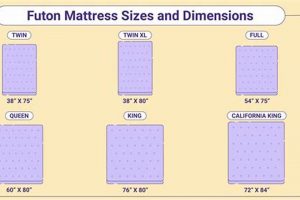

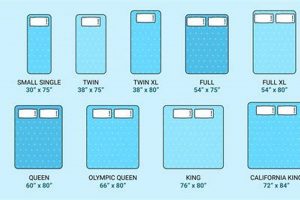

The measurement specifications for a sleeping surface designed for a multi-functional furniture piece are critical in ensuring both comfort and proper fit. These measurements typically adhere to standard twin sizes, allowing for versatility in bedding options. Deviations from these established measurements can result in ill-fitting sheets and compromised support. For example, a standard sleeping surface for this furniture type measures approximately 39 inches wide and 75 inches long.

Adhering to precise size specifications is paramount for maximizing the usability and aesthetic appeal of the furniture. The correct size promotes comfortable sleep and lounging, while preventing premature wear and tear on the frame. Historically, these pieces have served dual purposes in smaller living spaces, underscoring the need for standardized measurements to facilitate ease of use and replacement of sleeping surfaces.

The subsequent sections will delve into specific considerations for selecting the appropriate sleeping surface, including thickness, material composition, and factors influencing overall comfort and durability. This exploration will provide a comprehensive understanding of the parameters impacting the choice of a suitable sleeping solution for this versatile furniture item.

Guidance on Sleeping Surface Specifications

The following guidelines address critical considerations for selecting a sleeping surface for a multi-functional furniture item to ensure optimal comfort and longevity.

Tip 1: Confirm the frame’s internal measurements prior to purchase. Inaccurate measurements may lead to an incompatible fit, rendering the sleeping surface unusable.

Tip 2: Prioritize density and support. A sleeping surface with inadequate support can lead to discomfort and potential physical strain.

Tip 3: Consider the material composition. Different materials offer varying levels of firmness, breathability, and durability, impacting sleep quality and the lifespan of the product.

Tip 4: Evaluate the intended usage frequency. A sleeping surface intended for daily use necessitates a higher level of construction and material quality compared to one used infrequently.

Tip 5: Adhere to standard sizing where possible. Opting for standard dimensions simplifies the process of finding compatible bedding and accessories.

Tip 6: Account for potential compression over time. Some materials may compress over extended use, impacting the overall height and support provided.

Tip 7: Investigate warranty and return policies. A comprehensive warranty can provide assurance against manufacturing defects and premature degradation.

Adhering to these guidelines will contribute significantly to selecting a compatible and comfortable sleeping solution, maximizing the functionality and lifespan of the furniture item.

The subsequent section will provide information of cleaning sleeping surface.

1. Standard twin size

The correlation between standard twin size and sleeping surface dimensions designed for multi-functional furniture is fundamental to the functionality and user experience of these pieces. Standard twin size serves as the primary dimensional reference point, dictating the overall length and width, typically 39 inches by 75 inches, of the sleeping surface. This standardization ensures compatibility with readily available bedding accessories such as sheets, blankets, and mattress protectors. A deviation from standard twin size would necessitate custom-made bedding, increasing costs and limiting options. For instance, an undersized sleeping surface would leave gaps within the frame, while an oversized one would not fit properly.

Further illustrating the importance, consider the implications for furniture manufacturers. Adhering to standard twin size simplifies production processes, reduces material waste, and lowers inventory management complexities. Consumers benefit through the ease of replacing worn or damaged sleeping surfaces without requiring specialized dimensions. In practical terms, a homeowner can readily purchase a new sleeping surface from a wide variety of retailers if the original conformed to standard twin size. Conversely, non-standard dimensions lead to increased search time and potentially higher prices for suitable replacements.

In conclusion, the utilization of standard twin size as a foundational element for sleeping surface dimensions associated with these furniture pieces provides a significant advantage in terms of cost-effectiveness, availability of accessories, and ease of replacement. Challenges may arise when dealing with antique or custom-built frames, requiring careful measurement and potentially custom-made sleeping surfaces. However, the broad adoption of standard twin size simplifies the process for the vast majority of consumers and manufacturers. This dimensional standardization benefits both parties involved.

2. Thickness variations

The degree of vertical measurement in sleeping surfaces for multi-functional furniture is a critical variable, directly influencing support, comfort, and aesthetic integration within the furniture’s frame. Divergences in this dimension necessitate careful consideration to ensure both ergonomic functionality and visual harmony.

- Support and Spinal Alignment

A thinner sleeping surface, typically ranging from 5 to 6 inches, may lack sufficient support for individuals requiring enhanced spinal alignment. Conversely, excessively thick options, exceeding 8 inches, can elevate the sleeping surface too high, potentially compromising ease of access and creating an ungainly profile. Selection should be predicated on the intended user’s weight and sleep preferences.

- Frame Compatibility and Aesthetics

The internal dimensions of the furniture frame dictate the acceptable range for sleeping surface thickness. Exceeding these limits can lead to compression, damage, or an inability to properly seat the sleeping surface within the frame. Aesthetically, the visible portion of the sleeping surface should complement the overall design, avoiding a disproportionate or unbalanced appearance.

- Material Compression and Longevity

The material composition of the sleeping surface directly impacts its compression rate over time. Thinner options constructed from lower-density materials are more susceptible to rapid degradation, reducing support and comfort levels. Selecting higher-density materials, or a thicker sleeping surface overall, can mitigate this effect and extend the product’s lifespan.

- Bedding and Accessory Compatibility

Thickness variations influence the fit and appearance of standard bedding accessories. Thicker sleeping surfaces may require deep-pocket sheets, while thinner options may result in excess fabric. Consideration should be given to the availability and cost of compatible bedding, as well as the overall aesthetic effect achieved.

The selection of an appropriate thickness for a sleeping surface designed for multi-functional furniture requires a balanced assessment of ergonomic needs, frame compatibility, material properties, and aesthetic considerations. A well-informed decision contributes significantly to the long-term satisfaction and usability of the furniture piece.

3. Weight capacity

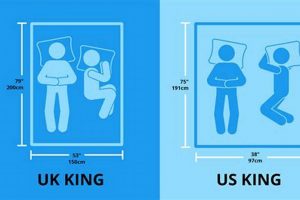

The specified load-bearing limit forms a critical, yet often overlooked, component of sleeping surfaces designated for convertible furniture. Its relationship with the surface’s physical dimensions is directly proportional; a larger surface area may not automatically equate to a greater load-bearing ability. Instead, the internal construction, core materials, and frame support mechanisms determine the total weight a sleeping surface can safely accommodate without compromising structural integrity or user safety. Exceeding the stated maximum weight results in accelerated wear, potential material failure (such as sagging or deformation), and a significant reduction in overall lifespan. For example, a surface designed for a single occupant with a 250-pound limit is unlikely to perform adequately, or safely, if subjected to a combined weight of two adults. Selecting a sleeping surface with appropriate load-bearing specifications necessitates a thorough understanding of anticipated usage patterns and typical user weight.

The correlation between internal construction and load-bearing limit is often reflected in the thickness and material composition. A thinner sleeping surface may utilize high-density foam or innerspring systems to compensate for reduced material volume, thereby achieving a comparable weight capacity to a thicker, less densely packed alternative. Conversely, a thicker sleeping surface constructed from lower-density materials may exhibit a lower load-bearing limit due to increased material compression under load. Manufacturers typically provide detailed specifications outlining both the maximum weight and the corresponding density or construction characteristics to enable informed consumer choices. A real-world example is the selection of a futon sleeping surface for a guest room; if frequent use by multiple adults is expected, a heavier-duty option with a higher load-bearing capacity and durable core materials is essential.

In summary, the safe load limit is not merely an adjunct detail but an integral facet. Overlooking this element compromises support, hastens material fatigue, and endangers users. Awareness of the correlation between the sleeping surface’s structure, overall measurements, and recommended weight restriction ensures that the selection and use of sleeping solutions for convertible furniture contribute to safety, long-term performance, and user satisfaction. Neglecting this factor poses risks to both the longevity of the product and the well-being of those who use it.

4. Corner rounding

The geometric property of corner rounding holds direct implications for the fit and functionality of sleeping surfaces within multi-purpose furniture. Square corners, while geometrically simple, often present fitting challenges within frames designed with radiused or chamfered corners. An unyielding 90-degree corner may interfere with the frame’s internal structure, preventing the sleeping surface from seating correctly. Therefore, specifying a degree of corner rounding mitigates potential interference and ensures compatibility. For instance, a furniture frame with a -inch radius corner necessitates a matching or slightly smaller radius on the sleeping surface to ensure a flush, uninterrupted fit.

Furthermore, the integration of rounded corners enhances safety and reduces the likelihood of sharp edges presenting a hazard. In environments frequented by children or individuals with mobility limitations, this design feature minimizes the potential for accidental injury. Practical applications extend to simplified bedding installation. The absence of sharp corners allows for easier maneuverability and reduces stress on bedding materials during the fitting process. Specifically, sheets and mattress protectors conform more readily to rounded edges, minimizing wrinkles and improving overall aesthetics.

In conclusion, careful consideration of corner rounding contributes significantly to a functional and aesthetically pleasing integration of sleeping surfaces within multi-purpose furniture. The specified radius should correspond directly to the frame’s internal geometry, balancing safety, ease of use, and compatibility. Neglecting this design element increases the probability of fitting issues and reduces the overall satisfaction with the finished product. Proper integration ensures a seamless look and mitigates any potential safety concerns.

5. Inner frame fit

The precise correspondence between the interior dimensions of a frame and the external measurements of a sleeping surface is paramount for structural integrity and functional performance. A discrepancy in these dimensions creates instability, compromises support, and accelerates wear on both the sleeping surface and the frame itself. An undersized sleeping surface, for example, allows excessive movement, potentially leading to uneven weight distribution and premature sagging. Conversely, an oversized sleeping surface will be difficult to install and may experience compression or distortion, negatively affecting comfort and longevity. Therefore, meticulous attention to the inner frame dimensions is a prerequisite for selecting a compatible sleeping surface.

Practical implications of a proper fit extend beyond mere stability. A securely fitted sleeping surface prevents slippage, minimizing the risk of injury during use. It also ensures uniform support, promoting proper spinal alignment and mitigating discomfort. Moreover, a well-fitted sleeping surface contributes to the overall aesthetic appeal of the furniture. Gaps or overlaps detract from the intended design and create a visually unappealing effect. For instance, consider a convertible sofa; a sleeping surface that does not accurately conform to the inner frame dimensions disrupts the clean lines and seamless transformation between seating and sleeping configurations.

In conclusion, the inner frame fit represents a foundational element. Dimensional accuracy ensures safety, enhances comfort, improves aesthetics, and extends the lifespan of both the sleeping surface and the furniture frame. Overlooking this critical aspect introduces a cascade of potential problems that undermine the intended functionality and overall value. Precision in measurement and selection remains crucial for optimal outcomes.

Frequently Asked Questions

This section addresses common inquiries regarding the measurement specifications of sleeping surfaces intended for use with this furniture type.

Question 1: What are the standard measurements?

The most common sleeping surface measures approximately 39 inches wide and 75 inches long, corresponding to a standard twin size.

Question 2: How does thickness impact performance?

Thickness affects support and comfort levels. Thicker sleeping surfaces generally provide greater cushioning and may be preferable for heavier individuals or those seeking enhanced support. A thickness between five and eight inches is typical.

Question 3: Are corner shape important?

Corner shape is significant for proper fit within the frame. Rounded corners mitigate interference and ensure a seamless integration.

Question 4: What if the frame has non-standard dimensions?

Frames with non-standard dimensions may require custom-sized sleeping surfaces. Accurate measurements of the frame’s interior are essential for ordering a compatible option.

Question 5: How does weight capacity relate to dimensions?

Weight capacity is independent of surface area. Internal construction and material composition determine the maximum load a sleeping surface can safely support.

Question 6: Is it necessary to adhere strictly to the specified dimensions?

Adhering to the specified dimensions is crucial for ensuring proper fit, stability, and longevity. Deviations from these measurements can compromise safety and comfort.

Accuracy in selecting dimensions maximizes both functionality and user satisfaction.

The next section will provide information about cleaning a sleeping surface.

Daybed Mattress Dimensions

The preceding sections have thoroughly examined the importance of precise measurement specifications for sleeping surfaces intended for multi-functional furniture. The analysis underscored the critical role of standard sizing, thickness variations, weight capacity, corner rounding, and inner frame fit. Adherence to these dimensional parameters directly influences product longevity, user safety, and overall comfort. Deviation from established specifications compromises functionality and diminishes value.

The information provided herein serves as a foundational guide for manufacturers and consumers alike. By prioritizing dimensional accuracy and understanding the interrelationship between various measurement specifications, stakeholders can ensure optimal performance and long-term satisfaction. Continued adherence to established standards will foster greater compatibility and contribute to an improved user experience.