A support structure designed to elevate and provide stability to inflatable sleeping surfaces, characterized by its collapsibility for ease of storage and transport, offers an alternative to placing an air-filled bed directly on the floor. This type of bed base generally consists of interconnected segments that can be unfolded to form a level platform and subsequently folded for compact storage when not in use. The frame offers a more traditional bed-like experience when used in conjunction with an inflatable sleeping surface.

The implementation of such a structure offers several advantages. It enhances comfort by raising the sleeping surface, making it easier to get in and out of bed. Elevation also improves air circulation around the mattress, potentially reducing moisture buildup and regulating temperature. Historically, similar support structures have been used to provide a stable, off-the-floor sleeping arrangement in environments where permanent bed frames are impractical or undesirable, such as guest rooms, camping, or temporary housing.

The following sections will delve into the different types of these supports, materials used in their construction, factors to consider when selecting a suitable model, and maintenance practices to ensure longevity. Furthermore, considerations for optimal usage in various settings will be addressed.

Tips for Selecting and Using a Foldable Support for Inflatable Beds

The following tips are designed to maximize the effectiveness and longevity of a foldable support used with inflatable sleeping surfaces, ensuring user comfort and safety.

Tip 1: Assess Weight Capacity. Prior to purchase, verify that the support’s specified weight capacity exceeds the combined weight of the mattress and all occupants. Exceeding the weight limit can lead to structural failure and potential injury.

Tip 2: Evaluate Frame Material and Construction. Opt for supports constructed from durable materials such as steel or reinforced aluminum. Examine the joints and hinges for sturdiness and secure fastening, ensuring long-term reliability.

Tip 3: Consider Storage Space. Measure the available storage space prior to purchasing. Collapsed dimensions vary significantly between models; selecting a support that fits within the designated storage area is crucial.

Tip 4: Inspect Locking Mechanisms. Ensure that the support features reliable locking mechanisms to secure it in the open position. These mechanisms prevent accidental collapse during use, enhancing safety.

Tip 5: Prioritize Level Surface Placement. Always position the support on a level surface. Uneven surfaces can compromise stability, leading to discomfort and potential damage to the support structure.

Tip 6: Use a Mattress Protector. Employ a mattress protector between the inflatable bed and the support frame. This minimizes friction and potential abrasion, extending the lifespan of both the bed and the frame.

Tip 7: Follow Manufacturer’s Instructions. Adhere strictly to the manufacturer’s assembly, usage, and maintenance instructions. Deviations from these guidelines can void warranties and compromise safety.

These tips emphasize careful selection, proper setup, and consistent maintenance as essential factors in ensuring the safe and effective utilization of a foldable support for inflatable beds.

The subsequent sections will provide a detailed exploration of available models, material science pertaining to these supports, and comprehensive troubleshooting guides.

1. Portability

Portability is a critical attribute of a foldable frame for air mattress, directly influencing its suitability for diverse applications ranging from temporary guest accommodations to mobile living arrangements. The ease with which the frame can be transported and stored significantly impacts its practicality and user appeal.

- Folded Dimensions and Weight

The folded dimensions and overall weight are primary determinants of portability. A smaller, lighter frame is inherently easier to transport, particularly in vehicles with limited cargo space or for individuals with physical limitations. Material selection, such as aluminum versus steel, directly affects weight, while design intricacies dictate the compactness of the folded configuration. The reduction of volume and mass is paramount.

- Carrying Mechanisms

The inclusion of integrated carrying mechanisms, such as handles or dedicated carrying bags, substantially enhances portability. These features facilitate easier handling during transport and protect the frame from damage. Ergonomic design considerations, such as handle placement and grip comfort, further contribute to the user’s ability to maneuver the folded frame with minimal effort.

- Setup and Breakdown Time

Portability extends beyond the physical act of carrying the frame; it also encompasses the ease and speed of setup and breakdown. A frame that can be quickly deployed and disassembled streamlines the process of establishing and dismantling sleeping arrangements, making it more convenient for short-term or frequently changing environments. Intricate or time-consuming assembly procedures detract from the overall portability.

- Durability During Transport

A truly portable frame must also possess sufficient durability to withstand the rigors of transport. Robust construction and protective features, such as padded bags or reinforced corners, minimize the risk of damage during handling and transit. Susceptibility to damage during transport negates the benefits of a lightweight and compact design.

The confluence of folded size and weight, incorporated carrying mechanisms, setup efficiency, and resistance to transport-related damage collectively defines the portability of a foldable frame for air mattress. The degree to which these factors are optimized directly determines its viability as a practical and convenient sleeping solution for a mobile lifestyle.

2. Weight Capacity

Weight capacity is a critical engineering specification for a foldable frame designed to support an air mattress. This parameter defines the maximum combined mass of the mattress and its occupants that the frame can safely bear without structural failure or compromise to its intended function. The relationship between the frame’s design, materials used in its construction, and the resulting weight capacity is a direct cause-and-effect relationship. Insufficient weight capacity can lead to bending, breakage, or collapse of the frame, resulting in discomfort, potential injury, and rendering the product unusable. Real-life examples of inadequate weight capacity include frames buckling under the combined weight of two adults, or welds failing due to excessive stress, necessitating urgent replacement and representing a significant inconvenience for the user.

The stated weight capacity is therefore a key selection criterion for potential buyers. Manufacturers typically specify this value prominently, often in the product description and on warning labels affixed to the frame itself. It is imperative for users to select a frame with a weight capacity that exceeds their anticipated combined weight, providing a safety margin to account for dynamic loading (e.g., movement during sleep) and potential manufacturing tolerances. For instance, a frame intended for a single adult might have a listed weight capacity of 300 lbs, while a larger frame designed for couples could have a capacity of 500 lbs or more. Overlooking this aspect of the frame’s specification poses risks, as it directly pertains to the structural integrity and safety of the product in use.

In summary, the weight capacity of a foldable frame for an air mattress represents a fundamental design constraint and a vital safety consideration. Selecting a frame with appropriate weight capacity ensures stable and safe operation, extends the lifespan of the product, and prevents potential injuries. Misunderstanding this crucial specification can lead to negative consequences. Future product development should focus on enhancing weight capacity through improved material selection and optimized structural designs while maintaining portability and ease of use.

3. Material Durability

The service life of a foldable frame for air mattress is directly contingent upon the durability of its constituent materials. Material selection dictates the frame’s capacity to withstand stresses associated with repeated folding, unfolding, weight-bearing, and environmental exposure. Premature material failure, such as corrosion, metal fatigue, or joint separation, renders the frame unusable and negates its intended benefits. Consider the instance of a steel frame exhibiting rust formation due to inadequate coating. This corrosion weakens the structural integrity, ultimately leading to collapse under load. Such failures highlight the critical role material durability plays in the overall functionality and longevity of these products.

The practical significance of material durability extends beyond the immediate user experience. Durable materials translate to reduced replacement frequency, contributing to decreased resource consumption and environmental impact. For example, a frame constructed from high-grade aluminum with reinforced joints can withstand years of use, whereas a comparable frame made from lower-quality steel may require replacement within a shorter timeframe. This distinction has ramifications for both consumer expenditure and sustainable manufacturing practices. The longevity of these bed platforms becomes an environmental consideration.

In summary, material durability is a paramount consideration in the design and selection of foldable frames for air mattresses. Prioritizing materials known for their strength, resistance to degradation, and ability to withstand repeated stress cycles ensures a product that is both reliable and sustainable. Addressing challenges associated with material selection, such as cost constraints and manufacturing complexities, will ultimately lead to the development of more durable and environmentally responsible products in this category.

4. Storage Dimensions

Storage dimensions represent a primary constraint in the design and utility of a foldable frame for an air mattress. These dimensions, specifically the spatial volume occupied by the frame when collapsed, directly influence its suitability for various storage environments. A larger collapsed volume restricts storage options, potentially limiting its usability in apartments, recreational vehicles, or other space-constrained settings. Conversely, a compact design expands storage possibilities, increasing its appeal for individuals with limited storage capacity. A real-world illustration involves a frame that, while robust and durable, occupies an excessive volume when folded. This could render it impractical for residents of smaller apartments lacking ample storage space. This spatial requirement directly impacts consumer adoption.

The practical significance of understanding storage dimensions extends beyond mere convenience. It influences the product’s ability to be effectively integrated into different lifestyles and living spaces. For instance, a foldable frame with optimized storage dimensions can be easily transported and stored in a vehicle for camping trips or readily stowed away in a closet when not in use. This adaptability enhances its overall value proposition and addresses the needs of consumers seeking space-saving solutions. Manufacturers recognize this demand and continually strive to minimize storage dimensions through innovative folding mechanisms and material selection. These efforts aim to maximize usability and appeal to a broader consumer base.

In summary, storage dimensions are a defining characteristic of foldable frames for air mattresses, influencing their practicality, usability, and market appeal. Overlooking this parameter can lead to consumer dissatisfaction and limited product adoption. The ongoing pursuit of compact storage designs represents a key area of innovation within this product category, driven by the ever-increasing demand for space-saving solutions in modern living environments.

5. Ease of Setup

Ease of setup constitutes a critical determinant of the overall user experience associated with a foldable frame for air mattress. The direct correlation between setup complexity and user satisfaction is evident; convoluted assembly procedures diminish the product’s appeal, while streamlined setup enhances its practicality. The time and effort required to transition the frame from its folded state to a stable, functional support structure directly impacts the user’s willingness to utilize the product regularly. Complex assembly steps can discourage frequent use, especially in situations where time is limited or the user possesses limited physical dexterity. One illustration is a frame requiring specialized tools or multiple individuals for assembly; this negates its intended convenience and reduces its practicality for spontaneous use or travel. A simpler system would enhance usability.

The practical significance of prioritizing ease of setup manifests in diverse scenarios. For instance, a guest requiring a temporary sleeping arrangement benefits greatly from a frame that can be deployed quickly and effortlessly. Similarly, campers or individuals relocating frequently value a frame that minimizes setup time and complexity. Manufacturers are increasingly recognizing the importance of intuitive design and implementing features such as pre-assembled components, color-coded instructions, and tool-free assembly mechanisms to streamline the setup process. These design innovations directly address user needs and enhance the product’s marketability. Minimizing setup time is critical for real world use.

In summary, ease of setup is an indispensable attribute of a foldable frame for air mattress, significantly impacting user satisfaction and product utility. Prioritizing simplicity and intuitiveness in the design and assembly process ensures a product that is both practical and appealing to a wide range of users. Future innovations should focus on further minimizing setup time and complexity through advanced engineering and user-centered design principles, ultimately enhancing the overall value proposition of these portable sleeping solutions.

6. Stability Design

The stability design of a foldable frame for an air mattress is paramount to its functionality and user safety. A stable frame ensures the air mattress remains level and prevents tipping or collapse during use. The design must account for static and dynamic loads, ensuring a safe and comfortable sleeping surface.

- Leg Configuration and Support Distribution

The arrangement and number of legs significantly influence the frame’s stability. A wider leg stance provides a broader base of support, reducing the likelihood of tipping. Examples include frames with six or more legs strategically positioned to distribute weight evenly across the surface. Insufficient leg support can lead to instability, particularly near the edges of the mattress. The implementation of cross-bracing can also drastically increase stability.

- Locking Mechanisms and Joint Integrity

Secure locking mechanisms are essential to maintain the frame’s rigidity in its deployed state. These mechanisms prevent accidental folding or collapse, particularly under load. Hinges and joints must be robust and tightly fitted to minimize wobble or play. Weak locking mechanisms or loose joints compromise stability, increasing the risk of sudden failure. Quality locking designs are essential.

- Material Selection and Structural Rigidity

The materials used in the frame’s construction directly impact its overall stability. High-strength materials, such as steel or reinforced aluminum, provide greater resistance to bending and deformation. The structural design, including the thickness and shape of frame members, must ensure adequate rigidity to support the weight of the mattress and occupants. A frame constructed from flimsy materials or with a poorly designed structure is prone to instability. Strong materials must be used.

- Surface Contact and Anti-Slip Features

The design of the feet or base of the frame influences its stability on various floor surfaces. Anti-slip materials, such as rubber or textured plastic, provide increased friction and prevent the frame from sliding or shifting during use. Smooth, hard feet on a slick floor can lead to instability and potential accidents. Effective feet can dramatically reduce these situations.

These facets of stability design are interdependent and collectively contribute to the overall safety and reliability of a foldable frame for an air mattress. Compromises in any of these areas can undermine the frame’s stability and diminish its suitability for providing a stable sleeping surface. The design requirements must be met for safe usage.

7. Compatibility

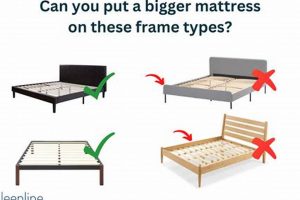

The compatibility between a foldable frame and an air mattress dictates the functionality and safety of the combined sleeping system. Mismatched dimensions or weight capacities can lead to instability, mattress damage, or even frame failure. A frame designed for a twin-sized air mattress, for instance, will not adequately support a queen-sized one, resulting in sagging, uneven weight distribution, and potential tipping. Similarly, an air mattress exceeding the frame’s maximum weight capacity may cause structural damage to the frame, compromising its integrity. In real-world scenarios, incompatible setups often result in discomfort, reduced mattress lifespan, and increased risk of accidents. Correctly aligning the frame’s size and weight specifications with those of the air mattress is therefore fundamental to ensuring a secure and comfortable sleeping surface.

Practical implications of understanding compatibility extend to the selection process. Manufacturers typically specify compatible air mattress sizes and dimensions for each frame model. Buyers must meticulously verify these specifications to ensure a proper fit. Consideration should also be given to the air mattress’s thickness, as some frames may have height limitations that affect comfort or stability. Moreover, certain air mattress materials may be incompatible with the frame’s surface, potentially causing slippage or abrasion. Thorough assessment of these factors prior to purchase mitigates the risk of incompatibility and maximizes the lifespan and performance of both the frame and the air mattress.

In summary, compatibility represents a critical factor in the successful integration of a foldable frame and an air mattress. Proper alignment of size, weight capacity, and material characteristics is essential for ensuring stability, safety, and longevity. Overlooking these considerations can lead to compromised performance and potential hazards. Future product development should focus on standardized sizing and compatibility guidelines to simplify the selection process and enhance user satisfaction and safety.

Frequently Asked Questions

The following questions address common inquiries regarding foldable support structures for inflatable sleeping surfaces, providing detailed explanations and relevant considerations for prospective users.

Question 1: What is the typical lifespan of a foldable support for inflatable beds?

The lifespan is contingent upon material quality, usage frequency, and adherence to maintenance guidelines. Frames constructed from high-grade steel or aluminum, when subjected to moderate use and proper care, can typically last for several years. Conversely, frames made from inferior materials or subjected to excessive weight or rough handling will exhibit a shorter lifespan.

Question 2: Can these frames be used outdoors?

While certain models are designed with weather-resistant materials, prolonged outdoor exposure can accelerate wear and tear. It is advisable to consult the manufacturer’s specifications regarding suitability for outdoor use. Protecting the frame from direct sunlight, rain, and extreme temperature fluctuations will extend its lifespan.

Question 3: What are the primary safety considerations when using these frames?

Key safety considerations include ensuring that the frame is placed on a level surface, adhering to the specified weight capacity, and verifying that all locking mechanisms are securely engaged before use. Failure to heed these precautions can result in instability, collapse, and potential injury.

Question 4: How should these frames be cleaned and maintained?

Cleaning typically involves wiping the frame with a damp cloth and mild detergent. Avoid abrasive cleaners or solvents that can damage the finish. Regularly inspect the frame for loose screws, damaged joints, or signs of corrosion. Lubricating moving parts can help maintain smooth operation.

Question 5: Are there specific types of inflatable beds that are incompatible with these frames?

While most standard-sized inflatable beds are compatible, it is essential to verify the dimensions and weight capacity. Extra-thick or unusually shaped air mattresses may not fit securely or may exceed the frame’s weight limit. Air mattresses with built-in pumps or elevated designs may also present compatibility challenges.

Question 6: What are the advantages of using a foldable support versus placing the inflatable bed directly on the floor?

Employing a foldable support elevates the sleeping surface, providing easier access and egress. It also improves air circulation around the mattress, reducing moisture buildup and regulating temperature. Furthermore, it offers a more stable and bed-like sleeping experience compared to placing the mattress directly on the floor.

In summary, proper selection, usage, and maintenance are critical to maximizing the benefits and lifespan of a foldable support for inflatable beds. Adhering to manufacturer guidelines and exercising caution will ensure a safe and comfortable sleeping experience.

The next section will explore advanced features and design innovations in foldable supports, examining emerging technologies and future trends in this product category.

Foldable Frame for Air Mattress

This exploration has elucidated the multifaceted nature of the support structure. Key aspects, including portability, weight capacity, material durability, storage dimensions, ease of setup, stability design, and compatibility, have been thoroughly examined. The importance of these factors in determining the functionality, longevity, and overall value of this product has been underscored through detailed analysis and practical examples.

Given the diverse applications and increasing demand for adaptable sleeping solutions, further innovation and adherence to stringent quality standards are essential. Manufacturers and consumers alike should prioritize these considerations to ensure that the structure continues to provide a reliable, safe, and convenient alternative for temporary or space-conscious sleeping arrangements.

![Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Find Your Perfect Queen Mattress & Bed Frame Set [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3165-300x200.jpg)

![Best Extra Long Twin Mattress Frame [Deals!] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Extra Long Twin Mattress Frame [Deals!] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3164-300x200.jpg)

![Best Bed Frame for Tempurpedic Mattress [Guide 2024] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Best Bed Frame for Tempurpedic Mattress [Guide 2024] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3163-300x200.jpg)

![Choosing the Right: Bed Frame, Box Spring, & Mattress [Guide] Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions Choosing the Right: Bed Frame, Box Spring, & Mattress [Guide] | Organic & Natural Mattress Buyer’s Guide: Non-Toxic Sleep Solutions](https://mattressworldpa.com/wp-content/uploads/2025/07/th-3162-300x200.jpg)