A structure designed to support a sleeping surface made of foam, the combination provides both elevation and a stable foundation. This pairing combines the conforming comfort of memory or latex foam with the support and aesthetics of a dedicated platform. Such a setup is frequently found in residential bedrooms, guest rooms, and temporary living arrangements, replacing traditional innerspring mattress and box spring combinations.

The significance of a solid foundation for a foam sleeping surface cannot be overstated. It provides necessary support, preventing sagging and premature wear, thus prolonging the lifespan of the foam material. Furthermore, the elevation provided facilitates ease of access and can contribute to overall bedroom aesthetics. Historically, the evolution of sleep systems has moved from simple floor mats to elaborate elevated structures, driven by needs for comfort, hygiene, and space utilization. The integration of foam and specialized support structures represents a modern iteration of this ongoing development.

The subsequent discussion will delve into various aspects of these combined sleep systems, including types of support structures available, considerations for optimal performance and longevity, and the potential impact on sleep quality. Furthermore, it will address factors such as material composition, size variations, and relevant consumer information for prospective buyers seeking to optimize their sleep environment.

Optimizing a Foam Mattress Bed Frame System

The following recommendations address key considerations for selecting and maintaining a system composed of a foam sleeping surface and its corresponding support. Adhering to these guidelines can contribute to improved sleep quality and extended product lifespan.

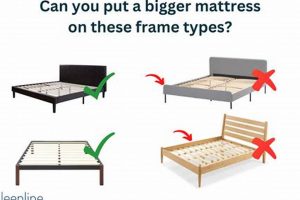

Tip 1: Select an Appropriately Sized Frame: Dimensions should precisely match those of the foam sleeping surface. Overhang or insufficient support can compromise structural integrity and comfort.

Tip 2: Prioritize Frame Material Strength: Durable materials, such as solid wood or reinforced steel, are critical for supporting the weight of the foam and occupants over extended periods.

Tip 3: Ensure Adequate Ventilation: Foam materials can trap heat. Select a support structure with sufficient spacing or slats to promote airflow and regulate temperature.

Tip 4: Inspect Frame Assembly and Stability: Prior to use, verify all connections are secure and the frame is level. Instability can lead to uneven wear and potential damage.

Tip 5: Consider Weight Distribution: For larger sleeping surfaces, a center support beam is advisable to prevent sagging and maintain even distribution of weight.

Tip 6: Protect Against Moisture: Moisture can degrade foam integrity and promote mold growth. Use a waterproof mattress protector to shield the foam from spills and humidity.

Tip 7: Rotate the Foam Sleeping Surface Regularly: Periodic rotation can help distribute wear and prevent impressions from forming in high-pressure areas.

Consistent application of these principles will contribute to a more comfortable and durable sleep system. Selecting the appropriate frame and implementing preventative maintenance measures are key to optimizing the long-term performance of foam materials.

The concluding section will summarize the critical points discussed and offer broader perspectives on sleep system selection and maintenance.

1. Material Compatibility

Material compatibility is a critical, yet often overlooked, element in achieving optimal performance and longevity within a foam sleeping surface and supporting structure system. The interaction between the materials used in the foam construction and those of the structure itself can significantly impact comfort, durability, and even safety. Understanding these interactions is essential for informed selection and maintenance.

- Off-Gassing and Frame Finishes

Certain foam materials, particularly memory foam, may undergo a period of off-gassing, releasing volatile organic compounds (VOCs). If the supporting structure is finished with paints, stains, or sealants that also release VOCs, the combined effect can result in an unpleasant odor and potentially impact air quality. Selecting frames with low-VOC finishes or allowing adequate ventilation during the initial setup can mitigate these concerns. Real-life examples include complaints about strong chemical smells associated with new foam mattresses and cheaply constructed frames, leading to health concerns and product returns.

- Frame Material Reactivity

In some instances, certain foam types may react negatively with the materials used in the supporting structure. For example, certain wood preservatives or metal coatings could degrade specific foam compositions over time, leading to premature breakdown or discoloration. Thorough research into the properties of both the foam and the frame materials is crucial. An example of this can be seen when a foam mattress is used with a metal frame that has not been properly coated, leading to rust and subsequent damage to the mattress.

- Support and Breathability

The type of frame material and its design influence the foam’s ability to breathe. Solid platforms, while providing uniform support, can restrict airflow, potentially leading to heat retention and moisture buildup within the foam. Frames with slats or mesh surfaces promote ventilation, reducing these risks. For instance, memory foam, known for trapping heat, benefits from a slatted wood frame to dissipate warmth effectively. Failure to consider this can lead to uncomfortable sleep and a reduced lifespan for the foam.

- Weight Capacity Considerations

Different frame materials possess varying weight capacities. Overloading a frame with a heavy foam and occupants can lead to structural failure, resulting in sagging or collapse. Metal frames generally offer higher weight capacities compared to wooden frames, but specific product specifications should always be consulted. An example of this would be a lightweight metal frame bending under the weight of a dense latex mattress and two adults, leading to frame damage and an unlevel sleeping surface.

In conclusion, the selection of a foam sleeping surface and a supporting structure requires careful consideration of material compatibility. Addressing off-gassing concerns, preventing material reactivity, ensuring adequate breathability, and respecting weight capacity limitations are all vital factors. By taking these aspects into account, one can optimize the comfort, durability, and safety of the combined system, ensuring a more restful and longer-lasting sleep experience. These insights demonstrate why a holistic approach to selecting and maintaining the sleep system is crucial for its long-term performance.

2. Structural Integrity

Structural integrity is a paramount attribute of any structure designed to support a foam sleeping surface. The ability of the supporting structure to withstand the static and dynamic loads imposed by the foam material and its occupants directly influences the lifespan, performance, and safety of the entire system. A compromised structure can lead to uneven weight distribution, sagging, and ultimately, a reduction in the comfort and support provided. Consider, for example, a bed frame constructed from low-grade wood. Over time, the wood may warp or crack under the consistent pressure of a dense memory foam mattress and two sleepers, resulting in a noticeable dip in the sleeping surface and potential back pain for the users. This illustrates the cause-and-effect relationship between inadequate structural design and compromised sleep quality.

The importance of structural solidity extends beyond immediate comfort. A well-engineered structure ensures even weight distribution across the foam surface, which prevents localized compression and prolongs the lifespan of the material. Uneven stress can cause premature degradation of the foam, leading to indentations and reduced resilience. Furthermore, a stable structure is critical for safety. A poorly constructed structure risks collapse, potentially causing injury to occupants. A practical application of this understanding lies in the selection of frames. Individuals should assess the materials used, the joinery methods employed, and the overall design of the support to ensure it can adequately bear the intended weight. Reinforced steel frames, for instance, offer a higher degree of structural reliability compared to lightweight, low-density fiberboard options, particularly when paired with heavier foam types like latex.

In conclusion, structural integrity is not merely an aesthetic consideration but a fundamental requirement for a functional and durable foam sleeping surface system. The interaction between the support structure and the foam material is a critical determinant of comfort, longevity, and safety. While material selection and design play a crucial role, the ultimate goal is to ensure a stable, level, and supportive foundation that maximizes the benefits of the foam sleeping surface and minimizes the risks associated with structural failure. This understanding underscores the need for informed decision-making when choosing and maintaining a foam bed system, highlighting the challenges associated with prioritizing cost over long-term value and performance.

3. Ventilation Design

Ventilation design within a foam sleeping surface support structure directly influences the microclimate surrounding the sleeping surface, impacting both comfort and hygiene. The nature of foam materials, particularly memory foam, to retain heat necessitates careful consideration of airflow. Insufficient ventilation leads to heat buildup, increasing body temperature and potentially disrupting sleep patterns. Moreover, trapped moisture creates a breeding ground for allergens and microorganisms. As a direct consequence, the choice of bed frame significantly contributes to the overall sleep experience. A solid platform, for example, obstructs airflow compared to a slatted structure, leading to heat accumulation and potentially diminishing the lifespan of the foam. Real-life instances of this phenomenon include complaints of overheating and discomfort associated with foam surfaces placed directly on solid bases, resulting in compromised sleep quality.

Practical application of ventilation design principles involves selecting support structures that promote airflow. Slatted platforms, mesh foundations, or designs incorporating open spaces beneath the foam surface facilitate the dissipation of heat and moisture. Furthermore, the materials used in the structure itself can contribute to or detract from ventilation. Breathable materials, such as certain types of wood, enhance airflow compared to impermeable surfaces like plastic. The selection of a support structure with adequate ventilation characteristics becomes increasingly critical with denser foam types, such as high-density memory foam or latex, which exhibit greater heat retention properties. Ignoring ventilation design considerations often results in a trade-off between the conforming comfort of foam and the negative effects of heat retention and moisture buildup.

In conclusion, ventilation design is not an ancillary feature but an integral component of a foam sleeping surface and its support. Adequate airflow mitigates heat retention, reduces moisture accumulation, and promotes a healthier sleep environment. The selection of a frame that prioritizes ventilation contributes significantly to both comfort and the longevity of the foam material. The challenge lies in balancing support requirements with ventilation needs, demanding a comprehensive understanding of material properties and design principles. The integration of ventilation design into the broader context of sleep system optimization underscores its practical significance.

4. Size Precision

Size precision represents a fundamental aspect of a functional and durable system involving foam sleeping surfaces and their supporting structures. Deviations from precise dimensions can compromise structural integrity, diminish comfort, and accelerate wear. The following facets detail the consequences of dimensional inaccuracies.

- Optimal Support Distribution

Accurate sizing ensures the foam sleeping surface receives uniform support across its entire area. Gaps between the foam and the support structure result in concentrated pressure points, leading to localized compression and premature degradation of the foam. For instance, a full-size foam mattress placed on a queen-size frame will experience unsupported areas, causing sagging and reducing its overall lifespan. Such misalignment leads to uneven weight distribution, impacting comfort and support. It represents the importance of precise fitment.

- Prevention of Edge Collapse

Edges of a foam sleeping surface are inherently more vulnerable to deformation than the central area. Precise dimensions prevent overhang, which can cause edge collapse and reduce the usable sleeping area. Consider a scenario where a foam surface slightly exceeds the perimeter of its frame. The unsupported edges tend to compress and deform over time, creating an uncomfortable and aesthetically unappealing sleeping surface. This effect shows the importance of exact dimensions.

- Frame Stability and Safety

Dimensional mismatches compromise the stability of the overall system. A foam sleeping surface that is too small for its supporting structure can shift during use, potentially leading to instability and safety hazards. For example, a twin-size foam surface placed on a full-size frame can easily slide off, posing a risk of falls. Such misalignment also affects the structural integrity of the frame itself, potentially causing damage. It explains the safety concern.

- Optimized Comfort and Sleep Quality

Beyond structural considerations, accurate sizing contributes directly to comfort and sleep quality. A well-fitted foam surface provides a consistent sleeping plane, free from inconsistencies and pressure points. Conversely, dimensional inaccuracies can lead to discomfort and restless sleep. An example includes a queen-size foam surface slightly smaller than its frame. This can create a noticeable “lip” or edge, disrupting sleep comfort by reducing the smooth, uniform surface.

In conclusion, size precision extends beyond mere aesthetics. It encompasses structural integrity, safety, and sleep comfort. Accurate alignment is not just a detail but a fundamental requirement for maximizing the longevity and performance of foam sleeping surfaces and supporting structures. Inaccurate sizes lead to safety issues, degrade comfort, and shortens a foams life span and stability.

5. Weight Distribution

Weight distribution represents a critical engineering consideration in the design and selection of support structures for foam sleeping surfaces. The uniform dissemination of load exerted by the foam and its occupants across the supporting structure significantly influences structural integrity, lifespan, and overall performance. Uneven load distribution can lead to localized stress points, accelerated material fatigue, and diminished sleep quality.

- Support Structure Design and Load Capacity

The design of the frame, including slat spacing, material thickness, and the presence of central support beams, directly correlates with its capacity to distribute weight effectively. Inadequate support structures, particularly those with widely spaced slats or insufficient bracing, may exhibit sagging or deflection under load. For example, a queen-size foam mattress placed on a frame with only perimeter support and widely spaced slats will likely sag in the center, especially with two occupants. This situation will also stress the outer portions of the frame. It demonstrates the consequence of insufficient structural design.

- Foam Density and Load Transfer

The density and composition of the foam material also influence weight distribution. Higher-density foam, such as memory foam or latex, tends to distribute weight more evenly compared to lower-density alternatives. However, the increased weight associated with denser foam places a greater demand on the supporting structure. Consider a scenario where a high-density latex mattress is placed on a lightweight metal frame designed for a lighter innerspring mattress. The concentrated weight may cause the frame to bend or buckle over time. The selection of proper support design needs to consider the foam used.

- Occupant Weight and Distribution Patterns

Variations in occupant weight and sleeping positions contribute to non-uniform load distribution. Individuals with higher body mass exert greater pressure on the sleeping surface, and specific sleeping positions, such as side sleeping, concentrate pressure on smaller areas. To counteract these effects, support structures should be designed to accommodate a range of occupant weights and sleeping patterns. Frames with reinforced center supports are particularly effective in mitigating sagging caused by concentrated weight in the middle of the sleeping surface. It is even more important if multiple occupants are sleeping.

- Long-Term Effects of Uneven Distribution

The cumulative effects of uneven weight distribution can manifest over time. Localized compression of the foam material, coupled with structural fatigue in the supporting structure, can result in permanent indentations and reduced support. Furthermore, an unstable or sagging support structure can compromise sleep quality by creating an unlevel sleeping surface, potentially leading to discomfort and musculoskeletal strain. Regular inspection of the frame and rotation of the foam surface can help to mitigate these long-term effects. Regular care helps to retain and improve structural properties.

In summary, effective weight distribution is a critical determinant of the overall performance and longevity of the foam sleeping surface system. Attention to both the structural design of the frame and the material properties of the foam contributes to a stable, supportive, and comfortable sleeping environment. Ignoring these design considerations causes stability issues and a loss of sleep comfort.

6. Assembly Security

Assembly security is a crucial, yet often underestimated, factor in the overall performance and longevity of a system comprised of a foam sleeping surface and its supporting structure. The stability and integrity of the assembled components directly impact the structural soundness, safety, and comfort provided by the combination. A compromised assembly undermines the intended benefits of both the foam material and the frame, potentially leading to premature wear, instability, and even hazardous situations.

- Joint Integrity and Load-Bearing Capacity

The strength and security of the joints connecting various frame components directly determine its ability to bear the weight of the foam surface and its occupants. Weak or improperly secured joints can lead to sagging, wobbling, and eventual collapse. Real-world examples often involve frames with poorly designed or inadequately tightened bolt connections, resulting in structural failure under normal use. Regularly inspecting and tightening these joints are crucial preventative measures.

- Locking Mechanisms and Stability

Many frames utilize locking mechanisms to ensure secure connections between components. These mechanisms, such as locking pins, cam locks, or dovetail joints, must be properly engaged to prevent movement and maintain structural stability. Failure to correctly engage these mechanisms can lead to instability and potential separation of frame elements. Instances have been documented where improperly locked frames collapsed during use, highlighting the importance of adhering to assembly instructions and verifying the secure engagement of all locking features.

- Material Compatibility and Fastener Selection

The selection of appropriate fasteners, such as screws, bolts, and dowels, is critical for ensuring a secure and durable assembly. The materials used in the fasteners must be compatible with the frame materials to prevent corrosion, loosening, or stripping of threads. Using undersized or low-quality fasteners can compromise the integrity of the joints, leading to premature failure. Selecting fasteners specifically designed for the frame material and intended load is essential for maintaining assembly security.

- Adherence to Assembly Instructions and Torque Specifications

Following the manufacturer’s assembly instructions is paramount for ensuring a secure and stable structure. Ignoring instructions or deviating from recommended assembly procedures can compromise the integrity of the joints and create points of weakness. Furthermore, tightening fasteners to the specified torque levels is crucial for achieving optimal clamping force without over-stressing the materials. Failing to adhere to these guidelines can lead to loose connections, premature wear, and a reduced lifespan for the combined foam and frame system.

In conclusion, assembly security is not merely a matter of convenience but a fundamental requirement for ensuring the structural integrity, safety, and performance of a foam sleeping surface supported by a frame. Proper joint construction, secure locking mechanisms, appropriate fastener selection, and adherence to assembly instructions all contribute to a stable and durable system. Neglecting these considerations can have significant consequences, potentially compromising both comfort and safety.

Frequently Asked Questions

The following addresses common inquiries concerning the selection, use, and maintenance of systems that combine foam sleeping surfaces with supporting structures.

Question 1: What types of support structures are most suitable for foam mattresses?

Slatted platforms, solid platforms with adequate ventilation, and adjustable support bases are generally appropriate. The selection depends on the type of foam, desired firmness, and budget.

Question 2: How does a support structure impact the lifespan of a foam mattress?

A properly designed and maintained support structure prevents sagging, distributes weight evenly, and promotes ventilation, all of which contribute to extending the lifespan of the foam material.

Question 3: What are the potential consequences of using an incompatible support structure?

Incompatible structures can lead to uneven weight distribution, localized compression, reduced airflow, and premature degradation of the foam.

Question 4: How should weight capacity limitations be considered when selecting a support structure?

The combined weight of the foam surface and its occupants should not exceed the specified weight capacity of the support structure. Exceeding these limits can compromise structural integrity and pose safety risks.

Question 5: What maintenance practices are recommended to ensure the longevity of both the foam mattress and support structure?

Regular inspection of the frame, tightening of fasteners, rotation of the foam surface, and the use of a protective mattress cover are recommended maintenance practices.

Question 6: How does the design of the support structure influence sleep quality?

A stable, level, and well-ventilated support structure promotes proper spinal alignment, regulates temperature, and minimizes motion transfer, all of which contribute to improved sleep quality.

Key takeaways emphasize the importance of selecting compatible components, adhering to weight capacity limitations, and implementing preventative maintenance measures. Ignoring these factors can lead to discomfort, reduced product lifespan, and potential safety hazards.

The subsequent section will explore common misconceptions surrounding systems combining foam sleeping surfaces with supporting structures, offering clarification based on established principles.

Foam Mattress Bed Frame

The preceding discussion has systematically explored the interrelationship between the foam sleeping surface and its supporting structure. Key factors such as material compatibility, structural integrity, ventilation design, size precision, weight distribution, and assembly security have been identified as critical determinants of overall system performance and longevity. The optimization of these elements is essential for maximizing both comfort and the lifespan of the constituent components.

The appropriate selection and diligent maintenance of the foam mattress bed frame system represents a significant investment in sleep health and product durability. By prioritizing these considerations, individuals can expect enhanced comfort, extended product life, and a reduced risk of structural failure. Continuous awareness and responsible decision-making in this area contribute to a more restful and sustainable sleep environment.

![Best Frame Mattress [Guide] The Right Mattress Frame Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Frame Mattress [Guide] The Right Mattress Frame | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3168-300x200.jpg)

![Best Foldable Mattress Frame [Space Saver!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Foldable Mattress Frame [Space Saver!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3167-300x200.jpg)

![Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3165-300x200.jpg)

![Best Extra Long Twin Mattress Frame [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Extra Long Twin Mattress Frame [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3164-300x200.jpg)

![Best Bed Frame for Tempurpedic Mattress [Guide 2024] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Bed Frame for Tempurpedic Mattress [Guide 2024] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3163-300x200.jpg)