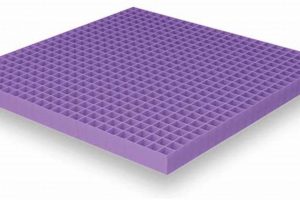

A convoluted foam overlay, typically designed for placement on a queen-sized bed, offers a textured sleeping surface. This type of bedding accessory aims to modify the feel of the underlying mattress. It is characterized by a pattern of raised knobs and recessed areas, resembling the packaging material for eggs. Its dimensions are specifically engineered to fit a standard queen mattress.

The primary function of such a product is to enhance comfort and potentially alleviate pressure points, contributing to a more restful sleep experience. Its design promotes air circulation, which can help regulate temperature and minimize heat retention. Historically, these overlays gained popularity as a cost-effective method for improving the quality of older or less comfortable mattresses, providing an alternative to complete mattress replacement. They are particularly valued by individuals seeking affordable solutions for enhanced sleep support.

Subsequent sections will delve into the material composition, density variations, appropriate usage scenarios, and maintenance guidelines associated with this category of bedding accessory. Furthermore, consideration will be given to comparing these overlays with alternative mattress enhancement options available in the market.

Optimal Utilization Strategies

The following outlines key considerations for maximizing the efficacy and longevity of the specified bedding accessory. Adherence to these guidelines contributes to both comfort and the sustained integrity of the product.

Tip 1: Ensure Proper Mattress Compatibility: Confirm that the dimensions of the convoluted foam overlay correspond accurately to those of the underlying queen-sized mattress. Overhang or insufficient coverage compromises support and can lead to premature degradation of the overlay.

Tip 2: Rotate Regularly: Implement a rotation schedule, ideally every three months, to distribute wear evenly. This mitigates localized compression and prolongs the lifespan of the foam.

Tip 3: Employ a Protective Cover: Encase the overlay within a washable mattress protector. This shields against stains, moisture, and dust mites, contributing to hygiene and preventing damage to the foam structure.

Tip 4: Follow Cleaning Instructions Meticulously: Consult the manufacturer’s guidelines for cleaning procedures. Avoid harsh chemicals and excessive moisture, which can degrade the foam’s integrity. Spot cleaning is generally preferred.

Tip 5: Evaluate Density and Firmness: Select a density and firmness level appropriate for individual body weight and sleep preferences. Overlays of insufficient density may compress excessively, negating the intended support.

Tip 6: Consider Material Composition: Be aware of the overlay’s material composition, particularly for individuals with allergies or sensitivities. Hypoallergenic options are available and may be preferable.

Tip 7: Assess Air Circulation Needs: For individuals prone to overheating, select an overlay with enhanced air circulation properties. The convoluted design facilitates airflow, but certain materials may be more breathable than others.

In summary, conscientious application of these strategies ensures the sustained benefits and extended usability of the designated bedding accessory, promoting enhanced sleep quality and comfort.

The subsequent section will address comparative analyses with alternative bedding solutions and explore potential advancements in foam technology relevant to this product category.

1. Pressure Point Relief

The primary connection between pressure point relief and a convoluted foam overlay designed for a queen-sized mattress lies in the physical distribution of weight. The characteristic “egg crate” topography, with its alternating peaks and valleys, alters the surface contact area between the body and the mattress. This design aims to reduce concentrated pressure on specific areas of the body, such as the hips, shoulders, and knees, when lying down. Reduced pressure at these points can alleviate discomfort and potentially improve circulation. For example, individuals with conditions like fibromyalgia or arthritis often experience heightened sensitivity to pressure; the altered surface provided by such an overlay can mitigate pain and improve sleep quality.

The effectiveness of pressure point relief depends on several factors, including the density and type of foam used in the overlay. Higher density foams provide more support and prevent excessive compression, while memory foam conforms to the body’s contours, further distributing weight. Individuals who sleep on their sides often benefit most from this type of overlay, as it provides cushioning for the shoulders and hips, which are typically subjected to higher pressure. The reduced pressure encourages a more neutral spinal alignment, potentially diminishing back pain. Conversely, an overlay of insufficient density or inappropriate material may compress entirely, negating its pressure-relieving benefits.

In summary, the convoluted foam overlay enhances pressure point relief through its distinctive surface topography, promoting more even weight distribution across the body. While individual experiences may vary, the understanding of material properties, density, and individual sleep positions is crucial for maximizing the potential benefits. Further research into advanced foam technologies may offer enhancements to this already established product category, thereby addressing the remaining challenges in pressure redistribution and sleep comfort.

2. Airflow and Cooling

Effective temperature regulation is paramount for comfortable sleep, and the design of a convoluted foam overlay for a queen-sized mattress can significantly impact airflow and, consequently, cooling. The product’s structure inherently presents opportunities to improve ventilation compared to flat, solid surfaces. The degree to which this is realized depends on material properties and design implementation.

- Convoluted Surface Geometry

The peaks and valleys of the overlay create channels that allow air to circulate between the sleeper and the mattress surface. This geometry reduces the contact area between the body and the sleeping surface, minimizing heat retention. The effectiveness of this airflow depends on the depth and spacing of the convolutions; deeper and more widely spaced patterns generally promote greater ventilation. The design allows for the dissipation of body heat and the introduction of cooler air, which can contribute to a more comfortable sleep environment. Inadequate convolution depth can result in minimal airflow, negating the potential cooling benefits.

- Foam Material and Open-Cell Structure

The type of foam used in the overlay significantly influences i

ts breathability. Open-cell foams, characterized by interconnected air pockets, allow for greater air movement compared to closed-cell foams. This open structure enables moisture and heat to dissipate more readily. Latex foam and certain types of memory foam are specifically engineered with open-cell structures to enhance airflow. The selection of appropriate foam material directly affects the overlay’s cooling capabilities, influencing its suitability for individuals prone to overheating during sleep. Closed-cell foam types will inherently trap more heat, diminishing the product’s value in improving cooling. - Moisture Wicking Properties

Some convoluted foam overlays incorporate materials with moisture-wicking capabilities. These materials draw moisture away from the body, preventing it from accumulating on the sleeping surface. This moisture transport enhances evaporative cooling, further regulating temperature. The effectiveness of moisture wicking depends on the fabric and its proximity to the skin. While the foam itself may contribute to airflow, an added cover that wicks moisture adds another layer of protection against trapped heat and moisture.

- Overlay Thickness and Density

The thickness and density of the overlay also play a role in airflow and cooling. Thicker overlays may provide greater insulation, potentially increasing heat retention if not properly ventilated. Denser foams can restrict airflow compared to less dense foams. It is crucial to balance the need for support and pressure relief with the desire for adequate ventilation. Excessive thickness paired with high density creates a product that minimizes airflow, regardless of the convoluted structure.

In summation, the efficacy of a convoluted foam overlay in promoting airflow and cooling depends on a combination of geometric design, material selection, and physical properties. Proper consideration of these facets is essential for realizing the potential benefits of such a product in temperature regulation. The interplay between the material, the design and the individuals body creates an environment that either supports a cooler sleeping environment or a hotter one.

3. Density and Support

The density of a convoluted foam overlay designed for queen-sized mattresses is directly proportional to the support it provides. Density, measured in pounds per cubic foot (lbs/ft), indicates the amount of material packed into a given volume. Higher density implies more material, resulting in greater resistance to compression and consequently, improved support. A low-density overlay will compress easily under body weight, negating its intended function of enhancing comfort and pressure relief. Conversely, a high-density overlay maintains its shape and provides a more stable sleeping surface. For example, an individual weighing 200 pounds would require a higher density overlay to receive adequate support compared to an individual weighing 120 pounds. Without sufficient density, the overlay will bottom out, rendering it ineffective and potentially exacerbating discomfort. The practical significance lies in the ability of the overlay to maintain proper spinal alignment, reducing back pain and promoting restful sleep.

The type of foam material used in the overlay further influences the relationship between density and support. Memory foam, known for its viscoelastic properties, conforms to the body’s contours, distributing weight evenly. High-density memory foam provides both conforming comfort and robust support, preventing sinking and ensuring proper spinal alignment. Conversely, polyurethane foam, often used in lower-cost overlays, typically offers less support at the same density due to its lower resilience. In a practical application, a side sleeper with a history of shoulder pain would benefit from a high-density memory foam overlay, as it cushions the shoulder while preventing the spine from collapsing out of alignment. The durability of the overlay is also directly linked to its density; higher density overlays resist compression and degradation over time, maintaining their supportive properties for a longer duration.

In conclusion, density is a critical determinant of the support offered by a convoluted foam overlay. A higher density overlay provides greater resistance to compression, ensuring adequate support and proper spinal alignment. The choice of foam material further influences the relationship between density and support, with memory foam offering superior conforming comfort and support compared to polyurethane foam. Selection of an overlay with appropriate density is essential for maximizing comfort, minimizing pain, and prolonging the product’s lifespan. The challenge lies in balancing the need for adequate support with the desired level of cushioning and pressure relief, necessitating careful consideration of individual body weight, sleep position, and preferences.

4. Material Composition

The inherent properties and performance characteristics of a convoluted foam overlay designed for queen-sized mattresses are fundamentally determined by its material composition. A thorough understanding of the materials utilized is crucial for evaluating the product’s suitability, durability, and potential impact on sleep quality.

- Polyurethane Foam

Polyurethane foam is a common material in these overlays due to its cost-effectiveness and versatility. However, the density and quality of polyurethane can vary widely. Low-density polyurethane offers minimal support and compresses easily, while higher-density formulations provide better pressure relief and durability. The production process and chemical additives can influence the foam’s resilience, odor, and potential for off-gassing. For instance, overlays made with CertiPUR-US certified polyurethane foam meet specific standards for low emissions, indicating a lower risk of volatile organic compounds (VOCs) that can affect air quality.

- Memory Foam (Viscoelastic Foam)

Memory foam is prized for its ability to conform to the body’s contours, providing personalized pressure relief. This material is often used in convoluted overlays to enhance comfort and reduce strain on pressure points. The density of memory foam affects its responsiveness and support; higher density memory foam is typically more durable and provides greater support. However, some memory foam formulations can retain heat, leading to discomfort for individuals prone to overheating. Gel-infused memory foam is designed to mitigate this issue by improving airflow and dissipating heat. An example is a convoluted overlay using gel-infused memory foam offering a cooler and more comfortable sleeping surface for hot sleepers.

- Latex Foam

Latex foam, derived from either natural rubber or synthetic materials, offers a combination of support, resilience, and breathability. Natural latex is derived from the sap of rubber trees and is known for its durability and hypoallergenic properties. Synthetic latex provides a similar feel but may be less durable and more prone to off-gassing. Both Dunlop and Talalay processes are used to manufacture latex foam, each resulting in slightly different properties. For example, a convoluted overlay made with Talalay latex offers enhanced breathability due to its open-cell structure, making it a suitable choice for those seeking a cooler sleeping environment.

- Specialty Foams

and AdditivesManufacturers may incorporate specialty foams or additives to enhance specific performance characteristics of the overlay. Copper-infused foam is marketed for its antimicrobial properties, while charcoal-infused foam is designed to absorb odors and regulate temperature. These additives can improve the hygienic qualities of the overlay and contribute to a fresher sleeping environment. Silver infusions offer antimicrobial protection, minimizing bacterial growth and odor retention. An example application is the use of a lavender-infused foam additive, offering a calming scent designed to promote relaxation and improve sleep quality.

In summary, the selection of materials for a convoluted foam overlay is paramount, influencing its comfort, support, durability, and potential impact on health. The choice between polyurethane, memory foam, latex, or specialized blends should be guided by individual preferences, budget considerations, and specific needs related to sleep quality and potential sensitivities. The long-term performance of the bedding accessory is inextricably linked to the properties of the materials used in its construction.

5. Durability and Longevity

The service life of a convoluted foam overlay designed for a queen-sized mattress is intrinsically linked to the materials used in its construction and the conditions to which it is exposed. Durability, referring to the product’s resistance to wear and tear under normal usage, directly influences its longevity, which is the duration it maintains its intended function. The density of the foam core, the quality of any surface treatments or covers, and the presence of reinforcing structures all contribute to the overlay’s ability to withstand prolonged use. For example, a low-density polyurethane overlay will compress and degrade far more rapidly than a high-density memory foam alternative, resulting in a significantly shorter lifespan. The practical consequence is a diminished level of comfort and support, necessitating premature replacement and incurring additional expense. Furthermore, the degradation of the foam can lead to the release of particulate matter, potentially affecting air quality and posing a concern for individuals with respiratory sensitivities.

Environmental factors also play a critical role in determining the durability and longevity of the product. Exposure to direct sunlight, excessive humidity, and improper cleaning practices can accelerate material degradation. Ultraviolet radiation can break down the chemical bonds in the foam, causing it to become brittle and lose its resilience. High humidity promotes the growth of mold and mildew, compromising the structural integrity of the overlay and creating an unsanitary sleeping environment. Harsh cleaning chemicals can damage the foam and strip away protective coatings. Proper maintenance, including the use of a mattress protector, regular vacuuming, and adherence to the manufacturer’s cleaning instructions, can substantially extend the overlay’s lifespan. Consider, for instance, the frequent replacement cycles associated with overlays used in high-humidity climates compared to those used in drier environments, highlighting the direct impact of environmental conditions.

In summary, the durability and longevity of a queen-sized convoluted foam overlay are multifaceted attributes determined by material quality, environmental factors, and maintenance practices. Investing in a higher-quality overlay constructed from durable materials, such as high-density memory foam or latex, offers a cost-effective approach over the long term by reducing the frequency of replacement. Consistent adherence to proper care guidelines further enhances the overlay’s lifespan, preserving its comfort and support capabilities and mitigating potential health concerns. The challenge lies in balancing initial cost considerations with the long-term benefits of enhanced durability and extended service life, requiring a discerning assessment of material properties and usage conditions.

Frequently Asked Questions

This section addresses common inquiries regarding queen-sized convoluted foam overlays, providing concise and factual responses to aid in informed decision-making.

Question 1: How often should a queen-sized convoluted foam overlay be replaced?

Replacement frequency depends on factors such as material composition, density, usage intensity, and maintenance. Lower-density polyurethane overlays may require replacement every 1-2 years, while higher-density memory foam or latex options can last 3-5 years or longer with proper care.

Question 2: Can a queen-sized convoluted foam overlay correct a sagging mattress?

While it may offer some temporary improvement in comfort, a convoluted foam overlay is not a substitute for a supportive mattress. It cannot rectify significant sagging or structural deficiencies. Its primary function is to enhance surface comfort, not to provide foundational support.

Question 3: Are all queen-sized convoluted foam overlays hypoallergenic?

Not all convoluted foam overlays are inherently hypoallergenic. The hypoallergenic properties depend on the material’s resistance to dust mites, mold, and mildew. Latex overlays and those with antimicrobial treatments are often marketed as hypoallergenic. Review product specifications carefully to determine suitability for individuals with allergies.

Question 4: Does a convoluted foam overlay trap heat?

Some materials, particularly closed-cell foams, can trap heat. Overlays made with open-cell foams or infused with cooling gels promote airflow and dissipate heat more effectively. Select materials based on individual temperature regulation needs during sleep.

Question 5: How should a queen-sized convoluted foam overlay be cleaned?

Spot cleaning with a mild detergent is generally recommended. Avoid harsh chemicals or soaking the foam, as this can damage its structure. Allow the overlay to air dry completely before use. A mattress protector can help prevent stains and minimize the need for frequent cleaning.

Question 6: Will a queen-sized convoluted foam overlay fit all queen-sized mattresses?

While designed to conform to standard queen-sized mattress dimensions, slight variations may exist. Confirm the overlay’s dimensions before purchase to ensure a proper fit. An ill-fitting overlay may not provide adequate support or pressure relief.

In summary, queen-sized convoluted foam overlays offer a cost-effective means of enhancing mattress comfort. However, their efficacy is contingent upon material quality, proper usage, and adherence to maintenance guidelines. They are not a replacement for a structurally sound mattress.

The following section will explore alternative mattress enhancement options and compare their performance characteristics with those of queen-sized convoluted foam overlays.

Concluding Remarks

This exploration has illuminated the multifaceted nature of the queen-sized convoluted foam overlay, emphasizing its utility as a supplementary bedding component designed to augment comfort and potentially alleviate pressure. Factors influencing the effectiveness of this product encompass material density, airflow characteristics, durability, and user-specific needs. While offering an economical means of enhancing a sleeping surface, the overlay’s capacity to rectify underlying mattress deficiencies remains limited. Prudent selection hinges upon a comprehensive assessment of these variables to ensure alignment with individual requiremen

ts and expectations.

The efficacy of a queen-sized convoluted foam overlay is contingent upon informed purchasing decisions and diligent maintenance practices. Given the diverse array of available options, prospective consumers are encouraged to prioritize thorough evaluation of material properties, density specifications, and user reviews to optimize product selection. As advancements in sleep technology continue, ongoing research into innovative foam formulations may yield further enhancements to comfort, durability, and overall sleep quality within this product category. A comprehensive understanding of these bedding accessories remains crucial for informed consumers seeking to optimize sleep environments.

![Top-Rated Best Mattress Pad Warmer of [Year] Stay Cozy! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Top-Rated Best Mattress Pad Warmer of [Year] Stay Cozy! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-4744-300x200.jpg)