The foundational element beneath a crib mattress, typically constructed from metal springs, wooden slats, or a solid platform, is critical for ensuring the stability and longevity of the sleep surface. This structural component prevents sagging, maintains a level plane, and contributes to the even distribution of an infant’s weight. For instance, a platform crafted from solid wood provides a rigid, unyielding base, whereas a system of interconnected springs offers a degree of flexibility and potential for enhanced airflow.

Proper function is paramount for infant safety and comfort, affecting spinal alignment and reducing the risk of suffocation or entrapment due to mattress deformation. Historically, variations in materials and designs reflected differing beliefs about infant care and available resources. Modern designs prioritize safety standards and structural integrity, often exceeding minimum requirements to provide parents with added assurance.

Understanding the various types available, assessing their impact on mattress lifespan, and recognizing the role they play in overall crib safety are essential considerations for selecting appropriate bedding. Subsequent discussions will delve into specific material properties, construction techniques, and regulatory guidelines related to the structural base within the crib environment.

Guidance on Crib Mattress Foundation

The following recommendations are intended to inform caregivers about best practices regarding the structural element under a crib mattress. Adherence to these guidelines can contribute to a safer and more supportive sleep environment for infants.

Tip 1: Verify Compatibility: Always ensure the selected foundation is specifically designed for the crib model in use. Deviations in size or shape can compromise stability and introduce safety hazards.

Tip 2: Inspect for Damage: Prior to each use, conduct a thorough visual inspection for any signs of cracking, warping, or breakage. Compromised components must be replaced immediately.

Tip 3: Confirm Secure Attachment: If the foundation is designed to attach to the crib frame, verify that all fasteners are correctly installed and tightened according to the manufacturers instructions. Loose connections can lead to instability.

Tip 4: Evaluate Surface Evenness: A level and uniform surface is crucial. Use a level to assess the plane across the entire foundation. Unevenness may indicate underlying damage or improper installation.

Tip 5: Adhere to Weight Limits: Respect the manufacturer-specified weight capacity. Exceeding this limit can cause structural failure and potential injury.

Tip 6: Ensure Proper Ventilation: If the foundation incorporates ventilation holes or slats, ensure these are clear and unobstructed. Adequate airflow helps prevent moisture buildup and potential mold growth.

Tip 7: Refer to Manufacturer Guidelines: Always consult the crib and mattress manufacturer’s documentation for specific recommendations and maintenance procedures related to the foundation.

Implementing these practices promotes structural integrity and minimizes potential risks associated with the crib’s foundational components, contributing to a safer sleep environment for the infant.

The subsequent sections will address the selection criteria for new components and outline the process for identifying potential hazards.

1. Firmness

Firmness is a critical attribute influencing the effectiveness of the foundational structure under a crib mattress. It dictates the degree to which the structure resists deformation under an infant’s weight. Insufficient firmness compromises the structural integrity, leading to sagging or uneven surfaces. This deformation elevates the risk of infant suffocation by creating pockets or indentations where a baby’s face could become entrapped. An example is a metal spring grid that has lost its tension; it will no longer provide adequate resistance, causing the mattress to dip when weight is applied. The consequence of inadequate firmness is a sleep surface that fails to meet safety standards.

The materials and construction methods employed directly impact the firmness of the structure. Solid wood platforms offer inherent rigidity, while properly tensioned metal spring systems provide a balance of support and ventilation. However, over time, even robust materials can lose their firmness due to wear and tear. Regular inspection is essential to ensure that the structure maintains its intended level of resistance. This proactive approach can prevent gradual degradation and maintain the necessary support for the mattress.

In summary, firmness is an indispensable element of a secure and well-functioning structure for an infants mattress. Its primary function is to provide consistent, unyielding support, thereby minimizing the risks associated with an unstable or uneven sleep surface. Ensuring that the underlying structure maintains its firmness throughout its lifespan is crucial for infant safety.

2. Material

Material selection exerts a direct influence on the functionality and safety of the foundational structure beneath a crib mattress. The chosen material dictates inherent properties such as strength, durability, and resistance to deformation. A metal spring grid, for example, relies on the tensile strength of the metal to maintain its shape and provide adequate support; a lower-grade metal could bend or break under stress, compromising the entire structure. Similarly, solid wood platforms derive their support from the wood’s density and resistance to warping. The material’s inherent characteristics are the primary determinant of the overall structure effectiveness.

Beyond structural properties, material selection also impacts other critical factors. Wooden platforms, if not properly treated, are susceptible to moisture absorption, potentially leading to mold growth and weakening of the structure. Metal components, without proper coating, can rust, similarly compromising structural integrity. The choice of material influences ventilation; open spring designs allow for greater airflow compared to solid platforms, which may require ventilation holes to prevent moisture accumulation. Therefore, material impacts not only physical support but also influences long-term durability and hygiene.

In summary, material choice is fundamental to effective structure beneath a crib mattress, influencing its ability to provide stable, long-lasting, and safe support. Careful consideration of material properties, their potential vulnerabilities, and their impact on related factors like ventilation is essential for ensuring the crib’s underlying structure fulfills its intended function and contributes to a safe sleep environment. Regulatory standards often specify material requirements to ensure minimum safety thresholds are met.

3. Ventilation

Ventilation, concerning a crib’s structural foundation, plays a crucial, often underestimated role in maintaining a safe and hygienic sleep environment for infants. It influences both the health and longevity of the mattress and the well-being of the child using it.

- Moisture Regulation

Adequate airflow through the structural element minimizes moisture accumulation from humidity, spills, or the infant’s perspiration. Trapped moisture creates an environment conducive to mold and bacterial growth within the mattress, posing potential respiratory and dermatological risks. Structural designs incorporating open slats or strategically placed ventilation holes facilitate the evaporation of moisture, maintaining a drier, more hygienic sleep surface.

- Temperature Regulation

Ventilation aids in dissipating heat that may accumulate within the mattress core, preventing overheating, particularly in warmer climates or during seasons. A structure allowing for airflow helps maintain a more consistent and comfortable sleep temperature for the infant. Lack of proper ventilation could contribute to discomfort and restless sleep, potentially disrupting the infant’s sleep cycle.

- Material Longevity

Consistent airflow through the structure reduces the likelihood of material degradation due to moisture-related issues. Wooden components are less susceptible to warping or rot, and metal components face reduced risk of corrosion. This, in turn, extends the lifespan of both the structure and the mattress, saving replacement costs and ensuring the ongoing structural integrity of the crib.

- Odor Control

Proper ventilation helps to dissipate odors that may accumulate within the mattress. Trapped smells, whether from bodily fluids or environmental factors, can contribute to an unpleasant sleep environment. By promoting airflow, the structural component assists in maintaining a fresher, cleaner-smelling surface, enhancing the infant’s overall sleep experience.

The design and material selection of the foundational structure are therefore essential in promoting optimal ventilation. A well-ventilated foundation contributes significantly to a healthier, more comfortable, and safer sleep environment, reinforcing the critical role it plays in infant care.

4. Durability

The longevity and continued effectiveness of a crib mattress foundation directly correlate with its inherent durability. This attribute determines its capacity to withstand repeated use, weight fluctuations, and environmental factors without compromising its structural integrity or safety performance.

- Material Resistance to Degradation

The materials used in construction must exhibit resistance to common forms of degradation, such as corrosion in metals, rot in wood, or breakdown in plastics. A structure composed of low-grade steel prone to rust will degrade far quicker than one built from treated hardwood or corrosion-resistant alloys. The implications of material degradation include weakening of the structure, potential release of harmful particles, and a reduced capacity to provide consistent support.

- Joint and Fastener Integrity

The points at which different components connect represent potential weak spots in the structure. Joints and fasteners must be designed and implemented to withstand repeated stress and vibration without loosening, breaking, or causing misalignment. For example, screws used to secure a wooden slat frame must be of sufficient size and strength to resist stripping under load. Failure of these connections can lead to instability, uneven support, and potential hazards for the infant.

- Weight Capacity Retention

A durable crib mattress framework will maintain its ability to support the manufacturer-specified weight limit throughout its intended lifespan. Gradual deformation or weakening of the structure under repeated loading will reduce its ability to provide adequate support and increase the risk of mattress sagging or collapse. Testing procedures that simulate long-term use under varying weight conditions are essential for evaluating weight capacity retention.

- Resistance to Environmental Factors

Exposure to humidity, temperature fluctuations, and cleaning agents can impact the longevity of a crib mattress’s structure. A framework resistant to these environmental stressors will maintain its structural integrity and aesthetic appearance over time. Materials that are prone to warping, cracking, or discoloration under changing environmental conditions will exhibit reduced durability and may require more frequent replacement.

In summary, the durability of a crib’s foundational component is paramount. It ensures consistent, safe support throughout the crib’s use. Compromised durability can lead to structural failure, impacting infant safety. High-quality materials and robust construction techniques are crucial for meeting and exceeding required safety standards.

5. Compatibility

The functional effectiveness of a crib mattress relies directly on the congruence between the mattress and its underlying support structure. Incompatibility between these elements introduces potential safety risks and diminishes the overall performance of the sleep system. The following considerations outline critical aspects of compatibility within the context of “crib mattress support.”

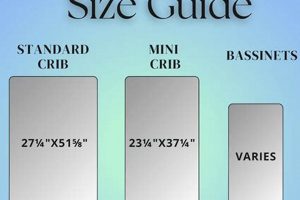

- Dimensional Conformity

The dimensions of the support system must precisely match the internal dimensions of the crib frame and the external dimensions of the mattress. Deviations can result in gaps between the mattress and the crib sides, posing entrapment hazards. A support structure that is either too large or too small fails to provide uniform support across the entire mattress surface, potentially leading to sagging or instability.

- Weight Capacity Matching

The support system’s weight capacity must equal or exceed the weight of the mattress plus the anticipated weight of the infant. A support structure with insufficient weight-bearing capacity may deform or fail over time, creating an uneven sleep surface and increasing the risk of structural collapse. Manufacturers’ specifications regarding weight limits should be strictly adhered to.

- Attachment Mechanism Integration

If the support structure is designed to attach to the crib frame, the attachment mechanisms must be fully compatible with the crib’s design. Incompatible attachment points can compromise the structural integrity of the entire crib assembly, rendering it unstable and unsafe. Secure and properly aligned connections are essential for maintaining the intended stability and support.

- Ventilation Alignment

If the mattress features ventilation channels, the support system must allow for unobstructed airflow. A solid support surface covering the ventilation channels hinders the mattress’s ability to dissipate moisture and regulate temperature. Proper alignment of ventilation features is crucial for maintaining a hygienic and comfortable sleep environment.

The aforementioned compatibility facets highlight the interconnectedness of various components in a crib system. Proper dimensional conformity, weight capacity matching, attachment mechanism integration, and ventilation alignment, when addressed comprehensively, culminate in a safe and supportive sleep environment for the infant. Failure to account for these compatibility factors compromises the intended performance of both the mattress and its supporting structure.

6. Regulation

Regulatory standards exert a fundamental influence on the design, manufacture, and performance of crib mattress foundations. These regulations, established by governmental bodies and industry organizations, aim to ensure a minimum level of safety and quality for infants’ sleep environments. A direct consequence of such regulation is the implementation of specific design criteria, material requirements, and testing protocols that manufacturers must adhere to before their products can be legally sold. Examples include mandated minimum firmness levels to reduce suffocation risks and restrictions on the use of potentially harmful chemicals. The importance of regulation stems from its ability to protect vulnerable infants from preventable hazards associated with poorly designed or constructed foundations. The impact is evident in the reduced incidence of injuries and fatalities related to crib malfunctions in regulated markets.

Furthermore, regulations often mandate specific testing procedures that assess the structural integrity, durability, and flammability of these structures. These tests simulate real-world use conditions and subject the foundation to stress, impact, and fire hazards. For instance, load-bearing tests verify that the foundation can support the weight of the mattress and infant without collapsing or deforming. Flammability tests ensure that the materials used resist ignition and slow the spread of flames in the event of a fire. Adherence to these regulations is not merely a legal obligation; it’s a practical demonstration of a manufacturer’s commitment to infant safety, guiding product development and quality control processes.

In summary, regulation functions as a cornerstone in the creation of secure sleep foundations. Though challenges remain in consistently enforcing these regulations globally and adapting them to evolving product innovations, their role in safeguarding infant well-being is undeniable. Understanding the interplay between regulation and crib mattress foundation design is crucial for manufacturers, retailers, and consumers seeking to prioritize safety and mitigate potential risks in the infant’s sleep environment.

Frequently Asked Questions about Crib Mattress Support

The following questions address common concerns and misconceptions related to the foundation upon which a crib mattress rests. The information provided is intended to promote informed decision-making regarding infant sleep safety.

Question 1: What materials are typically used in the manufacture of crib mattress foundations, and what are the advantages and disadvantages of each?

Common materials include solid wood, metal springs, and metal grids. Solid wood provides rigid support but may limit airflow. Metal springs offer flexibility and ventilation, but can degrade over time. Metal grids provide strength, but require proper coating to prevent rust. The suitability of each material depends on factors such as budget, crib design, and environmental conditions.

Question 2: How frequently should a crib mattress structure be inspected for damage?

A thorough inspection should be conducted at least every three months and whenever the crib is disassembled or moved. Particular attention should be paid to joints, fasteners, and the overall structural integrity of the framework. Any signs of cracking, warping, or corrosion necessitate immediate replacement of the component.

Question 3: What are the potential safety hazards associated with a compromised crib mattress foundation?

A damaged base can lead to uneven mattress support, creating pockets or indentations that pose a suffocation risk. Instability can cause the crib to collapse or become unstable, leading to potential injury. Sharp edges or protruding components from damaged framework can also present cutting or puncture hazards.

Question 4: How does the design of the structural framework impact mattress ventilation?

Open slat designs and ventilation holes facilitate airflow, reducing moisture buildup within the mattress. Solid surfaces restrict airflow, potentially contributing to mold and bacterial growth. The design should prioritize adequate ventilation to maintain a hygienic sleep environment.

Question 5: Are there specific regulations or safety standards governing the construction of crib mattress supports?

Yes, governmental and industry organizations establish minimum safety standards for crib mattress frameworks. These standards address issues such as structural integrity, material safety, and flammability. Manufacturers are obligated to comply with these regulations to ensure product safety.

Question 6: How does the weight capacity of the underlying foundation affect its performance and longevity?

Exceeding the manufacturer-specified weight limit can cause the structure to deform or fail prematurely. This can lead to uneven support, increased risk of collapse, and reduced lifespan of the foundation. Adhering to weight limits is essential for maintaining structural integrity and safety.

The above questions highlight the essential considerations for maintaining a secure and functional crib environment. Understanding these points facilitates well-informed decisions. Prioritize adherence to safety guidelines for optimal infant well-being.

The subsequent section will elaborate on the proper disposal of crib mattress structures.

Crib Mattress Support

This exploration has underscored the critical role of the underlying structure within a crib. Proper framework, often overlooked, directly influences an infant’s safety, health, and well-being. Factors such as firmness, material composition, ventilation, durability, compatibility with the mattress, and compliance with regulatory standards were outlined as indispensable components.

Given the potential consequences of inadequate design or compromised integrity, vigilance is paramount. It is thus imperative for caregivers to prioritize informed selection, rigorous inspection, and diligent maintenance of the structural element, ensuring a safe sleep environment for the most vulnerable population. This dedication contributes directly to reducing the risk of preventable accidents and promoting healthy development.

![Best Babyletto Pure Core Mini Crib Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Babyletto Pure Core Mini Crib Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1348-300x200.jpg)

![Best Babyletto Midi Crib Mattress [Guide] For Your Crib Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Babyletto Midi Crib Mattress [Guide] For Your Crib | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1347-300x200.jpg)

![Crib Mattress vs. Twin Size Bed: Choosing Right [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Crib Mattress vs. Twin Size Bed: Choosing Right [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-1346-300x200.jpg)