The physical size of a portable crib sleeping surface is a key consideration for infant safety and comfort. These measurements dictate the compatibility with fitted sheets and impact the available space for the child within the playard. Precise knowledge of these measurements ensures a secure and appropriate sleeping environment, preventing potential hazards associated with ill-fitting bedding.

Adherence to standardized portable crib sleeping surface sizes promotes safer sleep practices. The correct size provides a snug fit, reducing the risk of entanglement and suffocation. Historically, variations in sizing posed safety concerns; therefore, current standards aim to minimize such risks. This consistent form factor facilitates the selection of appropriate accessories and ensures a predictable sleeping area for the child during travel or when away from home.

The following sections will elaborate on specific measurement guidelines, explore variations in size among different manufacturers, and discuss the implications for selecting suitable bedding and accessories for a portable crib.

Selecting a Portable Crib Sleeping Surface

Proper selection and use of a portable crib sleeping surface contributes significantly to infant safety and restful sleep. The following guidelines provide essential information for caregivers.

Tip 1: Verify Standard Compliance: Ensure the portable crib and its associated sleeping surface meet current safety standards established by regulatory bodies. This verification minimizes the risk of product defects or design flaws.

Tip 2: Measure Accurately: Prior to purchasing a replacement or additional sleeping surface, meticulously measure the interior of the portable crib. Record length and width in inches or centimeters to ensure precise fit.

Tip 3: Choose a Firm Sleeping Surface: Select a sleeping surface that is firm and flat, providing adequate support for the infant. Avoid excessively soft or plush surfaces that could pose a suffocation hazard.

Tip 4: Use Fitted Sheets Designed for Portable Cribs: Employ only fitted sheets specifically designed for portable crib sleeping surfaces. Ensure the sheet fits snugly, without any looseness or bunching, to prevent entanglement.

Tip 5: Inspect for Gaps: After placing the sleeping surface into the portable crib, carefully inspect all sides for gaps between the surface and the crib frame. Gaps can create entrapment hazards.

Tip 6: Avoid Additional Padding: Refrain from adding extra padding, blankets, pillows, or soft toys to the portable crib. These items increase the risk of suffocation or Sudden Infant Death Syndrome (SIDS).

Tip 7: Regularly Inspect the Sleeping Surface: Periodically examine the sleeping surface for signs of wear and tear, such as tears, cracks, or deformation. Replace the sleeping surface if any damage is detected.

Adhering to these tips contributes to the creation of a safe and comfortable sleep environment for infants within portable cribs. Prioritizing safety through informed product selection and diligent use is paramount.

The subsequent sections will address specific considerations related to material selection, cleaning protocols, and storage recommendations for portable crib sleeping surfaces.

1. Standard Length

The standard length of a portable crib sleeping surface is a critical element defining its overall dimensions and usability. As a primary measurement, length directly impacts the fit within a compatible playard frame. Deviation from established length standards can lead to safety compromises, such as gaps between the mattress and the frame that pose entrapment hazards. For example, if the measured length of a replacement mattress is significantly shorter than the intended standard length, a dangerous space can form, potentially endangering a child.

The correlation between standard length and the overall dimensions also influences the type and availability of compatible accessories. Fitted sheets, in particular, are designed to conform to specific dimensional ranges. A non-standard length necessitates custom or ill-fitting sheets, increasing the risk of loose bedding, which is considered unsafe. Practically, caregivers rely on standardized lengths for ease of replacement and accessory procurement, knowing that commonly available products will fit appropriately.

In summary, the standard length of a portable crib sleeping surface is an indispensable component of its overall dimensions. Maintaining adherence to established standards ensures a safe, secure, and practical sleep environment for infants. Challenges arise when manufacturers deviate from these standards, highlighting the need for careful measurement and verification prior to purchase and use.

2. Standard width

The standard width constitutes a foundational dimension of the portable crib sleeping surface, directly impacting its compatibility and safety. It defines the lateral space available for the infant and, when deviating from the norm, introduces risks related to fit within the playard frame. For instance, a width narrower than standard could lead to lateral movement of the mattress during use, potentially creating hazardous gaps between the sleeping surface and the playard sides. This contrasts with mattresses designed to adhere to standard measurements, ensuring a snug fit and reducing the likelihood of entrapment.

The correlation between the standard width and accessory usability is evident in the design and availability of fitted sheets. A standard width allows for easy procurement of appropriate bedding, designed to securely encase the mattress without excessive looseness. Conversely, a non-standard width necessitates custom-made or makeshift bedding, raising safety concerns due to the potential for bunching or detachment. This connection is particularly significant for parents traveling or requiring frequent bedding changes, as standard-sized sheets are readily available.

In conclusion, the standard width of a portable crib sleeping surface is integral to its overall dimensions and contributes directly to infant safety. Adherence to standard dimensions minimizes hazards associated with improper fit and simplifies the selection of compatible accessories, creating a secure and practical sleeping environment. Challenges arise when non-standard widths are introduced, necessitating careful measurements and a focus on bedding fit to mitigate safety risks.

3. Thickness Tolerance

Thickness tolerance, as it relates to the overall dimensions of a portable crib sleeping surface, is a critical factor influencing both safety and functionality. It defines the acceptable range of variation from the nominal, or intended, thickness of the mattress. Excessive deviation from this tolerance, even within acceptable length and width parameters, can have cascading effects. For example, a mattress that is significantly thicker than specified may create undue stress on the playard frame, potentially compromising its structural integrity and leading to instability. Conversely, a mattress that is too thin may not provide adequate support, increasing the risk of positional asphyxia, especially for infants who lack the strength to reposition themselves.

The specified thickness tolerance also affects the effectiveness of fitted sheets designed for the intended dimensions of a portable crib sleeping surface. Sheets sized for a standard thickness may fit improperly on a mattress that deviates significantly from this specification. This can lead to either a sheet that is too loose, creating a risk of entanglement, or a sheet that is too tight, potentially compressing the sleeping surface and affecting its firmness. In real-world scenarios, this can manifest as difficulty in securing the sheet properly, requiring constant readjustment and introducing a persistent safety concern. Understanding thickness tolerance is therefore essential for caregivers to ensure proper sheet fit and a safe sleep environment.

In summary, thickness tolerance is an indispensable element of the overall dimensions of a portable crib sleeping surface. Maintaining adherence to specified tolerance levels is paramount for ensuring the structural integrity of the playard, providing adequate infant support, and ensuring proper fit of fitted sheets. Failure to account for thickness tolerance can introduce significant safety risks and compromise the intended functionality of the portable crib system. Therefore, careful consideration of this dimensional aspect is essential during both manufacturing and consumer selection of a portable crib sleeping surface.

4. Corner Radius

The corner radius of a portable crib sleeping surface is a design specification that interacts directly with the overall dimensions of the mattress, impacting both safety and fit within the playard frame. This seemingly minor detail plays a crucial role in preventing binding, ensuring proper sheet fit, and minimizing potential hazards.

- Prevention of Binding

The corner radius determines how well the mattress fits into the corners of the portable crib. A sharp, non-radiused corner could bind against the playard frame, preventing the mattress from sitting flush and creating uneven support. A well-defined radius ensures a smooth transition, preventing such binding and allowing for even distribution of weight. This is particularly important in maintaining a level sleeping surface for the infant.

- Fitted Sheet Compatibility

Fitted sheets are designed with a specific corner radius in mind. If the radius of the mattress corners deviates significantly from the standard, the sheet may either be too tight, potentially deforming the mattress, or too loose, increasing the risk of entanglement. The appropriate corner radius ensures a snug and secure fit, minimizing the chance of loose fabric posing a hazard. Examples of this issue arise when using standard-sized sheets on mattresses with atypically sharp or rounded corners, requiring the use of custom-fit sheets instead.

- Structural Integrity

The corner radius contributes to the structural integrity of the mattress itself. A sharp corner is more susceptible to damage and wear over time, potentially leading to tears or deformation of the mattress material. A rounded corner distributes stress more evenly, increasing the longevity and durability of the sleeping surface. This consideration is particularly relevant given the frequent use and potential for rough handling that portable cribs often experience.

- Overall Safety

A properly designed corner radius can help prevent small gaps between the mattress and the playard frame. Sharp corners, or corners with too small of a radius, may not fully fill the corner space, creating potential entrapment hazards for small limbs. A well-executed radius minimizes these gaps, contributing to a safer sleep environment for the infant. Measurements of the corner space within the frame must be carefully considered, and should match the measurements of the mattress corners.

In summary, the corner radius is an integral aspect of the dimensions of a portable crib sleeping surface. Its careful consideration during design and manufacturing is essential for ensuring proper fit, preventing hazards, and maximizing the safety and longevity of the product. Deviations from standard corner radii necessitate careful attention to sheet fit and overall compatibility, highlighting the importance of adherence to established guidelines.

5. Weight capacity

Weight capacity, in the context of portable crib sleeping surfaces, is intrinsically linked to the overall dimensions of the mattress. It represents the maximum weight an infant can safely exert on the sleeping surface without compromising structural integrity or increasing the risk of hazardous conditions. Understanding this relationship is critical for ensuring safe usage.

- Mattress Support Structure

The internal support structure of a portable crib sleeping surface is directly engineered in response to the dimensions of the mattress. A larger surface area requires a more robust support system to distribute weight evenly and prevent sagging. For instance, a longer or wider mattress must incorporate stronger internal bracing or denser foam to maintain its shape and firmness under the specified weight limit. Exceeding this limit can lead to structural failure, increasing the risk of collapse or uneven sleeping surfaces.

- Material Density and Compression

The materials used in a portable crib sleeping surface are selected, in part, based on their ability to withstand compression under a specified weight. Higher density materials are often necessary for larger mattresses to prevent excessive compression that could reduce the mattress’s thickness below safe levels. For example, a thinner, low-density foam may adequately support a newborn, but a heavier infant might compress the foam to a point where it loses its firmness and compromises the childs breathing space. This is why, for a given material, a thicker mattress is often required to handle a higher weight capacity.

- Frame Compatibility

The dimensions of the mattress must be compatible with the weight capacity of the portable crib frame itself. A larger, heavier mattress places increased stress on the frame, potentially exceeding its designed limits. For example, if a caregiver uses a mattress that is both thicker and heavier than recommended for a particular playard, the frame may become unstable or develop structural weaknesses, increasing the risk of collapse. Frame integrity testing should occur prior to use of any mattress or playard. This is where proper quality control is vital.

- Safety Standard Compliance

Regulatory bodies often specify weight capacity standards based on mattress dimensions. These standards are designed to ensure that mattresses of certain sizes meet minimum performance criteria regarding firmness, support, and overall safety. For example, a mattress intended for larger infants will typically have a higher weight capacity requirement than one designed for newborns. Deviation from these standards can result in non-compliant products that pose a significant safety risk to infants.

In summary, weight capacity and dimensions are intricately linked in portable crib sleeping surfaces. The size and construction of the mattress directly impact the support structure, material density, and frame compatibility required to ensure safety and compliance. Understanding these interdependencies is crucial for selecting an appropriate sleeping surface and adhering to recommended usage guidelines, minimizing potential hazards for infants.

Frequently Asked Questions

This section addresses common inquiries regarding the dimensions of portable crib sleeping surfaces, providing concise and authoritative answers to ensure informed decisions.

Question 1: What are the standard dimensions for a portable crib sleeping surface?

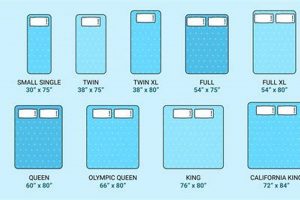

The generally accepted standard dimensions are approximately 24 inches in width and 38 inches in length. However, slight variations may exist among different manufacturers. Verification of specific product dimensions is always recommended.

Question 2: Are there different sizes of portable crib sleeping surfaces?

While the aforementioned dimensions are common, variations do exist. Some manufacturers offer smaller or larger models. It is crucial to measure the interior of the portable crib to ensure compatibility before purchasing a sleeping surface.

Question 3: What is the significance of the thickness of a portable crib sleeping surface?

The thickness impacts both comfort and safety. A sleeping surface that is too thin may not provide adequate support, while one that is too thick may compromise the structural integrity of the portable crib. Recommended thicknesses typically range from 2 to 3 inches.

Question 4: How does the corner radius of the sleeping surface affect its fit?

The corner radius ensures a snug fit within the portable crib frame and prevents binding. An improperly sized radius can create gaps or cause the sleeping surface to sit unevenly. A smooth, rounded radius is generally preferred.

Question 5: Is it acceptable to use a non-standard sized sleeping surface if a proper fit seems achievable?

Using a non-standard sized sleeping surface is strongly discouraged. Even if a seemingly acceptable fit is achieved, subtle incompatibilities can compromise safety, potentially leading to entrapment hazards. Adherence to recommended dimensions is paramount.

Question 6: Where can precise dimensional specifications for a specific portable crib model be found?

Precise dimensional specifications are typically located in the product manual or on the manufacturer’s website. Consulting these resources is essential for ensuring compatibility and safe usage.

Understanding the dimensional considerations of portable crib sleeping surfaces is essential for ensuring infant safety and proper product functionality.

The subsequent section will address practical guidelines for selecting appropriate bedding and accessories, further enhancing the safety and comfort of the portable crib environment.

Conclusion

This exploration has highlighted the critical importance of understanding the dimensions of pack and play mattress. Accurate measurements, adherence to safety standards, and informed selection of compatible accessories are essential for ensuring a secure and comfortable sleep environment for infants. Key aspects, including length, width, thickness, corner radius, and weight capacity, directly impact the functionality and safety of the portable crib system.

Careful consideration of these factors minimizes potential hazards and promotes responsible caregiving. Continued adherence to established guidelines and vigilance in product selection will further enhance the safety and well-being of infants utilizing portable cribs. The responsibility rests with caregivers to prioritize safety by maintaining a thorough understanding of portable crib dimensions and best practices.