A sleeping surface addition designed to enhance comfort, typically constructed with soft, voluminous materials. This layer is placed atop a mattress to provide an increased level of cushioning. As an example, one might choose this item to mitigate the firmness of a new mattress or to revitalize an older one exhibiting signs of wear.

The importance of such a bedding component lies in its ability to improve sleep quality. Benefits can include pressure relief, enhanced support, and a more comfortable sleep environment. Historically, similar bedding enhancements were crafted from materials like feathers or down; modern versions often employ synthetic alternatives for improved hygiene and ease of care.

Subsequent sections will delve into the various materials used in their construction, factors to consider when selecting one, and proper maintenance techniques to ensure longevity and continued comfort.

Tips for Selecting a Bedding Comfort Layer

Maximizing sleep quality involves careful consideration of bedding accessories. The following tips provide guidance for selecting a suitable bedding comfort layer.

Tip 1: Material Assessment: Evaluate the composition of the filling. Down alternatives offer hypoallergenic properties, while memory foam provides targeted support. Natural materials, such as cotton or wool, offer breathability and moisture-wicking capabilities.

Tip 2: Thickness Considerations: Determine the appropriate thickness based on individual comfort preferences. A thicker layer will provide more cushioning, while a thinner one offers subtle enhancement without significantly altering the mattress’s feel.

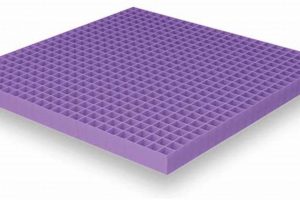

Tip 3: Density Evaluation: For foam-based options, consider the density. Higher density translates to greater durability and support, while lower density may prioritize softness and conforming properties.

Tip 4: Construction Examination: Inspect the construction of the cover. A well-constructed cover will enhance durability and prevent shifting of the filling. Look for features like baffle box construction to maintain even distribution.

Tip 5: Size Verification: Ensure the chosen size aligns precisely with the mattress dimensions. An ill-fitting layer can lead to discomfort and premature wear.

Tip 6: Maintenance Requirements: Understand the cleaning and care instructions. Some materials require professional cleaning, while others can be laundered at home. Regular cleaning prolongs the lifespan and maintains hygiene.

Tip 7: Warranty and Return Policies: Review the manufacturer’s warranty and return policies. This provides recourse in the event of defects or dissatisfaction with the product.

Adhering to these guidelines facilitates the selection of a bedding comfort layer that promotes optimal sleep quality and long-term satisfaction.

The subsequent section will explore advanced topics such as specialized options for specific sleep needs and strategies for maximizing the lifespan of the chosen bedding component.

1. Material Composition

The material composition of a sleeping surface enhancement directly influences its comfort, durability, and suitability for various individuals. The specific materials utilized determine factors such as breathability, temperature regulation, and the degree of support offered. In essence, the choice of materials is paramount in defining the overall performance characteristics of this bedding component. For instance, a surface layer filled with natural down will offer superior insulation and a soft, plush feel, but may present challenges for individuals with allergies. Conversely, synthetic alternatives, such as polyester fiberfill, provide hypoallergenic properties and ease of care, often at the expense of the luxurious feel of natural down.

Consider the impact of memory foam as another example. This material conforms to the body’s contours, providing targeted pressure relief and promoting spinal alignment. However, its inherent density can result in heat retention, which may be undesirable for individuals prone to overheating during sleep. In contrast, cotton offers excellent breathability and moisture-wicking properties, promoting a cooler and drier sleep environment. Understanding these material-specific characteristics enables informed decision-making when selecting the optimal bedding accessory to meet individual needs and preferences.

In summary, the material composition is a critical determinant of the performance and suitability of a fluffy sleeping surface addition. Careful evaluation of the material’s properties, including breathability, support, and hypoallergenic potential, is essential for ensuring a comfortable and restful sleep experience. The selection process should prioritize materials that align with individual needs, preferences, and potential sensitivities, optimizing the benefits derived from this bedding component.

2. Thickness and Density

The thickness and density of a bedding comfort layer are defining characteristics that significantly influence its performance. Increased thickness generally correlates with enhanced cushioning and a greater capacity to absorb pressure. A thicker layer provides a more substantial barrier between the sleeper and the underlying mattress, potentially alleviating pressure points on areas such as the hips and shoulders. Conversely, a thinner layer may offer a subtle enhancement to the existing mattress’s comfort profile without drastically altering its feel. Density, in this context, refers to the mass of the material per unit volume. Higher density materials, particularly in foam-based versions, tend to offer greater support and durability. A high-density memory foam, for example, will resist compression over time, maintaining its shape and providing consistent support. Lower density materials may compress more readily, potentially leading to a less supportive and shorter-lasting experience. The interplay of these two characteristics determines the overall level of comfort and support provided.

Consider two practical examples. A bedding addition with a thick layer of low-density fiberfill will provide a plush, soft feel, but may lack adequate support for heavier individuals or those with back pain. The fibers will compress easily, reducing its ability to distribute weight evenly. In contrast, a layer with a moderate thickness of high-density memory foam will offer a more supportive and contouring experience. The higher density ensures that the foam conforms to the body’s shape while maintaining its structural integrity, providing targeted pressure relief and promoting proper spinal alignment. Choosing the appropriate combination of thickness and density is therefore crucial for achieving the desired level of comfort and support.

In summary, both thickness and density are critical parameters that define the characteristics of a “fluffy sleeping surface addition.” While th

ickness dictates the degree of cushioning, density affects the level of support and durability. Selecting a combination of thickness and density that aligns with individual needs and preferences is essential for maximizing sleep quality and ensuring long-term satisfaction. Understanding these parameters allows for a more informed decision-making process when choosing a bedding component designed to enhance sleeping surface comfort.

3. Support and Comfort

The relationship between support and comfort in the context of a “fluffy mattress pad” is inextricably linked. Support refers to the ability of the layer to maintain spinal alignment and distribute body weight evenly, preventing pressure points that can lead to discomfort and disrupted sleep. Comfort, conversely, pertains to the subjective feeling of ease and relaxation experienced while lying on the surface. A well-designed layer achieves a delicate balance between these two elements. Insufficient support can lead to back pain and postural issues, while a lack of comfort can result in restlessness and an inability to fall asleep. Therefore, these attributes are not mutually exclusive, but rather synergistic, contributing to the overall quality of the sleep experience. An instance of inadequate support can be seen in a layer comprised solely of loosely packed fibers, which compress unevenly, failing to provide adequate lumbar support. This scenario results in spinal misalignment and potential discomfort.

Practical applications of this understanding are significant. Individuals seeking to enhance an existing mattress’s comfort level must consider the support characteristics of the enhancement. For example, a person with existing back pain may benefit from a memory foam layer that contours to the body and provides targeted support to the spine, mitigating pressure points. Conversely, someone seeking a softer sleeping surface might opt for a down-filled option, which provides plush comfort but may require consideration of the underlying mattress’s support capabilities. Evaluating the existing mattress and individual needs is crucial in selecting an option that optimizes both support and comfort. Furthermore, recognizing this relationship informs product design and manufacturing, guiding the selection of materials and construction techniques that prioritize both attributes.

In conclusion, the synergy between support and comfort is a defining characteristic of a well-designed bedding layer. Failure to address both aspects can lead to compromised sleep quality and potential discomfort. Understanding this relationship is essential for both consumers seeking to enhance their sleep environment and manufacturers striving to create effective bedding solutions. The challenge lies in achieving an optimal balance, catering to individual needs and preferences while adhering to fundamental principles of spinal alignment and pressure relief. Further research into material science and sleep ergonomics may lead to more advanced designs that effectively integrate support and comfort, ultimately improving sleep quality for a wider population.

4. Maintenance Requirements

The longevity and hygiene of a sleeping surface enhancement are directly correlated with adherence to specified maintenance requirements. Failure to follow recommended cleaning and care protocols can result in diminished performance, reduced lifespan, and potential health risks. The material composition of the layer dictates the appropriate maintenance procedures. For instance, a down-filled component typically necessitates professional cleaning to prevent clumping and maintain loft, whereas a synthetic-filled alternative might be machine washable. The practical significance lies in the prevention of allergen accumulation, the control of microbial growth, and the preservation of the layer’s structural integrity.

Consider a scenario where a liquid spill occurs on a memory foam layer. Improper cleaning, such as the use of excessive water or harsh chemicals, can damage the foam’s structure, leading to permanent deformation and reduced support. Similarly, neglecting to air out a layer regularly can trap moisture, fostering the growth of mold and mildew, particularly in humid environments. Real-world applications include routine vacuuming to remove dust mites and debris, spot cleaning to address stains promptly, and periodic professional cleaning to maintain optimal hygiene. Proper rotation, as directed, will improve the pressure distribution.

In summary, understanding and adhering to the maintenance requirements of a fluffy sleeping surface addition are essential for maximizing its lifespan and ensuring a hygienic sleep environment. Ignoring these requirements can lead to diminished performance, potential health risks, and the need for premature replacement. The challenge lies in selecting a layer with maintenance needs that align with individual lifestyles and capabilities, ensuring consistent adherence to recommended protocols. Future advancements in material science may lead to easier-to-maintain and more durable options, further simplifying the care process and extending the lifespan of these essential bedding components.

5. Hypoallergenic properties

The presence of hypoallergenic properties in a sleeping surface addition significantly impacts the quality of sleep for individuals with allergies or sensitivities. These properties mitigate the risk of allergic reactions, creating a more conducive sleep environment. The selection of materials and construction techniques directly influences the hypoallergenic nature of the item.

- Material Selection and Allergen Mitigation

Certain materials, such as synthetic fibers like polyester or microfiber, are inherently less prone to harboring allergens compared to natural materials like down or feathers. These synthetic materials do not provide a hospitable environment for dust mites, a common trigger for allergies. This characteristic is crucial for individuals with respiratory sensitivities or allergic rhinitis. For instance, a “fluffy mattress pad” constructed with hypoallergenic microfiber fill minimizes the risk of dust mite proliferation, reducing exposure to allergens during sleep.

- Barrier Protection and Dust Mite Resistance

The outer fabric of a bedding comfort layer plays a vital role in preventing allergen penetration. Tightly woven fabrics create a barrier against dust mites and other allergens, effectively encapsulating the fill material and preventing exposure. This barrier protection is particularly important for individuals with sensitivities to dust mite feces, a potent allergen. An example includes a “fluffy mattress pad” with a tightly woven cotton or polyester cover treated with an antimicrobial finish, further inhibiting dust mite growth and allergen accumulation.

- Washability and Allergen Removal

The ability to launder a bedding item is essential for removing accumulated allergens, such as dust mite debris and pet dander. Regular washing at appropriate temperatures effectively eliminates these allergens, maintaining a hygienic sleep environment. A “fluffy mattress pad” that is machine washable allows for convenient allergen removal,

reducing exposure and mitigating allergy symptoms. Instructions should specify the appropriate water temperature and detergent to maximize allergen removal without damaging the item. - Certifications and Standards for Hypoallergenic Products

Various certifications and standards exist to verify the hypoallergenic claims of bedding products. These certifications, such as OEKO-TEX Standard 100, ensure that the materials used are free from harmful substances and meet specific criteria for allergen reduction. A “fluffy mattress pad” bearing a recognized hypoallergenic certification provides assurance that it has been tested and verified to minimize the risk of allergic reactions, offering greater peace of mind for sensitive individuals.

The hypoallergenic properties of a “fluffy mattress pad” represent a critical consideration for individuals seeking to minimize allergen exposure and improve sleep quality. Careful selection of materials, construction techniques, and certifications contribute to the effectiveness of the product in mitigating allergy symptoms and creating a healthier sleep environment. Understanding these facets enables informed decision-making when choosing a bedding comfort layer that aligns with individual sensitivities and promotes restful sleep.

Frequently Asked Questions

The following section addresses common inquiries regarding the selection, use, and maintenance of a sleeping surface enhancement. Understanding these points is crucial for maximizing the product’s benefits and ensuring long-term satisfaction.

Question 1: How does the addition influence the temperature of the sleep surface?

The impact on sleep surface temperature varies depending on the materials used. Natural fibers, such as cotton or wool, generally promote breathability and temperature regulation. Synthetic materials, like memory foam, can retain heat. Consider individual temperature preferences when selecting a material.

Question 2: Is professional cleaning required?

The need for professional cleaning depends on the filling material. Down-filled options typically necessitate professional cleaning to prevent clumping and maintain loft. Synthetic-filled alternatives may be machine washable. Refer to the manufacturer’s instructions.

Question 3: How often should the item be cleaned?

The frequency of cleaning depends on usage and environmental factors. Routine vacuuming to remove dust mites and debris is recommended. Spot cleaning should address spills or stains promptly. Periodic professional cleaning is advised to maintain optimal hygiene.

Question 4: How does the quality of the mattress beneath impact the effectiveness?

The underlying mattress significantly influences the effectiveness. A supportive mattress provides a stable base, allowing the to function optimally. A worn-out mattress will compromise the layer’s ability to enhance comfort and support.

Question 5: What is the expected lifespan of a quality product?

The lifespan depends on the quality of materials, construction, and maintenance. High-quality options, properly cared for, can last for several years. Visible signs of wear, such as flattening or loss of support, indicate the need for replacement.

Question 6: How is the presence of hypoallergenic claim been verified?

Various certifications and standards exist to verify hypoallergenic claims. These certifications ensure that the materials are free from harmful substances and meet specific criteria for allergen reduction. Look for recognized certifications when purchasing.

The information presented addresses key concerns regarding these products. Consistent adherence to recommended maintenance practices is essential for long-term performance and hygiene.

The subsequent section will explore innovative developments in sleeping surface technology and potential future trends in the bedding industry.

Concluding Remarks on Sleeping Surface Enhancements

This exposition has explored the critical attributes of the “fluffy mattress pad,” including material composition, thickness, support characteristics, maintenance requirements, and hypoallergenic properties. Understanding these elements is essential for making informed decisions that optimize sleep quality and ensure product longevity. Failure to consider these factors may result in diminished performance, compromised hygiene, or potential discomfort.

The integration of these sleeping surface solutions into the bedding system represents a significant opportunity to enhance sleep environments. Ongoing research and development in material science and design hold the potential for further advancements, improving comfort and hygiene. Continued diligence in product selection, combined with adherence to appropriate maintenance protocols, will maximize the benefits derived from this bedding component, contributing to improved sleep quality and overall well-being.

![Top-Rated Best Mattress Pad Warmer of [Year] Stay Cozy! Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Top-Rated Best Mattress Pad Warmer of [Year] Stay Cozy! | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-4744-300x200.jpg)