping platform directly influence its overall weight. Larger dimensions generally translate to increased weight, which can be a critical factor in RVs where weight distribution is a concern. Overly heavy sleeping surfaces can negatively impact fuel efficiency and vehicle handling. Therefore, optimizing dimensions to minimize weight without sacrificing comfort is essential.

The interplay of these dimensional factors directly impacts the usability and comfort of the recreational vehicle bunk sleeping surface. Precise measurements and careful consideration of the bunk’s geometry are indispensable for selecting a suitable solution. Ultimately, dimensional accuracy underpins both the functionality and safety of the sleeping arrangement.

2. Material Composition

The selection of materials significantly influences the performance and longevity of a recreational vehicle bunk sleeping surface. The materials used determine its comfort, support, durability, and resistance to environmental factors commonly encountered during travel. Therefore, careful consideration of material composition is essential when choosing an RV bunk sleeping solution.

- Foam Density and Type

Foam density, measured in pounds per cubic foot, dictates the support and durability of the sleeping surface. Higher density foams offer increased resistance to compression and deformation, providing greater support over time. Memory fo

am, polyurethane foam, and latex foam are common choices, each with distinct characteristics. Memory foam conforms to the body, offering pressure relief, while latex provides a more resilient and responsive feel. Polyurethane foam serves as a cost-effective option with varying density levels. The foam type and density directly impact the overall comfort and lifespan of the RV bunk sleeping surface. - Cover Fabric Durability and Breathability

The outer fabric of the sleeping surface plays a crucial role in its durability and breathability. Durable fabrics, such as reinforced polyester or nylon blends, resist tearing and abrasion during frequent use and transport. Breathable fabrics, like cotton or specialized moisture-wicking materials, promote airflow and minimize heat retention, contributing to a more comfortable sleeping environment. The fabric’s ability to withstand UV exposure and resist mildew growth is also important for prolonged use in varying climates. Choosing a suitable cover fabric is critical for maintaining hygiene and comfort within the confined space of an RV bunk.

- Flame Retardant Treatments

Regulations often mandate flame-retardant treatments for sleeping surfaces to enhance safety in the event of a fire. These treatments involve the application of chemical compounds to reduce the flammability of the mattress materials. While flame retardancy is essential for safety compliance, it’s also important to consider the potential health implications of the specific chemicals used. Selecting sleeping surfaces with certifications indicating compliance with safety standards and the use of environmentally responsible flame retardants is advisable. The balance between fire safety and potential health concerns necessitates careful scrutiny of flame retardant treatments.

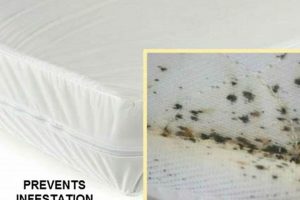

- Moisture Resistance and Antimicrobial Properties

Recreational vehicles are often exposed to varying humidity levels and potential moisture intrusion. Materials with inherent moisture resistance or antimicrobial treatments are beneficial in preventing mold and mildew growth, which can compromise the hygiene and longevity of the sleeping surface. Waterproof or water-resistant barriers can protect the inner materials from spills and moisture accumulation. Antimicrobial agents inhibit the growth of bacteria and fungi, reducing odors and promoting a healthier sleeping environment. These properties are particularly important in the enclosed spaces of RV bunks, where ventilation may be limited.

The interplay of foam type, cover fabric, flame retardant treatments, and moisture resistance properties determines the overall quality and suitability of an RV bunk sleeping surface. A well-chosen combination of these materials contributes to a comfortable, durable, and hygienic sleeping environment, enhancing the overall travel experience. Prioritizing materials with appropriate characteristics for RV use ensures a longer lifespan and sustained performance of the sleeping platform.

3. Thickness Limitations

The available vertical space within a recreational vehicle bunk bed directly dictates the acceptable thickness of a sleeping surface. This limitation arises from the need to maintain adequate headroom for occupants, prevent obstruction of access to upper bunks, and adhere to safety regulations regarding escape routes. A sleeping platform that is excessively thick can significantly compromise these factors, leading to discomfort, potential hazards, and non-compliance with safety standards. For instance, a bunk design intended for a 4-inch sleeping surface would experience significant headroom reduction and potential ladder obstruction if fitted with an 8-inch deep platform.

The impact of thickness limitations extends beyond immediate comfort and safety. An overly thick sleeping surface increases the overall weight of the bunk, potentially exceeding the bunk’s structural load capacity and compromising the vehicle’s weight distribution. Conversely, choosing a sleeping platform that is too thin may compromise support and pressure relief, leading to discomfort and potential health issues such as back pain. Therefore, optimal sleeping surface selection necessitates careful balancing between thickness, support, and weight considerations. Furthermore, specialized camper bunk sleeping surfaces are often constructed with multi-layered designs, combining thinner layers of high-density foam and supportive materials to achieve the desired comfort and support without exceeding thickness constraints.

In summary, the thickness limitation represents a critical design constraint in the selection of recreational vehicle bunk sleeping surfaces. Understanding its implications for headroom, safety, weight distribution, and comfort is essential for making informed purchasing decisions. Addressing this constraint through careful measurement, material selection, and consideration of multi-layered designs enables the creation of a safe and comfortable sleeping environment within the confines of a camper bunk. The challenge lies in maximizing comfort and support within the imposed dimensional limitations, ultimately enhancing the overall travel experience.

4. Support Requirements

Adequate support is a fundamental consideration when selecting a sleeping surface for recreational vehicle bunk beds. Given the confined spaces and potential for frequent use, the ability of the mattress to properly support the occupants body is paramount for comfort, spinal alignment, and overall health.

- Spinal Alignment and Pressure Relief

A primary support requirement involves maintaining proper spinal alignment during sleep. The mattress must contour to the body’s natural curves, preventing excessive pressure points and ensuring that the spine remains in a neutral position. Inadequate support can lead to muscle strain, back pain, and compromised sleep quality. For example, a mattress that sags excessively in the middle will misalign the spine and concentrate pressure on the hips and shoulders. The materials and construction of the mattress directly influence its ability to provide this essential spinal support.

- Weight Distribution and Load Capacity

RV bunk beds have specified weight limits, and the sleeping surface must be capable of evenly distributing the occupant’s weight without exceeding these limits. Uneven weight distribution can compromise the structural integrity of the bunk and potentially lead to collapse. Furthermore, exceeding the mattress’s load capacity can cause premature wear and tear, reducing its lifespan and compromising its support capabilities. Therefore, selecting a mattress with a suitable weight rating and appropriate weight distribution characteristics is crucial for safety and longevity.

- Edge Support and Stability

Edge support refers to the mattress’s ability to provide consistent support along its perimeter. Strong edge support prevents the occupant from rolling off the mattress and maximizes the usable sleeping surface. In bunk beds, where space is limited, good edge support is particularly important. Without adequate edge support, the mattress may compress excessively near the edges, leading to discomfort and a feeling of instability. Reinforced edges or the use of high-density foam in the perimeter construction contribute to improved edge support and overall mattress stability.

Material Density and Durability The density and durability of the mattress materials directly impact its long-term support capabilities. High-density foams and robust innerspring systems are better equipped to maintain their shape and supportiveness over time, resisting compression and deformation. Low-quality materials may break down quickly, leading to sagging and a loss of support. Investing in a mattress with durable materials and a construction designed for longevity ensures that the support requirements are met consistently throughout the mattress’s lifespan, even with frequent use in a recreational vehicle environment.

In summation, the ability of a recreational vehicle bunk sleeping surface to meet these support requirements is central to its functionality and value. Addressing spinal alignment, weight distribution, edge support, and material durability ensures not only a comfortable night’s sleep but also the long-term health and safety of the bunk occupant. The proper balance of these factors ultimately delivers a satisfying and supportive sleeping experience within the confines of a camper bunk.

5. Weight Capacity

The specified weight capacity of a camper bunk bed represents a critical safety parameter directly affecting the selection and performance of its sleeping surface. Exceeding this limit can lead to structural damage and potential injury, underscoring the importance of aligning sleeping surface choice with the bunk’s weight rating.

- Bunk Structure Integrity

The weight capacity is intrinsically linked to the structural design of the bunk bed itself. The frame materials, joining methods, and support systems are engineered to withstand a defined maximum load. Introducing a sleeping surface that, in combination with the occupant, surpasses this load can induce stress fractures, warping, or complete structural failure. For instance, a bunk bed designed for a 200-pound capacity, when loaded with a 30-pound mattress and a 220-pound occupant, exceeds its safe operating limit, potentially compromising its stability. This aspect is particularly critical in older or less robust bunk bed designs.

- Sleeping Surface Material Durability

The materials comprising the sleeping surface also possess inherent weight limits. Foam densities, coil spring gauges, and fabric tensile strengths are all factors influencing the mattress’s ability to distribute weight evenly and resist compression. An inappropriately chosen sleeping surface, especially one with low-density foam or insufficient support structure, may exhibit premature sagging or deformation under excessive weight. This not only reduces comfort but also diminishes the sleeping surface’s effective lifespan, necessitating more frequent replacement. A high-density memory foam mattress, while comfortable, may not be suitable for a bunk bed with a low weight capacity due to its inherent weight.

- Occupant Safety Implications

Exceeding the bunk bed’s weight capacity poses a direct threat to occupant safety. Structural failure can result in collapse, leading to potential falls and associated injuries. Even if complete collapse does not occur, excessive stress on the bunk frame can create instability, increasing the risk of accidental dislodgement during sleep. Moreover, an inadequately supportive sleeping surface can contribute to discomfort and musculoskeletal issues, particularly if the occupant’s weight is not properly accommodated. Compliance with weight capacity guidelines is paramount to mitigating these risks and ensuring a safe sleeping environment.

- Liability and Warranty Considerations

Operating a camper bunk bed beyond its specified weight capacity can void manufacturer warranties and expose owners to legal liability in the event of an accident. Manufacturers design and warrant their products based on adherence to recommended operating parameters, including weight limitations. Intentional or negligent disregard for these limitations can negate warranty coverage and create a basis for legal claims related to property damage or personal injury. Documenting weight capacity adherence is thus prudent for maintaining warranty validity and minimizing potential liability exposure.

The interplay between bunk bed structural integrity, sleeping surface material durability, occupant safety, and liability concerns underscores the importance of meticulous attention to weight capacity. Selecting a sleeping surface that aligns with the bunk’s weight rating is not merely a matter of convenience but a crucial element of responsible camper ownership and safe travel practices. Failing to do so can have significant repercussions, ranging from discomfort and material degradation to serious injury and legal ramifications.

Frequently Asked Questions

The following section addresses common inquiries regarding sleeping surfaces for recreational vehicle bunk beds. These questions and answers aim to provide clarity and informed guidance for making appropriate purchasing decisions.

Question 1: How does one determine the correct size for a replacement bunk sleeping surface?

Precise measurement of the existing bunk frame is essential. Length, width, and depth dimensions should be obtained using a measuring tape. It is advisable to subtract approximately one-quarter of an inch from each dimension to ensure ease of installation and prevent binding.

Question 2: What is the typical lifespan of a camper bunk bed mattress?

The lifespan varies depending on material quality, frequency of use, and maintenance practices. Generally, a high-quality sleeping surface can last between five to seven years with proper care. Regular rotation and the use of a mattress protector can extend its longevity.

Question 3: Are specialized flame-retardant treatments necessary for a bunk sleeping surface in a recreational vehicle?

Yes, adherence to flammability standards is crucial. Look for sleeping surfaces that meet or exceed relevant safety regulations, such as those established by the Consumer Product Safety Commission (CPSC). These standards ensure a degree of protection in the event of a fire.

Question 4: What types of materials are most suitable for a sleeping platform in an RV environment?

Materials that offer durability, breathability, and moisture resistance are recommended. High-density foam, breathable fabrics like cotton or linen blends, and antimicrobial treatments can enhance comfort and prevent the growth of mold and mildew.

Question 5: How can one mitigate motion transfer in a bunk bed with multiple occupants?

Sleeping surfaces constructed with individually wrapped coils or high-density memory foam can minimize motion transfer. These designs isolate movement, reducing disturbances to other occupants. Additionally, consider using separate sleeping surfaces for each bunk.

Question 6: What are the primary considerations for selecting a sleeping surface for a child’s bunk in a recreational vehicle?

Safety, support, and hygiene are paramount. Opt for a firm sleeping surface that provides adequate spinal support and is free from potentially harmful chemicals. A waterproof mattress protector is recommended to safeguard against spills and accidents.

In conclusion, selecting an appropriate recreational vehicle bunk sleeping solution requires careful attention to dimensions, materials, safety standards, and individual needs. A well-informed decision wil

l contribute to enhanced comfort, safety, and overall enjoyment of the travel experience.

The following section will offer insights on maintenance routines designed to extend the life of your “camper bunk bed mattress”.

Conclusion

The preceding discussion has thoroughly examined critical aspects of the camper bunk bed mattress. Considerations spanning dimensions, material composition, support requirements, weight capacity adherence, and safety standards were addressed. The objective has been to provide a comprehensive framework for informed decision-making regarding sleeping surface selection within the constraints of recreational vehicle bunk beds. Adherence to established guidelines and thoughtful evaluation of individual needs are paramount to ensuring both comfort and safety.

Effective utilization of the information presented herein should lead to improved occupant well-being and enhance the overall utility of recreational vehicle travel. Prudent application of these principles remains crucial to realizing the full potential of the camper bunk bed mattress as a vital component of the mobile living experience. Continued awareness and adaptation to evolving material technologies and safety standards will further optimize the selection process in the future.

![Space-Saving Mattress Firm Murphy Bed [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Space-Saving Mattress Firm Murphy Bed [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-7215-300x200.jpg)