A bedding accessory designed to overlay a standard-sized crib mattress, incorporating visco-elastic polyurethane foam as its primary cushioning material. This construction is intended to modify the firmness and potentially enhance the comfort of the underlying sleep surface for infants.

The integration of this type of foam in a baby’s sleeping environment aims to offer pressure relief and support, potentially contributing to improved sleep quality. Historically, parents have sought ways to optimize their children’s rest. Modern materials like this type of foam now offer advanced solutions beyond traditional padding.

The subsequent sections will delve into the material composition, safety considerations, cleaning guidelines, and selection criteria relevant to these bedding items, providing a comprehensive understanding for informed decision-making.

Selecting and Maintaining Crib Mattress Padding

Optimal utilization of crib mattress padding requires careful consideration and diligent maintenance to ensure infant safety and hygiene.

Tip 1: Prioritize Safety Certifications: Verify that any padding being considered adheres to established safety standards, such as those set by the ASTM International or similar regulatory bodies. Certification indicates the product has undergone testing for harmful chemicals and potential hazards.

Tip 2: Ensure a Snug Fit: Confirm that the chosen padding fits the crib mattress securely. Oversized or improperly fitted padding can create gaps that pose a suffocation risk.

Tip 3: Evaluate Foam Density: Opt for a padding with appropriate density. Excessively soft padding may not provide adequate support, while overly firm padding may be uncomfortable.

Tip 4: Consider Breathability: Certain foam structures offer enhanced breathability, reducing the risk of overheating. Look for features like open-cell construction or ventilation channels.

Tip 5: Implement Regular Cleaning: Follow the manufacturer’s instructions for cleaning. Periodic washing or spot cleaning helps to eliminate allergens and maintain hygiene.

Tip 6: Use a Waterproof Cover: Incorporating a waterproof cover safeguards the padding against spills and accidents, extending its lifespan and preventing the growth of mold or mildew.

Tip 7: Monitor for Wear and Tear: Routinely inspect the padding for any signs of damage, such as tears or indentations. Replace the padding promptly if any defects are identified.

Adherence to these recommendations promotes a safe and sanitary sleep environment, optimizing the benefits of the added crib mattress padding.

The subsequent sections will explore specific material properties and delve into the implications for infant health and well-being.

1. Density

Density, in the context of viscoelastic polyurethane foam used in infant bedding, refers to the mass per unit volume of the material. This parameter directly impacts several critical functional characteristics. A low-density product, while potentially exhibiting initial softness, may lack sufficient support to maintain a safe sleep surface for an infant. Conversely, excessively high density could render the surface uncomfortably firm. Therefore, the selection of a foam with appropriate density is paramount. For example, a very soft product could contour excessively to a baby’s face, which could pose a suffocation risk. A dense product may restrict movement or cause discomfort.

The density of viscoelastic foam directly affects its capacity to distribute pressure. Higher density foams tend to offer more uniform pressure distribution, reducing pressure points. This property is relevant for infants, although the specific benefits are less pronounced compared to adults due to their lower body weight. Furthermore, density impacts the durability and resilience of the item. Higher density materials generally exhibit greater resistance to compression and deformation over extended periods. Lower density material may have a limited lifespan.

In summation, density stands as a key determinant of the support, pressure distribution characteristics, and longevity of viscoelastic foam bedding. The optimal density range for a crib mattress overlay balances comfort and safety, providing adequate support without compromising the infant’s well-being. Evaluating product specifications related to density is thus essential for informed purchasing decisions.

2. Thickness

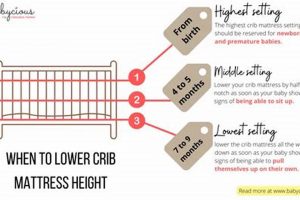

Thickness, when referring to a viscoelastic polyurethane foam overlay for a crib mattress, directly influences the degree of contouring and cushioning provided. A thinner profile offers minimal alteration to the underlying mattress’s firmness, primarily functioning as a protective layer. Conversely, a thicker profile significantly alters the sleep surface characteristics, potentially increasing softness and pressure redistribution. For example, a pad that is less than one inch thick might not provide enough comfort for babies with sensitive skin. A very thick option may increase the chance of suffocation and should be seriously considerd before purchasing.

The selection of appropriate thickness is further contingent upon the crib mattress construction and firmness. A firmer mattress may benefit from a thicker overlay to enhance comfort. A softer mattress may only require a thinner option to avoid compromising support. Furthermore, the overall thickness must be considered in relation to the crib’s safety rails. An excessively thick overlay could reduce the rail height, increasing the risk of the infant climbing out. Parents should also always ensure fitted sheets can be used for safety.

In summary, thickness is a critical determinant of the impact of a viscoelastic foam overlay on a crib mattress. Proper assessment of the existing mattress characteristics, the intended level of cushioning, and adherence to safety standards regarding crib rail height are paramount when selecting a product of suitable thickness. Understanding these aspects ensures both comfort and infant safety.

3. Composition

The composition of viscoelastic polyurethane foam used in infant bedding dictates not only its physical properties but also its potential impact on infant health and safety. A detailed understanding of the components is essential for informed decision-making.

- Polyol Type

The polyol component, a core building block of the foam, significantly influences its overall characteristics. Different polyols, such as polyester or polyether polyols, yield foams with varying degrees of resilience, durability, and hydrolysis resistance. For example, a polyether-based foam might exhibit superior moisture resistance, a critical factor in an infant environment, while a polyester-based foam could offer enhanced durability against compression. The selection of polyol directly impacts the foam’s long-term performance and suitability for crib applications.

- Isocyanate Type

The isocyanate reactant used in foam production, typically methylene diphenyl diisocyanate (MDI) or toluene diisocyanate (TDI), affects the foam’s curing process and final mechanical properties. TDI-based foams, while potentially more cost-effective, may present residual off-gassing concerns due to unreacted isocyanate molecules. MDI-based foams generally exhibit lower off-gassing and are often favored in products intended for infant use. The choice of isocyanate directly relates to potential VOC emissions and overall air quality within the sleeping environment.

- Additives

A range of additives, including blowing agents, catalysts, surfactants, and flame retardants, are incorporated to control the foaming process, enhance specific properties, and meet safety regulations. Blowing agents determine the cell structure and density of the foam, catalysts regulate the reaction rate, and surfactants stabilize the foam during formation. Flame retardants are often mandated to reduce flammability, but their potential toxicity is a subject of ongoing scrutiny. The selection and concentration of these additives significantly influence the foam’s performance, safety profile, and regulatory compliance.

- Cover Materials

The fabric encasing the foam padding contributes to its overall safety and functionality. Cover materials may range from natural fibers like cotton to synthetic blends with enhanced moisture-wicking or hypoallergenic properties. Some covers incorporate antimicrobial treatments to inhibit bacterial growth. The choice of cover material impacts breathability, cleanability, and the potential for allergic reactions. Opting for certified organic cotton or hypoallergenic synthetic fabrics can minimize exposure to potentially harmful substances.

In conclusion, the composition of viscoelastic polyurethane foam in infant bedding is a complex interplay of various components, each contributing to the material’s physical properties, safety characteristics, and overall suitability for infant use. Informed purchasing decisions require careful consideration of these compositional aspects and adherence to relevant safety certifications and regulations. Prioritizing materials with low VOC emissions, hypoallergenic properties, and compliance with flammability standards is crucial for ensuring a safe and healthy sleep environment for infants.

4. Breathability

Breathability, in the context of a viscoelastic polyurethane foam crib mattress overlay, directly correlates with the regulation of infant body temperature and the reduction of potential suffocation hazards. This foam, by its nature, tends to retain heat due to its dense cellular structure. Reduced air circulation within the material can lead to an elevated sleep surface temperature, increasing the risk of overheating, a known factor in Sudden Infant Death Syndrome (SIDS). Insufficient breathability can trap exhaled carbon dioxide near the infant’s face, also increasing suffocation risk.

Enhancing breathability within this product category typically involves modifications to the foam’s cellular structure or the incorporation of ventilation channels. Open-cell foam structures, for instance, allow for greater airflow compared to closed-cell structures. Some manufacturers incorporate perforations or channels into the foam to further improve air circulation. The use of breathable cover materials, such as cotton or specialized synthetic fabrics, complements these efforts by facilitating moisture wicking and further reducing heat retention. As an example, consider two identical products, one made from standard memory foam with a closed-cell structure and another from open-cell foam with ventilation channels. The latter, when tested, would demonstrate significantly lower temperature retention and improved air permeability.

In summary, breathability is a critical performance parameter. Addressing it requires careful consideration of the foam’s cellular structure, ventilation strategies, and cover material selection. Prioritizing products with enhanced breathability features mitigates the risks of overheating and suffocation, thereby contributing to a safer sleep environment for infants. The evaluation of breathability should be an integral component of the purchasing decision process for this type of bedding.

5. Flammability

The flammability of crib mattress pads that incorporate viscoelastic polyurethane foam, commonly termed memory foam, is a critical safety consideration. This material, in its untreated state, is inherently combustible. Regulations and standards, such as those enforced by the Consumer Product Safety Commission (CPSC), mandate that these products meet specific flammability requirements to mitigate the risk of ignition and fire propagation. Failure to comply with these standards poses a significant hazard to infants, potentially leading to severe injury or fatality in the event of a fire.

To achieve compliance, manufacturers typically employ flame retardant chemicals within the foam matrix or as surface treatments. These chemicals serve to slow down or inhibit combustion, providing valuable time for evacuation in the event of a fire. However, concerns exist regarding the potential health effects of certain flame retardant chemicals, particularly with regard to endocrine disruption and neurodevelopmental toxicity. As a result, some manufacturers are exploring alternative flame retardant technologies or utilizing inherently flame-resistant materials. The selection of flame retardant strategies represents a complex balancing act between fire safety and potential health risks.

In summation, flammability is a non-negotiable safety attribute. Adherence to regulatory standards, the careful selection of flame retardant strategies, and ongoing research into safer alternatives are essential to minimize the fire risk associated with crib mattress pads. Consumers should verify product compliance with relevant flammability standards and be aware of the potential risks and benefits associated with different flame retardant approaches to make informed purchasing decisions.

6. Cleanability

Maintaining the hygiene of a crib mattress pad composed of viscoelastic polyurethane foam is paramount to safeguarding infant health and ensuring product longevity. The porous nature of this foam makes it susceptible to absorbing liquids and harboring allergens, bacteria, and mold. Consequently, the ease and efficacy of cleaning procedures are critical considerations for product selection and usage.

- Material Permeability and Stain Resistance

The open-cell structure characteristic of many viscoelastic foams facilitates the penetration of liquids, rendering them vulnerable to staining from spills, bodily fluids, and other common contaminants. The inherent permeability of the foam necessitates the use of protective barriers, such as waterproof covers, to minimize direct exposure to potential staining agents. The effectiveness of stain removal techniques is directly proportional to the promptness of intervention and the composition of the cover material. For instance, untreated spills may permanently discolor the foam, whereas spills addressed immediately with appropriate cleaning agents are less likely to leave lasting marks.

- Cleaning Agent Compatibility and Residue Removal

The selection of cleaning agents for viscoelastic polyurethane foam requires careful consideration to avoid damaging the material or leaving behind harmful residues. Harsh chemicals, such as bleach or ammonia, can degrade the foam’s structure and compromise its integrity. Mild detergents and enzyme-based cleaners are generally recommended for their effectiveness and reduced risk of material damage. Thorough rinsing and drying are essential to remove residual cleaning agents, preventing skin irritation and minimizing the potential for microbial growth. Inadequate residue removal can lead to the accumulation of irritants and the development of unpleasant odors.

- Drying Procedures and Mold Prevention

Complete and thorough drying is crucial to prevent the proliferation of mold and mildew within the foam matrix. The dense nature of viscoelastic foam inhibits rapid evaporation, increasing the risk of moisture retention and subsequent microbial growth. Air drying in a well-ventilated area is generally preferred over direct heat exposure, which can cause the foam to degrade or shrink. Dehumidifiers or fans can expedite the drying process, minimizing the duration of moisture exposure. Failure to ensure complete dryness can result in persistent odors, allergenic reactions, and premature product degradation.

- Cover Material Washability and Durability

The washability and durability of the cover material significantly impact the overall cleanability of the crib mattress pad. Removable and machine-washable covers facilitate regular cleaning and disinfection. Cover materials should be selected for their resistance to shrinking, fading, and tearing. Durable, tightly woven fabrics are less prone to absorbing liquids and retaining stains. The use of waterproof or water-resistant linings enhances protection against spills and facilitates easier cleaning. Routine laundering of the cover material helps maintain hygiene and extend the lifespan of the underlying foam padding.

The cleanability attributes of a viscoelastic polyurethane foam crib mattress pad are inextricably linked to infant health and product longevity. A comprehensive cleaning regimen, encompassing prompt stain removal, appropriate cleaning agent selection, thorough drying procedures, and durable, washable cover materials, is essential to maintaining a safe and hygienic sleep environment for infants.

7. Dimensions

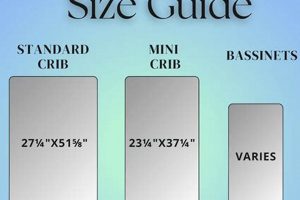

The dimensions of a crib mattress pad utilizing viscoelastic polyurethane foam are critically important to infant safety and product effectiveness. Precise measurements are essential to ensure a secure fit within the crib, preventing hazardous gaps and maximizing comfort.

- Length and Width Conformity

The length and width of the padding must precisely match the interior dimensions of the crib. A pad that is too small creates gaps between the edge of the pad and the crib frame, posing a significant entrapment risk. Conversely, a pad that is too large will not lie flat, potentially creating an uneven sleep surface. Regulations typically specify standard crib dimensions, and the padding must adhere to these standards to ensure compatibility. For example, a standard crib measures approximately 28 inches wide by 52 inches long; the padding should conform to these dimensions within a narrow tolerance.

- Thickness Considerations

The thickness of the padding impacts both comfort and the overall safety of the crib environment. While a thicker pad may offer increased cushioning, it also reduces the height of the crib rails. If the padding is too thick, it may lower the effective height of the rails below the minimum safety standard, increasing the risk of the infant climbing out. The thickness must be carefully balanced to provide adequate comfort without compromising the integrity of the crib’s safety features. For example, standards often dictate a minimum rail height; adding a thick pad should not reduce the rail height below this threshold.

- Tolerance and Manufacturing Precision

Dimensional tolerance refers to the allowable variation in the specified measurements. Tight tolerances are crucial for ensuring a consistent and secure fit. Inconsistencies in manufacturing can lead to variations in length, width, or thickness, compromising safety and performance. High-quality manufacturers implement rigorous quality control measures to minimize dimensional variations. For example, a tolerance of more than a quarter of an inch in either length or width could create a hazardous gap between the pad and the crib frame.

Precise dimensions are paramount. Non-conforming measurements compromise safety. Selecting padding with accurate dimensions, verified through manufacturer specifications and adherence to safety standards, is a critical aspect of providing a safe sleep environment.

Frequently Asked Questions

This section addresses common inquiries regarding crib mattress pads made with viscoelastic polyurethane foam, often referred to as “memory foam.”

Question 1: Does “crib mattress pad memory foam” pose a suffocation risk?

A primary concern is the potential for suffocation. While the foam conforms to an infant’s body, excessively soft or non-breathable materials can obstruct airways. Select products with appropriate firmness and demonstrable breathability features. Ensure proper fit to prevent gaps between the pad and crib sides.

Question 2: Is this type of pad safe for newborns?

Infant safety necessitates careful selection. Newborns require firm, flat sleep surfaces to reduce SIDS risk. Very soft materials are ill-advised. Seek certifications from reputable safety organizations, affirming that products meet stringent standards.

Question 3: How frequently should these pads be cleaned?

Cleaning frequency depends on usage and soiling. Regular spot cleaning of minor spills is recommended. Thorough cleaning should occur after significant soiling events. Follow manufacturer instructions carefully, as improper cleaning can damage the foam or leave harmful residues.

Question 4: Are there concerns about chemical off-gassing?

Viscoelastic polyurethane foam can emit volatile organic compounds (VOCs). Choose products certified by independent organizations, such as CertiPUR-US, indicating low VOC emissions. Airing out the pad before initial use can further mitigate potential off-gassing.

Question 5: How does the thickness of the padding affect safety?

Excessive thickness reduces crib rail height, increasing the risk of a child climbing out. Ensure that adding the pad does not lower the rail height below recommended safety standards. A balance between comfort and safety is paramount.

Question 6: How can one verify the material’s breathability?

Breathability is crucial for temperature regulation. Look for open-cell foam structures or ventilation channels, enhancing airflow. Check for third-party testing or certifications related to breathability and thermal regulation.

Careful selection and usage are essential for mitigating risks. Choosing certified products, maintaining proper hygiene, and adhering to safety guidelines contribute to a secure sleep environment.

The subsequent section provides a summary of the key considerations outlined in this article.

crib mattress pad memory foam

The preceding discussion has elucidated critical aspects pertaining to bedding utilizing viscoelastic polyurethane foam. Careful assessment of density, thickness, composition, breathability, flammability, cleanability, and dimensions is paramount. Deviation from established safety standards poses potential risks to infant health and well-being.

Prudent decision-making, informed by thorough research and adherence to safety guidelines, is indispensable. Prioritizing certified products and maintaining vigilant oversight of the sleep environment are essential for safeguarding infants.

![Best Babyletto Pure Core Mini Crib Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Babyletto Pure Core Mini Crib Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1348-300x200.jpg)

![Best Babyletto Midi Crib Mattress [Guide] For Your Crib Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Babyletto Midi Crib Mattress [Guide] For Your Crib | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1347-300x200.jpg)

![Crib Mattress vs. Twin Size Bed: Choosing Right [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Crib Mattress vs. Twin Size Bed: Choosing Right [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1346-300x200.jpg)