This equipment comprises an inflatable sleeping surface manufactured by Coleman, coupled with a device to introduce air and inflate it. It provides a portable and convenient solution for temporary sleeping arrangements. Models vary in size, material, and pump type, catering to diverse needs from camping to accommodating overnight guests.

Its value resides in the portability and ease of setup it offers. Compared to traditional mattresses, it occupies minimal storage space when deflated and can be deployed quickly with the integrated or accompanying pump. The history of inflatable mattresses reflects advancements in materials science and pump technology, leading to increasingly durable and user-friendly products.

The following sections will delve into specific aspects of this product category, including available models, features, performance characteristics, and considerations for optimal usage and maintenance.

Coleman Air Mattress and Pump

Proper utilization and care of inflatable sleeping solutions contribute significantly to their longevity and performance. Adherence to these guidelines ensures a comfortable and reliable experience.

Tip 1: Site Selection is Crucial: Before inflation, meticulously inspect the intended placement area. Remove any sharp objects such as rocks, twigs, or debris that could puncture the mattress material. A groundsheet or protective layer is recommended, particularly for outdoor use.

Tip 2: Controlled Inflation is Paramount: Avoid over-inflation. Excessive air pressure can stress the seams and compromise structural integrity. Refer to the manufacturer’s instructions for recommended pressure levels. Monitor firmness during inflation, erring on the side of slight under-inflation if unsure.

Tip 3: Temperature Considerations: Ambient temperature affects air pressure. Air expands in heat and contracts in cold. Adjust inflation levels accordingly. In cooler environments, add a small amount of air; in warmer environments, release a small amount to prevent over-expansion and potential damage.

Tip 4: Proper Deflation and Storage: Deflate the mattress completely after each use. Ensure all air is expelled to minimize stress on the material during storage. Fold the mattress neatly, following the manufacturer’s recommended folding pattern (if provided). Store in a cool, dry place away from direct sunlight and extreme temperatures.

Tip 5: Cleaning and Maintenance: Clean the mattress surface regularly with a mild soap and water solution. Avoid harsh chemicals or abrasive cleaners, which can damage the material. Ensure the mattress is completely dry before storage to prevent mold or mildew growth.

Tip 6: Pump Maintenance: Regularly inspect the pump for any signs of damage or wear. Clean the pump intake and output ports to ensure optimal airflow. Store the pump separately from the mattress to prevent accidental damage during storage.

Adhering to these guidelines will maximize the lifespan and usability of the equipment, providing a dependable sleeping solution for various needs.

The subsequent sections will discuss common issues, troubleshooting steps, and considerations for selecting the appropriate type of air mattress and pump for specific applications.

1. Durability

Durability is a primary consideration when evaluating inflatable sleeping solutions. The ability of a Coleman air mattress to withstand repeated use, varying environmental conditions, and potential punctures directly impacts its overall value and longevity. The following aspects contribute to the equipment’s robustness.

- Material Composition and Thickness

The materials utilized in construction, primarily PVC (Polyvinyl Chloride) or similar polymers, dictate puncture resistance. Higher denier fabrics and increased material thickness enhance the ability to withstand abrasion and sharp objects. Reinforced seams are crucial, minimizing the risk of air leakage due to stress or pressure. Premium models often incorporate multi-layered construction for increased protection.

- Seam Welding Techniques

The method used to join the mattress panels significantly influences its structural integrity. Radio Frequency (RF) welding or heat sealing techniques create strong, airtight bonds. Improper welding can lead to weak points and premature failure. Quality control during manufacturing is essential to ensure consistent and reliable seam integrity.

- Pump Reliability and Over-Inflation Protection

The included or compatible pump’s design impacts durability indirectly. A pump that delivers consistent and controlled inflation reduces stress on the mattress seams. Over-inflation protection mechanisms, such as pressure relief valves, prevent exceeding the material’s maximum pressure threshold, minimizing the risk of bursting or seam failure.

- Environmental Resistance

An air mattress’s ability to withstand varying temperatures, humidity, and UV exposure affects its lifespan. Prolonged exposure to direct sunlight can degrade the PVC material, leading to brittleness and cracking. Resistance to mold and mildew is also important for maintaining hygiene and preventing material degradation, especially when used in damp environments.

Ultimately, the durability of Coleman inflatable beds hinges on a combination of material selection, manufacturing processes, and the pump’s operational characteristics. Higher-quality materials and superior construction techniques translate to increased resistance to damage, longer lifespan, and enhanced user satisfaction. Proper usage and maintenance further contribute to extending the mattress’s operational life.

2. Portability

Portability is a defining characteristic of the Coleman air mattress and pump system, intrinsically linked to its utility across diverse scenarios. The inherent design facilitates ease of transport and storage when deflated, contrasting sharply with traditional mattresses that lack this capability. This attribute makes it exceptionally suitable for applications where space is limited or mobility is paramount.

The direct consequence of its portability is the expansion of usage environments. Camping trips, temporary accommodations during home renovations, and hosting overnight guests in smaller living spaces become feasible due to the system’s compact nature when not in use. Consider the practical example of a family embarking on a camping excursion; the deflated mattress and pump occupy significantly less volume in a vehicle than a conventional mattress, freeing up space for other essential gear. Similarly, in urban apartments where storage is at a premium, the ability to stow the sleeping solution in a closet or under a bed enhances its appeal. The reduced weight compared to standard beds also contributes to easier handling and transport.

However, the degree of portability is influenced by the specific model and pump type. Larger mattresses and those with integrated electric pumps may be heavier and bulkier than smaller, manually inflated alternatives. Understanding the trade-offs between size, comfort, and portability is crucial for selecting the optimal Coleman air mattress and pump system for a given need. Despite these variations, the fundamental principle of convenient transport and storage remains a core advantage, positioning it as a practical solution for situations demanding adaptable sleeping arrangements.

3. Inflation Speed

Inflation speed represents a critical performance characteristic of a Coleman air mattress and pump system. It directly influences user convenience and the practicality of deploying the sleeping surface in various settings. A faster inflation time translates to reduced setup effort and quicker readiness for use.

- Pump Type and Technology

The pump’s design and power source significantly impact inflation speed. Integrated electric pumps generally inflate mattresses more rapidly than manual pumps, which require physical exertion. Pump technology, such as dual-action mechanisms or high-volume output, further enhances inflation efficiency. For instance, a pump with a two-stage system might deliver high volume initially, then switch to high pressure for optimal firmness. Battery-powered electric pumps offer portability, while AC-powered pumps require a power source.

- Mattress Size and Volume

Inflation time is directly proportional to the mattress’s size and volume. A larger mattress, such as a queen or king size, requires a greater volume of air to reach its intended firmness. Consequently, it will take longer to inflate compared to a smaller, single-size mattress. The internal structure of the mattress also affects inflation time. Mattresses with complex support systems or multiple air chambers may require more time to inflate fully.

- Pump Capacity and Airflow Rate

The pump’s capacity, measured in liters per minute (LPM) or cubic feet per minute (CFM), dictates the volume of air it can deliver. A higher airflow rate translates to faster inflation. However, airflow rate must be balanced with pressure. Some pumps may deliver a high volume of air at low pressure, which is suitable for initial inflation but insufficient for achieving optimal firmness. A pump with adjustable pressure settings offers greater control over the inflation process.

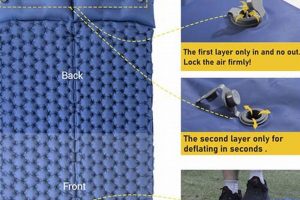

- Valve Design and Airflow Efficiency

The design of the mattress valve influences airflow efficiency and, consequently, inflation speed. A valve with a large opening allows for faster air intake. Valve materials and sealing mechanisms affect air leakage during inflation. Secure and airtight valves prevent air from escaping, minimizing the time required to reach the desired firmness. Some mattresses feature dual-valve systems, one for rapid inflation and another for fine-tuning the pressure.

The interplay of these factors determines the overall inflation speed of an inflatable sleeping surface. Selecting a Coleman air mattress and pump system involves considering the trade-offs between pump type, mattress size, and desired inflation time to match the specific needs of the user. A faster inflation time improves convenience, particularly in situations where quick setup is essential, such as camping or accommodating unexpected guests.

4. Material Composition

Material composition is a pivotal element dictating the performance, durability, and overall user experience of a Coleman air mattress and pump system. The selection of specific materials directly influences factors such as puncture resistance, comfort, weight, and environmental impact, thereby playing a crucial role in the product’s suitability for diverse applications.

- PVC (Polyvinyl Chloride) and its Variants

PVC is a commonly employed material in inflatable mattresses, providing a balance of cost-effectiveness and durability. However, different formulations of PVC exist, with varying degrees of thickness and flexibility. Higher-grade PVCs offer improved puncture resistance and enhanced air retention. Some manufacturers utilize reinforced PVC, incorporating woven fibers for increased strength and tear resistance. The use of phthalate-free PVC is increasingly prevalent, addressing concerns about potential health hazards and environmental impact.

- Flocking Materials and Surface Treatments

The material applied to the mattress surface significantly impacts comfort. Flocking, typically composed of nylon or rayon fibers, creates a soft, velvety texture that enhances tactile feel and reduces slippage. The density and quality of the flocking material influence its durability and resistance to wear. Some manufacturers employ specialized surface treatments to improve moisture resistance and prevent the growth of mold and mildew. Antimicrobial coatings can also be incorporated for enhanced hygiene.

- Internal Support Structures

The internal construction of an air mattress often incorporates support structures that influence its shape, stability, and weight distribution. These structures may consist of interconnected air chambers, vertical or horizontal beams, or coil systems. The materials used in these structures, typically variations of PVC or reinforced polymers, must be capable of withstanding repeated inflation and deflation cycles while maintaining structural integrity. The design and material composition of the internal support system directly impact the mattress’s ability to provide even support and minimize sagging.

- Pump Components and Materials

While the air mattress itself primarily consists of PVC and related materials, the pump’s composition is equally relevant. Pump housings often utilize durable plastics such as polypropylene or ABS (Acrylonitrile Butadiene Styrene), chosen for their impact resistance and dimensional stability. Internal components, such as pistons, valves, and diaphragms, may be constructed from rubber, silicone, or synthetic polymers, selected for their flexibility, resistance to wear, and ability to maintain an airtight seal. The quality of the materials used in the pump directly affects its reliability and lifespan.

In summary, the performance and longevity of the equipment hinge on careful consideration of the materials used in both the mattress and pump. Selection of appropriate materials, coupled with sound manufacturing practices, ensures a reliable and comfortable sleeping experience. As material science advances, newer and more sustainable options may emerge, further enhancing the performance and environmental profile of inflatable sleeping solutions. Further understanding the intersection of these materials enables consumers to make informed purchasing decisions and optimize the use and care of their equipment.

5. Pump Efficiency

Pump efficiency, in the context of Coleman air mattresses, directly influences user experience and operational effectiveness. It determines the speed and ease with which the mattress can

be inflated, the energy expenditure required (whether manual or electrical), and the overall reliability of the system. Efficient pumps minimize inflation time and effort, enhancing the convenience of the product.

- Airflow Rate and Pressure Output

Pump efficiency is fundamentally linked to its ability to deliver a sufficient volume of air at the required pressure. Higher efficiency pumps generate a greater airflow rate (measured in liters per minute or cubic feet per minute) while maintaining adequate pressure to inflate the mattress to its optimal firmness. Low efficiency results in prolonged inflation times and increased physical exertion for manual pumps. For electric pumps, it signifies wasted energy and potentially reduced lifespan. A pump designed to quickly and effectively fill the volume is paramount, particularly for larger mattresses.

- Energy Consumption and Power Source

For electric pumps, efficiency is measured by the electrical power consumed during operation. More efficient pumps require less energy to deliver the same airflow and pressure, resulting in lower operating costs and reduced drain on battery power for portable models. Manual pumps rely on human energy; therefore, an efficient design minimizes physical effort, maximizing the amount of air displaced per stroke or cycle. Understanding the energy source and its utilization is crucial for comparing the overall cost and convenience of different pump options.

- Pump Design and Mechanical Losses

The internal design and construction of the pump contribute significantly to its efficiency. Well-engineered pumps minimize mechanical losses due to friction, air leaks, and inefficient valve operation. Designs that incorporate optimized piston geometries, tight seals, and streamlined airflow paths maximize the amount of air displaced per cycle, whether powered manually or electrically. The selection of high-quality materials and precise manufacturing tolerances reduces wear and tear, prolonging the pump’s lifespan and maintaining its performance over time.

- Matching Pump to Mattress Size

Efficiency is also relative to the size of the air mattress. A pump that is highly efficient for a twin-sized mattress might be inefficient for inflating a king-sized one. Matching the pump’s capacity to the mattress’s volume is critical for achieving optimal inflation speed and minimizing strain on the pump. Using an underpowered pump can lead to overheating, reduced lifespan, and unsatisfactory inflation results. Conversely, an overpowered pump may be unnecessarily bulky and consume more energy than required.

In essence, pump efficiency is a multi-faceted characteristic that affects both the practicality and longevity of Coleman air mattresses. Careful consideration of airflow rate, energy consumption, pump design, and mattress size is essential for selecting a pump that delivers optimal performance and enhances the overall user experience. Improvements in pump technology continue to push the boundaries of efficiency, enabling faster, easier, and more reliable inflation for a wide range of applications.

6. Size Variations

The dimension of an air mattress exerts a primary influence on its suitability for specific applications. Coleman offers its inflatable sleeping surfaces across a spectrum of sizes, ranging from compact single units designed for individual use to expansive king-sized models intended to accommodate multiple occupants. This range of dimensions allows consumers to select a product that aligns with their anticipated usage scenarios and available space constraints. The physical size, therefore, directly dictates the comfort level and practicality within different environments.

For instance, a solo camper prioritizing lightweight portability would likely opt for a twin or single-sized mattress. This choice minimizes pack weight and volume, essential considerations when traversing distances on foot. Conversely, a family seeking comfortable accommodations within a large tent might select a queen or king-sized option. Similarly, individuals utilizing an air mattress as a temporary guest bed within a home environment must factor in available floor space. Selecting an oversized model would compromise room maneuverability, while an undersized selection could diminish guest comfort. The proper size selection balances comfort with spatial considerations, ensuring user satisfaction.

Understanding the interplay between size variations and the intended use-case is crucial for informed purchasing. The physical dimensions must align with both the user’s comfort expectations and the logistical parameters of the environment where it will be utilized. This understanding minimizes the likelihood of selecting an inappropriate product, thereby optimizing the investment and ensuring a positive user experience. Considerations related to inflation capacity, pump compatibility, and storage space should also be evaluated in conjunction with the selected dimensions.

Frequently Asked Questions Regarding Coleman Air Mattresses and Pumps

The following addresses common inquiries concerning the selection, utilization, and maintenance of these inflatable sleeping solutions.

Question 1: What is the typical lifespan of this product?

Longevity varies based on usage frequency, environmental conditions, and adherence to maintenance guidelines. With proper care, a lifespan of 3-5 years is achievable. Improper storage, over-inflation, and exposure to sharp objects can significantly reduce this timeframe.

Question 2: How is the mattress properly cleaned?

The mattress surface should be cleaned with a mild soap and water solution. Abrasive cleaners and harsh chemicals are to be avoided. Ensure the mattress is completely dry before storage to prevent mold and mildew growth.

Question 3: What is the recommended storage procedure?

Prior to storage, ensure the mattress is fully deflated and clean. Fold the mattress neatly and store it in a cool, dry place away from direct sunlight. Avoid storing the mattress under heavy objects, as this can damage the material.

Question 4: What is the best way to repair a puncture?

Small punctures can often be repaired with a PVC repair kit. Locate the puncture, clean the area, apply the adhesive, and apply the patch. Allow sufficient time for the adhesive to cure before inflating the mattress. Larger punctures may require professional repair or replacement.

Question 5: What pressure should the mattress be inflated to?

The optimal pressure varies depending on the mattress size and desired firmness. Avoid over-inflation, as this can stress the seams and lead to premature failure. Refer to the manufacturer’s instructions for recommended pressure levels. Monitor firmness during inflation and adjust accordingly.

Question 6: Are replacement pumps readily available?

Replacement pumps are generally available through the manufacturer or authorized retailers. Ensure the replacement pump is compatible with the mattress valve type and voltage requirements (for electric pumps).

Proper care and maintenance are crucial for maximizing the lifespan and performance of this inflatable sleeping equipment.

The subsequent section will address potential issues, troubleshooting steps, and methods to improve the overall user experience with the product.

Coleman Air Mattress and Pump

This exploration has detailed critical aspects of the inflatable sleeping equip

ment, emphasizing durability, portability, inflation speed, material composition, and pump efficiency. Understanding these elements enables informed decision-making when selecting a Coleman air mattress and pump system tailored to specific requirements. Furthermore, adherence to proper usage and maintenance protocols ensures optimal lifespan and performance.

The continued evolution of materials and pump technology promises further advancements in the functionality and sustainability of this category. Prospective purchasers are encouraged to prioritize informed evaluation of product specifications and maintenance requirements, thereby maximizing the value and utility of this versatile sleeping solution.