A bed designed for two occupants, inflated with air to provide cushioning and support, offers a portable and often more economical sleeping solution. These beds are commonly constructed from durable materials like PVC or reinforced fabrics, and feature integrated or external pumps for inflation and deflation. Their dimensions typically conform to standard full or queen mattress sizes, providing ample space for comfortable rest.

The utility of these beds stems from their ease of storage and transportation, making them suitable for guest accommodations, camping trips, or temporary sleeping arrangements during relocation. Their relatively low cost compared to traditional mattresses allows budget-conscious consumers to furnish a spare room or provide a comfortable sleeping surface without significant financial investment. Historically, air-filled bedding has evolved from simple rubberized canvas to sophisticated multi-chambered designs with enhanced support and comfort features.

The following sections will delve into specific aspects such as construction materials, inflation methods, features influencing comfort and durability, considerations for selecting an appropriate model, and maintenance practices to prolong the lifespan of such an item.

Essential Usage Tips

Maximizing the lifespan and comfort of the described sleeping surface requires careful consideration of several factors. The following tips offer guidance for proper usage and maintenance.

Tip 1: Select a Suitable Location: Prior to inflation, ensure the placement area is free from sharp objects or debris that could puncture the material. Use a protective layer, such as a blanket or tarp, beneath the mattress to mitigate abrasion.

Tip 2: Regulate Inflation Pressure: Avoid over-inflation, which can stress the seams and reduce longevity. Inflate to the recommended pressure level indicated by the manufacturer; slight adjustments may be needed based on ambient temperature.

Tip 3: Distribute Weight Evenly: Encourage occupants to distribute their weight evenly across the surface. Concentrated pressure in one area can lead to localized stress and potential material failure.

Tip 4: Monitor Temperature Fluctuations: Be aware that changes in temperature can affect air pressure. In cooler environments, the mattress may deflate slightly, requiring additional inflation. Conversely, heat can cause over-expansion.

Tip 5: Employ Proper Storage Techniques: When not in use, thoroughly deflate the mattress and store it in a dry, climate-controlled environment. Avoid folding it along the same creases each time to prevent weak points.

Tip 6: Address Punctures Promptly: Regularly inspect the surface for signs of damage. Small punctures can often be repaired with readily available patch kits. Ignoring minor issues can lead to more significant problems.

Following these guidelines contributes to a more comfortable and durable experience, extending the useful life of the product and enhancing user satisfaction.

The subsequent sections will offer further insights into troubleshooting common issues and exploring advanced features available in contemporary models.

1. Dimensions

The dimensions of an air mattress fundamentally dictate its usability and suitability for various applications. Precise measurements impact comfort, space requirements, and compatibility with standard bedding.

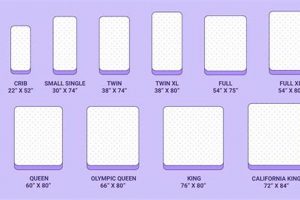

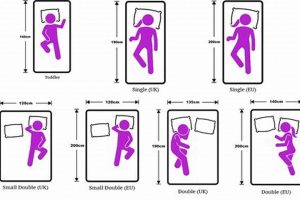

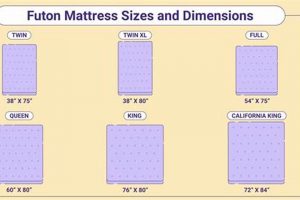

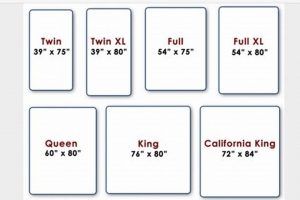

- Standard Sizing and Variance

While designated as “double size,” actual dimensions can vary slightly among manufacturers. The term generally aligns with full or queen mattress sizes, typically ranging from 54 to 60 inches in width and 75 to 80 inches in length. This variance necessitates careful measurement of available space prior to purchase.

- Height Considerations and Impact

Height, or thickness, is another crucial dimension. Thicker models, often exceeding 18 inches, offer increased comfort and ease of entry and exit, mimicking the feel of a traditional bed. However, increased height can also impact stability and require deeper fitted sheets.

- Inflated vs. Deflated Dimensions

It is important to note the difference between the stated dimensions when fully inflated and the much smaller dimensions when deflated for storage. The deflated size is critical for portability and storage space assessment.

- Edge Support and Usable Surface Area

The design of the edges affects the usable sleeping surface. Some models feature reinforced edges to prevent sagging, maximizing the available area for comfortable use. Lack of edge support reduces the effective sleeping space.

The interplay of these dimensional factors determines its overall functionality. Selecting a model with appropriate dimensions ensures a comfortable and practical sleeping solution that fits the intended space and accommodates the intended users.

2. Material Durability

Material durability is a paramount consideration when evaluating an air mattress. The lifespan and performance are directly contingent upon the materials used in its construction, influencing its resistance to punctures, stretching, and overall wear and tear. Understanding the properties of these materials is crucial for informed purchasing decisions.

- PVC Composition and Gauge

Polyvinyl chloride (PVC) is the most common material used in air mattress construction. The gauge, or thickness, of the PVC directly correlates with its resistance to punctures and abrasions. Higher gauge PVC offers increased durability but may also increase weight and reduce flexibility. The specific chemical composition of the PVC can also influence its resistance to environmental factors such as UV exposure and temperature fluctuations.

- Reinforcement Layers and Laminates

Many air mattresses incorporate reinforcement layers, such as nylon or polyester fabrics, laminated between layers of PVC. These reinforcements enhance tensile strength and reduce the likelihood of stretching or tearing under pressure. The quality and type of laminate adhesive are also important, as degradation of the adhesive can lead to delamination and structural failure.

- Seam Construction and Integrity

The method of seam construction is a critical factor in overall durability. Welded or heat-sealed seams are generally stronger and more resistant to air leaks compared to stitched seams. The width and uniformity of the seam are also important indicators of its strength and reliability. Stress testing of seams is a standard practice in quality control to ensure they can withstand repeated inflation and deflation cycles.

- Surface Coatings and Treatments

Surface coatings, such as flocked or textured finishes, can provide enhanced comfort and grip. However, the durability of these coatings is also a consideration. Low-quality coatings may peel or wear away over time, reducing the aesthetic appeal and potentially compromising the underlying material. Antimicrobial treatments can also be applied to inhibit the growth of mold and bacteria, contributing to long-term hygiene and material integrity.

The interplay between these material properties directly impacts the performance and longevity of a double size air mattress. Selecting a model constructed from high-quality materials with robust construction techniques ensures greater resistance to damage and extends its useful lifespan, ultimately providing better value for the investment.

3. Inflation Systems

The operational effectiveness of a double size air mattress is intrinsically linked to its inflation system. These systems facilitate the introduction and expulsion of air, dictating the ease of setup, adjustment of firmness, and overall user convenience. An understanding of various inflation system types and their respective characteristics is crucial for selecting an appropriate model.

- Integrated Electric Pumps

Many models incorporate an internal electric pump for automated inflation and deflation. These pumps typically operate on standard household current and offer rapid inflation within a few minutes. The integration eliminates the need for external devices, streamlining the setup process. Examples include models designed for guest rooms, where quick and effortless inflation is desired. However, integrated pumps can add to the overall weight and cost of the mattress, and failure of the pump renders the mattress unusable unless an alternative inflation method is available.

- External Electric Pumps

External electric pumps offer versatility as they can be used with multiple air mattresses or inflatable items. These pumps often include adaptors to fit various valve types and can provide higher inflation pressure compared to integrated pumps. Examples include models designed for camping, where a single pump can be used to inflate multiple sleeping surfaces and other inflatable gear. The need for a separate power source and the potential for pump malfunction are primary considerations.

- Manual Foot or Hand Pumps

Manual pumps provide an alternative inflation method when electrical power is unavailable or undesirable. These pumps rely on manual effort to introduce air into the mattress. Examples include lightweight models designed for backpacking or situations where portability and self-sufficiency are paramount. Manual inflation can be time-consuming and physically demanding, particularly for larger mattresses.

- One-Way Valves and Air Retention

Regardless of the inflation method, the valve design plays a critical role in air retention. One-way valves prevent air from escaping during inflation and maintain pressure over extended periods. Examples include high-end models that utilize advanced valve technologies to minimize air loss and maintain consistent firmness throughout the night. Valve failure or damage can lead to gradual deflation and necessitate frequent reinflation.

The selection of an appropriate inflation system depends on the intended use case, available power sources, and desired level of convenience. Each system presents a trade-off between inflation speed, portability, and reliability, influencing the overall user experience and the long-term suitability of the double size air mattress.

4. Weight Capacity

Weight capacity represents a crucial engineering specification for any double size air mattress, directly influencing its structural integrity and long-term performance. Exceeding the specified weight limit introduces significant stress on the internal baffles and seams, potentially leading to material fatigue, deformation, and ultimately, catastrophic failure resulting in air leakage. The weight limit is typically determined through rigorous testing conducted by the manufacturer, factoring in static and dynamic loads, material properties, and seam strength. This parameter is not merely a suggestion; it’s a design limitation intended to ensure safe and reliable operation. For example, a model designed for 500 pounds experiencing a sustained load of 700 pounds is likely to experience premature wear or immediate damage.

The practical significance of adhering to the weight capacity extends beyond preventing damage to the product. Overloading an air mattress can compromise the user’s comfort and safety. The mattress may sag excessively, leading to uneven weight distribution and discomfort. In extreme cases, the mattress could rupture, potentially causing a fall and resulting in injury. Furthermore, exceeding the weight limit voids the warranty on most models, leaving the user financially responsible for repairs or replacement. Consider a scenario where two adults and a child utilize an air mattress; their combined weight should be meticulously assessed against the manufacturer’s specifications to avoid potential issues. Accurate weight assessment and adherence to manufacturer’s guidelines are thus paramount for safe and responsible use.

In summary, weight capacity is a fundamental parameter governing the durability and safety of a double size air mattress. Understanding and respecting this limitation protects the product from damage, ensures user safety and comfort, and preserves warranty coverage. The challenges associated with weight capacity often stem from underestimation of actual load or a lack of awareness regarding the manufacturer’s specifications. A thorough evaluation of anticipated load against the stated capacity is, therefore, a necessary step in selecting and utilizing an air mattress effectively, linking directly to the broader theme of responsible consumerism and product stewardship.

5. Comfort Features

The comfort afforded by an air mattress is not solely a consequence of its inflated state; instead, it is significantly influenced by the incorporation of various comfort-enhancing design elements. These features are engineered to mitigate common issues associated with air-filled sleeping surfaces, such as uneven weight distribution, temperature regulation challenges, and the inherent instability associated with inflatable structures. For instance, the addition of a flocked top layer serves to reduce slippage, improve tactile comfort, and provide a degree of insulation, directly addressing the discomfort often experienced with bare PVC surfaces. Similarly, internal coil or beam structures work to distribute weight more evenly across the mattress surface, preventing the formation of pressure points that can disrupt sleep. Without these features, the inherent properties of the air-filled chamber would lead to a less than optimal sleeping experience.

The practical application of these comfort features extends beyond simple subjective comfort. Consider the use of a double size air mattress in a temporary living situation, such as during relocation or while hosting guests. The inclusion of features like edge support, which prevents the mattress from collapsing at the perimeter, allows for a more stable and usable sleeping surface, mitigating the feeling of instability that can be disorienting for users accustomed to traditional mattresses. Furthermore, integrated pillow tops or zoned support systems, which provide varying levels of firmness in different areas of the mattress, can address specific ergonomic needs, accommodating individuals with back pain or other musculoskeletal issues. These features transform an otherwise basic air mattress into a more functional and supportive sleeping environment, improving sleep quality and overall well-being.

In conclusion, the integration of comfort features represents a critical evolution in air mattress design, moving beyond simple inflation technology to address the nuanced requirements of a comfortable and supportive sleeping surface. The effectiveness of these features is directly linked to the quality of materials and the sophistication of the design, and their presence significantly impacts user satisfaction and the overall utility of the double size air mattress. The challenge lies in balancing these features with portability and durability, ensuring that the addition of comfort enhancements does not compromise the inherent advantages of an air-filled sleeping solution. Therefore, careful consideration of these features is paramount in selecting an air mattress that effectively meets individual needs and expectations.

6. Portability

Portability is a defining characteristic of the double size air mattress, directly impacting its appeal and utility across a diverse range of applications. The ability to deflate and compactly store the mattress for transportation and storage represents a significant advantage over traditional mattresses. This portability stems from the inherent properties of inflatable structures, allowing for substantial volume reduction when not in use. Consider individuals relocating to temporary housing: a deflated air mattress occupies minimal space in transit, mitigating the logistical challenges and costs associated with moving larger, more cumbersome items. Similarly, for outdoor enthusiasts, a lightweight and portable sleeping surface enables comfortable rest during camping trips without the burden of heavy or bulky bedding.

The level of portability varies depending on the materials and construction of the air mattress. Models constructed from lighter-gauge PVC or incorporating lightweight reinforcement layers prioritize portability over extreme durability. However, even more robust models designed for extended use retain a degree of portability unmatched by conventional mattresses. For instance, an emergency preparedness kit often includes a double size air mattress to provide temporary shelter and comfort during unforeseen circumstances, such as natural disasters or power outages. The ability to quickly deploy a comfortable sleeping surface in such situations underscores the practical significance of portability. Furthermore, the integration of features like carrying bags or straps further enhances portability, facilitating ease of transport and storage. The effect of portability on user convenience and operational efficiency is substantial and contributes to the value proposition of an air mattress.

In conclusion, portability constitutes a fundamental attribute of the double size air mattress, directly influencing its versatility and applicability in various scenarios. The ability to compress and transport the mattress easily differentiates it from conventional bedding solutions, enabling its use in temporary living arrangements, outdoor recreation, and emergency situations. The ongoing challenge lies in optimizing the balance between portability, durability, and comfort, ensuring that the air mattress remains a practical and convenient solution without compromising its functional performance. Ultimately, the practical significance of portability reinforces the value of the double size air mattress as a versatile and adaptable sleeping solution.

7. Repair Options

The availability and feasibility of repair options are integral to the long-term value and sustainability of a double size air mattress. Air mattresses, by their very nature, are susceptible to punctures and leaks, which can render them unusable if not addressed. The effectiveness of repair options, therefore, has a direct impact on the lifespan and overall cost-effectiveness. The inherent design of these mattresses, typically involving inflatable chambers constructed from PVC or similar materials, makes them vulnerable to damage from sharp objects, friction, and material fatigue. The ease with which these damages can be rectified determines, in part, the product’s overall utility. For example, a model with readily available patch kits and simple repair procedures is inherently more appealing than one requiring specialized tools or professional intervention for even minor damages.

The significance of repair options extends beyond simple cost savings. A readily repairable mattress minimizes waste, contributing to more sustainable consumption patterns. Consider the environmental impact of discarding a damaged air mattress versus repairing it with a simple patch. Furthermore, understanding the available repair options enables informed purchasing decisions. A consumer might opt for a slightly more expensive model with readily available repair kits and durable materials, knowing that the long-term cost of ownership will be lower due to increased lifespan and reduced likelihood of complete replacement. Practical application also includes preparedness for unexpected events; having a repair kit on hand ensures that a puncture during a camping trip or unexpected guest visit does not lead to immediate obsolescence of the sleeping surface.

In conclusion, the availability and effectiveness of repair options are critical factors in assessing the overall value and sustainability of a double size air mattress. Accessible repair solutions reduce waste, promote informed consumer choices, and extend the usable lifespan. The challenge lies in balancing ease of repair with the initial manufacturing cost and design complexity, ensuring that repairability remains a viable and economical alternative to complete replacement, contributing to responsible consumption and minimizing environmental impact.

Frequently Asked Questions

The following addresses common inquiries regarding this type of inflatable sleeping surface, providing concise and factual information to aid in understanding and decision-making.

Question 1: What are the standard dimensions of a double size air mattress?

The dimensions typically correspond to a standard full or queen mattress, ranging from approximately 54-60 inches in width and 75-80 inches in length. However, variations can occur between manufacturers, necessitating verification prior to purchase.

Question 2: What is the typical weight capacity?

Weight capacities vary significantly, generally ranging from 300 to 600 pounds. Exceeding this limit can compromise the mattress’s structural integrity and lifespan. Consult the manufacturer’s specifications for the specific model.

Question 3: How long does it typically take to inflate?

Inflation time depends on the type of pump used. Integrated electric pumps usually inflate the mattress within 3-5 minutes. Manual pumps require significantly more effort and time.

Question 4: What materials are commonly used in construction?

Polyvinyl chloride (PVC) is the most prevalent material, often reinforced with nylon or polyester layers. The gauge and quality of the PVC influence the mattress’s durability and resistance to punctures.

Question 5: How should an air mattress be stored when not in use?

The mattress should be fully deflated, cleaned, and stored in a dry, climate-controlled environment. Avoid folding it along the same creases to prevent weak points.

Question 6: What are common indicators that an air mattress needs repair?

Gradual deflation, hissing sounds indicating air leaks, and visible punctures or tears are all signs that repair is necessary. Prompt attention to these issues can prevent further damage.

These answers provide a foundation for understanding the specifications, maintenance, and potential issues associated with double size air mattresses. Adherence to these guidelines can contribute to extended product lifespan and user satisfaction.

The following section will explore advanced features and emerging trends in this product category.

Conclusion

This exposition has explored the double size air mattress from various perspectives, encompassing its definition, benefits, usage tips, critical attributes, and frequently asked questions. The discussion has emphasized the importance of material durability, inflation systems, weight capacity, comfort features, portability, and repair options in determining overall suitability and value. Furthermore, the FAQ section addressed common concerns and provided practical guidance for optimal usage and maintenance. A thorough understanding of these factors is crucial for informed decision-making and maximizing the lifespan of such a product.

The ongoing evolution of materials and technologies promises continued advancements in comfort, durability, and ease of use. Consumers are encouraged to carefully consider their specific needs and prioritize features that align with their intended use case. Responsible purchasing decisions, coupled with proper care and maintenance, will ensure that this type of mattress remains a practical and versatile solution for temporary sleeping arrangements, offering both convenience and value for years to come.