The measurements of a standard single inflatable bed are essential for consumers seeking a portable and convenient sleeping solution. These products are designed to comfortably accommodate one individual, providing a compact alternative to traditional mattresses. The size specifications are crucial when considering storage space, intended use, and compatibility with existing bedding.

The prevalence of these sleeping surfaces stems from their ease of use and versatility. They offer a readily available bed for guests, temporary living situations, or camping trips. Their inflatable nature allows for effortless deflation and storage, making them ideal for situations where space is limited. Historically, inflatable beds have evolved from basic rubberized canvases to sophisticated multi-layered structures with enhanced comfort features.

Understanding the precise scale of a single inflatable bed is paramount when selecting the appropriate model. Factors such as intended user, storage constraints, and compatibility with existing accessories must be considered. The subsequent sections will delve into the specifics of choosing and utilizing these convenient sleeping alternatives.

Considerations for a Standard Single Inflatable Bed

Selecting the appropriate single inflatable bed necessitates careful consideration of several factors to ensure user satisfaction and optimal product longevity.

Tip 1: Measurement of Available Space: Before purchasing, precisely measure the intended space where the inflated bed will be used. This prevents overcrowding and ensures adequate room for movement around the bed.

Tip 2: Height Considerations: The inflated height varies across models. Consider the user’s ability to easily get in and out of the bed, particularly for elderly individuals or those with mobility limitations. A higher profile may be preferable for ease of access.

Tip 3: Storage Requirements: When deflated, the packed size of the bed should be manageable for storage within the available space. Investigate the deflated dimensions to ensure easy storage within closets or designated storage areas.

Tip 4: Weight Capacity: Adhere strictly to the manufacturers specified weight capacity. Exceeding this limit can lead to premature wear, deflation, or structural failure of the bed.

Tip 5: Material Durability: Inspect the material composition of the bed. Thicker, more resilient materials are more resistant to punctures and abrasions, thereby prolonging the product’s lifespan.

Tip 6: Inflation/Deflation Mechanism: Investigate the type of inflation/deflation mechanism. Integrated pumps offer convenience, while separate pumps provide flexibility. Evaluate the speed and ease of use of the selected mechanism.

Tip 7: Surface Texture and Comfort: Assess the surface texture of the bed. Flocked surfaces provide enhanced comfort and prevent bedding from slipping. Consider adding a mattress topper for increased comfort if needed.

Prudent assessment of spatial limitations, user needs, and product specifications will contribute to a successful selection and ensure the long-term utility of the single inflatable bed.

The following sections will provide information on proper usage and maintenance protocols.

1. Length (inches)

The length of a single inflatable bed, measured in inches, dictates the user’s physical accommodation and space planning considerations. This dimension is fundamental to determining whether the inflated bed will fit appropriately within a designated area and comfortably support the user.

- Suitability for Intended User

The length dimension directly impacts user suitability. A bed that is too short will compromise the sleeper’s comfort, potentially leading to restless sleep or physical discomfort. Longer individuals require a bed of adequate length to fully extend without their feet hanging off the edge. Proper length ensures postural alignment and sufficient room for movement during sleep.

- Spatial Constraints

The available space in the intended room or location is a primary constraint. The length of the inflated bed must be carefully considered in relation to existing furniture, doorways, and pathways. Accurate measurement of the space and comparison to the bed’s length specification are essential to avoid overcrowding or logistical issues. This is particularly important in smaller rooms or shared spaces.

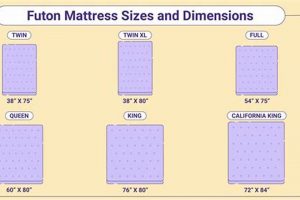

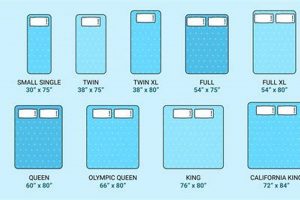

- Compatibility with Bedding

Standard bedding sizes are designed to correspond to specific mattress lengths. Single or “twin” sized sheets, blankets, and comforters are tailored for use with beds of a particular length. Choosing a bed length that deviates significantly from standard dimensions may require custom-made bedding or compromise the fit and appearance of standard linens.

- Storage Considerations

Although the length of the inflated bed is the primary concern during use, it is essential to consider the deflated length as this will influence the selection of the container or location where the product is stored. For instance a long product when deflated can still be hard to store due to its length.

Therefore, the ‘length’ dimension is critical for determining the suitability of a standard single inflatable bed for its intended purpose. Adequate length promotes user comfort and prevents spatial constraints, while adherence to standard dimensions ensures compatibility with existing accessories. Careful assessment of this metric is paramount to a satisfactory purchase.

2. Width (inches)

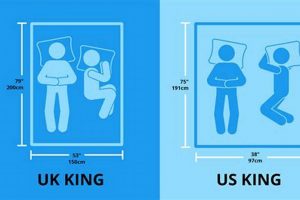

The width of a standard single air mattress, denoted in inches, is a critical dimension that directly influences user comfort and the allocation of space within a given environment. As a component of the overall size, the width determines the lateral area available to the user during sleep or rest. A product of inadequate width may lead to restricted movement and a diminished sense of comfort, while excessive width may occupy valuable space unnecessarily.

The width affects the choice of bedding and compatibility with bed frames designed for single mattresses. For instance, standard single or “twin” bedding is manufactured to fit a specific width. Deviation from this standard may necessitate custom-made or ill-fitting linens. In the context of camping, a narrow width enables easier accommodation within smaller tents, whereas a wider width offers enhanced comfort at the expense of increased spatial demand. Understanding width is also important if multiple mattresses are being placed in a single room as this width impacts traffic flow.

In summary, the width of a single air mattress plays a pivotal role in user experience and logistical considerations. Proper understanding of this dimension ensures appropriate comfort, efficient space utilization, and compatibility with existing bedding and environments. Failure to consider width adequately can result in discomfort, spatial inefficiency, and the need for specialized accessories.

3. Inflated Height

The inflated height of a standard single air mattress represents a critical dimension that significantly impacts usability, comfort, and suitability for diverse users. This dimension dictates the vertical distance between the supporting surface (floor, ground) and the uppermost point of the inflated mattress, influencing ease of access, perceived comfort, and overall user experience. Height variations across different models of single air mattresses can range considerably, reflecting design choices and intended usage scenarios.

A greater inflated height offers several advantages. It facilitates easier ingress and egress, particularly beneficial for elderly individuals or those with mobility limitations. A higher profile creates a more bed-like experience, often perceived as more comfortable and familiar compared to low-profile alternatives. Conversely, a lower inflated height presents benefits in situations where headroom is limited, such as within tents or cramped spaces. Low-profile models are generally more stable, reducing the risk of tipping or rolling. Height is also correlated to comfort because a higher profile is capable of supporting a thicker air chamber, giving a plusher and deeper feel.

Selection of an appropriate inflated height demands careful consideration of user needs and environmental factors. For temporary guest accommodations, a moderate height provides a balance of comfort and convenience. For camping or travel, a lower profile may be preferable due to space constraints and portability. Prioritizing user accessibility is essential; individuals with joint problems or limited mobility may require a higher mattress for ease of use. The correlation of comfort to greater volume of air must be balanced with stability and the need for compactness. The inflated height forms an integral aspect of the overall dimensional characteristics of a single air mattress, shaping its functionality and its ability to meet diverse user requirements.

4. Deflated Size

The deflated size of a “dimensions twin air mattress” is a critical consideration when assessing portability and storage feasibility. This attribute reflects the physical volume the mattress occupies when devoid of air, directly influencing its practicality for travel, compact storage, and situations where space is a premium.

- Impact on Portability

The deflated size governs the ease with which the air mattress can be transported. Smaller deflated dimensions allow for convenient packing in suitcases, backpacks, or car trunks. Larger deflated sizes may necessitate dedicated carrying cases or restrict transport options, rendering the mattress less suitable for camping, hiking, or air travel. For example, a tightly rolled, compact unit is far more appropriate for air travel when luggage volume is limited.

- Influence on Storage Space Requirements

Storage constraints are a primary concern for many users. The deflated dimensions dictate the amount of storage space required within a home, apartment, or vehicle. A compact deflated profile enables storage in closets, under beds, or within storage containers, minimizing the mattress’s footprint when not in use. Bulky, large deflated dimensions necessitate dedicated storage areas, potentially leading to inconvenience. Limited home space means that minimizing the amount of area consumed by a non-inflated air bed becomes important.

- Relationship to Material Thickness and Durability

The ability to achieve a small deflated size can correlate inversely with material thickness and overall durability. Thicker, more robust materials may resist compression, resulting in a larger deflated volume. Conversely, thinner, less durable materials may compress more readily, yielding a smaller deflated size but potentially compromising longevity. The material used to make a mattress will result in different sizes when deflated. This can influence how the mattress is stored.

- Effect on Ease of Handling

A smaller, more compact deflated size generally translates to easier handling and maneuverability. A lightweight, compact package is simpler to lift, carry, and position for storage compared to a bulky, unwieldy alternative. This factor is particularly relevant for users with limited physical strength or mobility, such as elderly individuals or those with physical disabilities.

In summary, the deflated size of a “dimensions twin air mattress” is intrinsically linked to its practicality and utility. The dimension affects portability, storage requirements, the user’s need for a material that will compress to a small package, and its handling. Therefore, assessment of the deflated volume is essential for alignment with individual needs and constraints.

5. Weight Capacity

Weight capacity represents a fundamental specification of a “dimensions twin air mattress,” dictating the maximum load the structure is engineered to support without compromising structural integrity or performance. Adherence to this specification is paramount for user safety and the longevity of the product. Exceeding the stated weight limit can result in material failure, seam rupture, or rapid deflation.

- Structural Integrity

The weight capacity rating reflects the air mattress’s ability to withstand internal pressure and external forces. Overloading the mattress introduces stress beyond its design parameters, potentially leading to deformation, bulging, or catastrophic failure of internal support structures. For example, repeated overloading can stretch the material, causing permanent sagging and diminished support. The overall size of the air mattress has a direct impact on the weight it can hold. A twin is naturally smaller, meaning that the air bladders are shorter.

- Material Stress and Fatigue

Continuous application of weight close to or exceeding the rated capacity accelerates material fatigue. The air mattress material, typically PVC or similar polymer, experiences increased tensile stress, leading to microscopic cracks and weakening over time. This process is exacerbated by temperature fluctuations and repeated inflation/deflation cycles. The dimensions, materials, and structural layout of the twin mattress determines how much weight that can be held.

- Seam Strength and Durability

Seams represent the weakest points in the structure of the air mattress. Excessive weight places undue stress on these bonded or welded areas, increasing the risk of seam separation or rupture. This can result in rapid air loss and rendering the mattress unusable. Weight at or above specifications causes high wear and tear. A twin air mattress is designed to have fewer seams. A queen or king mattress has much larger dimensions and, therefore, greater weight. This can increase the likelihood of failure.

- User Safety and Comfort

Adhering to the specified weight capacity ensures user safety and optimal comfort. Overloading can create an unstable sleeping surface, increasing the risk of falls or injuries. Moreover, exceeding the weight limit can compromise the mattress’s ability to provide adequate support, leading to discomfort and poor sleep quality. The air bladder of the “dimensions twin air mattress” might fail and cause safety and comfort problems.

Therefore, users should carefully consider the intended application of a “dimensions twin air mattress” and select a model with a weight capacity that comfortably accommodates the anticipated load. This measure ensures safety, prolongs the lifespan of the product, and maintains optimal comfort during use.

6. Material Thickness

Material thickness, a crucial determinant of durability and performance, is a significant factor in the context of a “dimensions twin air mattress.” The gauge or thickness of the material directly influences the air mattress’s resistance to puncture, abrasion, and overall longevity.

- Puncture Resistance and Air Retention

Thicker materials exhibit a heightened resistance to punctures from sharp objects, reducing the likelihood of air leaks. This attribute is particularly important for outdoor use or in environments where contact with abrasive surfaces is probable. The air mattress maintains inflation longer when constructed of a thicker material.

- Weight Capacity and Support

Material thickness directly correlates with the weight-bearing capacity of the air mattress. Thicker materials offer greater structural integrity and support, enabling the mattress to accommodate heavier loads without deformation or failure. Proper dimensions are important to a twin air mattress.

- Comfort and Conformability

While thickness primarily influences durability, it also impacts the overall comfort. Thicker materials often provide a more substantial and stable sleeping surface. This provides a more even distribution of weight, and can be softer to the touch. The firmness is also affected by the dimensions.

- Thermal Properties and Insulation

Increased material thickness contributes to improved thermal insulation. The additional material provides a barrier against heat loss, making the air mattress more suitable for use in cooler environments. Especially when camping the material thickness can be a major determinant of temperature.

The interplay between material thickness and the “dimensions twin air mattress” is paramount for ensuring a reliable and comfortable sleeping solution. Selection of an appropriate material thickness should consider the intended use, environmental conditions, and anticipated load to maximize the lifespan and performance of the air mattress. While dimensions dictate how much space an air mattress will take up, thickness informs users as to the properties of the material used.

7. Seam Strength

Seam strength is a critical factor in the performance and durability of a “dimensions twin air mattress.” It refers to the ability of the bonded or welded joints of the air mattress material to withstand stress and pressure without failing. The seams are typically the weakest points in the structure, and their integrity directly impacts the mattress’s ability to retain air and provide consistent support over time. Low seam strength can cause leaks that undermine the firmness of the mattress.

The dimensions of a twin air mattress influence the stresses experienced by the seams. Larger mattresses, even with similar seam construction, can exhibit greater stress concentration at the seams due to the increased surface area and internal pressure. Thicker materials used in construction also contribute to seam stress, as they require stronger bonding methods. Real-world examples of seam failure often manifest as slow leaks, bulging along the seams, or catastrophic ruptures. This is more common with twin air mattresses that are used often and/or overloaded.

Understanding the relationship between seam strength and the dimensions of a twin air mattress is paramount for both manufacturers and consumers. Manufacturers must employ appropriate bonding techniques and quality control measures to ensure sufficient seam strength. Consumers must adhere to the weight capacity and proper usage guidelines to minimize stress on the seams. Ultimately, a focus on seam strength results in a more reliable and durable “dimensions twin air mattress,” providing long-term comfort and value. Seam construction will dictate if the mattress can be a long term solution.

Frequently Asked Questions

This section addresses common inquiries regarding the spatial properties and practical considerations associated with standard single inflatable beds.

Question 1: What are the standard length and width measurements for a “dimensions twin air mattress?”

A standard twin air mattress typically measures approximately 75 inches in length and 39 inches in width. However, slight variations may exist between manufacturers. It is advisable to consult the product specifications for the exact dimensions.

Question 2: How does the inflated height of a “dimensions twin air mattress” affect its suitability for different users?

The inflated height influences ease of access and perceived comfort. A higher profile is often preferred for users with mobility limitations, while a lower profile may be more suitable for camping or situations with limited headroom.

Question 3: What is the deflated size of a typical “dimensions twin air mattress” and how does it impact storage?

The deflated size varies based on material thickness and construction. Compact deflated dimensions facilitate convenient storage in closets or small spaces, while larger deflated sizes may require dedicated storage areas.

Question 4: What is the recommended weight capacity for a “dimensions twin air mattress,” and what are the consequences of exceeding it?

The recommended weight capacity generally ranges from 250 to 300 pounds. Exceeding this limit can compromise structural integrity, leading to material failure, seam rupture, or rapid deflation.

Question 5: How does material thickness affect the durability and puncture resistance of a “dimensions twin air mattress?”

Thicker materials exhibit greater resistance to punctures and abrasion, thereby prolonging the product’s lifespan. Thinner materials may be more susceptible to damage and air leaks.

Question 6: What is the significance of seam strength in determining the overall reliability of a “dimensions twin air mattress?”

Seam strength is crucial for preventing air leaks and maintaining structural integrity. Weak seams are prone to failure under stress, resulting in reduced performance and premature product deterioration.

In summary, a thorough understanding of these dimensional and structural factors is essential for selecting a suitable “dimensions twin air mattress” that meets individual needs and ensures long-term utility.

The following section will focus on the optimal usage and maintenance practices.

Conclusion

This exploration of the “dimensions twin air mattress” has underscored the importance of understanding its spatial characteristics, material properties, and structural limitations. Considerations such as length, width, inflated height, deflated size, weight capacity, material thickness, and seam strength directly impact the product’s suitability, durability, and overall user satisfaction. A proper assessment of these elements is crucial for selecting an appropriate model for intended use.

The insights presented serve as a foundation for informed decision-making, promoting responsible consumer choices and maximizing the lifespan of the selected product. By understanding the nuanced aspects of “dimensions twin air mattress,” users can ensure their sleeping needs are met with a product that balances convenience, comfort, and long-term reliability.